ELBAK SA is one of the leading producers of canned fruit in Greece. It cooperates with more than 2,500 producers, produces and supplies more than 40,000 tons of fruit annually, and exports its products to more than 70 countries. The company has an extensive catalog of products and presentations, from canned peaches, apricots, fruit cocktails to red fruits in red wine.

Real-time Monitoring of All Production and Packaging Lines

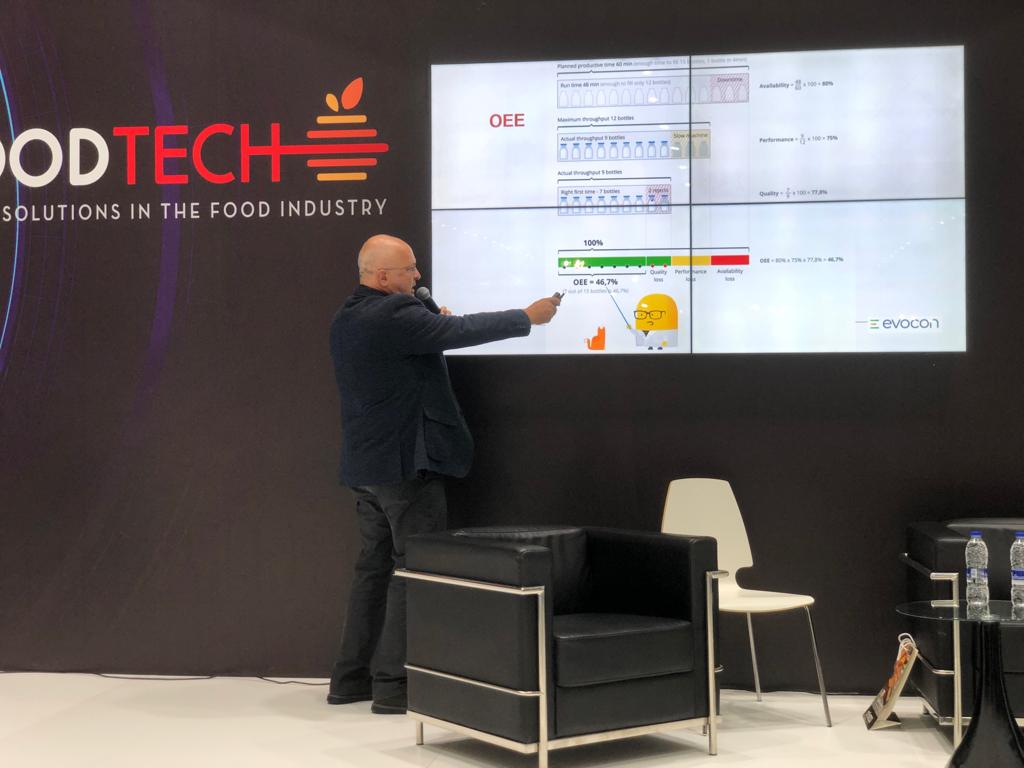

The company is using Evocon to monitor its production and track OEE in real-time and the solution is used on all its production and packaging lines. This year (2021) the company has already seen an increase in its OEE results, which translated into an equal reduction of production costs.

Reasons for choosing Evocon

On their journey to improve productivity and competitiveness, ELBAK faced many different challenges. Some of these were related to the efficient use of their machines:

- increasing productive work time,

- effective diagnosis of problems,

- focus on preventive maintenance,

- objective recording of production stops and their reasons.

The company also wanted to develop a culture of continuous improvement in the organization. To tackle these challenges, they chose Evocon.

The main reasons for selecting Evocon were the fast implementation of the system and its user-friendly interface which enabled ELBAK to quickly onboard their personnel.

Evocon’s free trial was another advantage for the company and the support both from Evocon’s team and the Authorized Partner in Greece, Spiros Vamvakas.

OEE Goal Exceeded by 3x

As a result of implementing Evocon, ELBAK increased its OEE by 6.9% compared to 2020, more than three times the original goal of 2% they had set. The company noted that this directly translated into an equal 6.9% reduction in production costs.

A major factor in getting these results was the speed at which the production and maintenance teams started to use Evocon. Since the onboarding went very smoothly, the teams got involved from the start and were able to quickly contribute to the improvement process.

Operators now have a crucial role in collecting information about production stops, speed loss, and quality issues on all production lines. This supports the company’s efforts on traceability and quality control. Moreover, this level of involvement is driving the change in their culture towards a continuous improvement mindset.

