We have already explained what is speed loss and how to measure it. In this article, we take a closer look at how manufacturers reduce speed loss to increase their production effectiveness. Where possible, we illustrate different types of speed loss with specific examples, which we take from the experience of our clients and a few recent research papers.

In this article, we would like to note that we focus on how to solve production speed problems without buying new or better equipment.

The Tradeoff

One more note, before we dive into the topic. Often there is a tradeoff between the three OEE components: performance (production speed), availability (duration of stops), and quality (rejects).

Increasing the speed too much can result in additional downtime and reduced quality. For example, running a machine too fast may cause higher levels of vibration, this can affect the quality and may result in rejected products. It can also speed up the wearing of the equipment, resulting in repairs, extra cost for spare parts, and shortened lifespan of the machine.

So, let’s remember that while we are discussing the problem of slow speed and micro stops, we need to keep in mind how it affects availability and quality.

But let’s dive in now. We discuss three types of speed loss problems:

Human factors

Optimal process

For production lines with a high degree of manual work, the biggest potential lies in organizing the process to make the manual work easier, faster, and more motivating. You may consider:

- The steps of the process. Perhaps it is possible to skip some steps or combine two tasks into one. In certain cases, it is useful to rearrange the order of the steps to create a more balanced flow, avoiding bottlenecks or waiting. Or, perhaps some tasks could be performed on several products at a time, instead of one.

- The right people in the right places. People perform differently at different tasks. Consider switching people around in the areas of problematic performance.

- The right tools. Check if the right tools are available and if they are working properly or malfunctioning all the time. Maybe there is a possibility of getting better tools, such as electrical tools instead of manual ones.

- Clean and tidy workspace. It is easier to move around and find tools and materials in a tidy environment. There is a psychological effect as well: it affects motivation.

- Design of tasks to be physically comfortable. When people are comfortable at work, they perform much faster. This is the area of ergonomics, a whole science with plenty of research material available.

Ergonomics

Ergonomics takes into account human posture, movement, balance, the field of vision, and strength required to do the tasks.

One example of application of ergonomics is a Japanese factory that started to make protective gowns. A worker noted that it is difficult to bend forward to reach for the edge of the material when folding it. She suggested that having two people to fold the sheets would make the task faster and easier, increasing the efficiency even when double the labor cost is taken into account.

As a result, the company was able to increase speed significantly.

The learning curve

The learning curve, also called the experience curve, basically means that experienced staff performs faster. While experience automatically increases with hours spent at performing the task, there are also ways to help it:

- Increasing specialization. People work faster when they perform the same task all the time. However, be careful not to specialize too much. The downside of this is a lack of motivation and inflexibility.

- Decreasing turnover. One great example of this is one of our clients, who created a bonus system around OEE to motivate workers.

- Standardizing procedures. Ensure that procedures are standardized and instructions are available to everyone so that people don’t experiment too much or fall into “bad habits”. However, don’t forget to welcome discussions or new ideas.

- Sharing best practices. Study how the best performers operate and encourage others to copy. Then, standardize practices that work universally.

Note: Evocon’s system has built-in functionality that enables recording and sharing best practices.

Let’s illustrate this last point using an example from one of Evocon’s clients, a metal component producer Meconet.

Meconet, had a “raw material filling” issue come up at the top of their downtime reasons’ list. Looking at the data, they saw that some operators filled the raw material feeder much faster than the others. A visit to the shop floor revealed that more experienced operators prepared material before machines ran out of it. So, the fastest operators were asked to share their way with the rest. This simple solution reduced the average filling time by 30%.

In this last example, the factory solved an availability issue, not a speed loss issue. However, with Evocon, both downtime and speed loss issues are recorded, as well as the reasons why those issues are occurring. This lets our clients deal with speed loss as effectively as with downtime.

Learn more: Meconet: 50% Increase in Operating Time in 5 Months

Low speed targets

Another human-related issue we see very often is when speed targets are set too low. The good news is that the solution is simple – to increase the target by adjusting ideal cycle time or maximum speed in your OEE software settings to be a realistic, but a more challenging number.

We have a guide on how to do this, even if your supplier hasn’t provided your machines’ official maximum speed. In summary, it works like this: find out what is the processes’ performance when it runs at it’s best, set it as the initial goal, and communicate to the personnel. Once this speed target is achieved with ease, see if you can increase the target again.

