Equatorial Coca-Cola Bottling Company (ECCBC), the bottling partner of The Coca-Cola Company across North and West Africa, is at the forefront of producing, commercializing, and distributing a portfolio of cherished global brands. Among these are iconic beverages such as Coca-Cola, Fanta, and Sprite. In this case study, we look at how ECCBC implemented Evocon to improve its line performance and achieve operational excellence.

ECCBC: Merging ESG and Operational Excellence

With operations spanning 13 African countries, ECCBC effectively connects with over 160 million consumers, services in excess of 250,000 retail locations, and records 2 billion transactions annually. Central to ECCBC’s operational strategy is a commitment to peak line performance and cost-efficiency, ensuring both customer satisfaction and business success. All are integrated into a comprehensive ESG Impact Strategy for 2030, aiming to enhance ECCBC’s value by integrating ESG (Environmental, Social, and Governance) considerations into the core business strategy, tied to the well-being of our environment, local communities, and governance practices.

But what is ECCBC’s blueprint for realizing these ambitious goals? To understand this, we will look into the operational ethos of Equatorial Coca-Cola Bottling Company and garner expert insights from Yassine Akhrif, the Performance and Excellence Manager at ECCBC.

The 5 Pillars and 2 Enablers of Equatorial Coca-Cola Bottling Company

To align organizational efforts toward excellence, ECCBC has established a robust framework comprising five strategic pillars and two dynamic enablers:

- Pillar 1: Safety, Quality, Operational Sustainability

- Pillar 2: Service Level, Production Capacity & Capability

- Pillar 3: Operations & Cost & Cash Efficiency COGS Supply Risks

- Pillar 4: Cash Capital Optimization

- Pillar 5: Standardization Operational Excellence

- Enabler 1: People Development

- Enabler 2: Technology and Digitalization

The two enablers act as catalysts, empowering the organization to transform the five pillars into actionable strategies. The Operations teams at ECCBC use this framework as a guiding process for all the projects and programs to achieve the vision of the company.

As of late, monitoring and improving line performance (OEE) is at the center of this framework, enabling the pillars and enablers to work together. This meant that ECCBC had to find a way to accurately track OEE In all their plants.

To achieve this, they decided to find an OEE software that would fit their needs and requirements:

- real-time access to data,

- ease of implementation,

- visualization of OEE on the shop floor,

- the ability to enhance the maturity of shift and daily performance meetings,

- and the possibility of tracking other process metrics.

To achieve the goal of OEE tracking at ECCBC plants, Yassine started a collaboration with Evocon and Mohamed Taher Mouni (Founder of Beyond 4.0 and authorized partner of Evocon in Morocco). Together, they rolled out a successful implementation of Evocon that changed the way of working on the shop floor.

Interview with Yassine Akhrif: OEE Implementation at ECCBC

In a short interview with Evocon’s Head of Product, Martin Lääts, Yassine explained his step-by-step approach and choices, which we are excited to share since it is a clear and repeatable OEE implementation process for other large enterprises.

Martin: What were your first steps in this project?

Yassine: The first step was to define why we need to monitor the OEE in real time and what specifications are needed for the solution.

For us, the WHY was to improve the quality, accuracy, reliability, and availability of data and go to 0 paper in our plants.

It is very important for us to make decisions based on a deep understanding of the line performance. For the solution specifications, we focused on user-friendliness and quick implementation time to ensure the adoption of the solution and the scalability.

The second step was to define the team and the pilot. We chose to run a small pilot only one line with Evocon in a smaller plant, with the right people, to focus on the deployment and see if Evocon answered our needs.