How ELBAK Uses Evocon

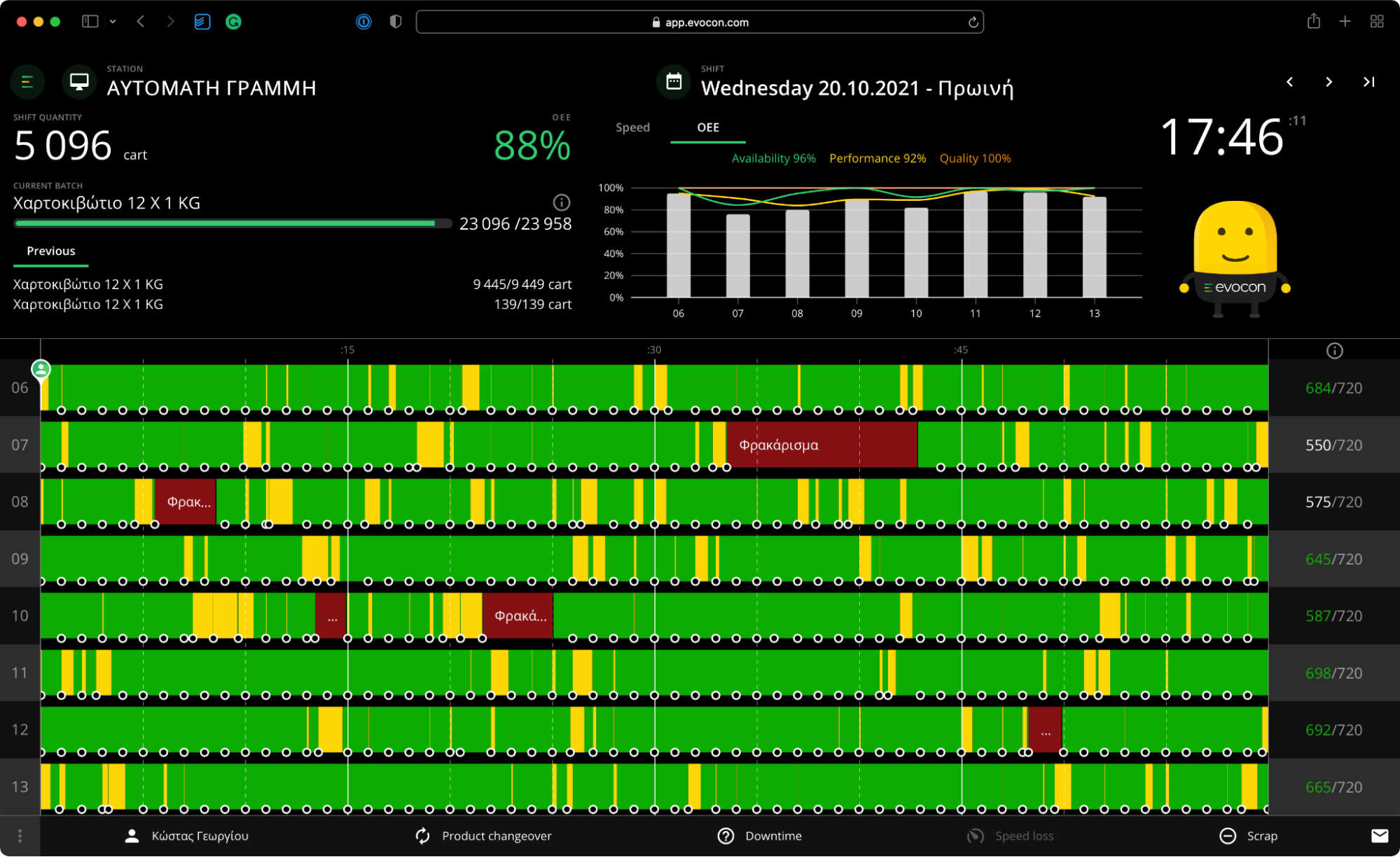

Real-Time monitoring of the production process

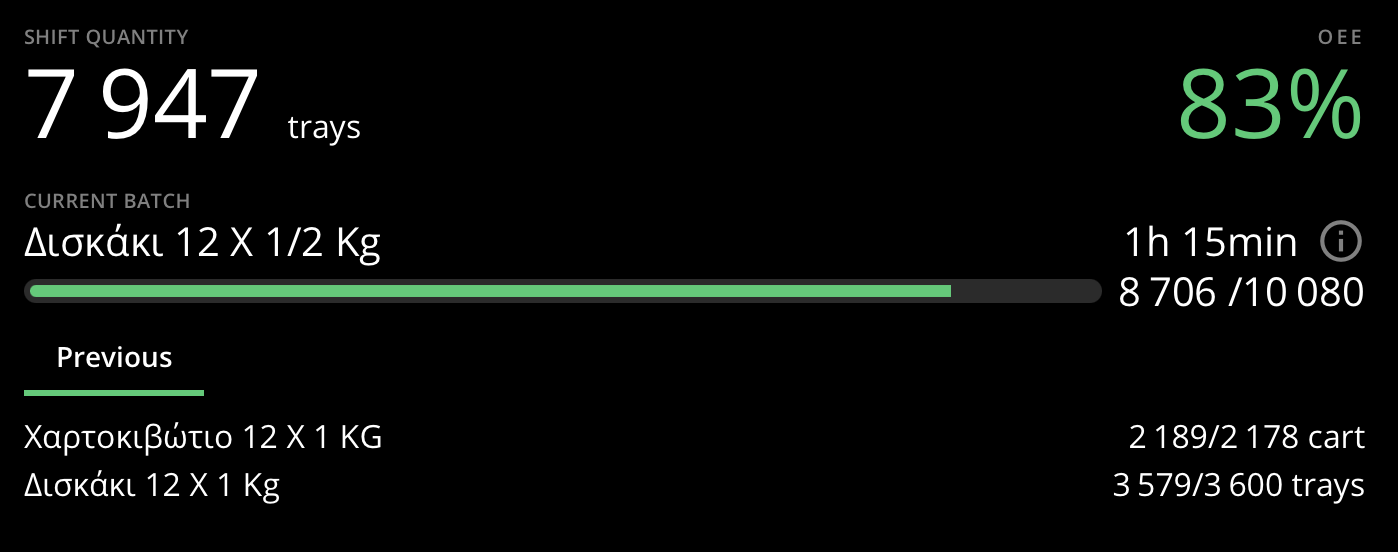

Immediately, after implementing Evocon, ELBAK started tracking their production process in real-time and analyzed information for every hour. Today, in addition