-

Automated Data Capture

Evocon utilizes sensors and IIoT devices to automatically collect production data, eliminating the need for manual entry and reducing the risk of human error. This ensures accurate real-time data collection, enabling manufacturers to make informed decisions and improve overall efficiency.

-

Real-Time Monitoring

With instant data visualization, operators and managers can continuously track production performance and identify inefficiencies as they occur. Real-time insights allow for swift responses to issues, helping to minimize downtime and maintain smooth operations across the production floor.

-

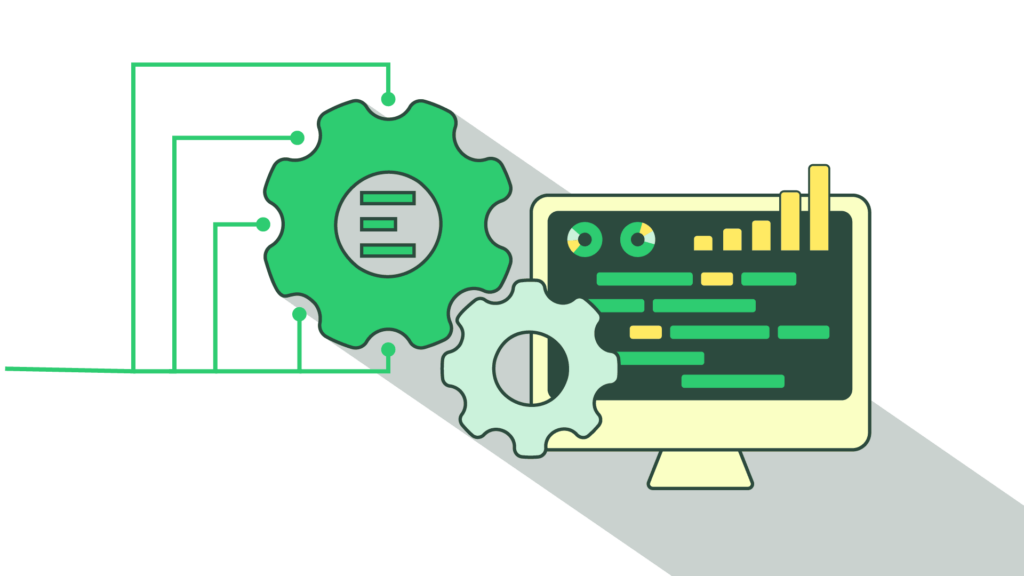

Seamless Integration

Evocon’s system integrates with existing machinery and ERP systems, ensuring a smooth transition to automated data collection. By working with your current infrastructure, Evocon enables quick deployment and immediate access to actionable insights, helping manufacturers enhance productivity without disrupting operations.

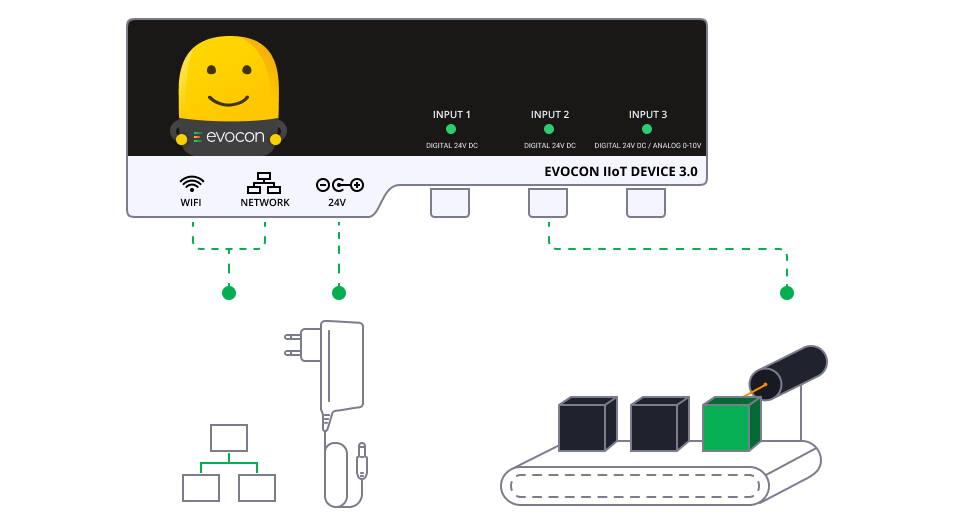

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Implementing Evocon

Implementing Evocon's manufacturing data collection system provides manufacturers with accurate, real-time production data, enabling informed decision-making and process optimization. By automating data capture, companies can reduce errors, enhance productivity, and drive continuous improvement, leading to increased profitability and competitiveness.

“Without Evocon, we would not have been able to realize the step-change in our continuous improvement program.”

-

Transform how you collect data

Experience the power of real-time manufacturing data collection. Track production effortlessly, reduce manual errors, and gain actionable insights to optimize efficiency and drive continuous improvement.

Watch a 5-minute demo and request a free 30-day trial below.