Jeld-Wen France is using Evocon on 26 production lines at their plants in the country. We recently talked to Aurelie Delaye, Project Manager at Jeld-Wen France, who has been in charge of the roll-out of Evocon. We also talked to Franck Capdordy, Continuous Improvement Manager at the company. Both have been using Evocon since the company started a pilot project in the summer of 2020 to compare Evocon to a competing tool to collect and monitor production data and track their OEE.

They shared with us their experience so far using our hardware and software solution to capture production data and visualize the production performance of their lines.

In Search of an Automated Way to Capture Production Data

Franck Capdordy has been at Jeld-Wen France for more than 25 years. He worked as a Production Manager at the plant in Eauze and is currently working as a Continuous Improvement Manager.

As part of his role, he works closely with the operational team at the two plants of Jeld-Wen France to improve the productivity of the machines at the plants. Capdordy explained that the company embarked on its continuous improvement journey 7 years ago, which has been full of different projects.

During that time, among other projects, they developed an internal tool to track different business KPIs in the company. Still, data about production stops and their reasons were recorded manually by the operators.

Delaye and Capdordy explained that one of the problems they encountered was that operators usually only recorded long stops and the ones they thought were significant, which resulted in a lot of subjectivity and underreporting.

“Operators most of the time write about long stops, but we missed the smaller stops of just a few minutes”, Delaye said.

Learn more: Manual vs. Automated Machine Data Collection in Manufacturing

Finding Evocon

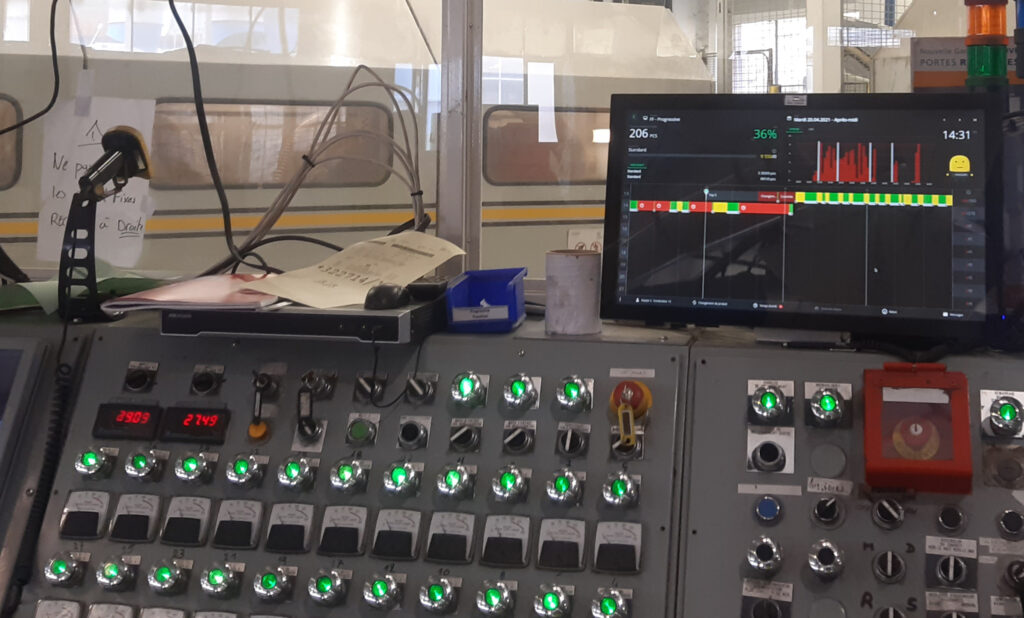

“The reason we implemented Evocon was that we can automate information flow and data coming to our Production Managers, Plant Directors, and others”, Delaye said.

Aurelie Delaye is an engineering student that combines her studies with her work at Jeld-Wen France as a Project Manager. She led the roll-out of Evocon from the beginning when the company evaluated Evocon and a competing OEE solution. Delaye explained that they chose Evocon as it was easier to install and set up and roll out.

“The installation at the plant went quite quickly”, Delaye pointed out.

