Maximize equipment usage

With Evocon, you can maximize equipment effectiveness by tracking machine performance and identifying underused resources. This allows for better scheduling, reduced idle time, and increased production capacity across all shifts.

-

How H+H improved OEE by implementing Evocon across borders

To improve OEE and move away from manual reporting, H+H implemented Evocon across multiple factories in Europe. The system gave their teams accurate, real-time data, enabling better decision-making and faster responses to production issues.

“It was the Wow-Effect – they (the board) could see the data in a very nice way, and it was data they could believe in.”

-

Real-time data tracking

Evocon is a real-time source of truth for daily production monitoring, providing operators and managers with instant visibility into performance. Clear indicators highlight stoppages, inefficiencies, and the status of recurring checks, enabling teams to quickly identify issues, take corrective action, and keep production on track.

-

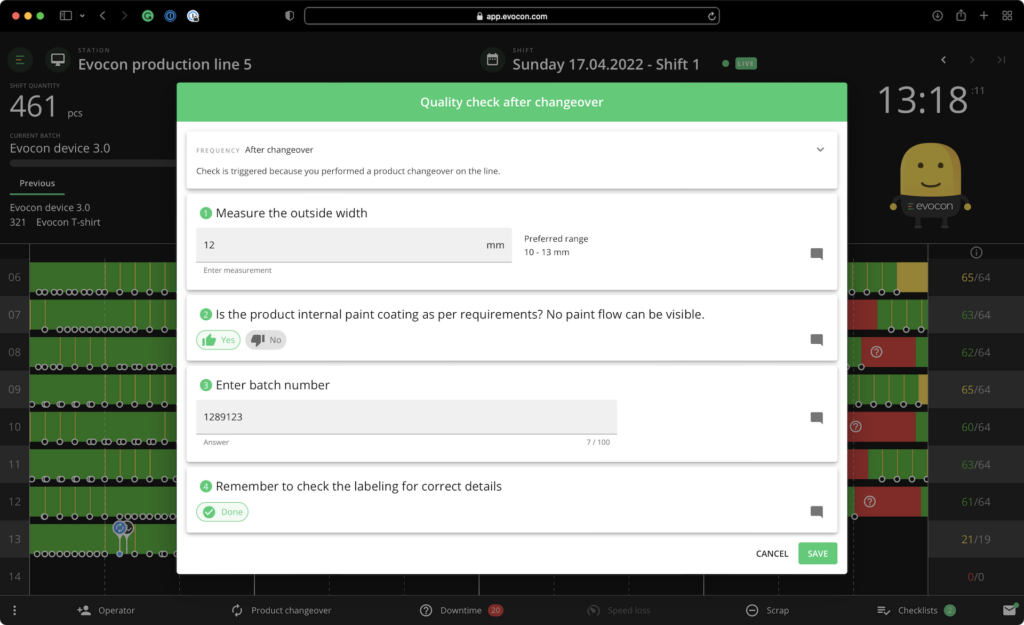

Checklists

Ensure consistent production quality and streamline operations with Evocon’s digital checklists. Automate recurring tasks for maintenance, safety, and quality checks, reducing manual errors and ensuring compliance with industry standards.

-

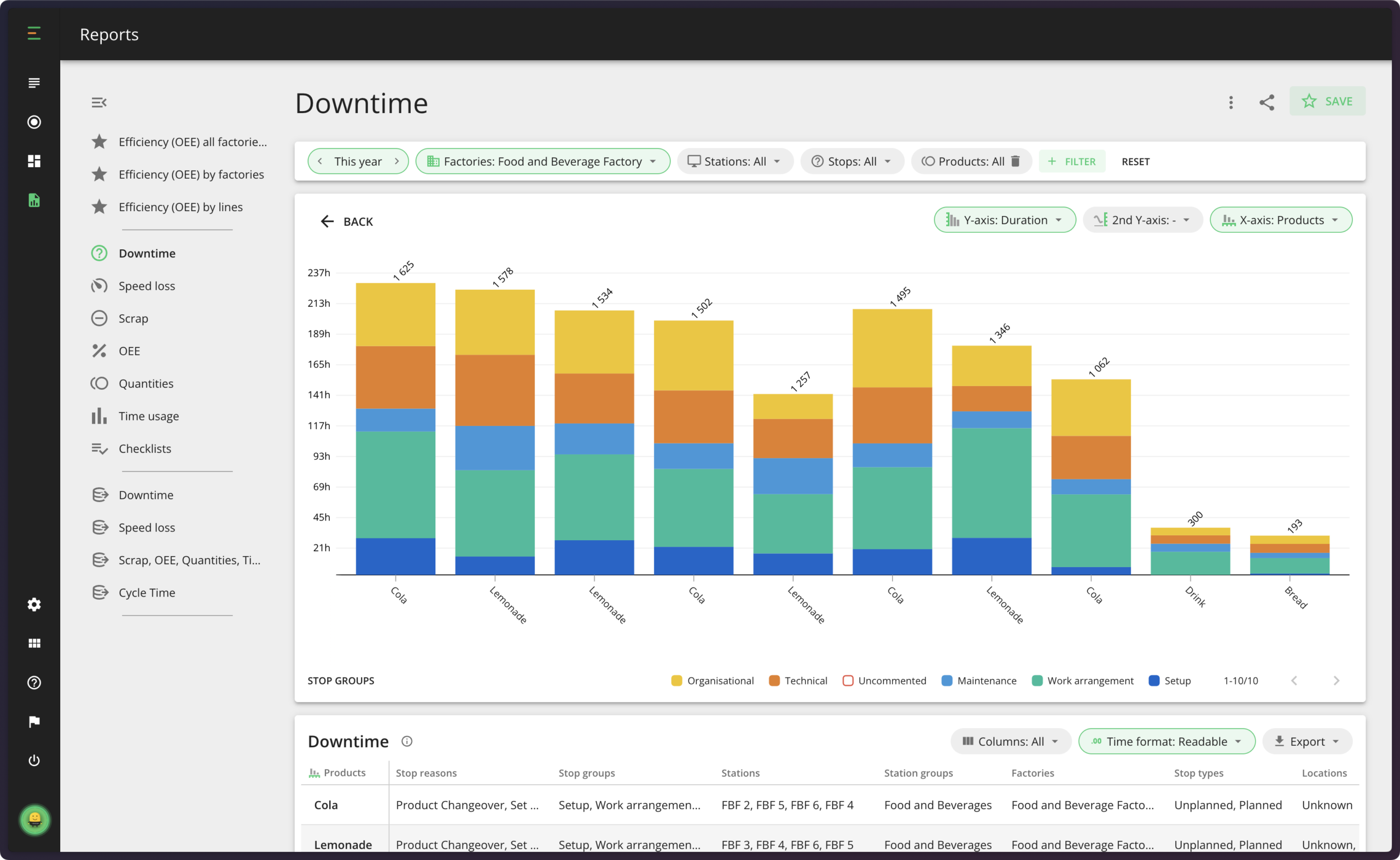

Analytics for production monitoring

Evocon’s manufacturing monitoring system keeps analytics simple and yet effective. It helps reveal bottlenecks, optimize the production process, and enhance quality, saving time and reducing costs. Transform your manufacturing process with clear, actionable reports tailored to your needs—all in one user-friendly platform.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

-

Talk to our team

Our experts are ready to help you unlock the full potential of your production process. Schedule a call with our team today and start your journey towards greater efficiency and profitability.

- Get tailored advice and solutions specific to your production needs.

- Our team will guide you through the setup and optimization process.

- Afterwards, you can try Evocon in your factory free for 30 days.