Every digital transformation begins with people – the visionaries, the implementors, and the beneficiaries. For Bohn de Mexico, a reputable distributor of refrigeration equipment, the visionaries were the leadership, the implementors were Rodrigo de Jesús Martínez López and Sergio Lewis Salazar, and the beneficiaries the whole company.

The Human Face of Manufacturing: Individual Heroes Driving Transformation

The journey for Bohn started when the leadership of their company and Cedar Solutions, the Digital Manufacturing Experts in Mexico and authorized partners of Evocon, came together and saw an opportunity to transform Bohn’s production processes using Evocon, an advanced production monitoring and OEE tracking system. After that, the project was given to Rodrigo and Sergio.

Rodrigo, a manufacturing coordinator at Bohn for five years, brought experience from several industries to his role. On the other hand, Sergio from Cedar Solutions brought his expertise in innovative IT solutions. When the two met, it marked the beginning of a year-long collaboration that continues today.

The Quest for Uptime: The Challenge and The Objective

Understanding machine uptime is a critical component of efficiency in the manufacturing industry. However, for Bohn, this proved to be a challenging task due to their unique processes.

The presence of semiautomatic machines posed a challenge in effectively monitoring real-time performance of machines and promptly addressing any issues that arose. Previously, this complexity had hindered the acquisition of precise data necessary for in-depth analysis of the actual situation of the factory.

In addition to that, the Querétaro plant, where Evocon was implemented, hosts 115 different machines (automatic, semi-automatic, and manual) with more than 250 operators. The software solutions they had tried before were either too complex or provided inaccurate data and just didn’t work for their scale.

With Evocon, a system known for its simplicity and accuracy, they felt it would be different, and they set out to integrate it into their process and try again. The goal of the initial stages of the transformation was not just to understand the uptime of their machines but also to explore what additional data could be extracted from Evocon.

From Fear to Confidence: Embracing New Technology

The transition to the new system was accompanied by initial opposition, especially given Bohn’s past experiences with unsuccessful software projects. However, Evocon stood out with its simplicity and intuitiveness, dissolving these fears.

Rodrigo’s confidence in the system played a pivotal role in winning over the industrial environment at Bohn and so they were able to move on with the implementation process on 53 machines.