Production scheduling

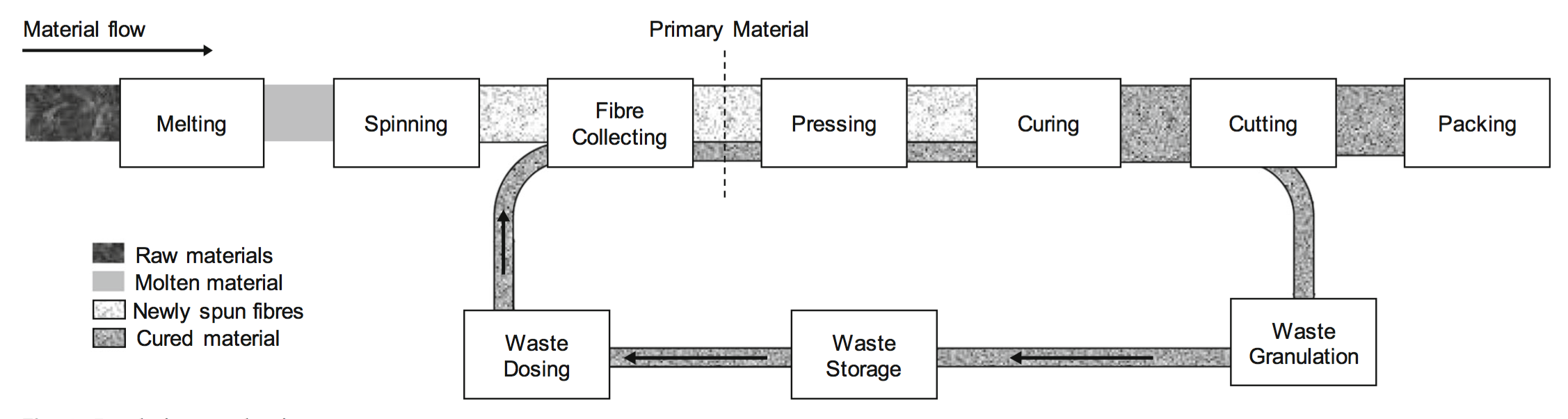

One interesting source of production line efficiency is the psychological effect of production scheduling. To illustrate this, we use a case study from the research paper “Why slow down? Factors affecting speed loss in process manufacturing”, which analyzes a building insulation factory in Europe.

The factory makes several different products using two production lines. Each product has a different speed target.

The factory collected detailed data for 3 months. Here is what they found after analysis.

- The psychological effect of different speed product schedule. Researchers noticed that the scheduling of product batches had an interesting effect on operators’ perception of speed targets. Whenever operators knew that their next product had a high speed target, they tended to increase the current product’s speed in preparation for the faster product. That way, if products with the most speed loss were scheduled just before products with high speed target, production became faster, resulting in lower speed loss for the whole product mix. Similarly, it took operators a while to “wind-down” after running a fast product. So, a product with high speed loss could be scheduled not only before a fast product but also after it.

- The length of run time. Another variable that was associated with decreased speed loss was the length of run time. The researchers had expected that longer run times would result in less speed loss. However, that was only true for run times that were longer than two hours. The analysis showed that for run times shorter than two hours, the relationship reversed: shorter run times resulted in less speed loss.

These two examples show that an in-depth analysis of production scheduling and its impact on speed can offer cost-effective solutions to reduce speed loss.

Product Factors

Product changeovers

While changeovers cause downtime and not speed loss, speed also decreases because frequent changes destabilize process settings. Therefore, it is important to analyze if it is possible to produce larger batches instead of smaller ones.

Product quality

Product quality of finished goods can cause small stops as the line has to be stopped to fix quality issues. For example, if boxes are not closed properly on a packaging line, an operator has to make small stops to close them. In a case like this, the solution could be either to slow the line down just enough to avoid quality issues or to investigate whether quality could be maintained without slowing down the process.

Also, consider if the quality of your products is too good. The product’s quality needs to be exactly as specified or a little bit better, but it does not need to be much better. For example, a metal part may not need a fine surface finish if it is going to be used somewhere where it doesn’t matter. So, you might speed up the process by accepting a higher level of roughness.

Material quality

The quality of material may slow down production lines. For example, a product is assembled from a few parts glued together. When a lower quality glue is used, the parts don’t stick together as well as usually. So, the line is run slower to give the glue time to do its job. In this case, measuring this speed loss helps to decide whether it is worth purchasing better quality glue.

