-

Automated downtime data collection

Evocon integrates with your production machinery and equipment to automatically capture downtime events in real time, eliminating manual reporting, minimizing errors, and providing a precise record of production stoppages.

-

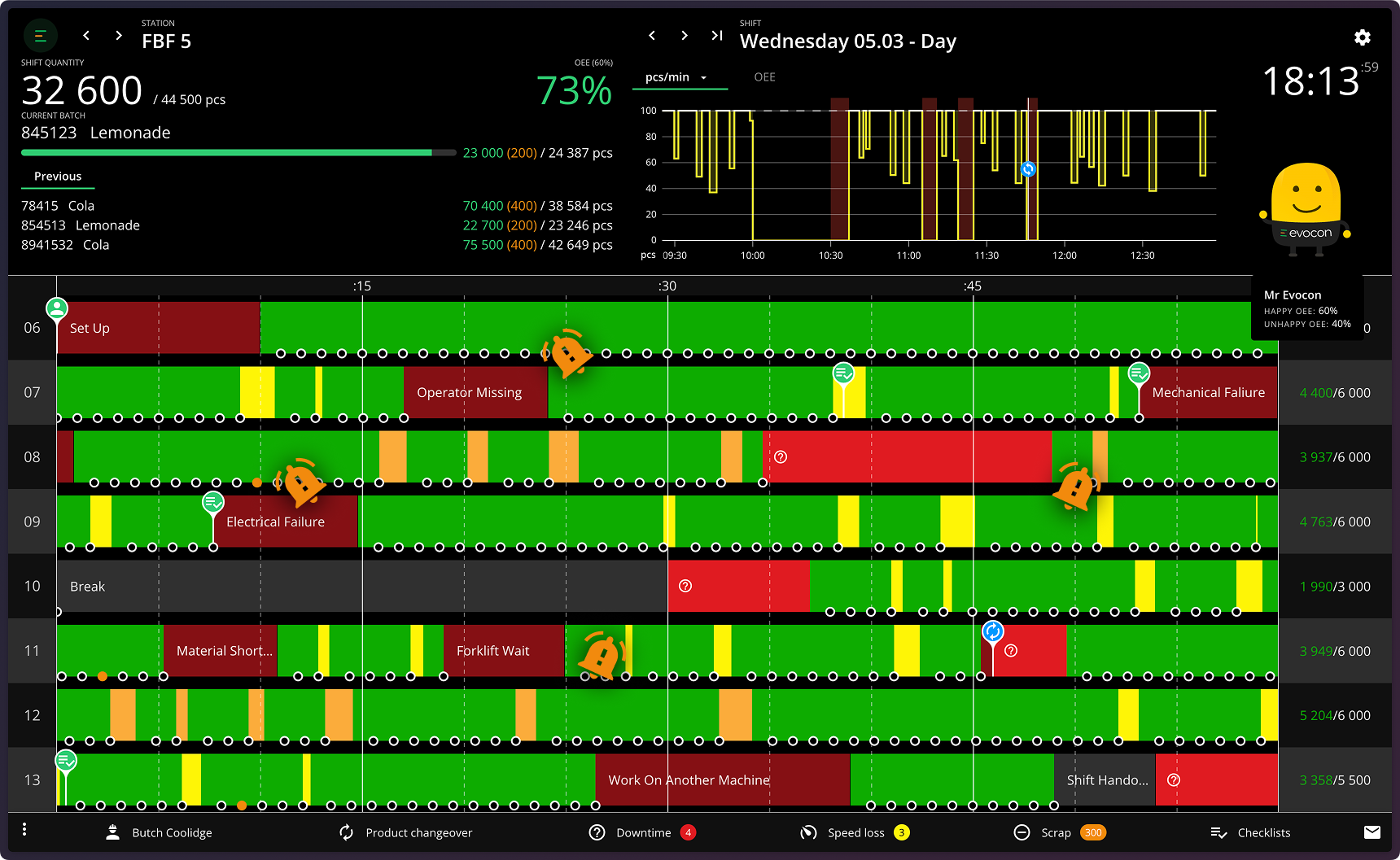

Real-time downtime tracking

Our user-friendly interface enables operators to quickly log downtime events with clear categorization. This ensures accurate data capture and provides immediate visibility into production stoppages for all stakeholders.

-

Alerts & checks for downtime

Setting up alerts and checks for production downtime is crucial to minimizing downtime and maximizing productivity. By notifying the appropriate personnel as soon as downtime occurs, you can resolve the issue before it escalates into a more significant problem.

-

Customizable dashboards

With Evocon’s downtime tracking system, you can upgrade your daily and weekly production meetings. Having access to data helps you identify patterns and trends, optimize production processes, prioritize production issues, allocate resources, and promote transparency among team members and departments.

-

Root-cause analysis of downtime

Furthermore, Evocon’s comprehensive downtime tracking system enables manufacturers to easily identify the underlying issues that cause downtime. By understanding the actual issues and analyzing the root cause, you can take preventive measures to avoid similar incidents, optimize production processes, and ultimately improve the bottom line.

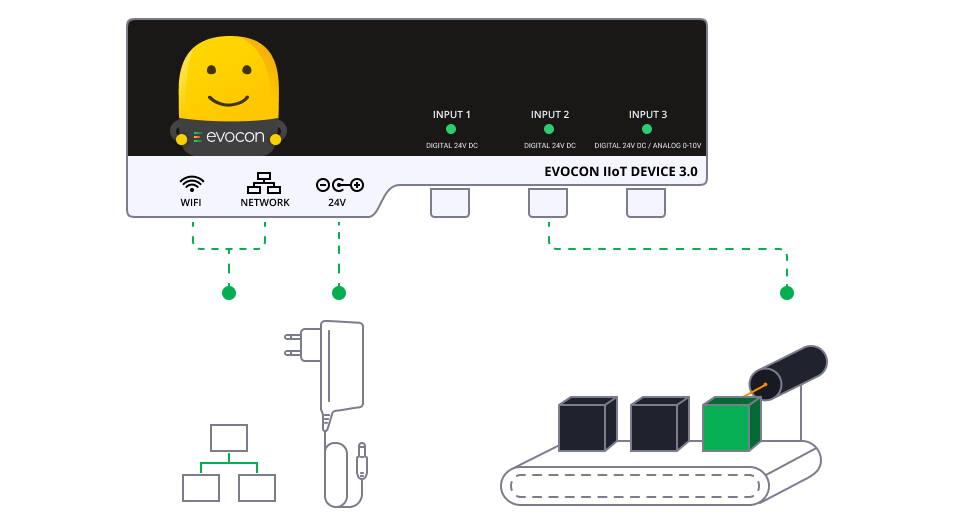

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Evocon

Evocon's dedicated downtime tracking software empowers manufacturing teams to proactively manage and significantly reduce production interruptions, leading to increased efficiency and profitability.

"Evocon enables us, in real-time, wherever we are, to see our production output, reasons of stoppages and loosing of speed on production lines in our factories."

-

See how downtime tracking works

Take control of your production with Evocon’s easy-to-use downtime tracking software. Monitor performance, minimize disruptions, and keep your manufacturing operations running smoothly.

Watch a video here.