Why choose Evocon for your food and beverage facility?

Evocon is trusted by food and beverage manufacturers across the world to improve performance, reduce losses, and increase visibility on the shop floor. Whether you produce beverages, ready meals, or frozen foods, Evocon helps teams make smarter decisions in real time.

-

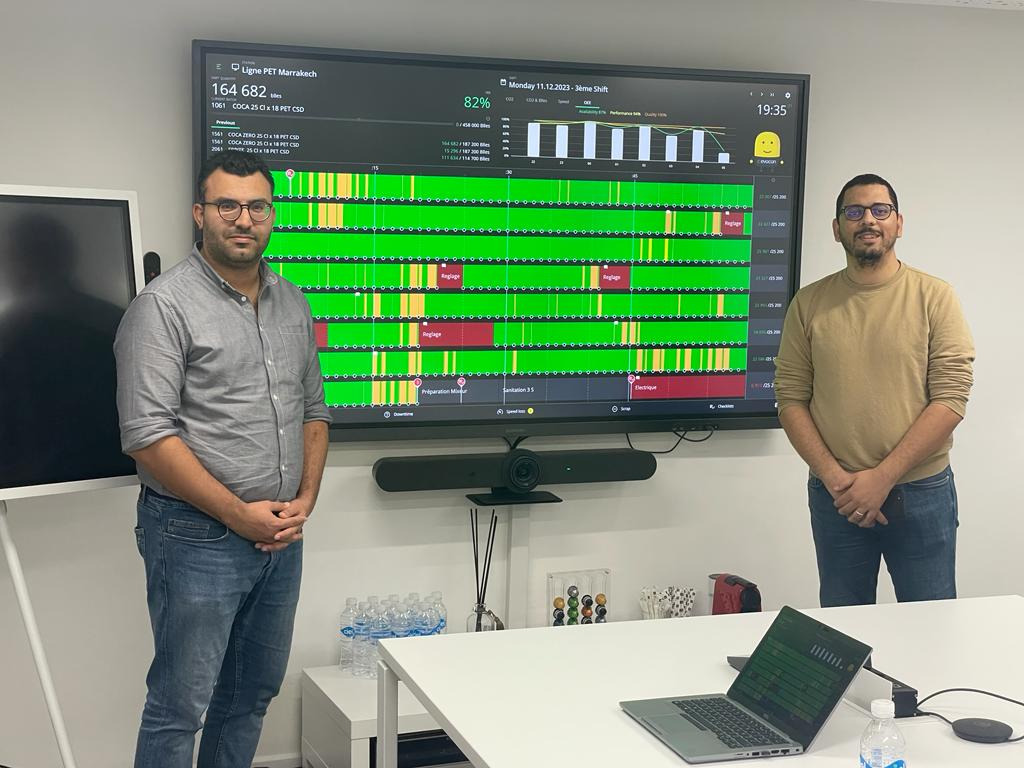

Operational excellence at Equatorial Coca-Cola Bottling Company

To improve visibility and reduce reliance on manual reporting, Equatorial Coca-Cola Bottling Company implemented Evocon across multiple sites. The system enabled line managers to make faster, data-driven decisions—resulting in improved efficiency, better shift planning, and a stronger focus on continuous improvement.

"For us, the WHY was to improve the quality, accuracy, reliability, and availability of data and go to 0 paper in our plants."

