Improving machine utilization starts with visibility. Without a clear understanding of how machines are used and why they stop, manufacturers risk missing major efficiency gains. This report explores the fundamentals of utilization, the hidden costs of downtime, and the key metrics that drive smarter decisions on the shop floor.

Key insights

-

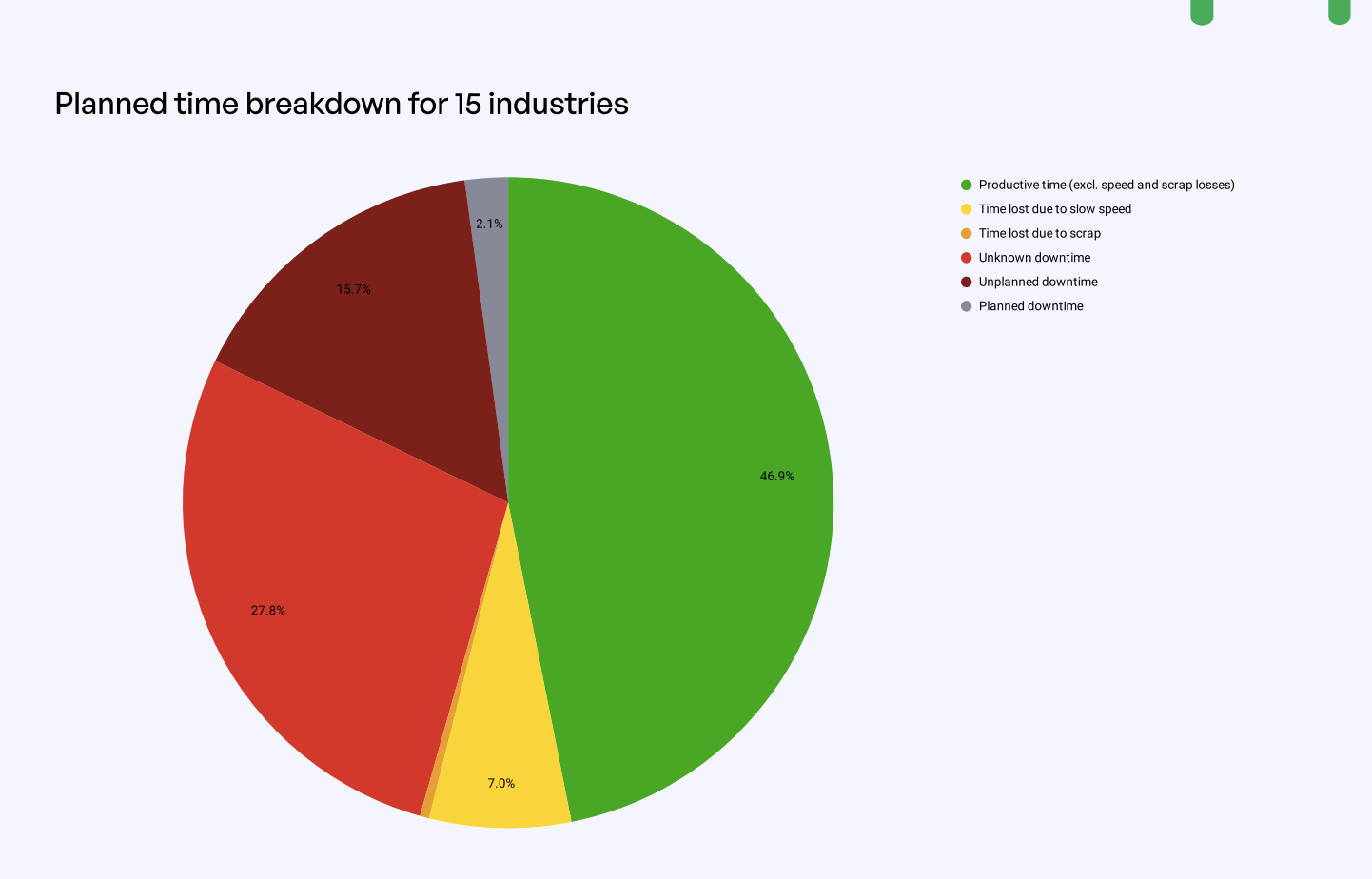

Planned production time

Almost half of the planned productive time is spent with machines down, which means that factories have a huge amount of hidden potential. By tackling your unknown and unplanned downtime, you can drastically improve your output.

