In the modern manufacturing industry, achieving maximum efficiency and productivity is crucial. Overall Equipment Effectiveness (OEE) is an essential metric that helps organizations understand and improve the performance of their production equipment. Simply put, OEE measures how effectively your manufacturing operations are utilized by analyzing three core components: Availability, Performance, and Quality.

In this guide, we will delve into the OEE formula and we’ll look at practical examples needed to calculate OEE, empowering you to identify areas for improvement and drive operational excellence.

How to Calculate OEE

The most accurate OEE calculation is based on the three OEE factors: Availability, Performance, and Quality.

- Availability = Run Time / Planned Production Time

- Performance = (Ideal Cycle Time x Total Count) / Run Time

- Quality = Good Count / Total Count)

- OEE = Availability x Performance x Quality

Here is the interactive visualization of the OEE formula:

This graph is interactive! (drag the dashed --- lines)

What needs adding to these formulas, though, is understanding. What do these values represent, and what do they mean for your manufacturing processes? As you can see, OEE is intrinsically linked to 3 key components: availability, performance, and quality. So what exactly are these 3 metrics, and why are they important?

OEE Calculation Example

Availability

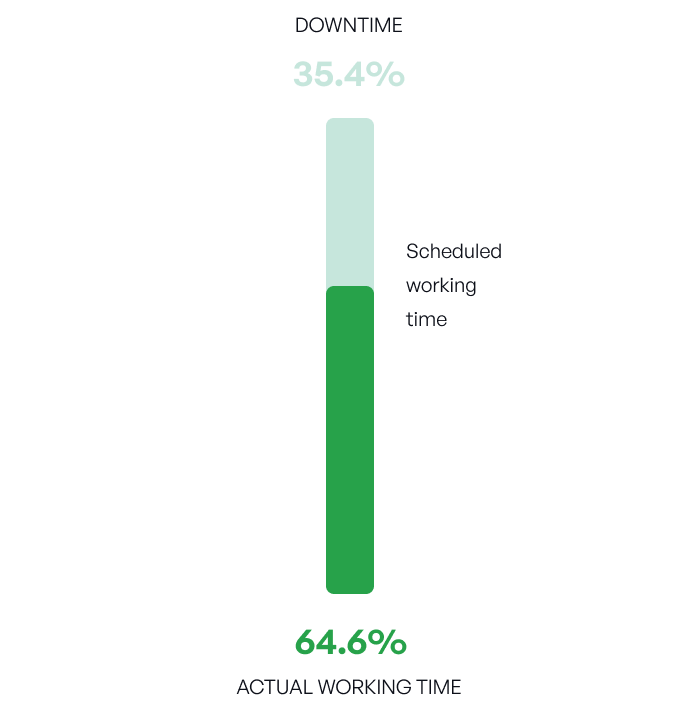

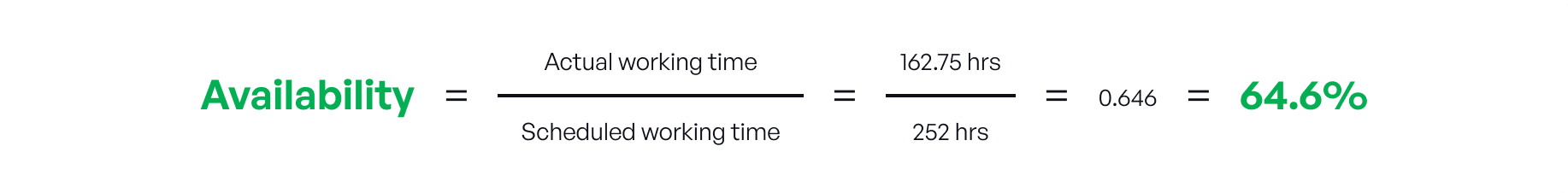

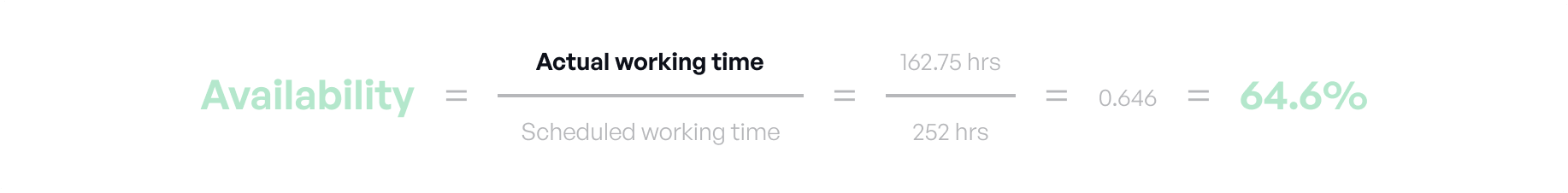

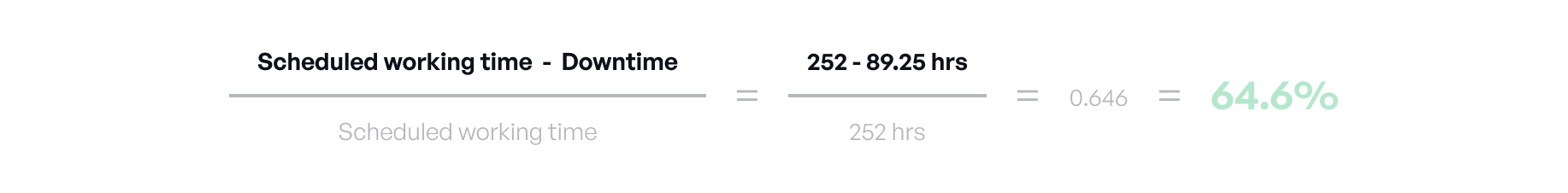

Availability is essentially the time that your machines are actually working, as a percentage of scheduled working time.

To find equipment/machine availability, divide the working time by the total scheduled time for that period. Then, multiply the result by 100 to show it as a percentage.

You already know your scheduled working time, but how do you find out your actual working time?

Doing that is simple. Register all stops (downtime) and subtract them from your scheduled working time.