-

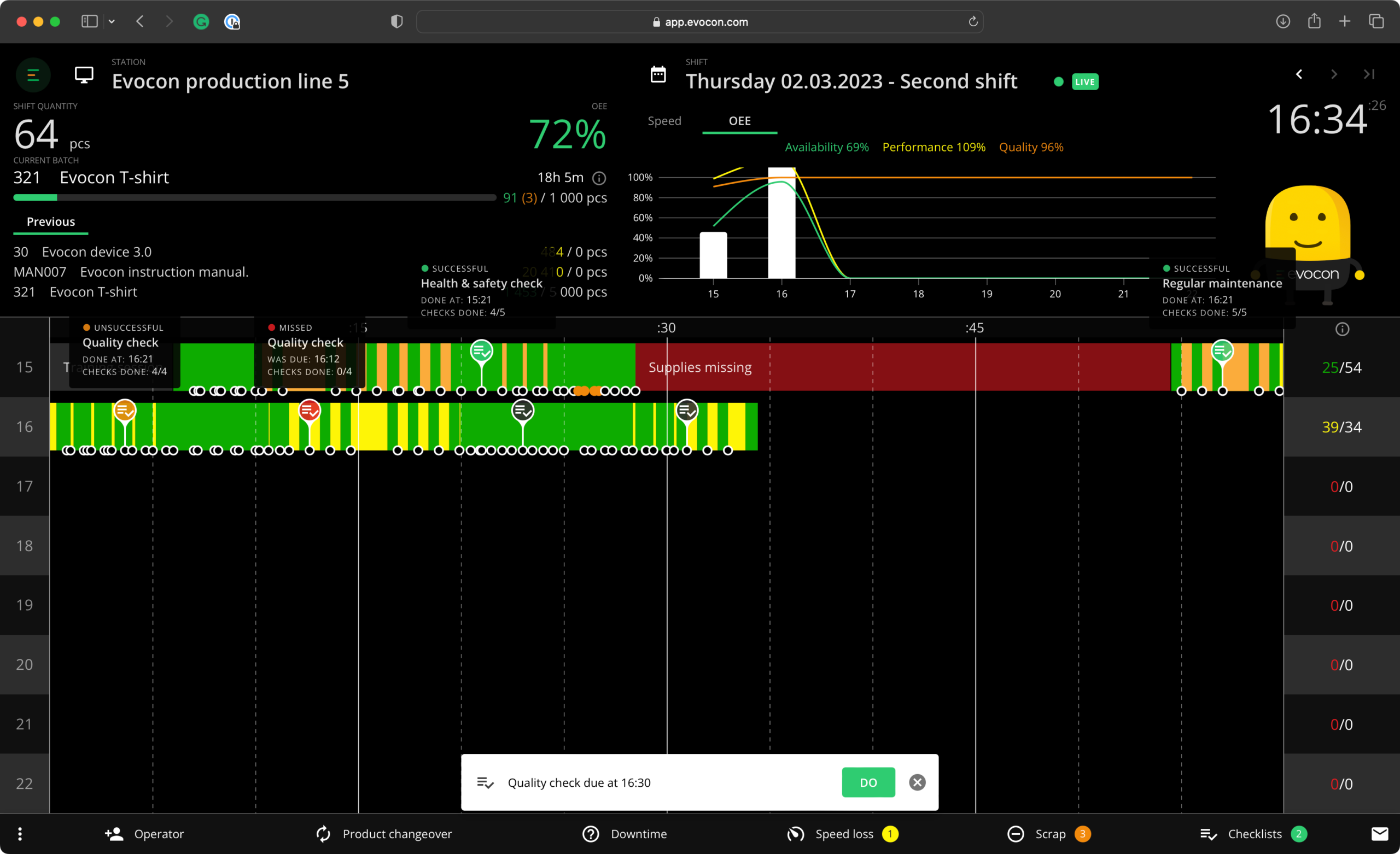

Stay on top of every batch

Track production performance in real time across shifts, lines, and machines. Evocon helps food and beverage manufacturers monitor output, detect issues instantly, and maintain consistency — crucial for meeting strict industry quality standards.

