To quote Marshall McLuhan, the man who predicted the Internet: “We shape our tools, and afterwards the tools shape us”. When using a downtime tracking system to monitor machine downtime, performance, and OEE, the outcome usually depends on how well your system is set up. Defining machine breakdown causes is one of the most important tasks to do.

This article will examine the most critical aspects you must focus on. You can apply these ideas, whether you are using Evocon or if you want to improve your current process of machine downtime tracking.

Building a Framework for Useful Machine Downtime Analysis

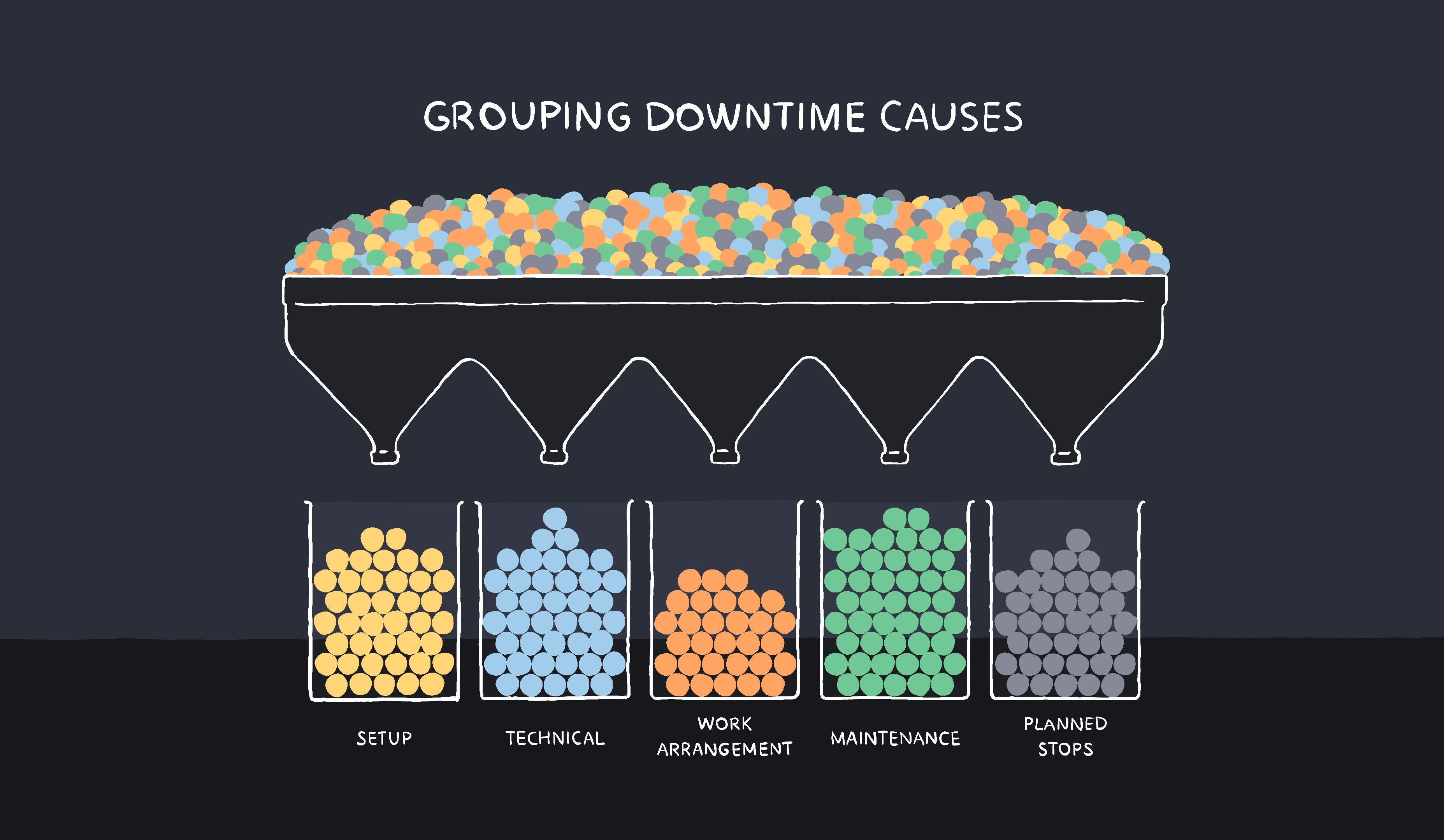

The first thing to think about is the structure of your machine breakdown causes. You want to keep it as simple as possible so that production operators on the shop floor can easily find the right reasons. To get started with this, put together the most frequent breakdown reasons in your production and see how you can group them.

