The benefits of monitoring Overall Equipment Effectiveness (OEE) have been known since Total Productive Maintenance (TPM) became a manufacturing buzz word in the 1980s. In that time, organizations have found that OEE can significantly improve productivity by opening the door to valuable improvement opportunities. On the other hand, making OEE calculation mistakes is, unfortunately, easy. Moreover, these mistakes are too common, considering the extent to which they diminish expected returns.

Discover the Main OEE Calculation & Monitoring Mistakes and What to Do Instead

To base your decisions on accurate data, conduct meaningful analysis, and harness the full potential of OEE within your manufacturing environment, this article aims to help you discover the top 8 mistakes organizations tend to make when monitoring and calculating OEE and provide recommendations of what to do instead.

Have a look at our OEE calculator to discover your hidden factory.

1. Not paying enough attention to all production stops

When it comes to mistakes in OEE calculation, not paying enough attention to all positive stops is one widespread error organizations tend to make. In manufacturing, reasons for stops are defined either as “planned” or “unplanned”.

Planned stops, or “positive stops”, consist of changeovers, setup time, cleaning and scheduled breaks such as lunchtime, amongst others.

When evaluating the stops in the production process, companies consider many of them to be “planned”, and by doing so, they miss the opportunity to improve. As it is often said, the first step to solving any problem is admitting that you have one. In this case, acknowledging that production stops are unplanned can sometimes be challenging, depending on the company culture.

Indeed, many managers may willingly choose to see the time spent on unplanned stops as necessary. This might be because experience has conditioned them to do so, but, as is also unfortunately common, there are cultures where data is used as a stick to discipline. So, to avoid the stick and gain a carrot, managers or operators may classify stops improperly.

Ultimately, realistic reporting and a desire to truly understand root causes are necessary. This will allow a company to optimize their production processes by minimizing both planned and unplanned production stops.

To fully realize the opportunity for growth and improvement, you must examine your culture. To this end, you must work to ensure that your culture allows for accurate reporting of production stops. Furthermore, our recommendation is to perform a close analysis of all machine breakdown causes.

