Built for the food industry

OEE is the gold standard metric for measuring manufacturing productivity among Food manufacturers. 75% of food processing operations measure OEE and closely monitor data to make continuous improvements in the plant.

Measuring OEE in a food manufacturing facility delivers a number of key benefits. By automating and digitizing the data collection process from machines, manufacturers have access to real-time data about down time, and cycle times, allowing them to increase production line availability, performance, and quality.

Evocon is built for the food industry. Medium and large manufacturers from more than 50 different countries trust Evocon to monitor their production and track their OEE.

“Evocon has visualized our entire production process, and now we precisely know what our challenges and bottlenecks are.”

Rein Remmelg, Operations Development Expert, HK Scan

4.7 out of 5 rating based on Capterra user reviews

Easy to use. Easy to understand.

Sensor automatically registers production data

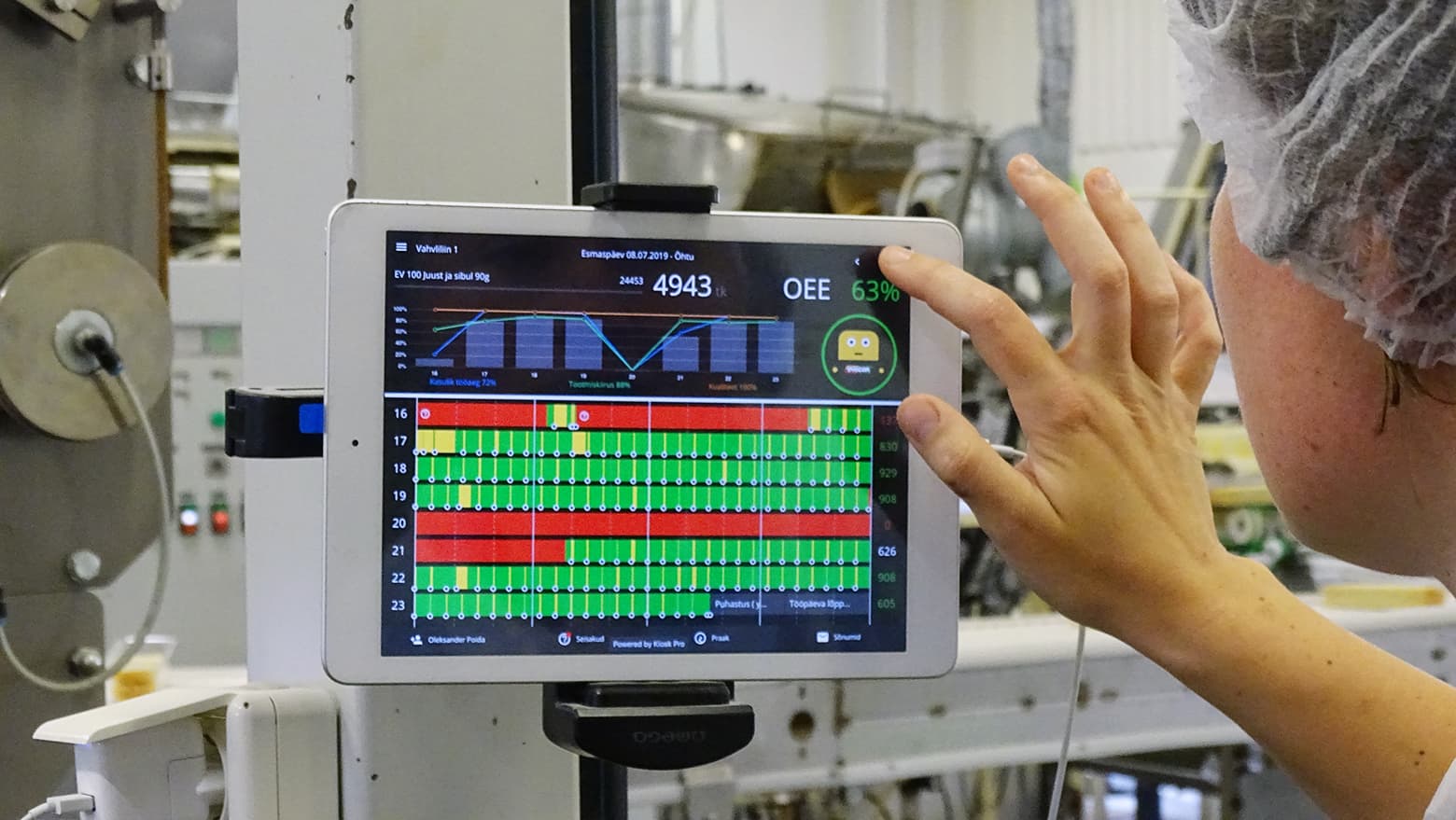

Production monitoring and OEE tracking is available in real-time to operators and office users

Operators can record reasons for stoppages

The perfect toolkit for your team

Evocon gives your team all the tools they need to improve OEE and understand the production process.

