A truly sustainable manufacturing process is the goal for many companies. In this article, we take a look at the Green Manufacturing framework that we deem to be the most practical and relevant to help reach that goal.

Can Manufacturing Be Sustainable?

Before we dive deeper into why Green Manufacturing can be a beneficial approach for your company, let’s clear up the terminology. As much as we’d like to see the manufacturing industry be sustainable, at the moment, it’s a bit of an oxymoron.

Manufacturing is the process of turning raw materials into finished goods. That, by definition, is not sustainable. A sustainable business creates interchangeable inputs and outputs. It’s a closed-loop, also known as cradle to cradle. Ideally, a sustainable manufacturing plant would:

- produce more energy than it uses;

- create more new materials than it uses;

- produce zero waste;

- clean more air and water than it pollutes.

Today reaching just one of the criteria mentioned above is a strong sign of a company’s leadership in environmental issues. Reaching all of them is something that seems impossible for most companies.

Learn more: How to Define Waste in Manufacturing?

Sustainable manufacturing examples

Truly sustainable manufacturing is no easy goal to achieve, but many good examples exist. We can’t vouch for these companies meeting all the criteria above, but they are definitely examples of the best practice.

For example:

- Sierra Nevada, a well-known California beer brand. In the company’s California facilities beermakers, compost waste generated from the brewery into the soil. This improves the soil’s fertility which is then used to grow new barley and hops to make more beer.

- Patagonia – an American retailer of outdoor clothing. As of 2020, they’re at 100% renewable electricity in the US and 76% globally, achieved through both on-site and off-site installations. And that’s not all of it – in 2020 94% of their product line used recycled materials and they repaired over 100 thousand garments to extend their life cycle. On top of that, they also have been contributing one percent (1%) of their annual net revenues to nonprofit charitable organizations that promote environmental conservation and sustainability.

- Germany’s Siemens AG also provides a story of reinvention. The company’s spin-off Siemens Energy Global established in 2020, has become a major supplier of renewable power and energy solutions for the developing world.

However, the majority of the manufacturers are far from the examples shared above. Due to various roadblocks, for many, it’s been challenging to move the needle in becoming truly sustainable. For these companies, the Green Manufacturing approach has been highly beneficial.

Begin your sustainability journey

Contact our team to start improving the efficiency of your operations and become more sustainable.

What is Green Manufacturing?

Green Manufacturing, also known as Lean & Green, is an approach to evaluating and improving the manufacturing process. It’s based on Lean manufacturing principles and thus provides a dynamic, proven, and successful approach to going green.

The Green Manufacturing framework is built around the 7 Green Value streams and offers a clear vision to strive for in each of them, for example reaching 100% renewable energy powered operations or zero waste sent to landfill.

It’s also important to note that there currently is no accreditation or external audits for implementing the Green Manufacturing framework. This framework is useful for manufacturers to improve their processes, track their progress and share that progress with stakeholders.

Green value stream approach

The difference between Lean and Green is that in the case of Lean, waste is viewed from the customer perspective, and in the case of Green – from the environment’s perspective.

The rest of the framework – principles, processes, and tools – are applied in the same way for both Lean and Green, which makes it familiar to manufacturers and therefore easy to apply in practice.