to that, they are keeping track of their production targets, what the actual output is, reasons for production stops, and continuous calculation of OEE.

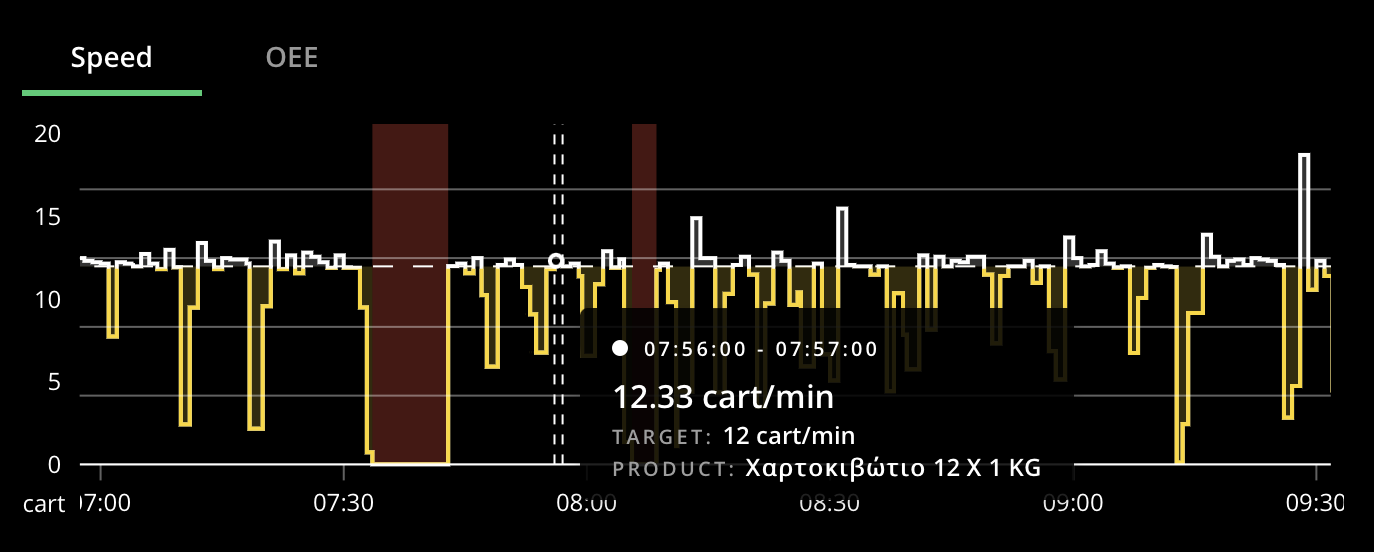

In addition, the production team is continuously monitoring the speed of each line and comparing it with their target.

