Evocon is a production monitoring and OEE tracking solution that helps manufacturing companies drive shop floor improvements. Machine operators are one of the most important players in driving these improvements. This article seeks to empower machine operators and other plant personnel with the knowledge needed to understand Evocon, OEE, and the benefits associated with each.

Why Machine Operators Matter?

Machine operators are the frontlines of the shop floor. They run the plant, day-in and day-out. The reason they play such an important role in OEE is that their actions have a significant influence on how well machines on the shop floor are run. These are, of course, the very machines that Evocon’s OEE software measures.

Ultimately, the person with the most knowledge about how to use a machine, particularly when it comes to what works, what doesn’t, or what it can and can not do, is the person who stands in front of it day after day. This is why we say that operators play a key role in driving shop floor improvements.

Is Evocon monitoring the machine or the machine operators?

At this point, a perfectly natural question for operators to ask is:

- What exactly is Evocon monitoring?

- Is it the machine I operate or is it my performance using the machine?

The honest answer is both.

Admittedly, this may unnerve or slightly offend some operators at first glance. But there are tried and true methods of working through this natural resistance to change. We discuss a real-world example of one of our clients working through resistance to change in a case study that you can find here.

Ultimately we have found that for hundreds of clients across a wide variety of industries, machine operators find Evocon overwhelmingly positive.

Shop Floor Challenges that Operators Face

Machine operators know all too well the challenges that come about on the shop floor:

- Machines break,

- Team members call in sick or move to other jobs,

- Suppliers fail to deliver material or deliver material that is not high quality.

The list can go on and on. For our purposes today, though, let’s focus on a few of the larger systemic challenges that operators may face.

Owning results but not the process

Perhaps you have encountered a situation like the following. Several months ago your company began producing a new product. During the roll-out, supervisors, engineering, and upper management were on the shop floor to smooth out the kinks in the production process. During this time, managers determine that a machine can produce 100 items an hour.

In the following months, though, every time the new product is run, your machine operator has only been able to produce 80 items per hour. All eyes are on the operator, and the plant manager wants to know what is going on.

The operator knows why.

He tells anyone that will listen, and still nothing changes. He suggests that if he were allowed to change the process slightly, then yes, 100 units per hour would be possible. Still, nothing changes.

Unfortunately, we have seen this situation play out time and time again. We call it owning the results but not the process that produces those results. It is, without a doubt, one of the most frustrating experiences a machine operator can encounter.

There is a better way, and Evocon can help.

OEE software

Equip your operators with the tools they need to boost productivity and streamline workflows. Free for 30 days.

Getting credit where credit is due: was anybody listening?

Continuing our example above, imagine now that several more months pass and nothing changes. Eventually, the operator becomes fed up with the situation and requests to move to a new position.

Once a new operator is trained, and the problem product is run, the previous operator is vindicated. It turns out that no one can produce more than 80 units per hour. They experience a short-lived victory imagining that finally something will change. Or, at the least, supervisors will see that they were not crazy.

Things do change. Engineering and management return to the floor and study the process for a week. At the end of the week, a young engineer proudly announces the solution at the daily start of shift meeting. Your operator recognizes it, of course, after all, it was what he suggested in the first place.

Trust, change and initiative fatigue

If you have worked for a manufacturing company long enough, then it is likely you have seen many new programs started. Each one comes with the promise that the change will bring about something desirable for management. Perhaps your operators ask tough questions about the proposed change. But instead of getting direct answers, they are asked to “trust that the change is for the best”.

Each new program has a list of new things to keep up with and stay on top of. We aren’t saying that every new program or change is a bad idea. We are saying that when new programs are introduced, a careful review of what all operators are being asked to do should be part of the roll-out. When it isn’t, your operators can end up with more to do because of the change. This is a problem when they can not see evidence of the promised improvements. Let’s call this initiative fatigue, and it is also a very frustrating and common experience.

The good news is that when implemented properly, Evocon and OEE tracking are not just another change initiative. Instead of adding tasks, we use data automation to give operators more time to focus on the things that matter. Like, making the product right the first time.

Unrealistic expectations: you need what by when?

A follow on consequence of initiative fatigue is unrealistic expectations. When you are progressively given more and more things to keep up with, without a careful review of what all you are being asked to do, it is easy to find yourself being asked to do a job that isn’t actually possible to do. There are few situations more frustrating for a machine operator, or anyone for that matter.