Delaye explained that the next step is to integrate the production data collected by Evocon with the internal software and information in their data center, which contains information from logistics, shipping, and other areas of the company.

“The plan is to put the data from Evocon to our system and make the information (about production) better and more precise”, Delaye explained.

For this integration, she is working with the Evocon team. She has also received feedback and help from Jeld-Wen Finland, where they have been using Evocon for several years and have integrated the data into their internal systems.

Integratable OEE Software

Try Evocon free for 30 days and seamlessly integrate it with your company's other systems.

Transforming Daily Meetings With Real-Time Data

Capdordy and Delaye both highlighted that the more precise production data collected has allowed the company to use this information in the everyday tasks of managers and plant directors.

Since the information that was gathered manually by the operators was not precise, it was mainly used to have a general idea of the production as a way to make daily, weekly, monthly comparisons. But more detailed information was missing.

Capdordy highlighted that for his work in continuous improvement, the possibility to visualize the production data collected from all the machines and their individual OEE percentage, as well as having the possibility to go more in-depth in the information, in case it is needed, is a great advantage for his work.

Now, Evocon’s Reporting module is used in the production meetings they have twice a day on the shop floor in the middle of each shift.

During these on-site meetings, people from the safety and maintenance departments also participate.

The real-time information from Evocon helps focus the meeting on issues that need to be addressed and can zero in on each machine. This helps them identify and follow up on any bottlenecks in their production.

Learn more: Downtime Tracking and Analysis – Find Out What’s Really Happening on the Shop Floor

Empowering Continuous Improvement With Data

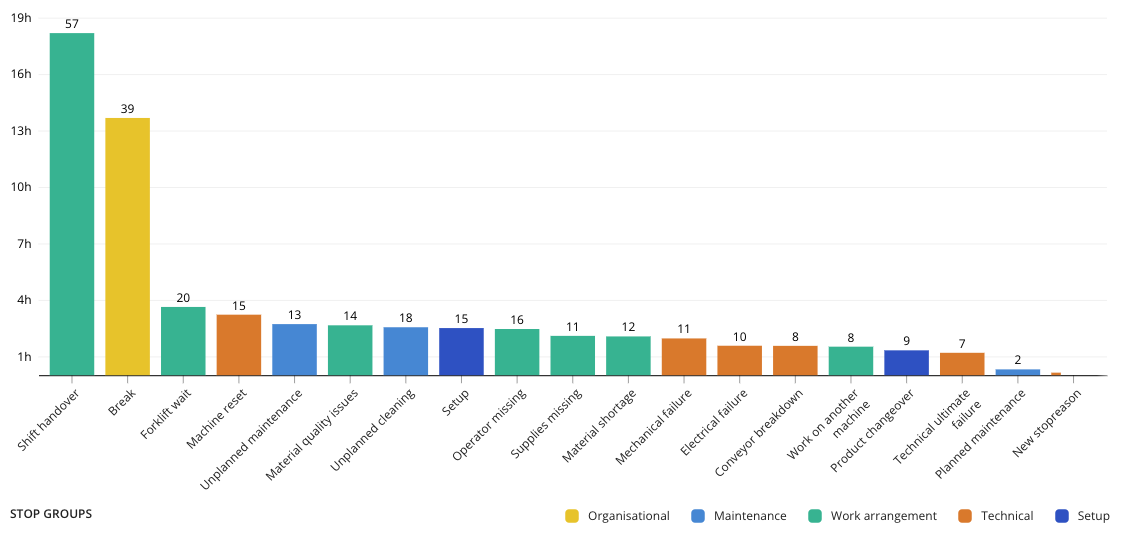

Additionally, Capdordy explains that the Improvements module, a beta feature available at the moment by request, has been very useful for them.

“This was very good for us”, said Capdordy, who explained that they can choose a specific reason for a stop, and Evocon can show them in a specific period the occurrences of that stop, and compare with different periods, and measure the cost of these stops.

Continuous improvement requires time and constant work, Delaye, and Capdordy pointed out. That is why they keep training the team on the use of Evocon, particularly on how to use data to inform the company’s decision-making in production and different departments.

Do you have any questions about Evocon? Please send us an email at info@evocon.com