By the end of Day 5, you will have moved from manual tracking to a fully operational OEE monitoring system that is installed, configured, and sending accurate machine data in real-time. Your trial team — from operators to admins — will be trained and confidently using the tool to collect minute-by-minute machine statuses, downtime reasons, and output quantities. You’ll also establish a verified OEE result you can actually trust, providing a clear picture of your hidden losses and the untapped production capacity you could be capturing right now.

Key insights

-

Why most OEE projects fail

Most manufacturers want better visibility into what’s happening on the shop floor. But many have already experienced failed software trials, abandoned improvement projects, or tools that never made it past the pilot phase.

The usual barriers — long timelines, high upfront costs, operator resistance, and fear of disrupting production stop teams before they even start. The result is that critical decisions are still made based on assumptions, paper logs, and spreadsheets, while hidden downtime continues to eat into margins.

This guide was created to remove these barriers and show a simpler way to start.

-

What you’ll achieve in 5 days

This guide walks you through a proven, day-by-day plan to launch real-time OEE monitoring.

You’ll go from preparation and initial setup to running a fully monitored shift, validating data accuracy, training operators and supervisors, and establishing your first verified OEE result. By the end of Day 5, you’ll have a live system, engaged users, and real production data you can trust.

No long projects. No heavy IT work. Just a focused, practical start.

-

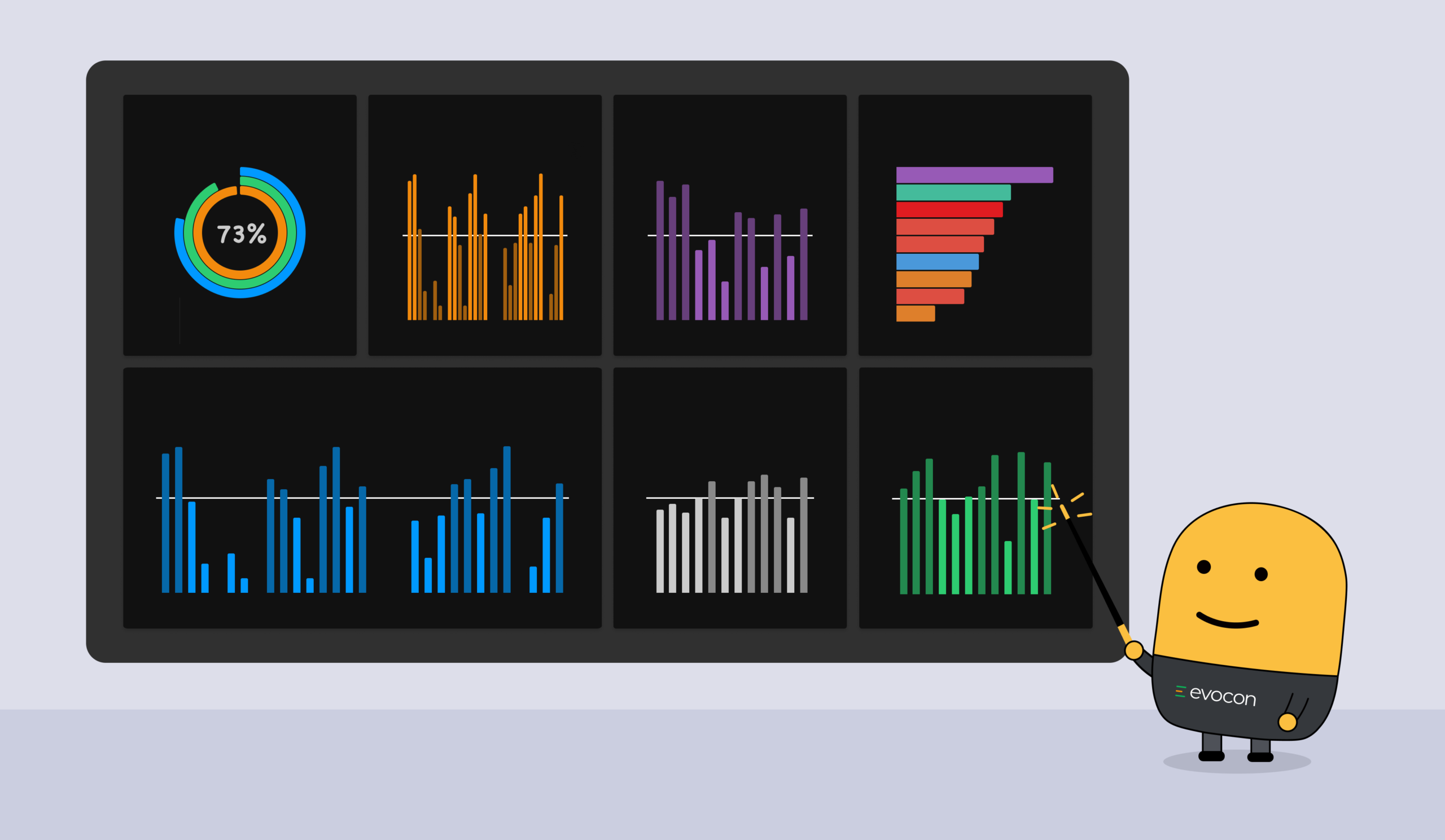

From data to decisions

Once your first verified data is in place, the focus shifts from setup to value.

The guide shows you how to review downtime patterns, identify your biggest losses, and estimate what even small improvements could mean for capacity and output. You’ll also get a clear Go/No-Go framework to evaluate data quality, adoption, and ROI — so you can decide how to move forward and scale with confidence.

"We needed a tool that provides live data, is easy to use for operators, and gives management the visibility needed to drive continuous improvement. Ease of use was critical; we didn’t want something that felt like extra work for the teams."