Phillip Crosby taught us that Quality is Free. What he meant was that doing things right the first time is always less expensive than the cost of defects, scrap, and rework. For manufacturers, this translates into a clear maxim: improving production quality reduces cost.

How to Improve Production Quality?

In today’s hyper-connected, highly competitive, and globalized manufacturing landscape, both production quality and cost are perhaps more important than ever. Simply stated, consumers have more choices and more information about your product and its alternatives than ever before.

Simultaneously, quality failures in the field are now more visible than ever due to reviews on sites like Yelp, Amazon, and, as is the case for a SaaS company such as Evocon on Capterra.

These forces have combined to drive manufacturers’ interest in improving product quality.

At Evocon, we are committed to helping our manufacturing clients wherever their interests and priorities take them. In this article, we look at three keys to improving production quality.

1. Create a Culture of Quality

Creating a culture of quality is a great way to set the stage for improvements to your manufacturing processes. While this is no small task, the journey has serious benefits. To start, we recommend that you define what quality means to your organization.

“You need to define what quality means, define quality goals, disseminate these objectives, measure group and individual performance, and then reward those who are making it happen.”

Jeffrey Ray, Director of Operations and Quality, Strategic Missile & Defense Systems, Boeing Defense, Space & Security

Define quality from the customers perspective

Customers define quality. It’s that simple. So to define quality, your company needs to be engaged in a continuous and interactive process. One aimed at understanding what is important from your customer’s perspective.

This means more than simply having an annual focus group report to the CEO. It is a full-time job. Arguably one of the most important in your company.

If you do not know how you make your customer successful and how your products are important to them, then any efforts expended to improve your production quality may not bring benefits that are of any consequence to the marketplace. So you must put time into understanding your customer’s needs. Then you must plan for how you will meet their demands.

Once you have a firm grasp of what quality means to your customer, you should use this understanding to create a customer-focused production environment.

Use lean to create a customer-focused environment

At the heart of lean manufacturing is the ruthless focus on eliminating waste. Moreover, lean is about finding improvements that are driven by the elimination of problems through a deeper understanding of waste, process flow, and Root Cause Analysis.

There is not a customer of any product that would be happy to pay for waste in your manufacturing process. Further, eliminating waste will save you time and money. Again, it really is that simple.

2. Track and Reduce the Cost-of-Quality

You understand what quality means to your customer. You have focused your production environment using lean. Now, if you haven’t already, let’s turn the organization’s focus to understanding the cost of quality. As we will see, this is an area where Evocon can be of benefit. To help you get started, though, lets first define exactly what is included in the cost of quality.

Define the Cost-of-Quality

The cost-of-quality (CoQ) consists of two components: the cost-of-conformance (CoC) and the cost-of-poor-quality (CoPQ). These components themselves also break down into several types of costs, which are discussed in the next two sections.

CoQ (Cost-of-Quality) = CoC (Cost-of-Conformance) + CoPQ (Cost-of Poor-Quality)

Cost-of-Conformance (CoC)

The cost-of-conformance is the total cost of maintaining acceptable quality levels. It contains both prevention and appraisal costs.

Prevention costs typically consist of the type of costs below. Though this can vary by industry and company size.

- Customer-related activities – such as meeting with customers to discuss new product specifications or to discuss a customer request to implement new QMS procedures.

- Supplier-related activities – such as sending quality personnel to a potential supplier’s facility to evaluate quality management systems.

- System-related activities – the cost associated with implementing and maintaining QMS records, procedures, etc.

- Manufacturing support – such as QA supervisor for managing QA business.

- Quality Technical Training – such as sending quality control technicians to become certified as internal auditors.

While appraisal costs include the cost associated with:

- Quality Control – such as inspection of incoming materials, work-in-process, and finished goods

- Product and Process Testing

- Test and Inspection Equipment

- Internal and Supplier Audits

- QMS certification costs.

Cost-of Poor-Quality (CoPQ)

The cost-of-poor-quality (CoPQ) is a popular and highly effective key performance indicator for manufacturers to monitor. It can be defined as the total cost of failing to maintain acceptable quality levels. These are the costs of internal and external failure.

- Internal failure costs include the cost of scrap and rework. This information should be readily available through your company’s accounting or ERP systems. Evocon provides further detail by providing input for this information by tracking the OEE quality of your production.

- External failure costs are difficult to know. They include things such as the cost of damaged reputation in the marketplace and the loss of all future revenue for customers. Despite this difficulty, we recommend thinking about external failures in terms of “quality escapes”. Quality escapes can come in two varieties: High-profile and low-profile.