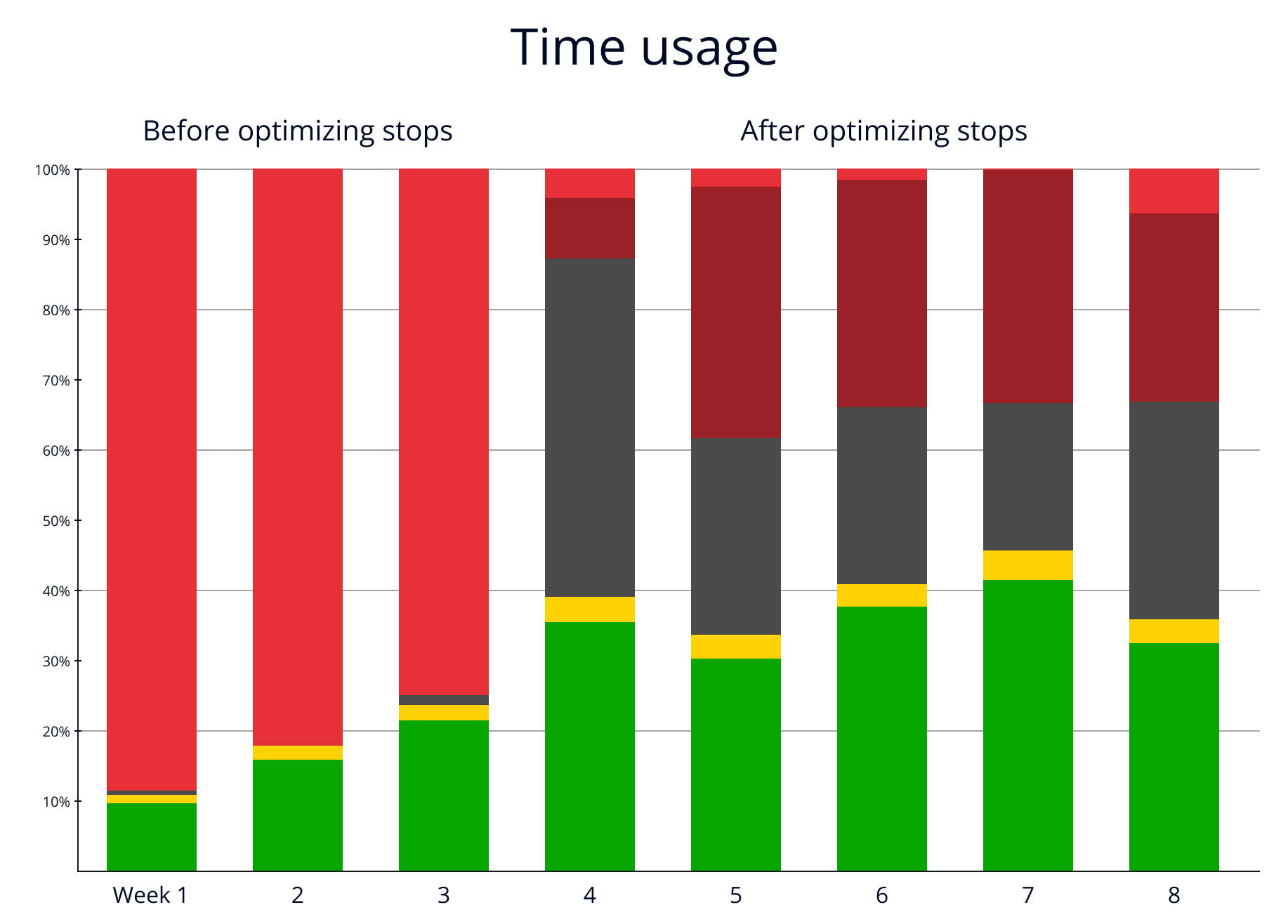

What to do: Optimize production stops

As an essential part of the production process, planned reasons for stops can present opportunities to improve productivity when included in the OEE calculation. Therefore, organizations must analyze each reason for production stops. The goal is to see the bottleneck behind it, rather than merely counting them as planned stops.

Production downtime, of the positive planned variety or otherwise, can hide technical and operational problems within the manufacturing process. Maybe a small machine issue is causing unnecessary losses in time and money. Much like a leaky faucet dripping in your home, this small drip is a big problem if left untreated. Or perhaps your Master Planner Scheduler needs to review the sequence of changeover times in order to truly optimize your production process. In any case, taking all the reasons for production stops into consideration is a best practice. This helps you see how and why they affect your productivity and design solutions to maximize process efficiency.

2. Excluding operators from the OEE implementation process

Operators are the frontline of manufacturing and play a key role in driving efficient daily production. In all likelihood, no one will have a more holistic understanding of what goes on with your machines than the individuals who work directly with them each day. Therefore, failure to gain their buy-in on OEE and its implementation will have significant adverse impacts on the results.

When you exclude operators from the implementation process, reductions in participation and commitment to driving OEE improvement is common. Not to mention that once a problem is identified by monitoring OEE, the valuable knowledge these individuals can (and in our experience, certainly do) contribute to understanding and then improving that process or problem can be lost.

Reduced communication, insufficient data, or merely a superficial understanding of the data itself is often the result. These types of problems are common mistakes in OEE calculation. When present, they reduce the potential improvement opportunities available to your organization.

