Monitor the heartbeat of your factory

With Evocon's Factory Overview, you make the status of your factory and machines visible to everyone on the team, giving them the transparency they need to monitor and manage the whole factory and quickly react to any issues.

Factory monitoring in real-time

Use the Live view to understand the current status of your production machines and how they have performed in the last hour.

The status of machines is color-coded intuitively, allowing you to immediately grasp the overall state of your factory.

Quick glance of the most important information

In addition to status, access is provided to the most relevant KPIs and information.

If your team discovers something out of the ordinary, then can immediately analyze it more closely by opening the machine in question.

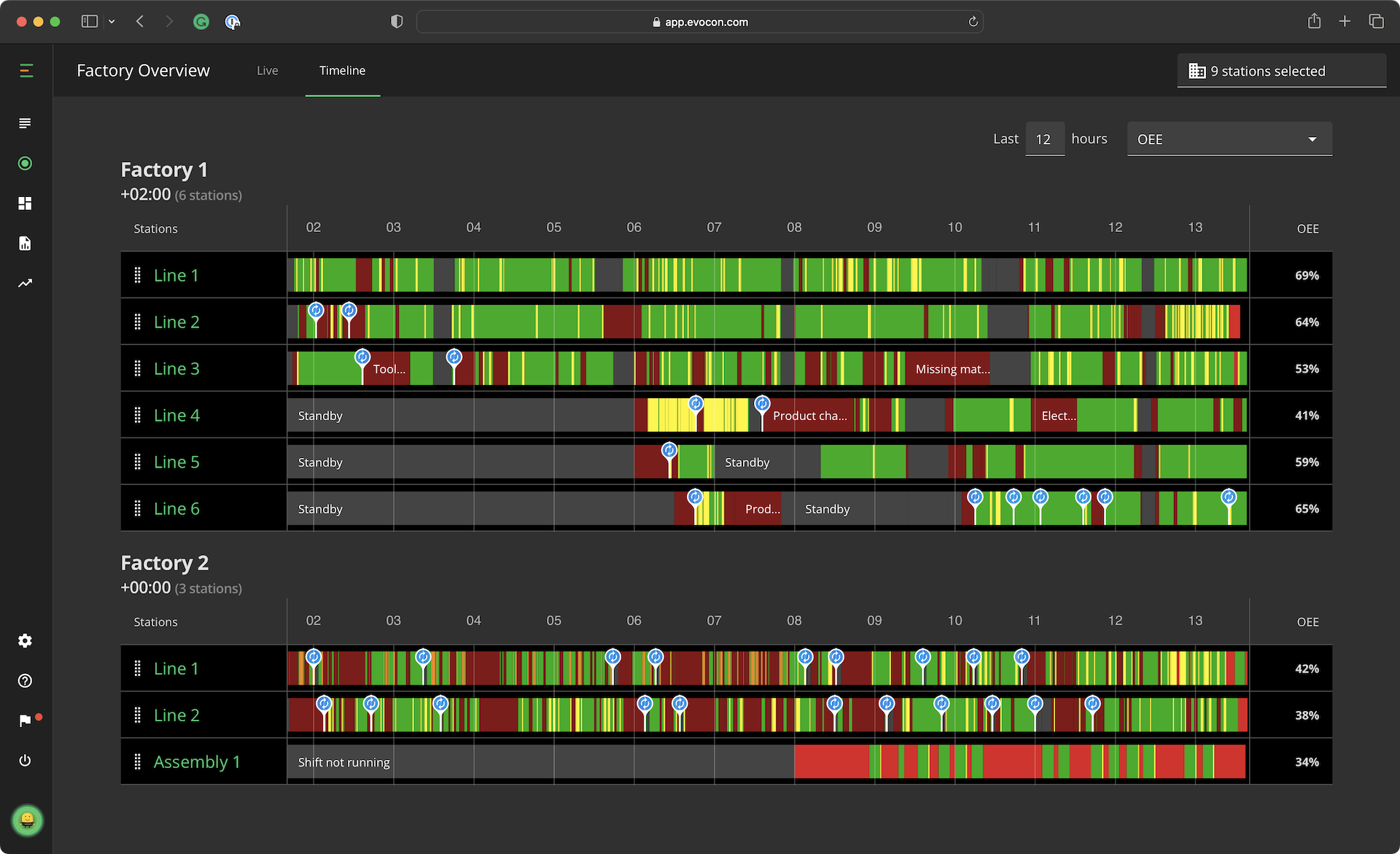

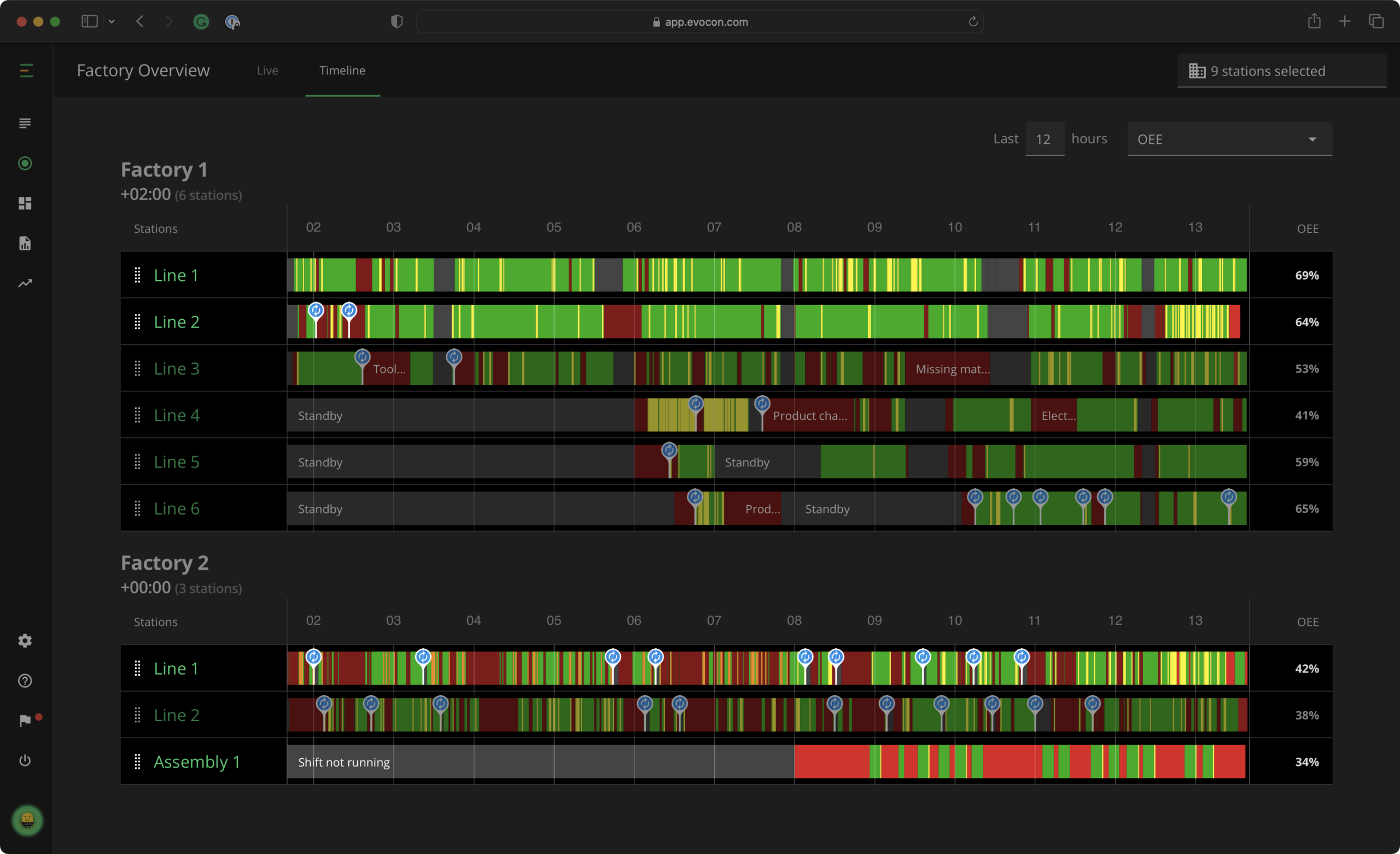

Understand the big picture

In Timeline, production data is visualized using the same principles as in Live view, but the focus is longer timeframes.