Technology Factors

Equipment design weakness

Sometimes machine producers are not the best specialists of the production process, or perhaps your production process is unique, and the machine does not fit the process ideally. You need to question existing solutions: are they the best for your environment and your processes? Maybe, small add-ons or changes to the machine could help increase the speed. Let’s look at an example of this problem and its solution.

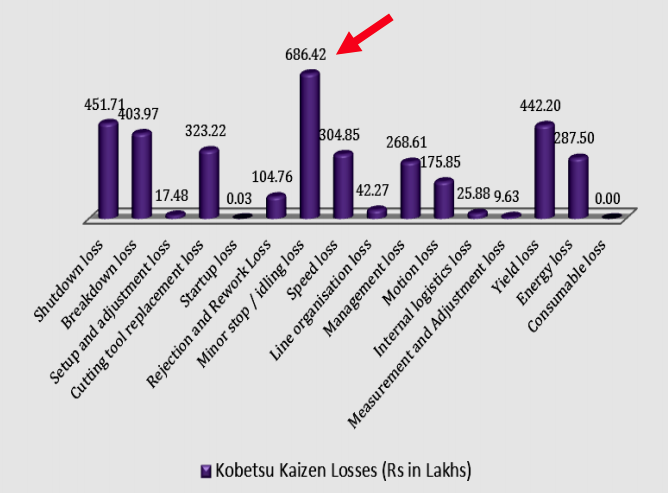

For this example, we use a case study of a steel plant in India from this research paper: “Kobetsu Kaizen Losses Analysis to Enhance the Overall Plant Effectiveness in Steel Manufacturing Industry.”

Example of an equipment design weakness

The data collected from May 2017 to July 2017 showed that out of 16 TPM losses, minor stops caused the biggest loss in monetary terms. This contributed to the fact that the performance rate was only 72%, the lowest of the three OEE components (availability, performance, and quality).

Researchers used 5 Whys analysis to find the root cause of the problem:

- Why is minor stoppage/idling loss so high? Due to frequent jamming of discharge chutes used to slide material from a conveyor belt to a lower level.

- Why does frequent jamming occur? Due to malfunctioning of the discharge chute.

- Why does discharge chute malfunction? Due to a heavy flow of material from it.

- Why is there a heavy flow of material from it? Due to no control at the inlet of the chute to control the incoming material flow.

- Why is there no control at the inlet of the chute?

ACTION: Corrective action recommended as Kaizen to establish effective control to prevent such type of failure.

RECOMMENDATION: A periodic hammering system needs to be established at the outlet to prevent blockage of material.

After implementing the solution, the performance rate increased from 72% to 87%, which saved the steel plant about Rs 530 lakhs ($941,000) per month.

Tip: From our experience, many of our clients experience minor stops that they were not aware of previously. By implementing an automated system to track production, you get the transparency you need to know if this is a waste that affects you or not.

Real-time Production Tracking

Monitor production in real time to gain the transparency needed to improve your processes. Free for 30 days.

Limits to the speed of physical processes

Whenever you work on increasing the speed of the physical handling of materials, you need to deal with four main constraints that limit your efforts. These are:

- Machine stiffness

- The ability of tools to accelerate

- Heat transfer

- Fluid flow

We will briefly review each of these constraints to the speed you can achieve and what are the options to increase the speed without buying new equipment. This chapter is based on the research paper “Manufacturing at double the speed” (Journal of Materials Processing Technology, March 2016).

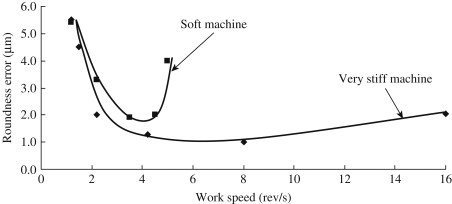

1. Machine stiffness

If you have ever driven a sports car, you may have noticed how “stiff” it is to sit in. This is because sports cars are designed for high speed. The same rule applies to machines in your factory.

As you run your machines faster, at some point, you get vibration and chatter. The stiffer your machines and materials are, the faster you can run them before this happens.

Here is an example from Principles of Modern Grinding Technology:

To increase stiffness in your production without new equipment, you could use stiffer materials that you are working with. Another option is to reduce the size of those materials and increase their weight. Generally, smaller and heavier things vibrate less.