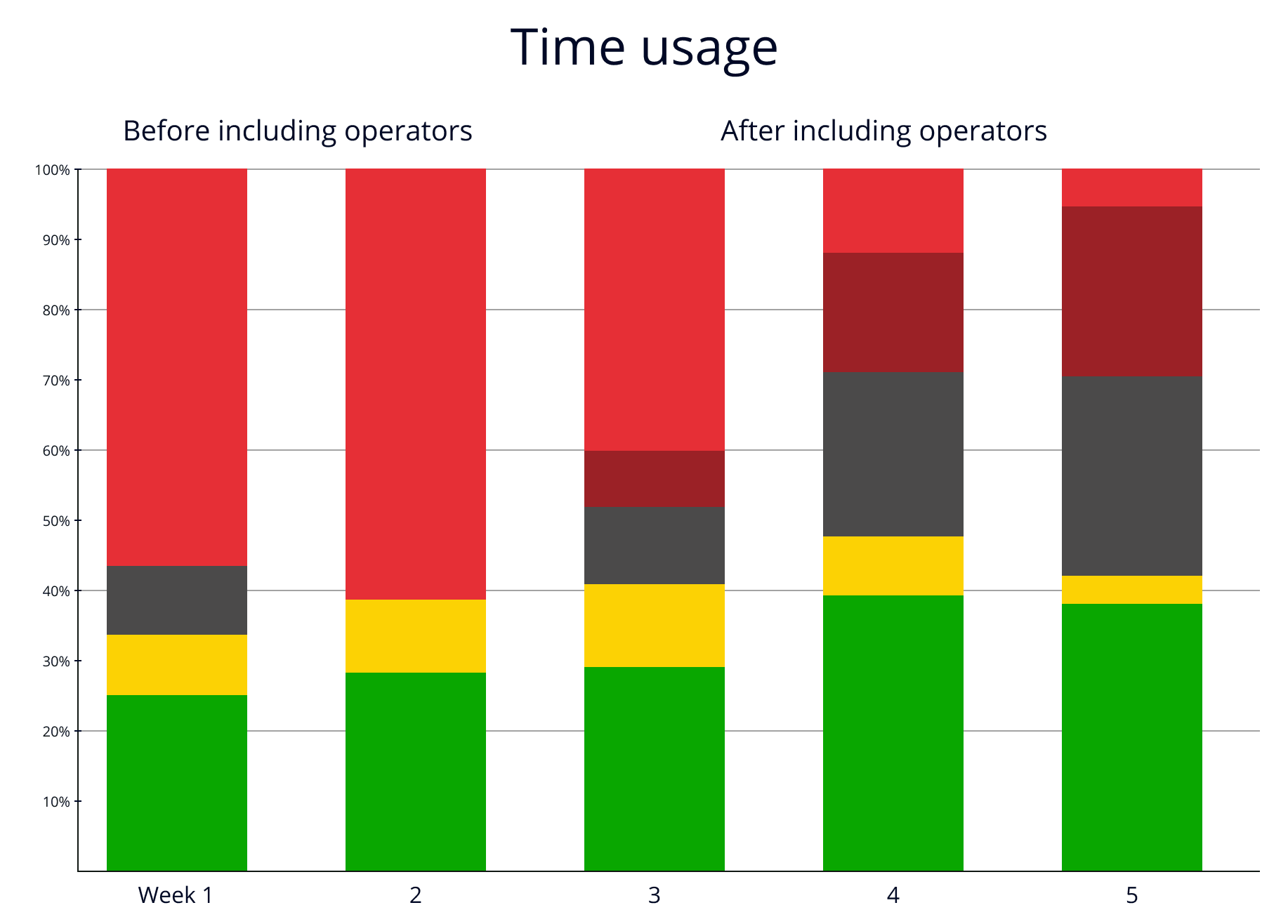

What to do: Include operators in the process

First, it is crucial to understand the degree to which your company culture determines the success of OEE implementation. Your culture influences operator engagement in the whole process.

We find that higher levels of operator engagement correlate to successful deployments. So, once you decide to implement OEE tracking, be sure to make everyone in your team part of the process.

You can begin by emphasizing the importance of the role they play in OEE results. Additionally, we recommend connecting OEE to a future where the company is healthy and competitive. You do not necessarily need another tool to get most of the OEE software. Awareness and education by your shift and team leaders will usually suffice.

Simply put, a competitive business doesn’t necessarily equal job security. Though ignoring the fact that an uncompetitive business will not usually last would certainly be foolish. When making this point, it’s best to avoid coming across as trying to exchange job security for operator buy-in. We have offered this point to stimulate thinking not to gain compliance by threatening job security.

A best practice is to find a way to demonstrate how operator commitment to OEE will benefit them directly. There is no one size fits all answer to this question. You will need to work to understand the specifics of your situation to answer the question authentically. That said, a method we have seen work well is to discover operators’ pain points.

What to do: Generate goodwill and buy-in by reducing operator pain points

Just about everyone can identify one thing about their daily work environment that bothers them. To discover this pain point, talk with your operators about their day-to-day work, and ask them directly. You may come across a problem that is widely and universally disliked, but that is easy to remedy. Perhaps if you’re fortunate, it will relate to OEE. Even if unrelated, solving the problem may be able to create goodwill and buy-in.

With more complex problems that require expensive solutions, we approach the situation differently. In this case, consider rewarding the obtainment of OEE performance targets with the implementation of the solution.

Regardless of how you go about generating buy-in from machine operators, your most important objective is to communicate the importance of using OEE software. By emphasizing your team’s role in keeping the company competitive, they become more likely to use the system.

When motivated, operators tend to share more about the production process, inserting more information into the system. More information means more accurate data, which eventually leads you to the desired OEE value and a smart action plan to improve step by step.

The plant can increase productivity as a result. Further, operators experience increased feelings of commitment, responsibility, and inclusion in the workplace.

3. Using standard speed instead of design speed (Nameplate Capacity, Ideal Cycle Time)

Some organizations make OEE calculation mistakes by using the standard speed instead of design speed. Standard speed in this context refers to historical data on average run rates or throughput. The term, design speed, refers to the production speed as designated by the manufacturer. This is the highest achievable speed that design engineers specify under ideal conditions.