Evocon uses real-time OEE data to estimate when an order will be completed on a production line. The production team then uses this estimate to prepare for the next product changeover and avoid overproduction.

Live Dashboard

Another way the company is benefiting from real-time data is the Evocon Dashboard. Each user has their own personal dashboard that they can modify to fit their needs. They can configure production widgets for any line, section, period, with different KPIs related to production.

Identifying opportunities for improvement

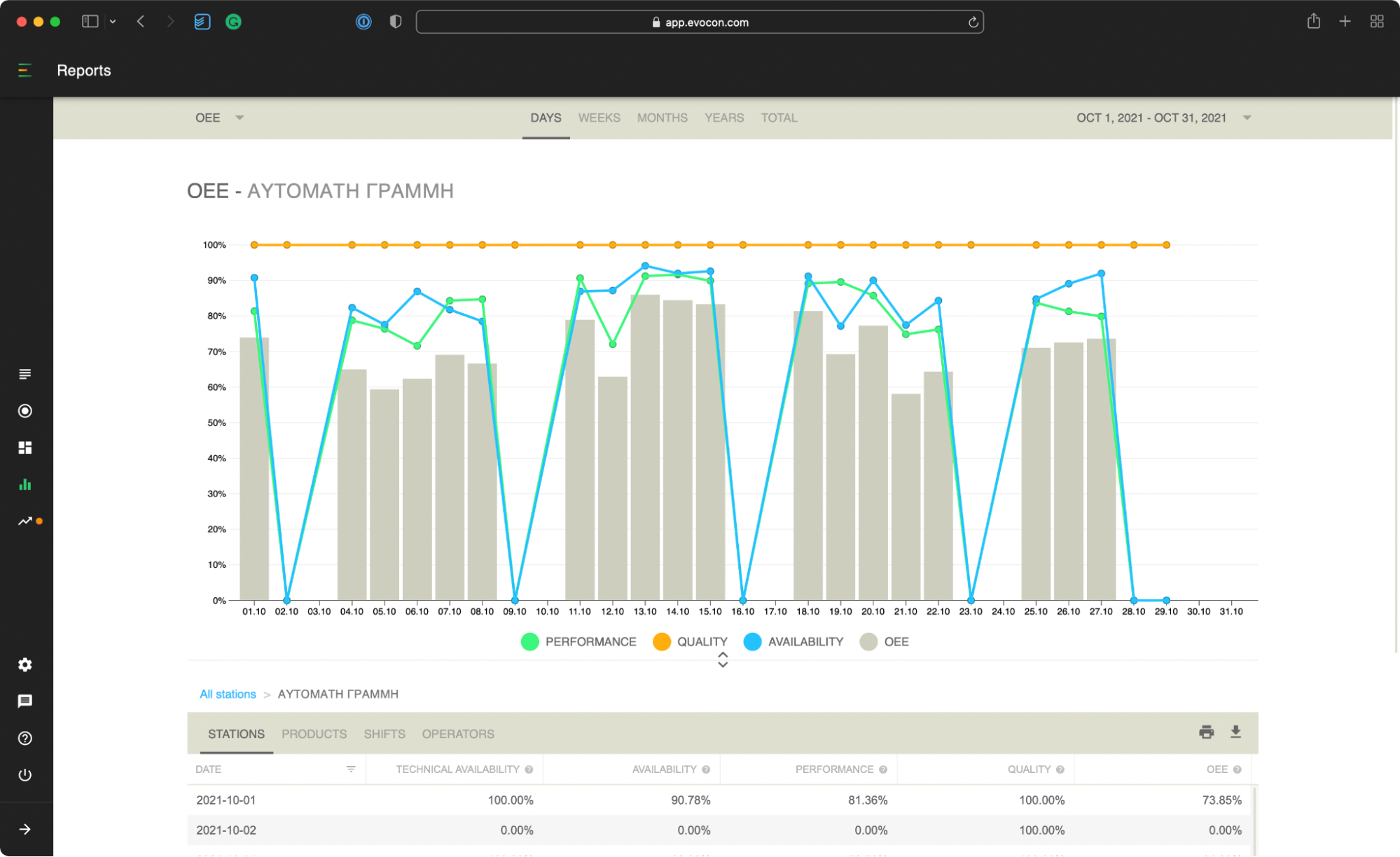

In order to continuously improve, they not only analyze real-time data. Additionally, they are using the Reporting section of Evocon to discover opportunities for improvement.

For example, the company analyzes OEE for every line and for different time periods. They look at OEE per shift, per product, and per operator. And if needed, they apply the available filters to go in-depth into specific categories.