This allows you to monitor factory performance over the previous 1 to 24 hours. It’s like having a time machine of your factory.

Monitoring all factories in one place

Having more than one factory connected to Evocon, allows you track the progress of all in one place.

You can focus on monitoring all factories, several of them, or specific machine groups with just a few clicks.

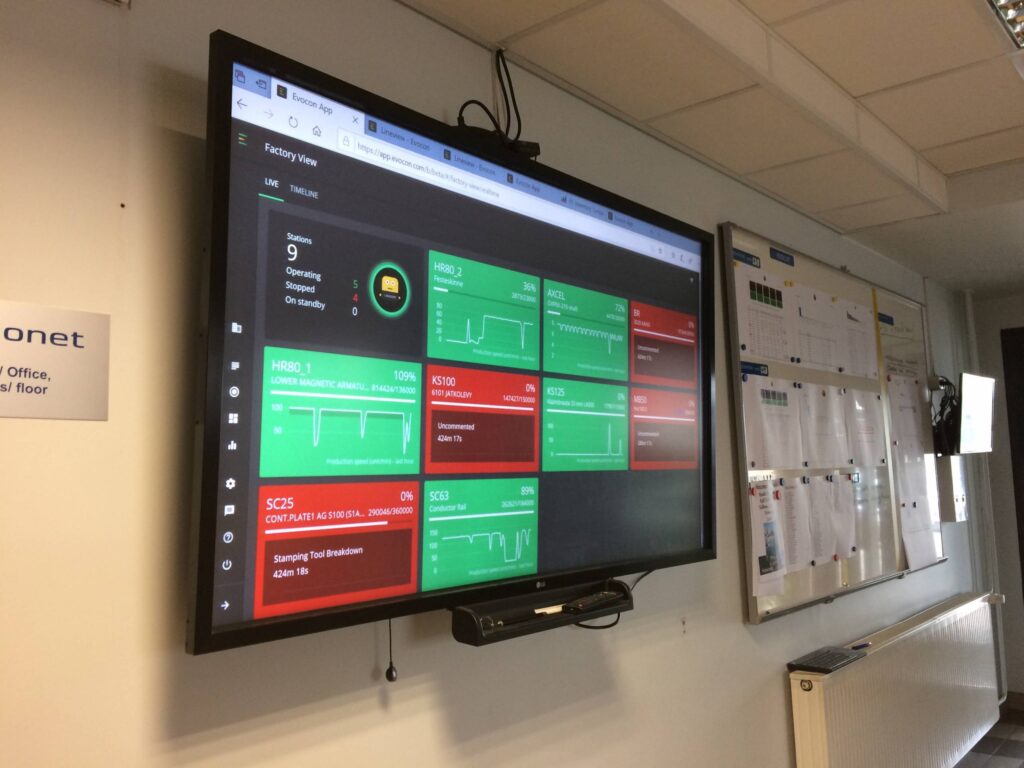

Show off your factory’s performance

By installing a TV or large monitor in your office, you can show off your factory’s performance to your team and your visitors.

Stand out from the competition by bringing your digital factory to the forefront.

"Evocon enables us, in real-time, wherever we are, to see our production output, reasons for stoppages, and loosing of speed on production lines in our factories."

