Use cases beyond efficiency

For many, Evocon is no longer only about increasing production efficiency. It's a tool that supports sustainability, waste reduction, and energy efficiency goals.

-

ISO-50001 and OEE

The ISO-50001 standard is an energy management system used by manufacturers globally. Part of the ISO-50001 process is to use data to understand energy consumption better.

From conversations with Evocon customers, we have learned that connecting energy consumption and OEE data can be beneficial. That way, a company can create a new metric described in scientific literature as OEEE to help identify the focus areas for improvement.

Access to real-time data can also help with behavior change on the shop floor, e.g., turning off machines, improving the maintenance schedule, and optimizing production speed.

-

Waste elimination and Green Manufacturing

Toyota’s Lean production principles provide a systematic process to eliminate non-value-adding activities, also known as waste. You can apply the same framework to implement Green Manufacturing principles and reach your corporate sustainability goals (e.g. reduce electricity consumption, reduce waste to landfill).

Evocon customers report as much as a 20% decrease in scrapped production. They achieve these results by measuring quality losses, ensuring relevant checks are done on time, and acting on the insights that data provides. Improving quality helps save money, increase efficiency, and become greener.

-

KPI tracking to reduce carbon footprint

Many of our customers use GHG Reporting Standard when calculating their carbon footprint. And many have already concluded – energy and water consumption are significant contributors to their carbon footprint.

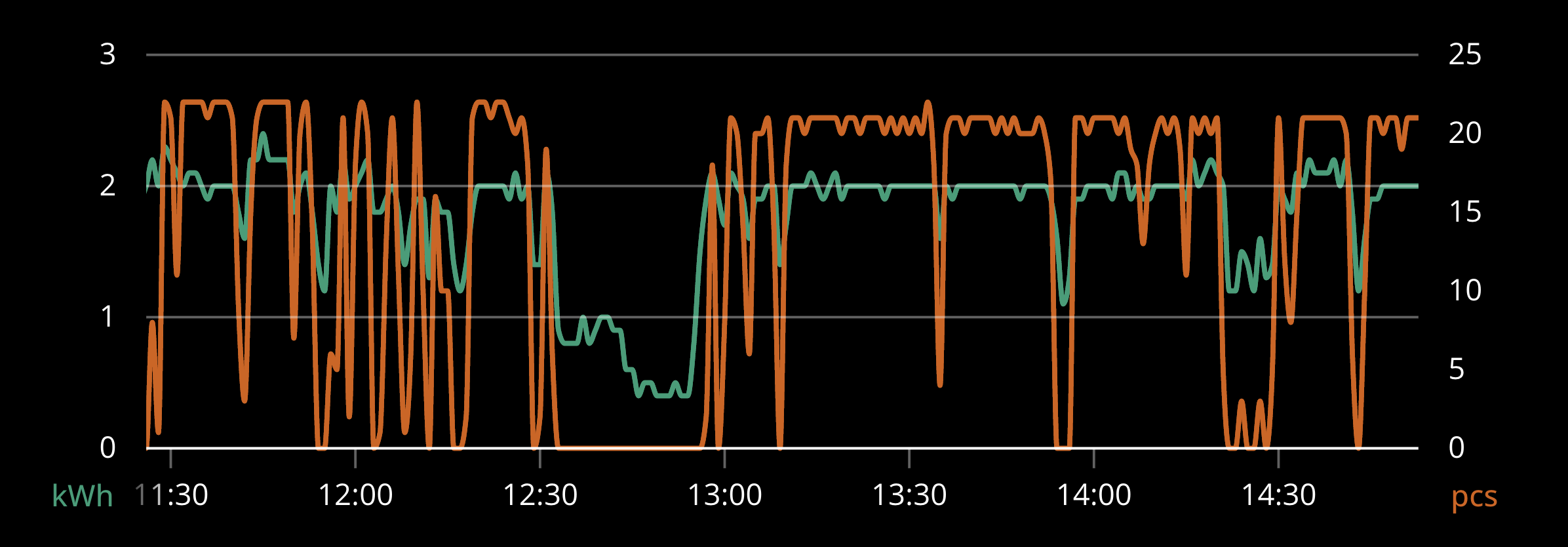

Manufacturers are using Evocon’s software to monitor electricity and temperature data together with efficiency. This provides a more comprehensive view of resource consumption and enables shop-floor managers to take impactful actions.

"Evocon has changed our company’s culture for the better. Operators want to make sure that all quality checks are done on time and according to expectations. As a result, decisions are made faster and we waste less."

The case for Green Manufacturing

The manufacturing industry in Europe emits an annual total of 880 million tonnes of CO2e, making it one of the largest emitters on the continent. According to the Environmental Protection Agency, the situation in the US is equally dire – manufacturing accounts for almost a quarter (23%) of direct carbon emissions.

The industry with such a significant impact has an equally great opportunity for significantly contributing to reaching climate goals.

Join forward-looking manufacturers

A growing group of manufacturers are changing how resources are used in a more sustainable way.

Our journey to empower sustainability in manufacturing

Zero-waste, one of the cornerstones of sustainable manufacturing, is where Evocon is most committed to helping manufacturers reach their sustainability goals. We provide user-friendly tools to discover and identify hidden waste and we develop our product to provide data that help make decisions that are good for the company and the environment.

Beyond the product, our goal is to publish helpful content that guides manufacturers on their sustainability journey. And as a team, we are committed to offsetting our carbon footprint, recycling the waste we generate, and investing in the conservation of Estonia’s nature. This page marks the very beginning of our journey.

Frequently asked questions

-

How is the electricity data integrated with Evocon?

-

How does Evocon help improve production quality?

-

What other data can be monitored in Evocon for sustainability purposes?

-

Can Evocon data be exported or integrated with other platforms?

-

Are there any social benefits to using Evocon?