The issue with using standard speed instead of design speed is that it places a false upper limit on improvement. Companies that use standard speed are comparing OEE scores with average values, and this is misleading. They believe they have reached the maximum available throughput, when in fact, there is more room from improvement.

What to do: Structurally shorten cycle times

Your goal should be to shorten the manufacturing cycle times, thus increasing productivity structurally. For example, process restrictions might justify using standard/nominal speed to avoid the drop in availability. But concentrating on shortening the cycle times and finding ways to solve issues that may arise is an excellent opportunity to increase productivity and make necessary changes.

By reducing cycle times, a client in the wood processing industry achieved higher speeds than those designated by the machine manufacturers.

So, in some industries, you should not take what machine producers give at face value and always pursue the goal of shortening cycle times.

4. Insufficient data collection

To calculate OEE correctly, it is essential to have enough data for availability, performance, and quality scores. Using erroneous values or omitting one of these metrics can significantly alter the results in unpredictable ways. For this reason, insufficient data collection is among the top OEE calculation mistakes that we see.

This mistake can occur for a variety of reasons. As noted previously, sometimes operators will not engage in the process to the extent that they should. Or perhaps, OEE calculation uses standard speed instead of ideal cycle time. Both situations can result in poor quality data, making your data collection efforts insufficient to calculate OEE correctly. This means you cannot fully rely on the score to improve your productivity.

While operator engagement and machine speed ratings are essential, the most common reason for insufficient data is paper-based production monitoring. Companies that manually collect process data to monitor OEE face several challenges in obtaining accurate and timely data. For example, using highly trained machine operators for data collection can be viewed as underutilized talent. This is because data collection is a low value add activity.

In addition to reducing value by underutilizing talent, manual collection is prone to error. This is because of increased variability in the collection process means that there are many more opportunities for mistakes. Incomplete and/or inaccurate data can also result when completing paperwork from memory at the end of a long shift. Companies that use manual data often make mistakes in OEE calculation.

What to do: Automate data collection

It has quickly become a best practice to automate data collection activities. This will dramatically improve accuracy by reducing variability. Further, it allows operators to focus on what they do best, and this is often higher-value activities. Therefore, a first step to collecting sufficient data is to automate its collection.

Another best practice is the implementation of a cloud-based OEE solution. This allows companies to benefit from the reliability and easy accessibility of the cloud.

To avoid mistakes in OEE calculation, you need to consider the correct values and set realistic targets. Once you receive the data, you need to evaluate it and identify the problems. Remember, accurate data can only make a difference when you analyze and act upon it. This is one method world-class operations use to create value with OEE.

By monitoring, observing, and learning from data collected on your production process, you can more easily set and adjust targets. Moreover, your goals will be more realistic.

As a rule, greater digitization and automation of production processes leads to improved visibility. The more clarity you have into your production process, the more opportunities you can identify to improve it.

Automate data collection

Get the visibility you need to start improving your production processes. Free for 30 days.

5. Focusing only on the OEE score

When calculating OEE, many companies tend to make the mistake of focusing solely on the OEE score itself. While an important metric, companies should not ignore the values which make up the OEE score: Availability, Performance, and Quality. These are the factors to analyze in order to unlock opportunities for improvement on the shop floor.

What to do: Focus on the underlying losses

Having the OEE score presents you with the “big picture” and your overall production performance. However, knowing the availability, performance, and quality values show you where the production losses are occurring. This is where we recommend that you focus: the underlying losses.

Knowledge of where losses occur allows you to perform root cause analysis in a more focused and meaningful manner. When you understand the root cause, you avoid the common problem of implementing solutions that address a symptom. To state the obvious, you will want to avoid creating solutions to symptoms. Not only will it not solve the problem, it usually creates new challenges as well.

Therefore, we recommend that instead of focusing on the OEE score, you take each of the elements in the production process into consideration.

Are you losing too much time during changeovers? What is the reason behind the defects? How is the overall performance of your machines?

The data will give you the answers to these and many other questions.

Looking at what is OEE as a whole, you can make improvements in availability and see how this affects performance and quality. If there is a need to increase performance, then you need to observe this in relation to the two other factors. Regardless of the size and industry of your organization, every decision you make defines the output of your production process.

6. Comparing the OEE scores of different plants and machines

Another widespread OEE calculation mistake is for organizations to compare the OEE scores of different plants, production lines, or machines. In some cases, companies tend to average over the whole plant or across a group of plants in a division. This can arguably have a place in a board meeting, but this is beyond the scope of this article.