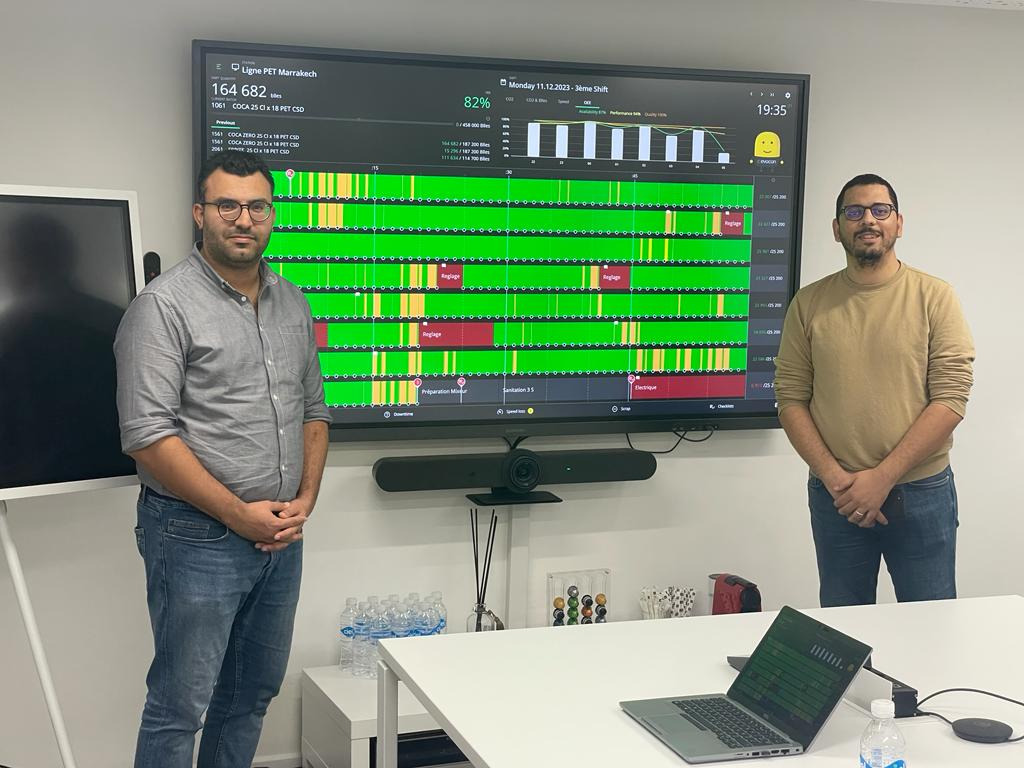

When I say “the right people,” I mean motivated people who have the same objective as us and with whom we have smooth and clear communication. Just like our communication with Mouni – he talks both technology and performance at the same time. He knows the exact context and the needs of the manufacturing team. Having the same language helped us have a quick implementation of Evocon in our Marrakech Plant, and once we showed success, it was easy to get buy-in from others – it happened automatically, as people saw the value.

Martin: And why did you choose Evocon, of all solutions?

Yassine: There are several factors. Firstly, the fast implementation enabled by Evocon’s IIoT technology which allowed us to quickly focus and ensure that our people started using the application in a short timeframe. Secondly, the visualization that Evocon offers lets us understand line performance for each shift without the need for unnecessary clicks or navigation. Thirdly, the ability to connect additional metrics like CO2 and Concentrate to calculate the Yield performance and understand its impact on line performance.

When Mouni first demonstrated Evocon to me, it was evident that it was a fitting solution. The Shift View clearly presents the performance of each shift, indicating problem areas and facilitating a straightforward analysis. The simplicity and intuitiveness of Evocon’s user interface are essential in encouraging people to embrace change. Congratulations are in order for this achievement!

Start your OEE implementation journey

Track and analyze the performance of all your production shifts across different stations, factories and countries. Free for 30 days.

Martin: Thank you. And what followed after the pilot project?

Yassine: After the successful pilot project, it was important to market the success story in the group to convince other plants to adopt the solution. We invited others to come and see the results, and the rest happened automatically.

Martin: What was so convincing about these results?

Yassine: First, because of real-time monitoring, we saw the real situation of the plant and the amount of unrecorded stoppages. Second, it was much less work to gather data, easier to run the meetings while looking at Shift View, and it was quicker to make decisions. Third, we eliminated a lot of paper from the plant because we started using Checklists to enter data straight into Evocon.

Martin: What are the challenges now?

Yassine: Our current challenge is making Evocon the only shop floor performance management platform and integrating Evocon with our ERP system to maintain data integrity. We’re doing this by adding materials consumption data to Evocon through Checklists and connecting Evocon to our energy platform. We’re also using Evocon’s devices to directly capture data from the source.

In addition, we’re focusing on reducing unrecorded stoppages and the frequency of these stoppages because we want to eliminate chronic problems. Finally, we aim to develop more BI reporting to visualize the complete performance of each line for better analysis and action planning.

Martin: Lastly, my favorite question – what would you do differently if you could do it all over again?

Yassine: I think we did our best to ensure that we move quickly with Evocon. In retrospect, involving key users from various countries right from the start of the pilot in Marrakech could have saved time during implementation. Involving key users would have also helped align the structure of stop reasons from the beginning, preventing having to revisit it later.

A Refreshing Finish: Wrapping up Our Analysis

Working hand-in-hand with Mohamed Taher Mouni and Evocon, Yassine has played a key role in changing how ECCBC’s plants work by ensuring data is accurate and easy to understand. To do this, he brought in the real-time monitoring solution of Evocon, which gives a clear picture of how the bottling lines in different plants are performing.

Even though there were worries at first about whether the new system would work and be accurate, Yassine and his team got Evocon working within their current operations. This has helped them make better decisions, improve their analysis, and make things more efficient and cost-effective.

Yassine’s way of slowly introducing Evocon’s production monitoring tool and blending it in smoothly could be a useful lesson for other enterprise organizations looking to succeed in the digital era.