As of 2016, Peeter Põder has been working as a Mill Manager at Toftan 2 – the state of the art mill in the south of Estonia. Toftan AS is the second biggest wood processing company in Estonia and the third largest in the Baltics.

In this case study, he shares their experience on how they incentivized improving their processes by implementing a bonus system based on OEE. The message was clear – if the company does well, the people do well.

Choosing OEE as a Success Metric

„To get started with the story, it’s important we lay the groundwork and understand what OEE is,” says Peeter Põder, the Mill Manager at Toftan 2

To understand what is OEE, it’s essential to understand the three components of OEE – performance, availability, and quality. To get an OEE measurement, you multiply the three with each other and in essence, if OEE is 100%, then that means that a machine is working non-stop, with ideal speed, and is producing products of 100% quality. A world-class OEE, for reference, is around 85%.

OEE is an important metric in manufacturing because it reflects how effectively equipment, a production line or a machine is being used. Once you have an understanding of the OEE of your machines, you know precisely how much untapped potential there still exists.

“To make accurate investment decisions and drive change, you need to understand how the current system works.”

And that is the first thing that Peeter set out to achieve when starting as Mill Manager at Toftan 2. Since Toftan 2 was newly built, it was the perfect place to try new things.

“We needed a metric for success and we decided to place our bets on OEE.”

Peeter Põder, Mill Manager at Toftan 2

Implementing Evocon – “The Instagram of Manufacturing”

To start tracking OEE, Toftan chose to implement Evocon throughout the Toftan 2 factory.

The selection process followed a few but very critical criteria that Evocon met.

- The first was that the implemented system must increase transparency.

- The second was the user-friendliness of the system.

- The third, and perhaps the most crucial aspect, was the ease of understanding of data.

“You can only drive change if everyone understands, in a unified way, what is happening in production and what are the problems,” says Peeter.

After implementing Evocon, collected data on OEE became easily understandable and visualized to everyone.

He explains: “If everything is green, we are good, if there are yellow areas, we are experiencing speed loss, and if there is red, then production has stopped.”

This gives a clear understanding of the health of the factory.

Peeter’s take on why the implementation of Evocon was a success:

“If everyone responsible for the success of the mill can see how much downtime there is, they can start to analyze what are the reasons. From there they can start to work out whether a reason is removable or avoidable. Evocon has made all of this very easy to understand – some of my colleagues have even called it the Instagram of manufacturing.”

User-friendly OEE software

Start tracking your OEE with Evocon today to boost transparency, simplify data visualization, and enhance factory performance.

Connecting the Improvement of OEE to a Bonus System

Once the groundwork for measuring OEE was laid and the data was made available to everyone, Peeter and the management team started to take the next steps – setting a goal and a plan on how to achieve it.

They knew they had to incentivize the goal in a way that made sense to people. That’s where the idea of tying the improvement of OEE to a bonus system came into play.