Disconnected feedback

Another common situation we see is where feedback is delayed or disconnected. That is, discussions on what worked or didn’t, isn’t discussed until 5-7 days after the fact. Sure, there was mention of it being a good or bad day during the next morning’s start of shift meeting. But the main feedback and focus comes too long after the fact for anyone to recall exactly what happened.

This is an example of disconnected feedback. Too much time has passed for the feedback to be actionable. Evocon is changing this situation by providing you with real-time visibility of how things are running on a moment-to-moment basis.

Connecting your actions to results: show me how this affects that?

Similar to disconnected feedback is the difficulty of being able to see, moment-to-moment, how your actions influence production. Your operators might find themselves sitting in the above mentioned weekly team meeting asking:

“Ok, sure we had good/bad day for production yesterday, but can someone please show me how my specific actions lead to this result?”

Evocon makes it possible for you to answer this question. This is accomplished by providing you with real-time visual feedback on how the line, including your specific machine and process, is performing. No longer do you have to wonder how your actions affect performance, you now only need to look at Evocon’s Shift View, and you can see for yourself.

Benefits of Evocon for Machine Operators

So far, we explored several interrelated challenges from the shop floor that machine operators may face. Let’s turn our attention now to how Evocon addresses these challenges. Specifically, let’s talk about how they benefit from Evocon and live OEE tracking.

Calling All Good Ideas

Remember the situation we described above where you had a good idea to change something, but no one seemed to be listening? Consider the same scenario, but this time your company is using Evocon.