-

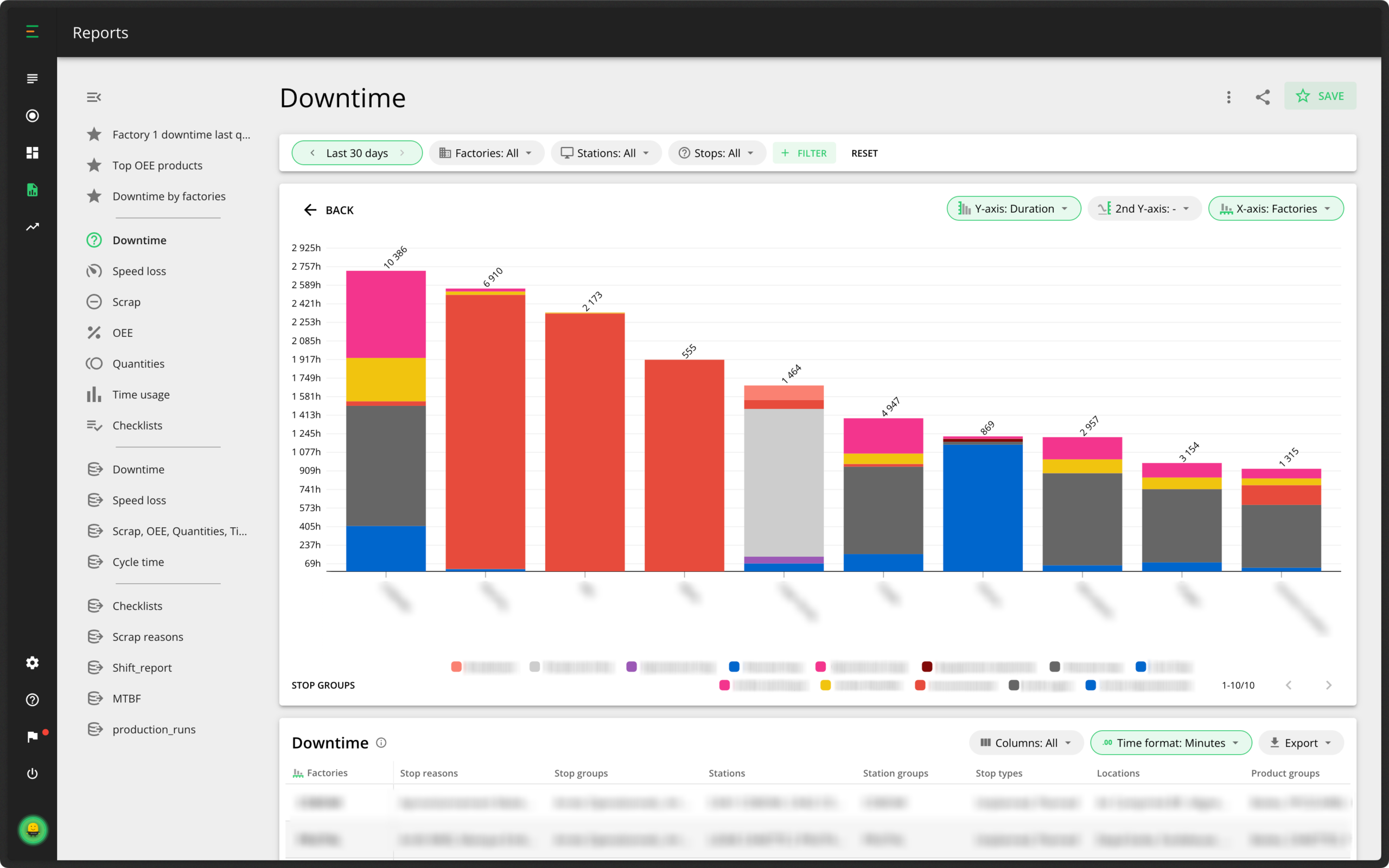

Reduce downtime, boost output

Evocon automatically detects and records machine stoppages, helping manufacturers quickly identify root causes. This feature minimizes unplanned downtime, ensuring smooth production flows and reducing costly interruptions in food processing.

-

Real-time visibility and alerts

Evocon strengthens quality control by continuously monitoring the production process and automatically triggering quality checks when they matter most. Results are displayed clearly on a live production timeline, with instant alerts pinpointing when things go wrong. This lets your team react to issues fast, fix them before they snowball, and keep everyone in the loop.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

-

Talk to our team

Our experts are ready to help you unlock the full potential of your production process. Schedule a call with our team today and start your journey towards greater efficiency and profitability.

- Get tailored advice and solutions specific to your production needs.

- Our team will guide you through the setup and optimization process.

- Afterwards, you can try Evocon in your factory free for 30 days.