- High profile escapes are defects that are reported by the end customer. You really should treat these almost as if someone were fatally injured.

- Low profile escapes are less serious. They are defects that are caught after the manufacturing, but before the end customer interacts with the product. For example, someone in your warehouse or reseller could notice and report a defect.

A best practice that we have seen is to assign a value of say $15k to high profile escapes, and $1.5k to low profile escapes. These costs will then be “charged” to CoPQ when they occur. By assigning these values to escapes, you can now monitor and track the CoPQ in financial terms. This can be very helpful in motivating improvement in both managers and line operators because quality is now stated in terms that resonate with people. Use this motivation to build process controls that limit the possibility of any internal or external escapes.

Track, monitor and continually reduce the CoQ

Once you understand CoQ, you need to implement methods that will allow you to collect the cost. With the means to track and monitor cost, try setting up weekly and monthly manufacturing corrective action meetings. These meetings should include key management, engineering, quality, and operational team leaders.

The purpose of these meetings is to review the different aspects of the CoQ, for example, the quantity of internal and external failures. Then assign someone with the task of investigating each occurrence. Further, have them perform root cause analysis and implement corrective and preventive action. These simple steps have helped countless large multinational manufacturers in continually improving production quality.

3. Leverage Emerging Technology

With the rise of the IIoT, manufacturers finally have at their disposal cost-effective solutions that go further than ever before at connecting and bringing granular visibility to the supply chain. It is imperative that manufacturers leverage this suite of emerging technologies. By harvesting the data that the manufacturing processes generate, they can learn new ways to remain competitive.

We are admittedly a little biased in our recommendation here, but it isn’t without good reason. As you’ll see, monitoring OEE can help guide your process improvement teams. And this is why we include it as our third key to improving production quality.