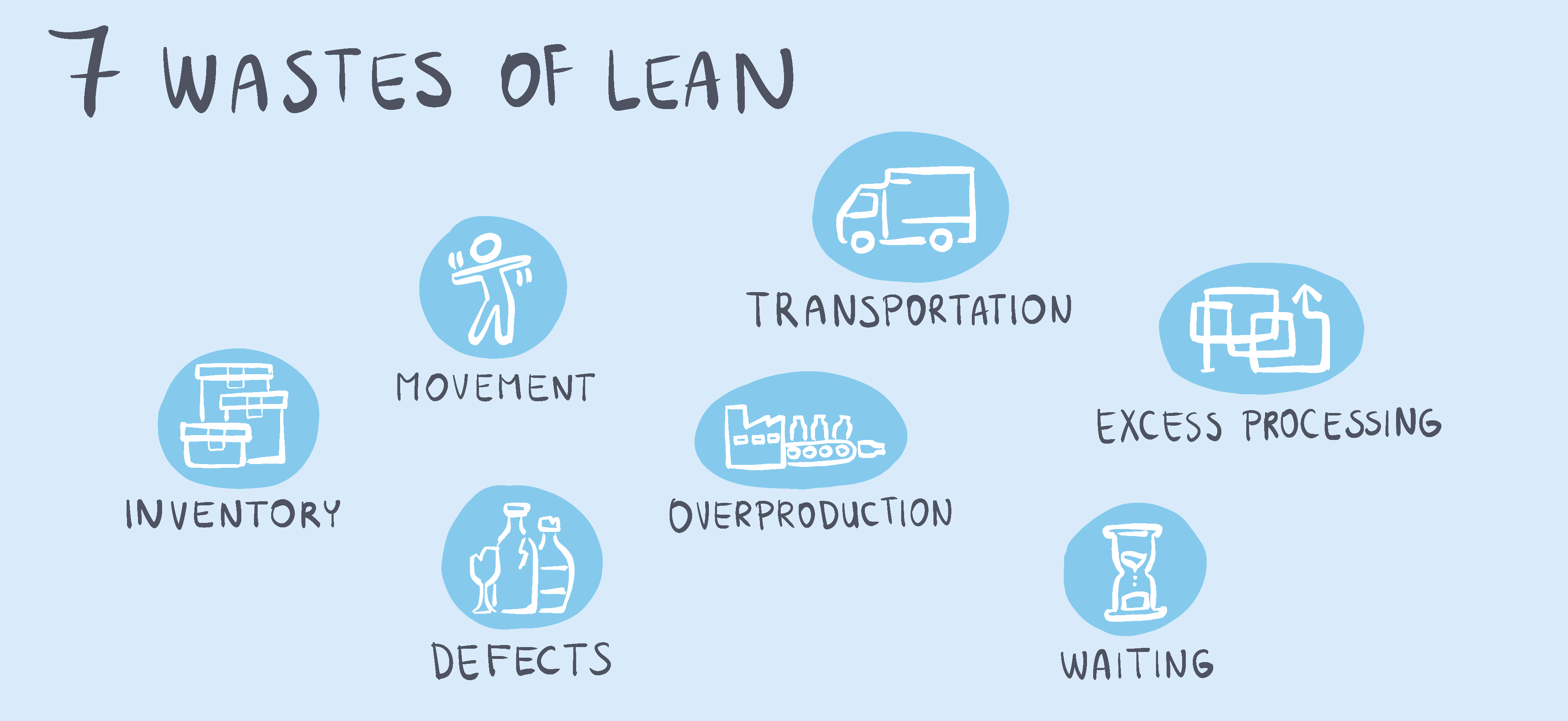

Lean

Waste in a non-value-adding activity from the customers perspective.