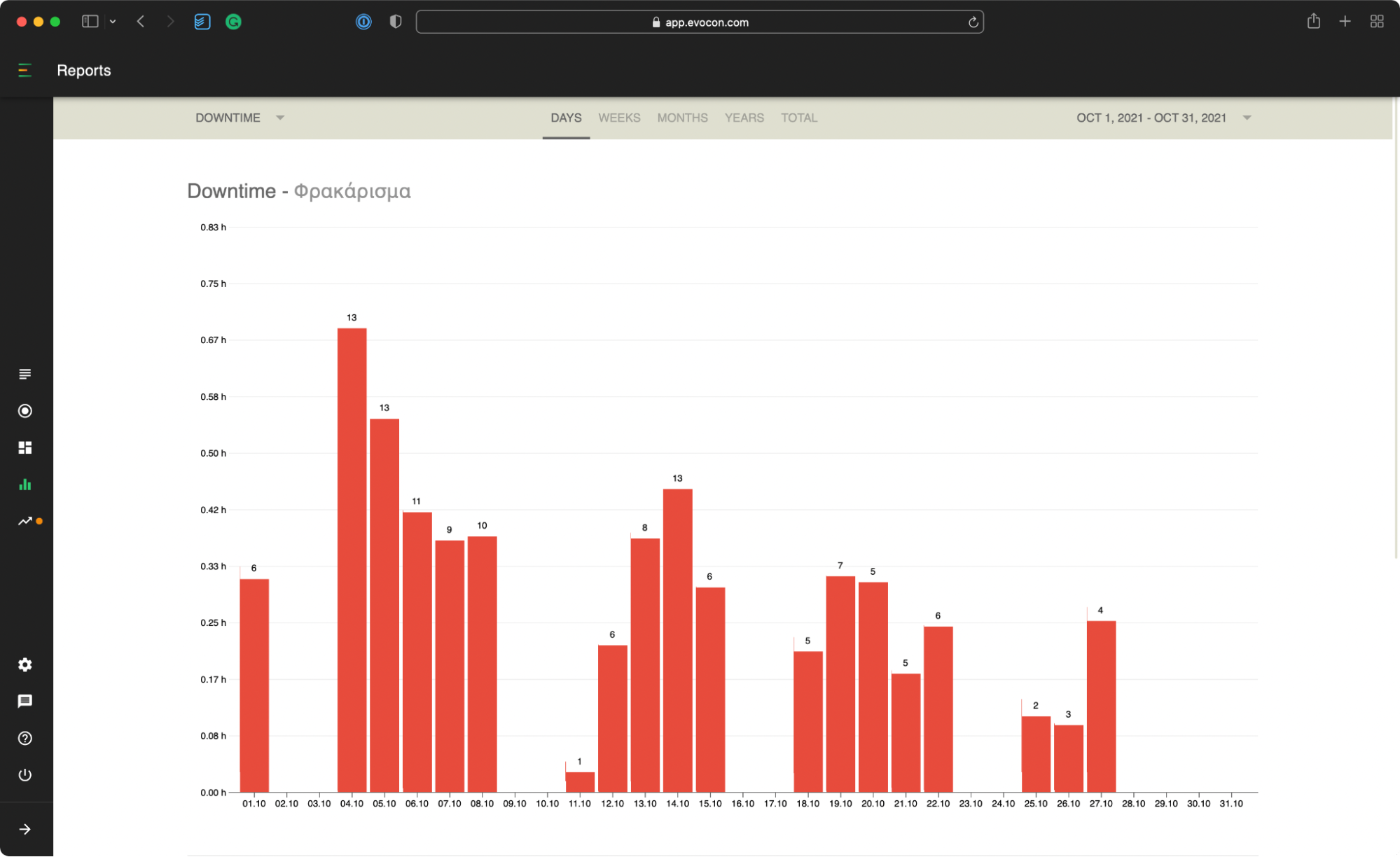

Another great source for identifying improvement opportunities is the downtime report. There they can zero in on any production stop reason that they are tracking to understand what the dynamic is. Furthermore, they have access to all the different comments registered by operators to better understand what is causing the stop reason to happen.

The Improvement Journey Continues

Since starting to monitor their production lines, ELBAK has faced many challenges, most of which they have overcome. But thanks to the access to real-time information and historical data they keep finding ways to improve their production process and this allows them to ensure their competitiveness and profitability.

ERP integration

To get more value out of OEE tracking, the company plans to integrate its ERP system with Evocon. This will allow operators to access the latest production schedule directly from Evocon. Moreover, actual data about machine utilization will be fed into their ERP to get more accurate cost calculations.

To learn about other success stories from our customers, visit our case studies section.