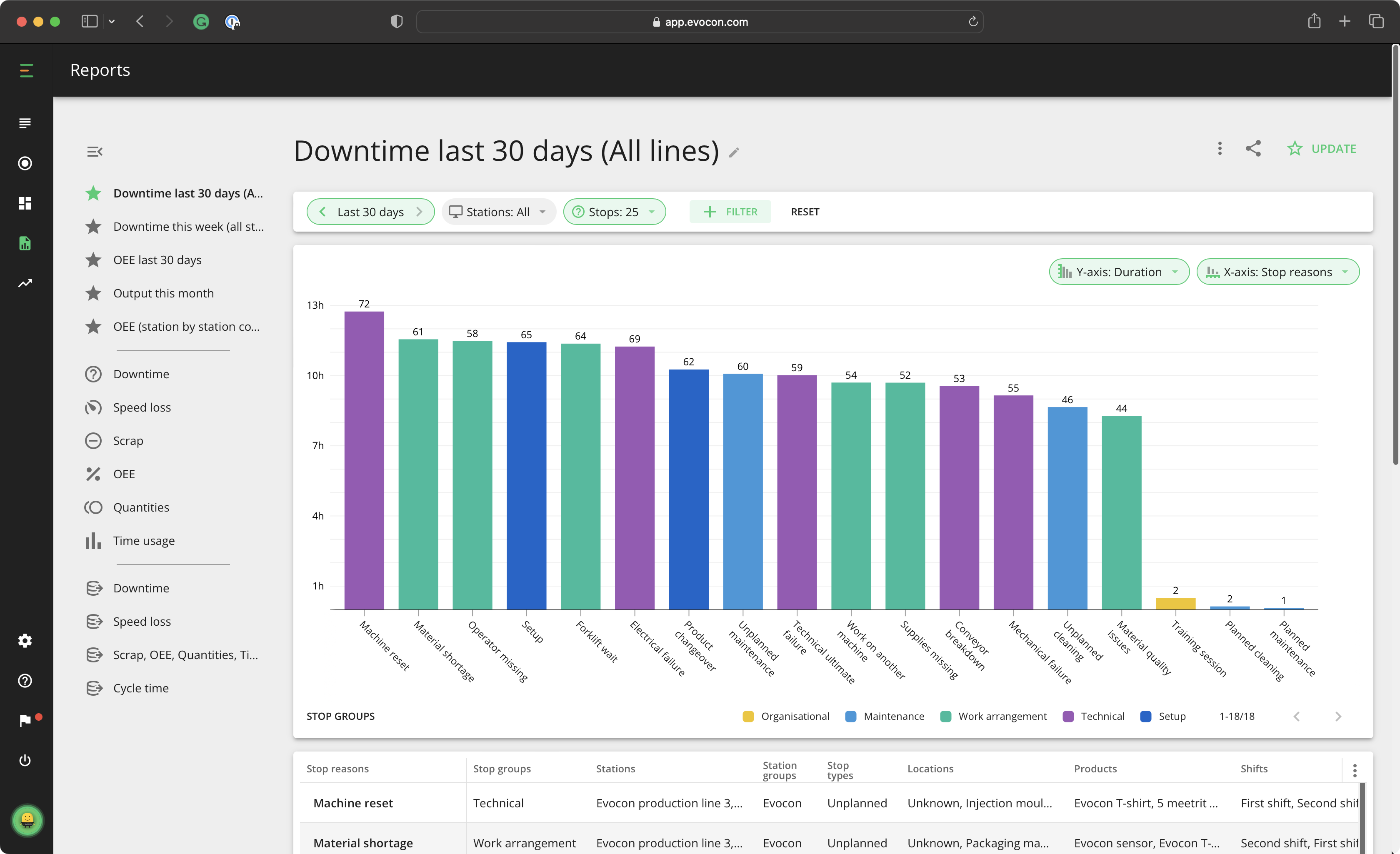

Production monitoring and live OEE tracking

OEE is the gold standard for understanding the performance of any production plant, production unit, workshop, or individual station. Further, monitoring OEE gives manufacturers visibility of where to focus resources to improve production quality.

If you’re new to OEE, you can check out our article What is OEE and How Does it Work. In general, though, this is where Evocon can greatly benefit you. By enabling your company to track OEE, you get more visibility into your processes than ever before and gain the most effective way to focus your process improvement teams.

It works like this. After tracking downtime and quality losses for a couple of months, you can easily open Evocon reports to see a Pareto chart showing downtime reasons. Then it is a matter of organizing a team or project to focus on the largest reasons for downtime. This is how you know that your limited process improvement resources are focused on the problems that, when solved, will yield the most return and improve performance the most.

Track and reduce quality losses

From the perspective of OEE, quality “is simply the proportion of actual production throughput, which meets the customer specification exactly, and is right the first time.”

Quality losses primarily impact productivity in three ways.

- Downtime required to investigate or fix quality issues.

- Slow production speed due to variation in material quality.

- Non-conforming product, scrap, rework, etc. Product that is not right the first time.

When it comes to tracking your quality losses, Evocon can help. In fact, we can help give you deeper insights into the reasons for quality losses ever before. And even better, we allow you to do this without taking up valuable operator time with manual, paper, or excel based tracking methods.

It works like this.

- You populate a list of common reasons for scrap, rework, etc. for your process.

- We store this in Evocons’ application settings.

- When scrap and rework does occur, your machine operators select the reason from a drop-down menu.

Over time, you build a database of reasons for scrap and rework. You can then track and analyze the data and see the primary reasons driving quality losses.

Your next step is to attack these primary reasons for losses with process improvement teams and root cause analysis and implement quality checks that make sure your products meet highest quality standards.

Improving production quality with RCA

In our article on the Benefits of Root Cause Analysis to Manufacturers, we discuss at length the problems that organizations experience when they fail to solve problems completely the first time. So if you are new to RCA, we highly recommend quickly going through the benefits. As you will learn, RCA is a very powerful improvement tool that can benefit your efforts to improve production quality.

Once you understand the benefits and you can learn more about How to Perform Root Cause Analysis in 6 Steps. These two articles prepare you to apply RCA to the primary reasons for production quality losses. And because you are using Evocon, you can easily identify them.

This will set you on the path to improving production quality by leveraging emerging technology. Primarily through the exploitation of the data and visibility that it provides. With this data in hand, you can apply tried and true process improvement techniques.