The Power of Simplicity: Implementing Evocon

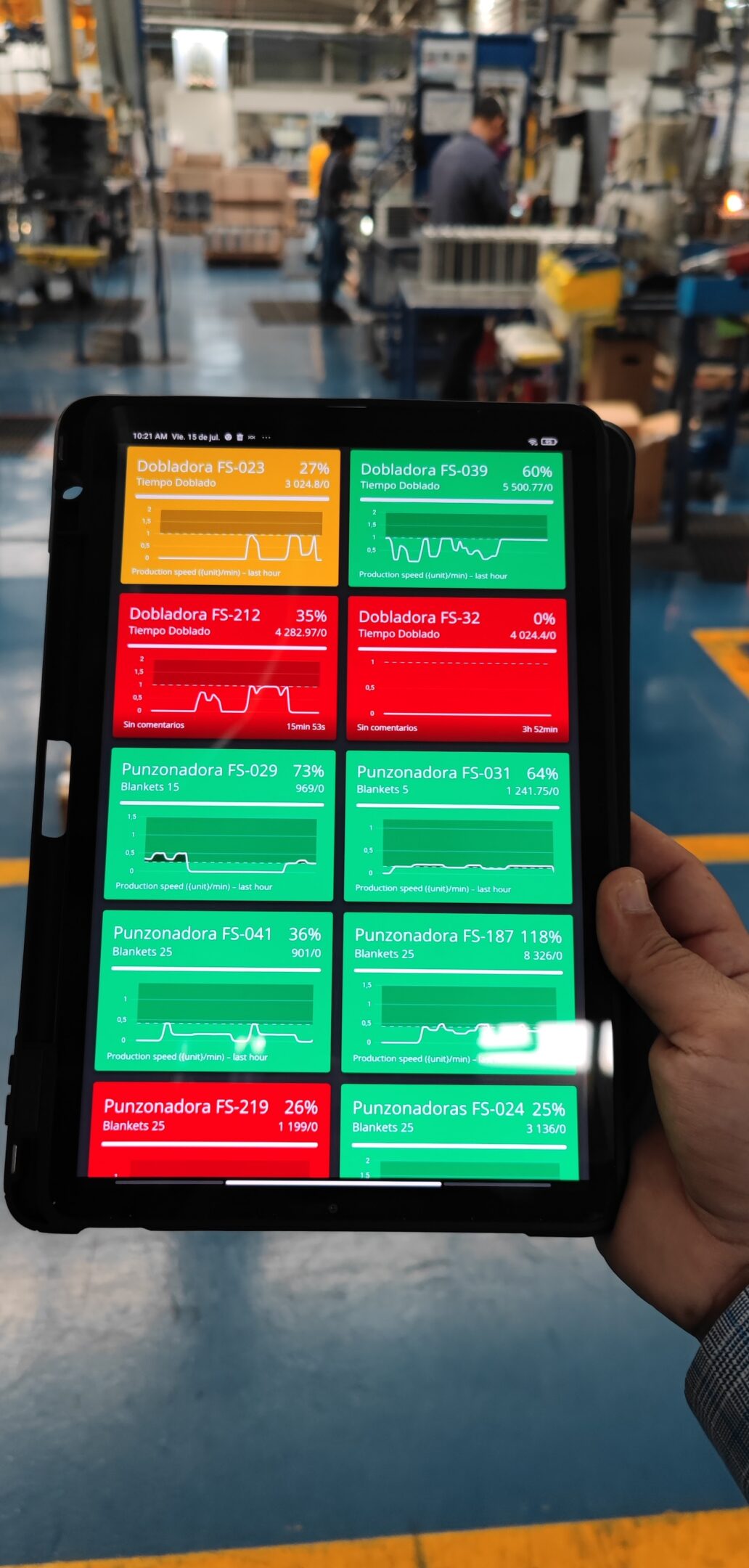

The implementation of Evocon marked a significant shift from the traditional, paper-based monitoring system that Bohn was used to. Evocon’s comprehensive set of features allowed Bohn to extract more than just uptime data. With Evocon, operators could easily track downtime and scrap and identify who was working on what and on which machine.

The system’s visualization capabilities led to a surprising and immediate improvement in machine uptime – the mere act of displaying data on the shop floor encouraged operators to proactively maintain and improve machine uptime.

Rodrigo, when analyzing their implementation process, emphasizes the importance of understanding the needs of top management, the usefulness of the data for operators, and seamless communication among all levels of the factory.

Evocon’s ability to provide real-time information enabled:

- top management to have a comprehensive view of every machine,

- operators to be aware of their machine’s status and next steps,

- and support personnel to fulfill operators’ needs, ensuring the smooth running of the machines.

With Evocon, all levels of the factory started to align with each other, fostering effective communication and collaboration.

Streamline Factory Operations

Get all the tools you need to improve collaboration and efficiency in your factory. Free for 30 days.

The Role of Cedar Solutions and The Evolution of KPIs

Cedar Solutions’s contribution was instrumental in getting Evocon running, defining goals, and developing a measuring system at Bohn. Rodrigo applauds Sergio for always being available to help him with any questions he had and for the ability to work around the needs of Bohn, rather than pushing for general solutions. This contrasts with previous experiences with other software solutions where Rodrigo was left to figure things out on his own.

In regards to goals and KPIs, the focus, initially, was solely on the uptime of machines – the availability component of OEE. However, as the project matured, the output – the number of products produced per machine (performance) – and the quality aspects of OEE came into focus.

This phased approach allowed Bohn to gradually build on their KPIs and avoid overwhelming their processes with complexity.

As a result, Bohn has improved availability on average by 25% on all of their machines.

When asked what he would do differently if he could start all over, Rodrigo had only one simple thing to say: “Start five years ago.”

Technology Empowering People

Ultimately, this case study is a testament to how technology empowers people. Evocon, with its simplicity and powerful data visualization capabilities, together with the help of Sergio from Cedar Solutions and Rodrigo, transformed the production floor at Bohn.

It empowered the operators with real-time data, allowing them to improve machine uptime and overall productivity. It facilitated a collaborative working relationship between Rodrigo and Sergio, bridging the gap between manufacturing and IT solutions. And most importantly, it showed that technology, when made accessible and understandable, can be a powerful tool in the hands of its users.

This case study serves as a reminder that at the heart of every technological transformation are people – the ones who dream, the ones who implement, and the ones who benefit. Bohn de Mexico, through its partnership with Evocon and Cedar Solutions, underscores this fundamental truth. And thanks to this Bohn is now planning on rolling out Evocon in their Monterrey and Santiago de Chile plants.