Grouping machine breakdown causes

The standard practice is to start with three to five groups, and each group should have no more than six breakdown causes. Six is the optimal figure as it helps keep the list short and manageable. However, we also have users who successfully manage up to eight stop reasons per group. This isn’t wrong, it just means more scrolling, more complexity, more time for your operators to find the right reason. Sometimes, depending on the production process, this is justified as it adds more insight to production downtime analysis.

Avoiding generalization

When you define machine breakdown causes, we strongly recommend to avoid definitions that are too general.

The reason is very simple – if your causes are general, then so is your downtime analysis. You won’t be able to make informed decisions on what to improve in order to increase OEE and reduce downtime.

For example, let’s look at a breakdown cause, called “Mechanical breakdown”. If your operators register this reason 30 times per month and you forward the problem to your maintenance team, there is not much they can do with this information. But if you use more specific reasons, such as “Conveyor breakdown” or “Packing machine breakdown”, your maintenance team can be more effective in solving problems.

How to handle infrequent breakdowns?

Once you have your main stop groups and reasons defined, you are already much better off than most manufacturers. In addition to the most frequent stop reasons, sometimes rare breakdowns occur. It is essential to keep track of those as well because they can give you precious information about your production.

There are different ways to keep track of these reasons. If you use Evocon, we recommend creating a breakdown group called “Other” or to define a breakdown cause called “Other” in one of the existing groups. Furthermore, in Evocon, operators can add extra notes to all breakdown reasons. These notes can often reveal crucial details about your downtime. You should go over these reasons periodically and see if there are any patterns and if you need to add a new breakdown cause to your main list.

Let’s say, after analyzing the “Other” reason you see that operators have entered reasons such as: “Material shortage”, “No Material” and “Material missing”. This means that in your list of reasons you should include a breakdown that is related to the shortage of material. After you do this, be sure to communicate the change to everyone on the shop floor, so that they know that the list of breakdown causes has been updated.

Registering breakdown causes on long production lines

Monitoring breakdown causes on long production lines can be tricky.

Difficulties may arise from the fact that a few production operators are managing the whole line or that only one part of the whole line has a system in place that automatically monitors breakdowns.

Thus if your operator is stationed at the end of the line and the line stops because there was a breakdown at the beginning of the line, you need data to reflect this.

In Evocon, this is solved by using a feature called “Locations”. This gives you the possibility to define different parts of your production line. Once locations are defined, all your operators have to do is include this piece of information when choosing the correct cause.

An excellent example of this is food and beverages industry, where bottling lines are ubiquitous. Typical locations on these lines include conveyor-in, filling, capping, labeling, conveyor-out. Once you have these locations defined in Evocon, everything becomes easy. If there is a conveyor breakdown, all your operators have to do is choose the correct machine breakdown cause – conveyor breakdown, and the location – conveyor-in.

Using this feature will significantly enhance the way you analyze your production downtime because it immediately adds an extra layer of transparency to the data that you collect.

Sample breakdown causes to help you get started

To help you get started we have put together a sample list of different machine breakdown causes that you can use. This information is based on our users that come from a wide variety of various industries.

Here are examples of different stop groups and reasons that can help you build a framework for effective machine downtime analysis:

- Setup

- Product changeover

- Measure change

- Material change

- Setup

- Technical

- Machine reset

- Conveyor breakdown

- Robot breakdown

- Aspiration failure

- Power failure

- Lubrication failure

- Work arrangement

- Material shortage/waiting

- Material of poor quality

- Forklift wait/bringing material/taking material away

- Supplies missing/searching/waiting

- Work on another machine

- Work order/working instruction missing

- Maintenance

- Cleaning the machine

- Daily maintenance

- Weekly maintenance

- Planned maintenance

- Unplanned maintenance

- Cleaning

- Planned stops

- Pause

- Lunch

- Meeting

- Training session

Avoid overthinking and start monitoring

There is one key thing to take away from here – avoid overthinking. You probably already have an idea about what the most frequent breakdown causes are in your production. So get your team together, define the reasons together, and look at it as a continuous improvement process.

Once you have your groups and causes identified, you are ready to start monitoring your breakdowns. Be sure to read our article on Downtime Tracking and Analysis so you can get the most out of your production data.

If you need help defining your breakdown causes or your looking for recommendations, contact our team, and we will be more than happy to help you.