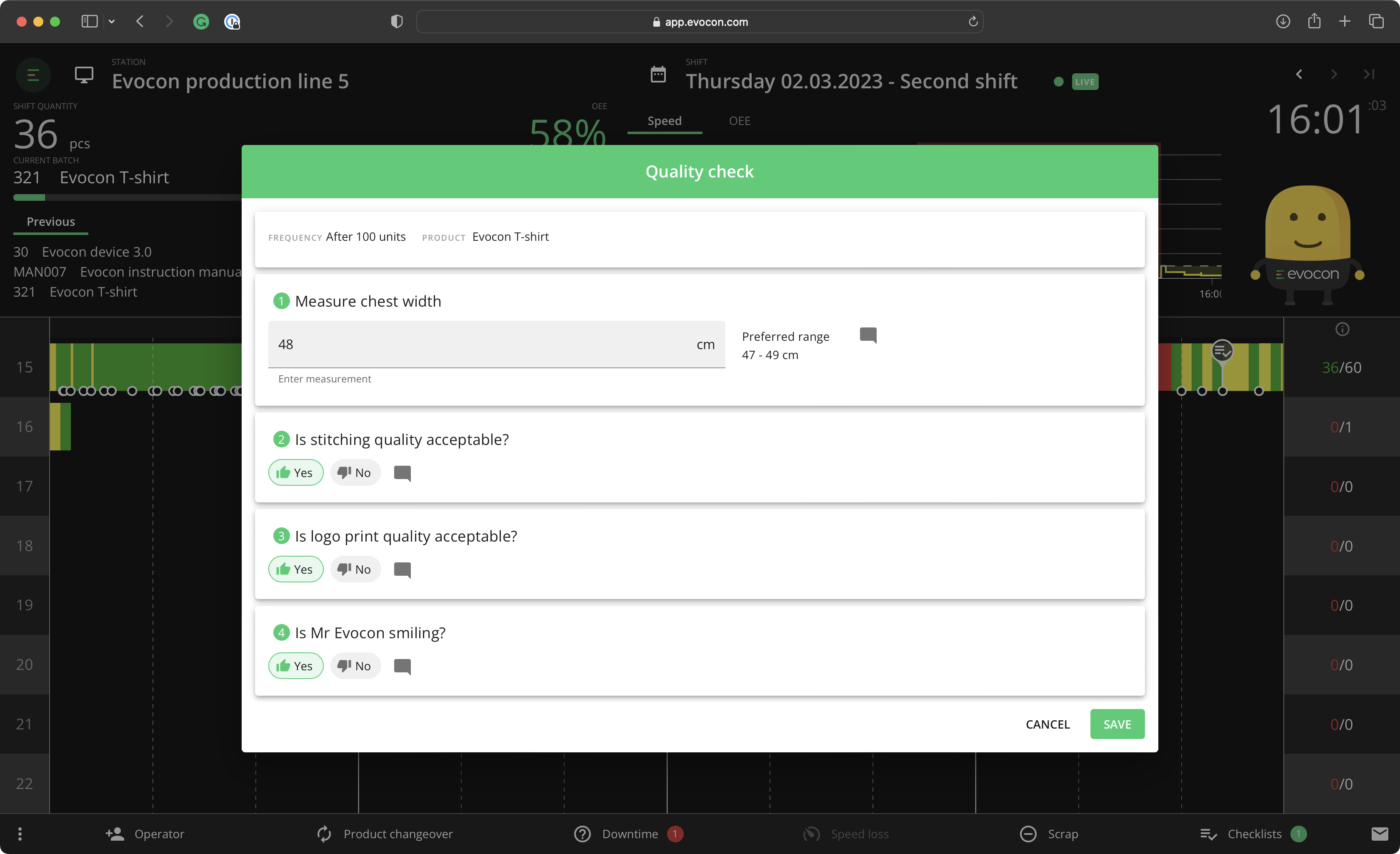

Using real-time data to trigger quality checks

Another option to improve quality and make quality assurance management more effective is to implement digital quality checks that are based on real-time data from your machines.

This is where Evocon can help again. Our quality control software enables you to define quality checks that are based on your specific needs. You can set up checks to appear on changeovers, or after a certain number of products produced. There are different task types that you can ask your operators to fill in – from doing measurements to doing visual inspections. All of this helps ensure you that you achieve the highest possible quality in your production.

Learn more: Chala Improves Quality Through Digitalization

Conclusion

In this article, we have discussed three keys that manufacturers can use to improve production quality. However, it is important to note that the subject of Quality Management is expansive. There are many process improvement tools for consideration.

Additionally, because of the many potential starting points for improvement, no one-size-fits-all approach can be suggested. Instead, we have attempted to share a few of the best practices we have encountered in our years of working with manufacturing clients.

Sources

- Wetherill, M., and Künnapuu, A. (2017). OEE at work. Paris: Bb&b, p.12.

- Dale, Barrie G. et al. Managing Quality 6E: An Essential Guide And Resource Gateway. John Wiley & Sons, Inc, 2016.

- Moore, Ron. Selecting The Right Manufacturing Improvement Tools. BUTTERWORTH-HEINEMANN (MA/PA)(HEALTH TTLS), 2007, p. xv.

- Ray, Jeffery. Culture Of Quality. Forbes Insights, 2020, Accessed 3 Feb 2020.