The answer is yes! All you need is management that is willing to think outside the box and a service provider who can help apply modern technology in smart ways. CHB Group, a leading Greek Company that produces canned fruit, fruit purées, diced fruit, and concentrated fruit juices, is doing exactly that.

Bringing Old Machinery to the Digital Age

Instead of relentlessly investing in new machinery, CHB Group focuses on continuously improving the performance of their existing machines. That way, they save funds for more needed investments in new innovative technologies and products.

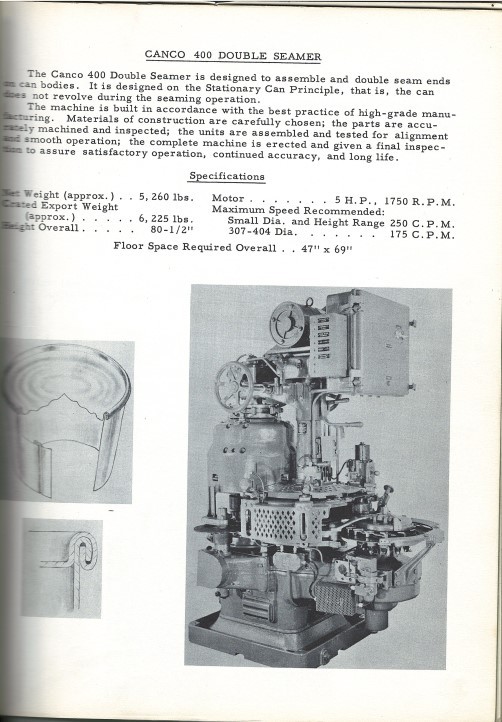

In the picture below, you can see a 50+ years old can seamer that is 100% compatible with Industry 4.0.

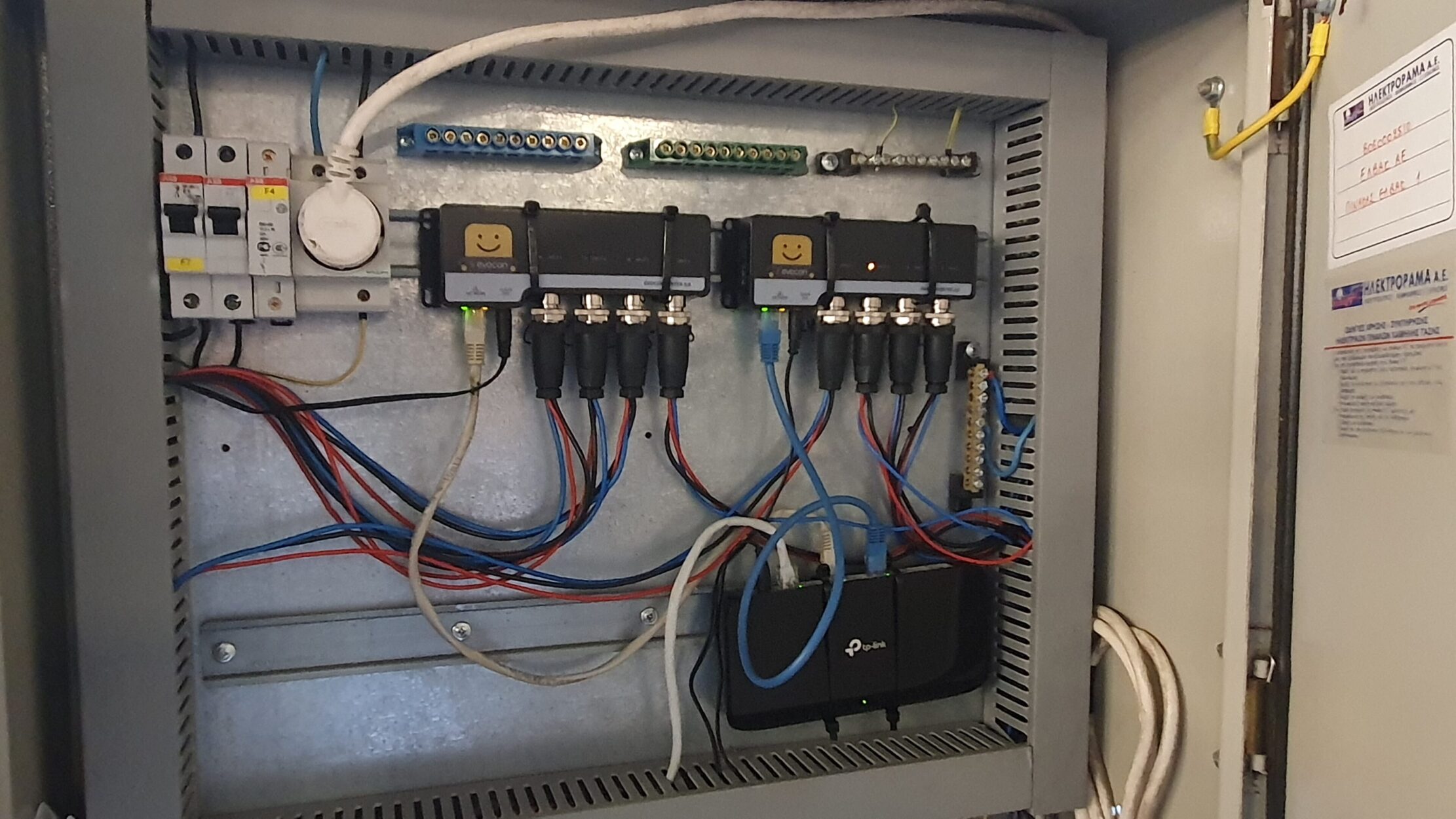

The compatibility with Industry 4.0 is achieved by using:

- Evocon’s IIoT device to automate data collection from the machine;

- Evocon’s cloud-based OEE software, that transforms collected data to actionable insights;

- and a 10″ tablet that visualizes the data to operators and managers.

The investment cost is less than €500. Everyone, including operators, managers, maintenance, quality control, and other departments, now has real-time access to information about the utilization of the seamer.

They monitor OEE in full detail and they know:

- how many cans are produced every minute,

- how many are not produced, and why.

In other words, by listening to the “heartbeat” of the machine, they can easily diagnose “diseases” and take actions, either reactive or – even better – proactive.

CHB have very tight timeframes: they need to process fresh fruits just a few hours after harvesting. Yet, they can rely on this overaged but still functional equipment and maintain excellent quality. Evocon enables it by providing all the data needed to support their decision-making.

It’s a great example of what the first steps of digital transformation can look like for most manufacturers around the world that are relying on their investments made decades ago.

To learn about other success stories from our customers, visit our case studies section.