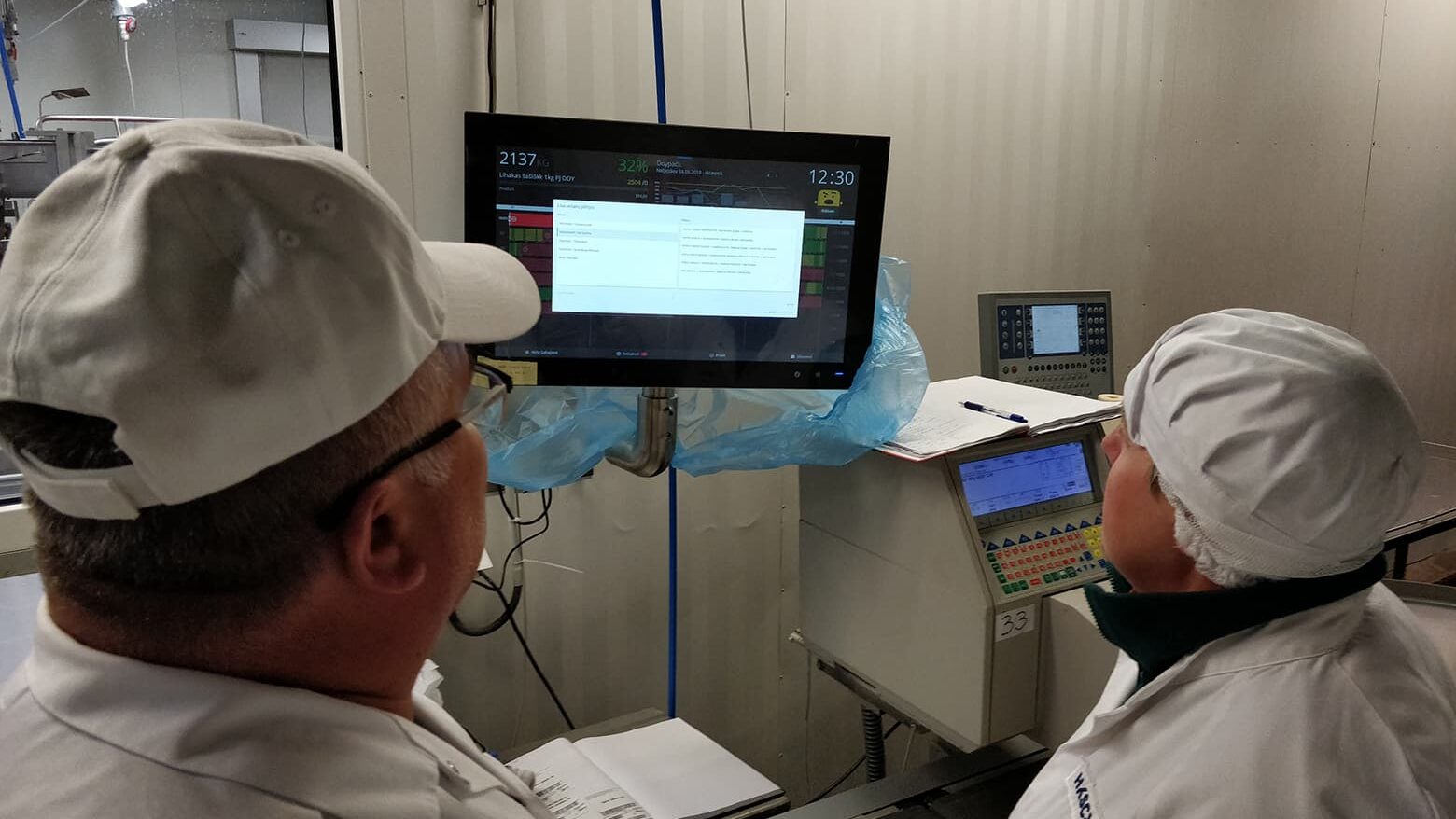

Unite people with actual data

Shift View helps you track and analyze all of your production shifts across different dates, stations, factories and countries. It gives you an hour-by-hour overview of what has happened (downtime, speed, quality) and helps you assess the efficiency of your shifts.

Empower everyone with information

Evocon’s Dashboard provides the means to visualize your production data and helps monitor production performance in real-time and on the go. Use it to upgrade your daily and weekly monitoring process.

Measure the heartbeat of your factory

With Factory Overview you make the status of all your machines visible to everyone. This gives your team the transparency they need to manage the factory in real-time and allows them to quickly react to any issues. No more unpleasant surprises.