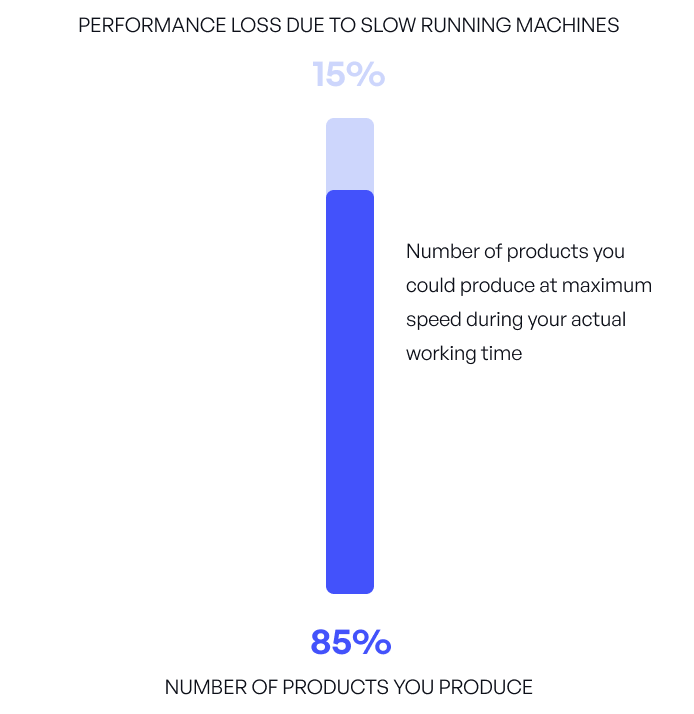

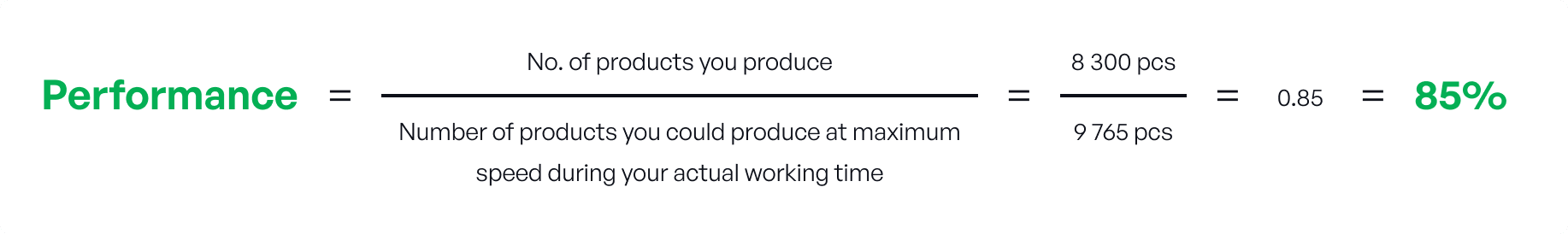

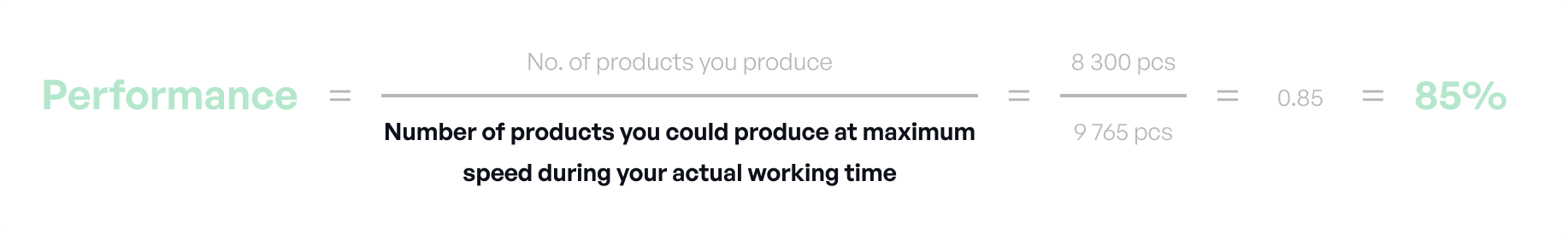

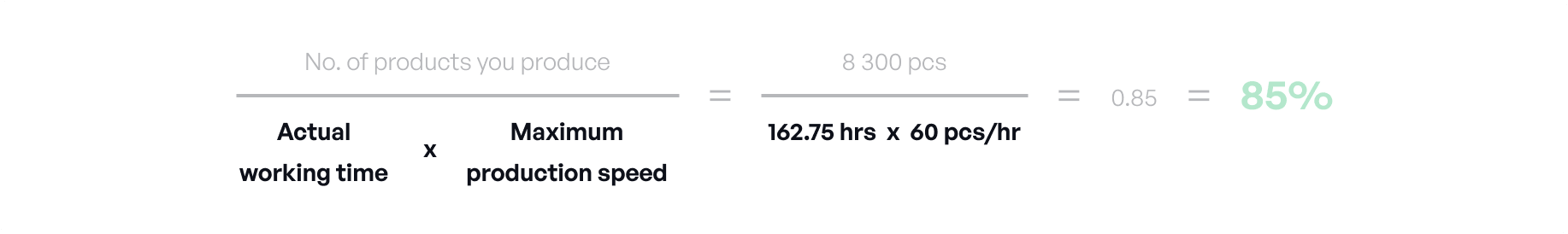

Performance

To calculate performance, you need to find out how many products you produce, and how it compares to the number of products that you could produce at maximum speed during your actual (not all scheduled, but actual) working time.

The formula of the Performance component of OEE is:

You already know how many products you produce (keep in mind, these are all products, including scrap), but how do you find out how many you could produce?

To do that, you simply multiply your actual working time and your maximum production speed.

How do you find out your maximum production speed?

Sometimes, the manufacturer of the machine specifies it (it might also be called “nameplate” or “ideal cycle time”). If not, you can identify the fastest recorded time. Firstly, look at the machines’ performance history. Next, calculate how many products you would make if your machine ran at that speed.

If you don’t have this data, we highly recommend implementing an OEE software that does these calculations for you and gives you the data you need to manage and improve OEE.

Real-time OEE Software

Track and analyze the performance of all your production shifts across different dates, stations, factories, and countries. Free for 30 days.