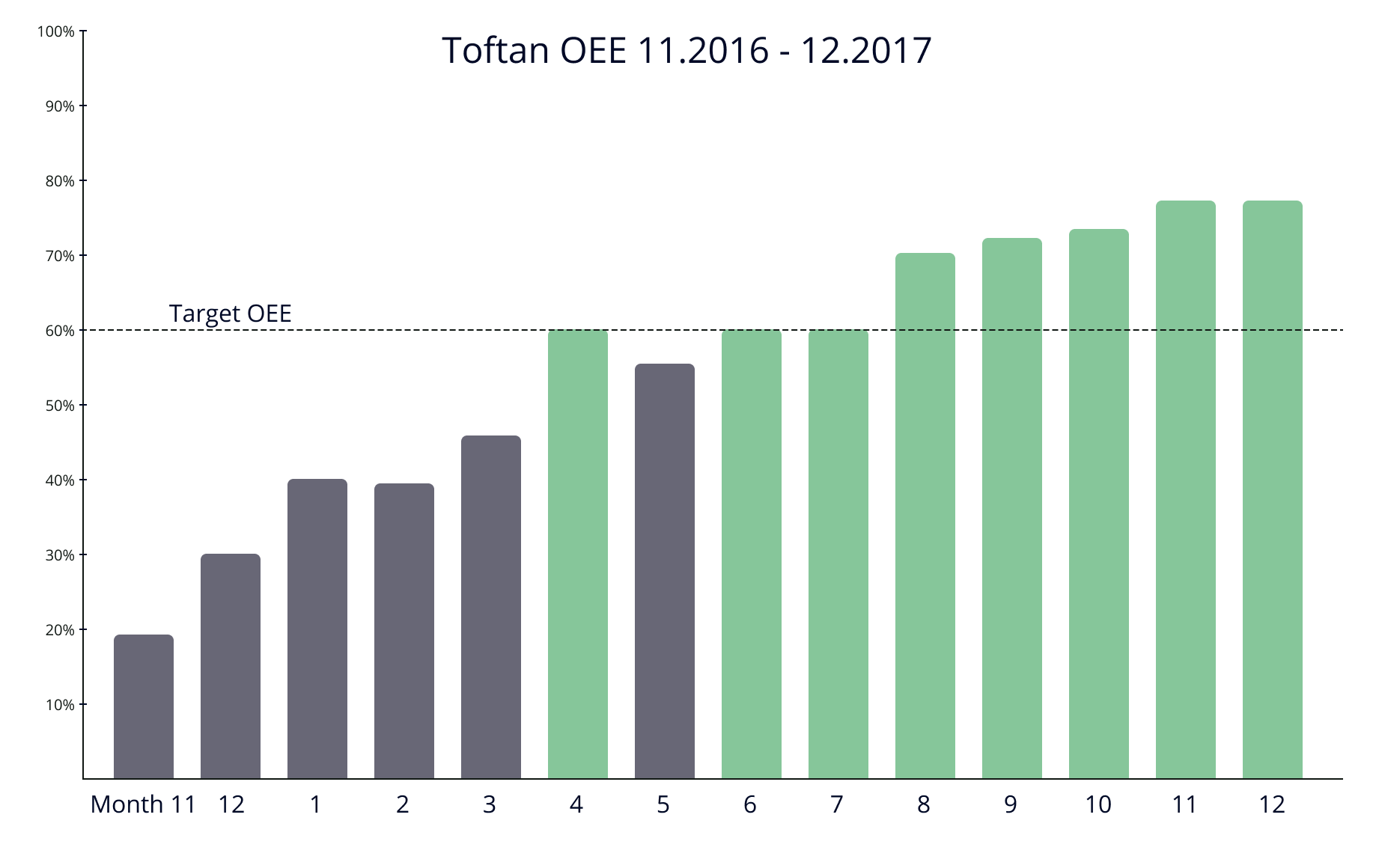

The first goal was set at achieving an OEE of 60%, whereas the baseline was around 40% at the time.

The reaction of the operators was as expected – the goal seemed impossible because people thought that they were already very efficient, and they really believed that they are doing it in the best way. However, this changed very quickly once they understood that achieving the goal will result in a team-based bonus.

Since the proposed bonus was team-based, people understood they putting their backs together will make the target easier to achieve.

Learn more: World-Class OEE: Industry Benchmarks From More Than 50 Countries

The Challenge of Building Trust

The first real challenge was that of trust in the system and the data.

Peeter: “In the beginning, everyone wrote down the data from the screens on paper and there was this huge math experiment making sure that the OEE software (Evocon) is not lying and the people are not being cheated. Some even asked whether implementing OEE can “break” the machines.”

For this reason, they worked very hard to educate their people on the importance of production monitoring. They also made sure that workers understood how everything works. Furthermore, there were lengthy discussions to understand and agree on how to classify downtime reasons unanimously.

The First Benefits of the System

Understanding what the actual problems in production are and what is the real efficiency is one of the most significant benefits of machine monitoring.

“If you know why a machine is not working, then you can find a solution. If you assume you know why a machine is not working, you are playing a game of hit ’n’ miss.”

Peeter Põder, Mill Manager at Toftan 2

The user-friendliness of Evocon is something that Peeter stressed as being one of the biggest benefits of the system:

“You don’t need eight Excel tables to find the right piece of information – it’s immediately clear how production time is used and what are the main losses. The clarity of data resulted in us having much more productive meetings. Emotions were left behind the door and we could focus on solving our actual challenges. Most importantly, we now look at our targets as a collective and work together to improve results both tomorrow and the next month.”

Learn more 3 Ways to Engage Production Operators and Improve OEE

The Results Kept on Improving

“Implementing the bonus system improved OEE by 10-15% in a very short time,” recalls Peeter.

Suddenly pauses, that previously went unnoticed in production, started to disappear. For example, lunch breaks used to be 2-4 minutes longer. But not anymore.

“The red areas in Evocon’s Shift View deflated like popped balloons as everyone was eager to improve the production process. Most importantly, the issues that were present in production became apparent and people could take action.”

“When we first started with the bonus system, our OEE was at 40%. We then increased it by 10%, then another 10%. Four months later, our OEE was at 60%. A year later it stood at 75%.”

Peeter also remembers that in the beginning, when he first introduced Evoocn and OEE tracking, many found reasons why it wouldn’t work and why it’s not right to do things like this. But once they saw that there was much more room to improve than they thought, then the perception of people started to change, and the focus of conversation pivoted to finding ways to make this work.

Developing the Culture

Peeter sums up their experience by stressing the importance of communication and culture.

“When you implement a production tracking system, you have to make sure that everyone understands the why as well as what people stand to benefit from it. You cannot expect people to do this on their own. You have to be proactive.“

The message that Toftan sent to their people was very clear – if the company does well, the people do well. And that was felt thanks to the bonus system that was implemented.

Finally, Peeter adds: “No system is a silver bullet to fix everything. If you want to change the way you do things, you first need to change your culture and provide your people with the right tools to make the change possible.”