As for machines themselves, let’s remember that machines are screwed into the floor to keep vibration low. Sometimes it is possible to do something in this manner when adjusting the machine to a specific situation or product. Basically, you can reduce the movement of the parts of your machine by “fixing” them in place when you don’t need full movement. In other words, if you don’t need all the flexibility that the machine offers, you can reduce it to achieve better stiffness.

2. Acceleration of tools

If you have a CNC machine, or robotic arms that move parts from one place to another, or cranes that lift and move heavy objects, the speed of this process depends on how fast these machines, arms, and cranes can move.

The tools move along a path, where they need to speed up, slow down, change direction. How fast this movement can happen depends on how fast these tools can accelerate.

You can improve acceleration with a good motion control system. A good system can create a smoother and faster movement while avoiding jerking motions.

Also, look at the path of the movement itself. Does it have to be as complex as it is? Can you achieve the same result with fewer movements? Is it possible to rearrange the path to shorten the distance?

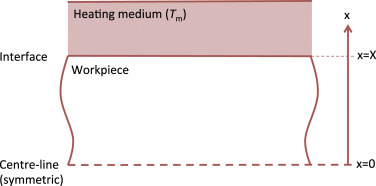

3. Heat transfer

An everyday example of a heat transfer problem is a chicken that you are trying to bake in the oven and ensure that it is well cooked inside but not burned outside. You would have to limit the cooking speed to allow the heat to reach the inside of the chicken.

The same challenge exists in manufacturing when you need to heat the middle of a workpiece as fast as possible without melting or transforming the surface of this workpiece.

What are the options to increase the speed in this case?

Generally, the speed of this process depends on the size and thermal conductivity of the part:

- Doubling conductivity at the point of conduct halves the time required for heating.

- Halving the thickness of the workpiece also halves the time required for heating.

4. Fluid flow

When cutting, grinding, or otherwise forming parts, you often need to use fluids for lubrication or to avoid overheating. These fluids usually reach the required location through a tube.

Here are the options you have:

- To use a thicker tube through which the fluid travels. This is the most effective solution, but it may require higher pressure.

- You could also shorten the tube or make sure there are no sharp bends in it. This helps, although it is usually less effective than a thicker tube.

- You could reduce the viscosity of the fluid. You could use a different, less viscous fluid, but fluids also change their viscosity when their temperature changes, so you could take advantage of that as well.

- And finally, it might be possible to submerge the entire process in the fluid, for example, when grinding a part, that way completely avoiding the need to deliver the fluid.

Interestingly, one of our clients had a speed loss issue related to the viscosity of the fluids, but in this case, it was the viscosity of the product itself. It was a juice manufacturer, and the juice on the bottling line was splashing too much in warm temperatures, resulting in the slow down of the line during summer. However, this is more of an environmental limitation rather than a technological one.

Environmental limitations

The last category of technology-related issues is environmental limitations.

One example of that we have just given above, concerning the manufacturer of juice. Another example would be fertilizers, where chemicals are sensitive to the temperature of the environment.

A different type of environmental limitations stems from regulations, such as limits on emissions.

Conclusion

Let’s sum up the types of speed loss problems discussed in this article and how to address them.

Human related

- Address process steps, rotate people, provide tools, tidy up the workspace

- Design tasks to be physically comfortable

- Speed up the learning curve

- Increase speed targets

- Find the optimal production schedule

Product related

- Reduce changeovers

- Find the right level of quality

- Use materials of better quality

Technology related

- Improve equipment design

- Increase machine stiffness

- Improve acceleration of tools or reduce the need to accelerate

- Speed up heat transfer

- Increase fluid flow

- Take into account the sensitivity of materials to the temperature

- Take into account the environmental regulations

Sources

- “Why slow down? Factors affecting speed loss in process manufacturing” Trattner, A., Hvam, L. & Haug, A.

- “Kobetsu Kaizen Losses Analysis to Enhance the Overall Plant Effectiveness in Steel Manufacturing Industry” Dr. Manish Raj, Shubham Swaroop, Saureng Kumar, Raj Bhushan, Vikalp Kumar, M G Borkar

- “Manufacturing at double the speed” Julian M. Allwood, Tom H.C. Childs, Adam T. Clare, Anjali K.M. De Silva, Vimal Dhokia, Ian M. Hutchings, Richard K. Leach, David R. Leal-Ayala, Stewart Lowth, Candice E. Majewski, Adelaide Marzano, Jorn Mehnen, Aydin Nassehi, Erdem Ozturk, Mark H. Raffles, Raj Roy, Islam Shyha, Sam Turner