-

Downtime reasons

We analyzed the top 100 downtime reasons reported by our clients and grouped them into 7 key categories. Download the report to see which of these reasons most affect your industry and how much planned time is being lost.

-

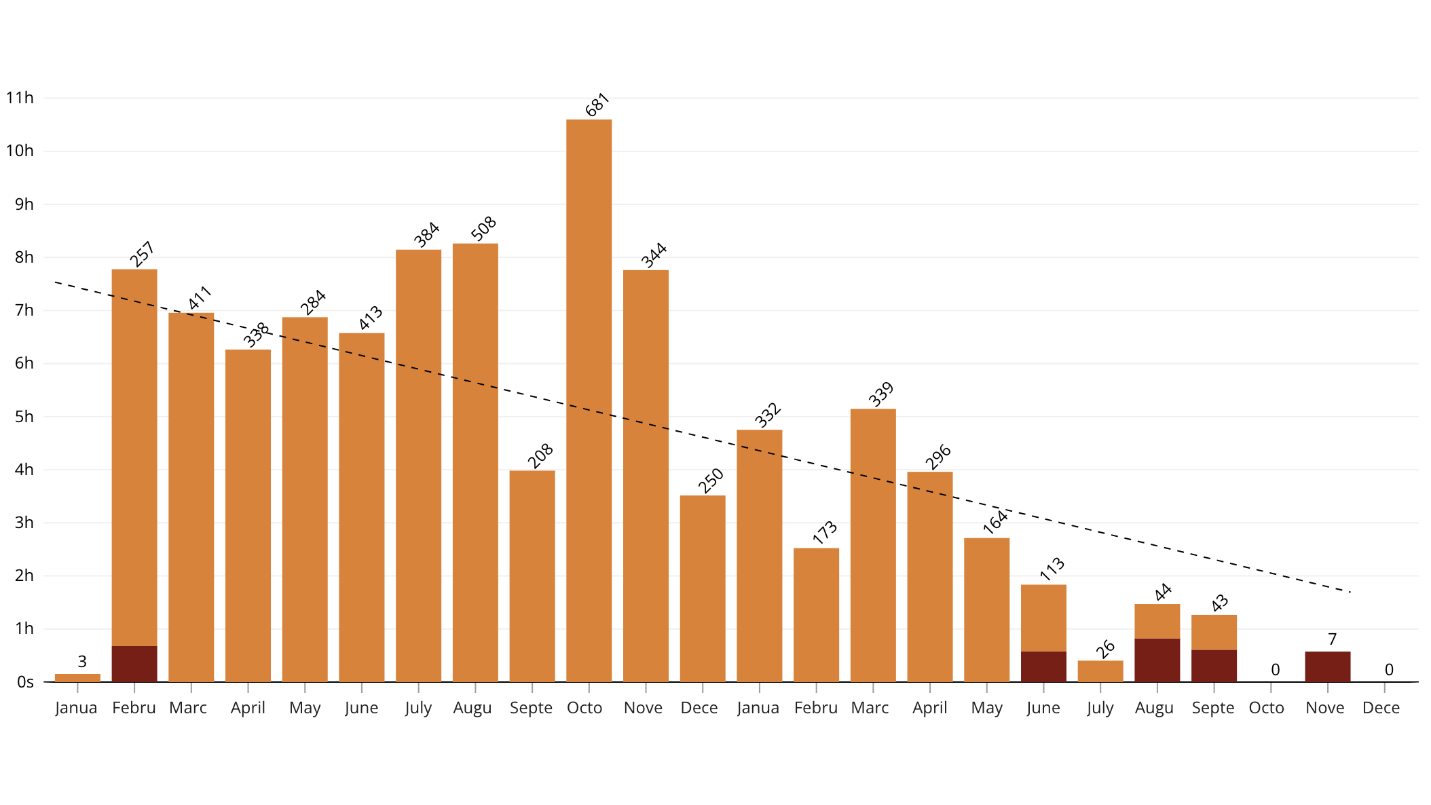

How Mars achieved 0% downtime

A few years ago, Mars began to modernize their operations hoping

to reduce downtime, improve quality, and achieve energy efficiency.

After implementing Evocon, Mars Cape town managed to not only

lessen their downtime, but they reduced their unaccounted time to 0%!