For our purposes here, we are focused on the plant operating level. At this level, comparing or averaging unlike plants, production lines or machine OEE is never a good idea. Comparisons like this will hide the actionable details — such as the reasons for stops. As such, this is among the top mistakes companies make in OEE calculation.

When comparing OEE scores of different plants or machines, you need to take their features into consideration. A machine producing small batches and another one creating bigger ones cannot be evaluated in the same context. Similarly, the same machines with different maintenance histories and different quality levels of input material can produce different outcomes as well.

What to do: Compare similar machines, processes, and materials

Regardless of size, though, all companies will benefit from having comparable results accessed through a single source. Each line or machine should be analyzed according to its OEE targets and environment. Most importantly, remember only to compare OEE scores when machines, processes, and materials are similar.

To compare other metrics, data collection should be standardized as much as possible. Reasons for stops are one of the most important metrics that you need to take into consideration.

To that end, we recommend benchmarking stops if configuration settings can be standardized. This will be much better than only focusing on the OEE number.

7. Not standardizing OEE calculation

When you implement OEE in different plants and factories, standardization will be required, or mistakes in OEE calculation can occur. Standardization will allow effective communication within your organization and ensures the calculation is correct.

Some companies fail to centralize their data collection from different plants and machines in one OEE software. This often results in various methods to calculate OEE and communication problems. Fragmented data is challenging to maintain, manage, and access across an organization. As a result, factories do not know about each other’s improvements. Additionally, managers may make less than optimal decisions when they have OEE scores that are based on non-standardized sources.

Ultimately, unlinked, plant by plant OEE tracking results in poor OEE implementation.

What to do: Standardize data collection and OEE calculation

OEE implementation gives the best results when the calculation is standardized. This is particularly relevant to large multinational businesses with many different plants. Regardless of size, though, all companies will benefit from having comparable results accessed through a single source. This avoids the problems of having non-standardized results existing in various fragmented sources.

Once you standardize your OEE monitoring, it becomes easier to monitor, track, and compare scores. Furthermore, scores are meaningful and insightful and maintaining historical values as a benchmark becomes possible.

The ability to standardize OEE calculation in this way significantly benefits your organization in return. You not only gather a shared database of logged information but also enhance communication across plants, factories, and departments. Improved communication and access to information leads to increased value-creation by reducing barriers to sharing best practices.

Learn more: The Advantages of Data Standardization in Manufacturing

8. Not taking action on data

You use OEE software, receive real-time data, and analyze it. Perhaps you have some ideas about what works and what doesn’t on your shop floor. This is a significant first step, but it is only half the battle. If you stop there, you can completely miss the opportunity to create value.

Your next step is to come up with solutions to the challenges you identify and take appropriate action. This is how you will improve your production processes. Without this step, your plant will forego the opportunity to unlock the full value which OEE monitoring presents. OEE will only improve when you act upon the data.

What to do: Take action on data

As a first step, you can analyze the data for easy-to-solve problems, which will have a high impact. This creates a feeling of success from the get-go. It also creates momentum to continue the effort which you can then build upon.

Next, you should conduct short daily performance reviews. This will allow you to start to discover the bottlenecks in the process and come up with solutions. The goal here is to make the process slightly smoother with each passing day. The daily review will improve your ability to track the process effectively and to predict problems. In contrast, working with accumulated results in a monthly report does not improve tracking and prediction.

What to do: Rank and address problems with a Prioritization Matrix

Many times, the “low-hanging fruit” will be obvious. These are the problems to address quickly. When problems become more complex, it may be challenging to determine the best order to tackle them in. In these situations, we recommend using a prioritization matrix (PM) to discover the optimal order to attend to problems.

A PM is a living document that lists all identified production problems and what must be done to improve. The improvement actions are then numerically scored in several prioritized categories, such as the impact of improvement or ease to implement. This quantifies the problem/solution by calculating a numerical value that allows for priority ranking. It also creates a record of improvement activities that can be beneficial in a variety of ways as well. For those new to this technique, you can download an easy-to-use template for the Prioritization Matrix.

In summary, production monitoring is a process. Start with small steps, include the whole team, and create significant change on your shop floor by setting well-defined goals and utilizing the data to meet those goals.

Avoiding these OEE calculation mistakes can enable you to receive accurate data regarding production, work on real numbers, and come up with solutions to get the results you want.

Once you start collecting the right numbers and identifying the real problems on your shop floor, taking action becomes much easier for you and your team.