- Inventory

- Movement

- Defects

- Transportation

- Overproduction

- Excess processing

- Waiting

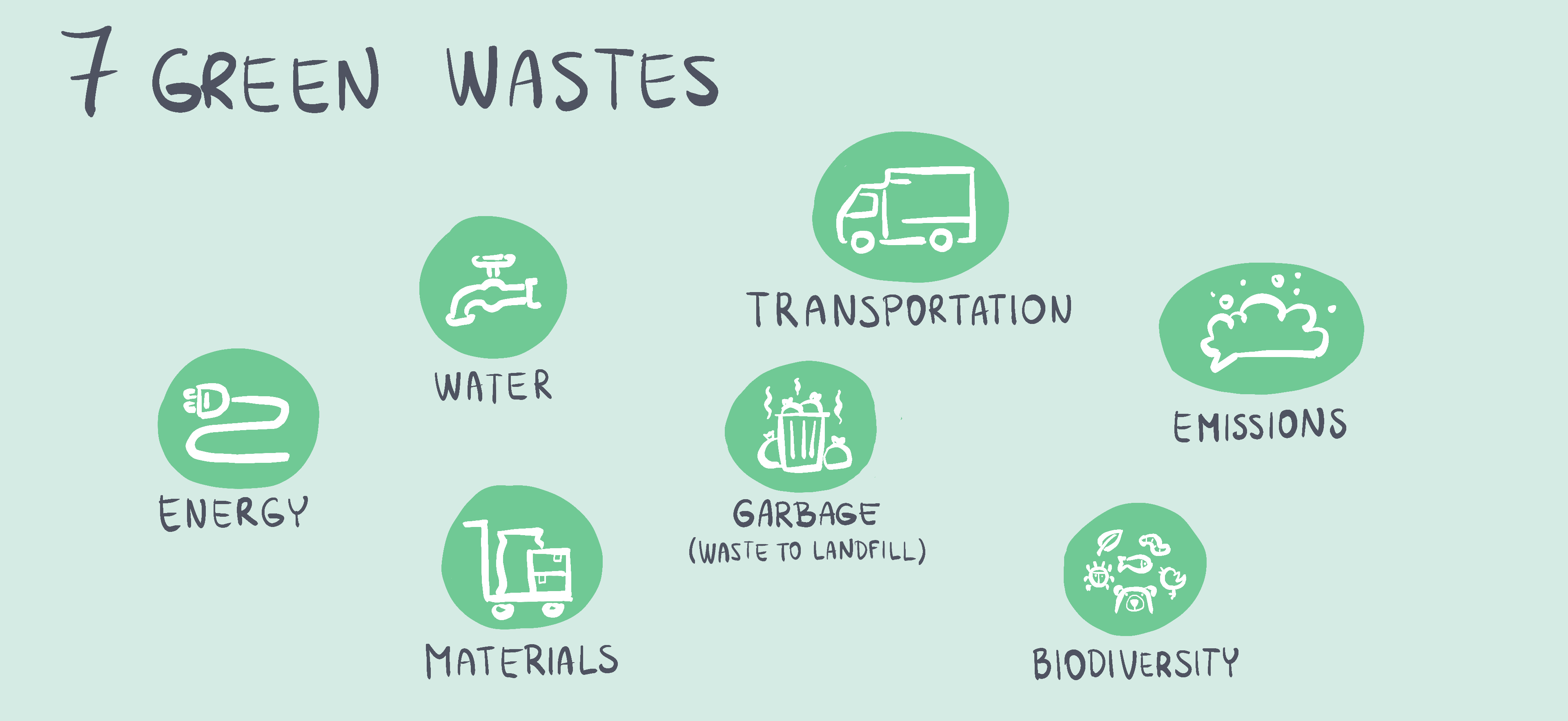

Green

Waste is considered from the environmental perspective.

- Energy

- Water

- Materials

- Transportation

- Waste to landfill

- Emissions

- Biodiversity

The frameworks used in the lean approach, for example, DMAIC (Define, Measure, Analyze, Improve, Control), can be used also for Green manufacturing implementation. That is possibly the best part about implementing Green – manufacturers can use the same time-tested approaches to tackle waste.

Learn more: Introduction to Lean Six Sigma DMAIC Methodology & DMAIC Project Example

Benefits of Green Manufacturing

The economic benefits of going green (and lean) are significant, and every business that has yet to move in this direction has an opportunity to discover it for themselves. Those who have already taken steps in this direction report many gains.

It has been proven that companies that work on their ESG (environmental, social, and governance) performance, do better financially. A meta-study evaluating over 2000 individual analyses of ESG performance across investment firms between 1970 and 2014 confirms this. In nearly half of the cases, companies with good ESG performance offered better financial returns. And only 11% showed a negative correlation.

Cost savings

The logic behind this one is straightforward – if you reduce the volume of raw materials and resources you use to produce the final product, you reduce their cost. Many companies benefit from these savings already by implementing new initiatives like energy-saving (reduce energy costs), pollution reduction (reduce taxes to the government), economical driving (reduce fuel costs), or raw material reuse and reduction (reduce costs of sourcing new materials).

In a survey executed by Deloitte in 2021, almost half of the 750 executives surveyed reported that their environmental sustainability initiatives measurably boosted their corporate financial performance.

Increased customer loyalty and attraction

While price and quality have long been—and remain—the dominant motivations in consumers’ choice rationale, the expectations have risen on other fronts, too. It is as important as ever for companies to show their responsibility, trustworthiness, and good reputation.

Beyond that, customers are ready to pay extra for sustainable products – 85% of consumers have become ‘greener’ in their purchasing in recent years*.* Making your products greener will help you keep your current customers while helping you attract new ones.

Improved employee engagement and retention

Many of us are acutely aware of the costs associated with attracting and keeping the best employees. With companies competing for talent globally, company values and way of working play an essential role. Employees are concerned with the environment and want to work for companies that share their values.

On top of that, numerous reports show just how important employee engagement is for keeping your teams functional. Working with Lean & Green methodology inevitably will help you engage your team to achieve all of these goals.

Innovation and development of new technologies

Going green will push you into looking into new technologies and ways of doing things better. And that is innovation. Striving to become a green manufacturer can’t happen without increased productivity, reduction of lead times, increased capacity, and so on.

For example, if you’re using new technologies to track and measure your OEE, your company will inevitably use fewer resources to produce the same product.

Increased profit and shareholder value

The profitability of going green has been proven in research for years, but it depends on the company’s ability to integrate best-practice sustainability approaches. In his book “The New Sustainability Advantage”, Bob Willard (an internationally renowned leader in sustainability subject) estimates that if a typical company were to implement best-practice sustainability practices, it could improve its profit by at least 51% to 81% within three to five years. The business opportunity is related to increased revenue, reduced energy, waste management, water, and material expenses among other factors.

Integrating Green Manufacturing Into Your Workflow

Sustainability is not a trend that will pass, but rather a vision for a low-carbon, low-waste future. And inevitably Green Manufacturing plays a crucial role in reaching that. The good thing about this framework is that you can use it as a standalone, continuous-improvement approach or easily integrate it with existing continuous-improvement efforts.

To learn more about Green Manufacturing topic, we suggest reading the book “Green Intentions” by Brett Wills. It’s a great and practical resource to help manufacturers on their journey and has inspired the content of this article.