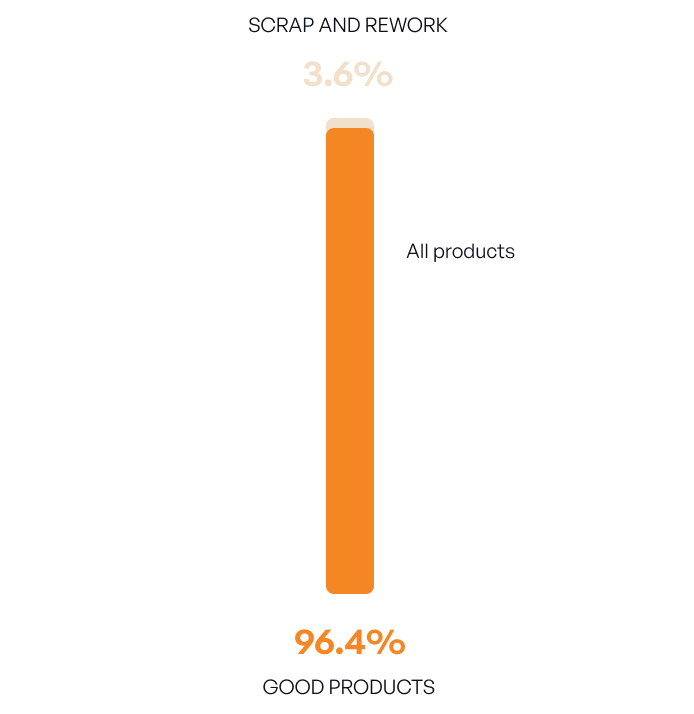

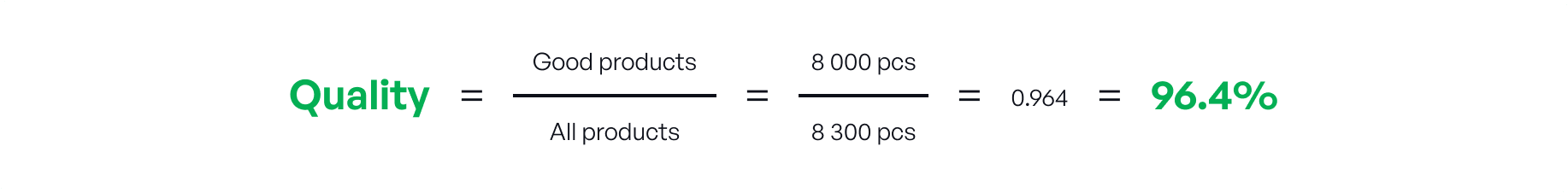

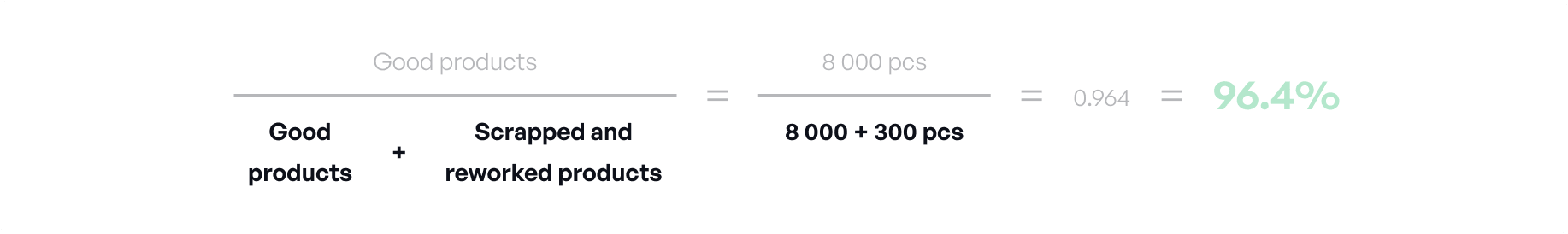

Quality

Simply put, quality shows the portion of good products among all products.

The formula for Quality is:

“All products” is simply good products + scrapped + reworkable products.

OEE Formula: Multiply the Three Components

If you multiply all OEE components, you will find the OEE value.

The best way to work this out is with our OEE calculator, but having the following formula is also incredibly useful. For example, if you know the other values, you could use them to discover a missing OEE component. If you know your OEE, performance, and quality, then you can find out availability like this:

OEE Calculator

Discover your hidden factory! Try our free OEE calculator to estimate your OEE and calculate its components.

OEE Implementation Guide: A Path to Manufacturing Excellence

Understanding and implementing OEE is a strategic move toward achieving optimal manufacturing efficiency. Once the OEE Calculation is complete, strive toward a systematic implementation that will set you up for success.

- Define your ‘Why’. What is the core problem you’re facing that OEE aims to address?

- Nominate a dedicated OEE ‘champion’ who takes ownership of the implementation from start to finish.

- Create a pilot project monitoring a specific machine or production line. Set clear, accessible goals. Always think about how to optimize resources and improve the bottom line.

For a detailed guide, consider reading the Modern Manufacturer’s OEE Implementation Guide.

Key Takeaways

Mastering the OEE formula is essential for any manufacturing organization aiming to boost operational efficiency and productivity. By understanding how to calculate OEE and breaking it down into its core components —Availability, Performance, and Quality — you can gain insightful data about your production processes. This guide has provided you with the formulas and examples necessary to calculate your OEE accurately. Applying these calculations enables you to identify inefficiencies, reduce downtime, and enhance overall product quality. Regular monitoring and optimization of OEE can lead to substantial improvements in manufacturing performance, ultimately driving better business outcomes.