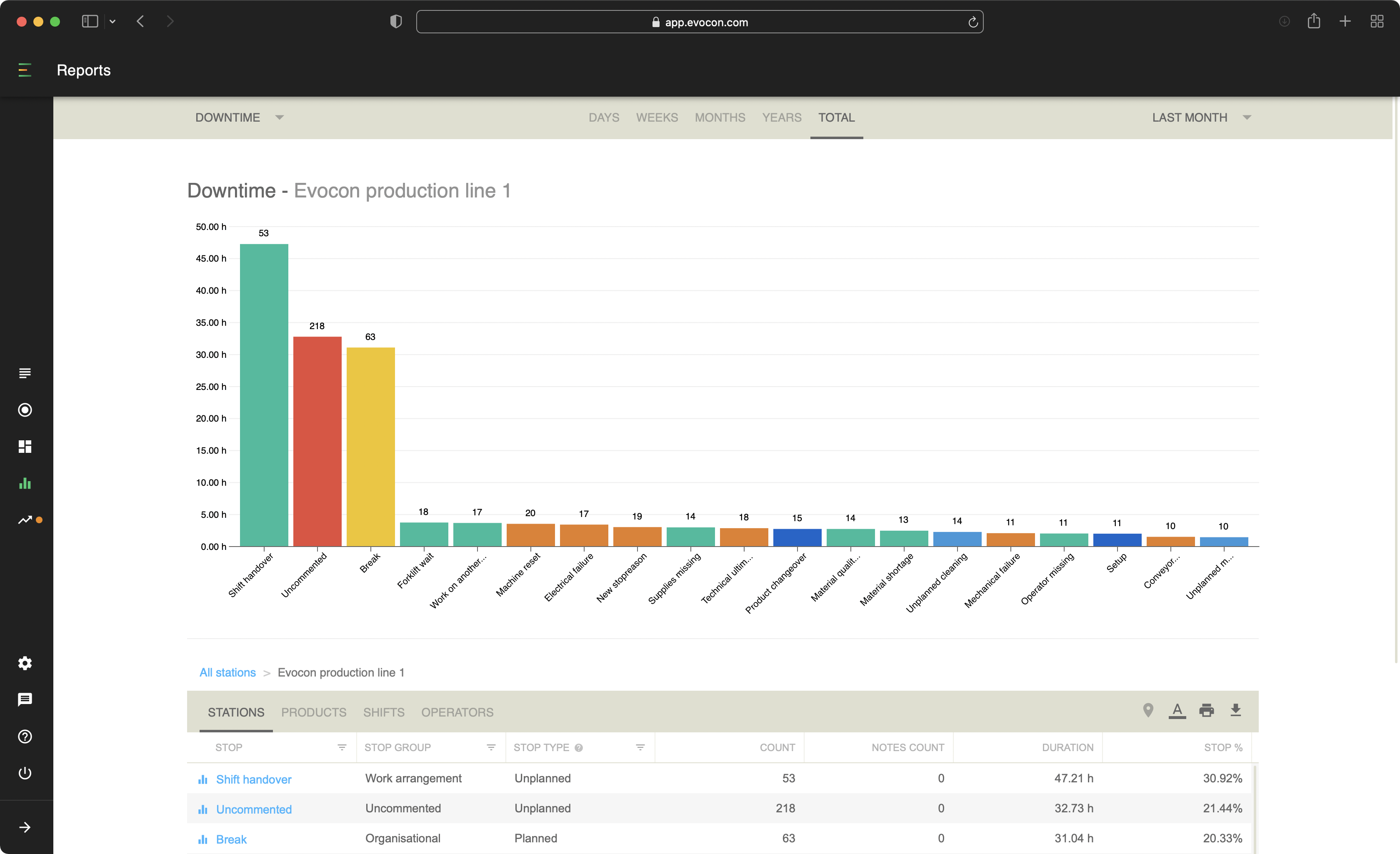

Automate reports and save time

Our Reporting module offers automated production reports that include the analysis of OEE, downtime, time usage, quantities, and cycle times.

Trusted choice by food manufacturers worldwide

Evocon helps companies around the world achieve their biggest goals, faster.

ELBAK SA is one of the leading producers of canned fruit in Greece. The company is using Evocon to monitor its production and track OEE in real-time. ELBAK has already seen an increase in its OEE results, which translated into an equal reduction of production costs.

Read more: Leading Producer of Canned Fruit in Greece Reduces Costs by 6.9%

HKScan is one of the biggest manufacturers of meat and food products in Scandinavia. The company operates in Denmark, Sweden, Finland, Estonia, Latvia, and Lithuania, and export to over 50 countries. Evocon has supported HKScan to maximize machine utilization.

Real more: How HKScan Uses Evocon to Maximize Machine Utilization