Liviu Vancea

Purchasing Director

Saint-Gobain Romania

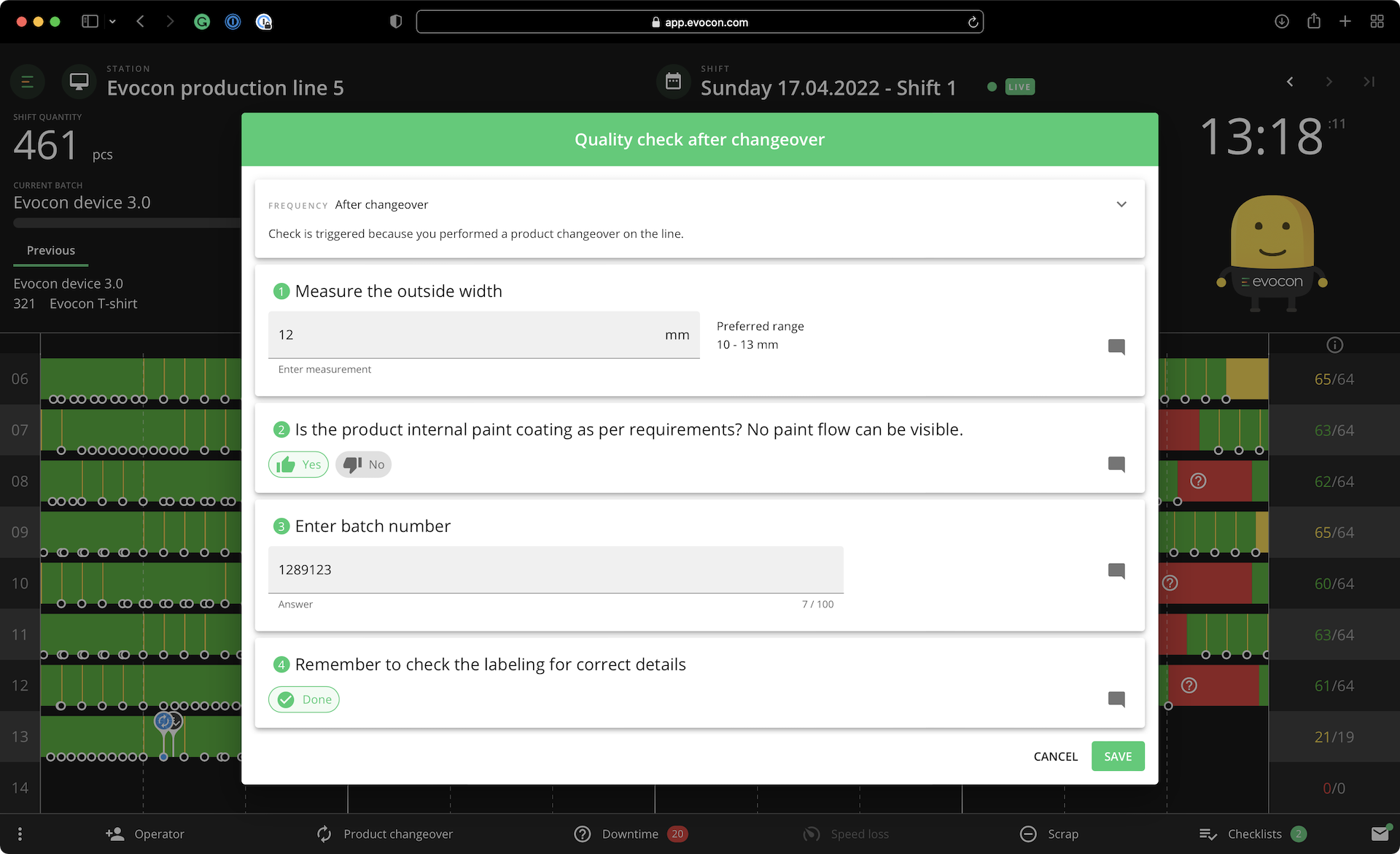

Features that help with factory monitoring

-

Live view with real-time data

-

Timeline view with a visual overview of the past hours

-

Production speed overview of last hour

-

Access production data of the last 1-24 hours

-

Visualized status of all machines

-

Quick event-by-event analysis for each machine

-

Progress tracking of production orders

-

Remote monitoring of factory performance