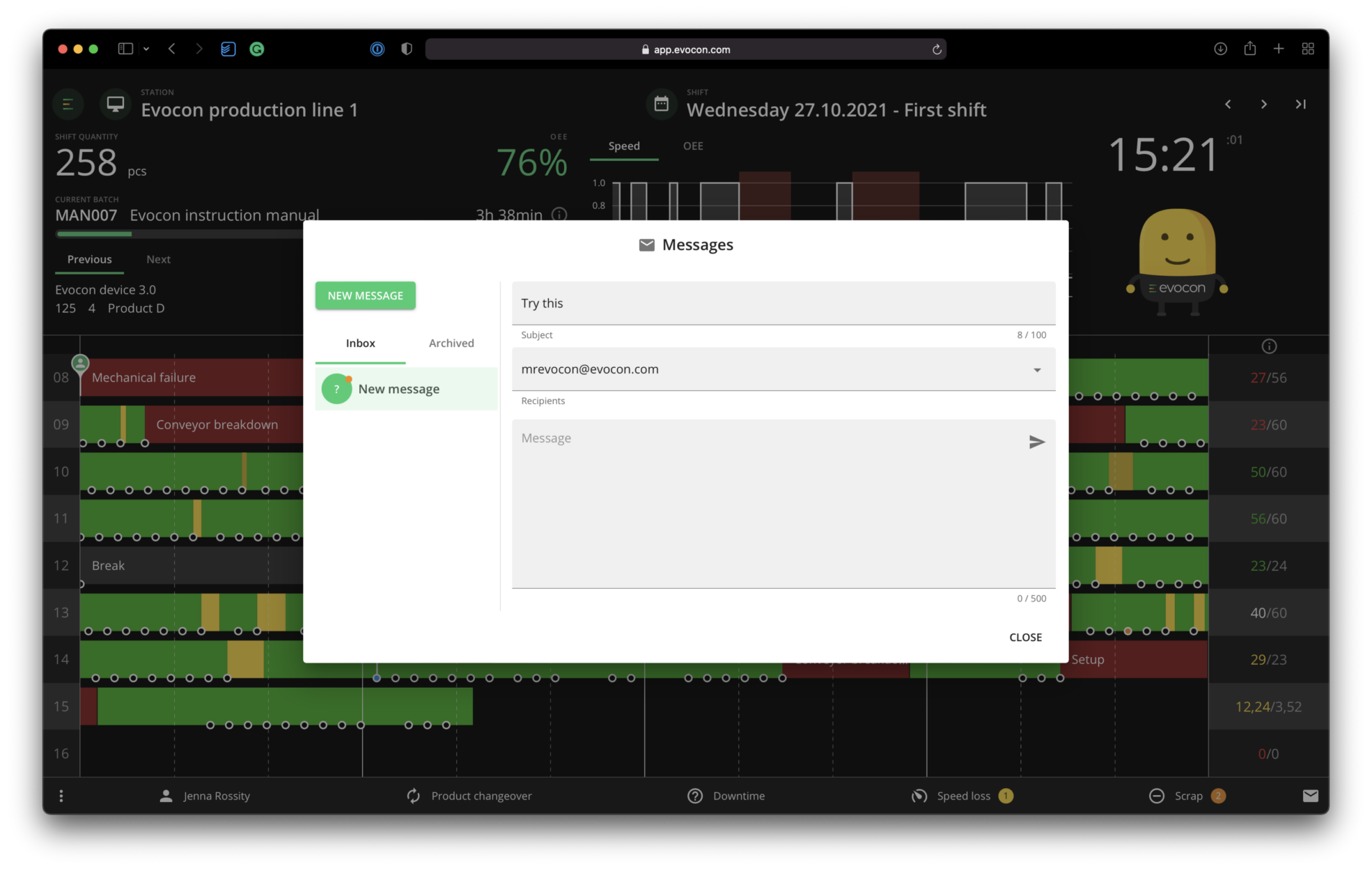

You run the product. As you expected, output declines. Instead of operators telling their supervisor directly, they send a message describing the issue. They include an idea for improvement and reference a specific time when production was slow.

During the next shift meeting, the operator calls attention to the message and asks if they can change the process. At first, there wasn’t much interest. But then a supervisor looks into how much the slow down in speed cost, and because your company is using Evocon, this is quite easy to answer.

This is because Evocon allows your company to easily understand the cost of slowdowns in production. Further, when you do try something new, you get immediate feedback on whether or not it works. This means that more good ideas get implemented faster.

Make your life easier

When more good ideas get implemented faster, all of our working lives get easier. This is what is truly at the heart of Evocon and OEE: improving production processes and, in turn, improving our work lives.

See how you are doing in real-time

With Evocon giving you and everyone on the production line real-time visual feedback, operators always know how they are performing. Gone are days of disconnected feedback and the inability to see how actions influence outcomes.

Easily report problems

When things do go wrong on the shop floor, be they operational or managerial, Evocon gives machine operators the ability to easily report them. Operators and managers agree that this helps avoid confusion. Confusion, that at times can lead to blame being placed incorrectly on operators.

The overall effect of being able to easily report problems is that issues become transparent so everyone can work together to solve them. Ultimately this makes for a friendly and more productive work environment.

Common Myths of Production Monitoring

Evocon is used to assign blame

It is, unfortunately, true that many supervisors have been guilty of playing “gotcha” with machine operators. They collect data, and then when they find any small detail that they believe they can connect to an operator, they pounce. To be very clear, this is the worst and most ineffective method of managing people. Moreover, instead of improving performance, processes, and production suffer.

At Evocon, we believe that machine operators are the key to improving production processes. We believe that if the process is not performing correctly, then 95% of the time, it is NOT a machine operator’s fault. Rather, the design of the process is poor.

While operators might be quick to point the finger at management for poorly designed processes, we recommend avoiding this situation. Trying to assign blame when things don’t go well is a waste of time. A better use of time is to work on formulating solutions. The latter has the power to change things, whereas the former primarily delays changes from taking place.

Companies use evocon to reduce headcount

When Evocon is first introduced at a company, sometimes rumors circulate that it is going to be used to cut costs and reduce headcount. Let’s tackle this head-on right here.

Evocon is not designed to reduce headcount. It is, however, designed to improve production processes that involve machine operators. This helps companies do more with the machines and the operators they have.

Conclusion

In this article, we discussed several of the common challenges that operators may encounter on the shop floor. We then went on to show how Evocon addresses these problems and explained the benefits operators stand to gain by fully participating in your company’s new OEE program. We also addressed some of the myths that most manufacturers face when implementing production monitoring. The bottom line is that in most cases, machine operators are the ones who benefit most from the use of an OEE software, however unlikely it might seem at first.

Sources

- Brunson, William H. OEE For Operators. (1999) Portland: The Productivity Development Team

- Wetherill, M., and Künnapuu, A. (2017). OEE at Work. Paris: Bb&b