-

Spot problems with real-time data

Evocon’s OEE and continuous improvement software pulls live production data straight from the floor and turns it into clear insights. No guesswork—just the facts on where you are losing time or materials. With automatic tracking, you can act on inefficiencies and keep things running smoother every shift.

-

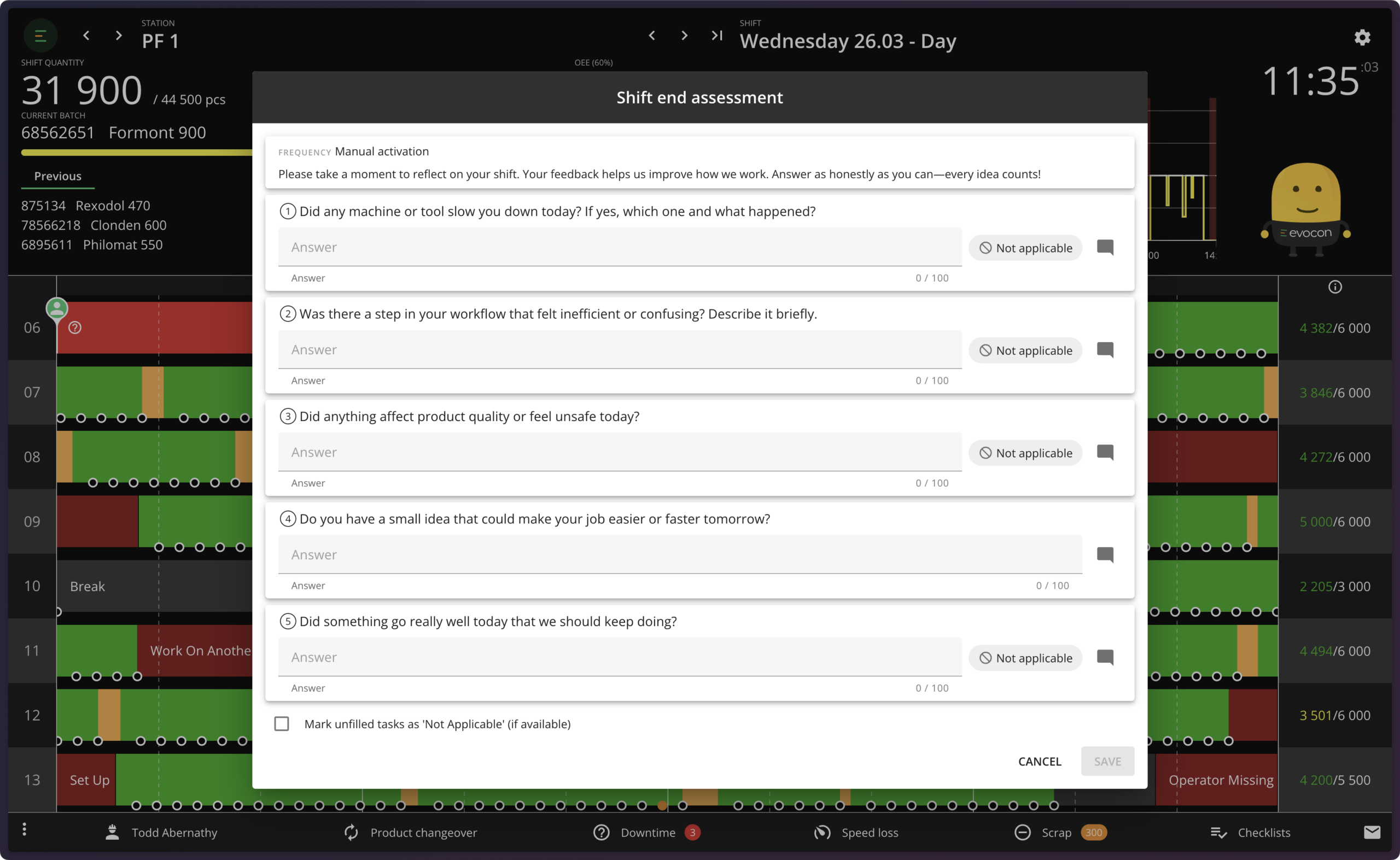

Capture ideas that work

Evocon supports continuous improvement in manufacturing by encouraging operators to log their ideas after or at the beginning of the shift. This allows you to collect potential improvement opportunities, pick the winners, and assign owners to get it done. It’s all about turning good ideas into real fixes, not just collecting data.

-

Customizable dashboards

With available continuous improvement tools, you can create dashboards to monitor KPIs—OEE, downtime, defect rates, and more—tailored to your manufacturing process. By focusing on the metrics that align with your continuous improvement goals, you ensure visibility into the most critical production factors.

-

Root-cause analysis and analytics

Evocon provides in-depth analysis of downtime, speed loss, and quality reasons helping teams identify underlying issues and implement preventive measures. By analyzing and understanding root causes, manufacturers can make data-driven improvements, reducing inefficiencies and enhancing OEE.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Evocon

Evocon’s continuous improvement software equips manufacturers with real-time production insights to streamline processes and boost long-term efficiency. It captures live data, highlights inefficiencies, and tracks trends, empowering teams to cut waste, improve productivity, and maintain operational excellence with confidence.

“Now we have 0% unaccounted time. Every single loss is accounted for, we have a very good understanding of the downtime and therefore we can plan improvement initiatives with solid data to make decisions."

-

Drive continuous improvement in your operations

See how Evocon’s continuous improvement software can help you improve efficiency, drive operational excellence, and implement data-based continuous improvement initiatives that support business growth.