-

Actionable OEE insights

Evocon’s intuitive interface makes complex production data easily understandable for everyone on the factory floor, from operators to management, fostering a culture of continuous improvement and driving performance gains.

-

Automated OEE monitoring

Evocon automatically collects real-time data directly from your machines, allowing your team to focus on core production activities while ensuring reliable data for informed decision-making and optimal factory performance.

-

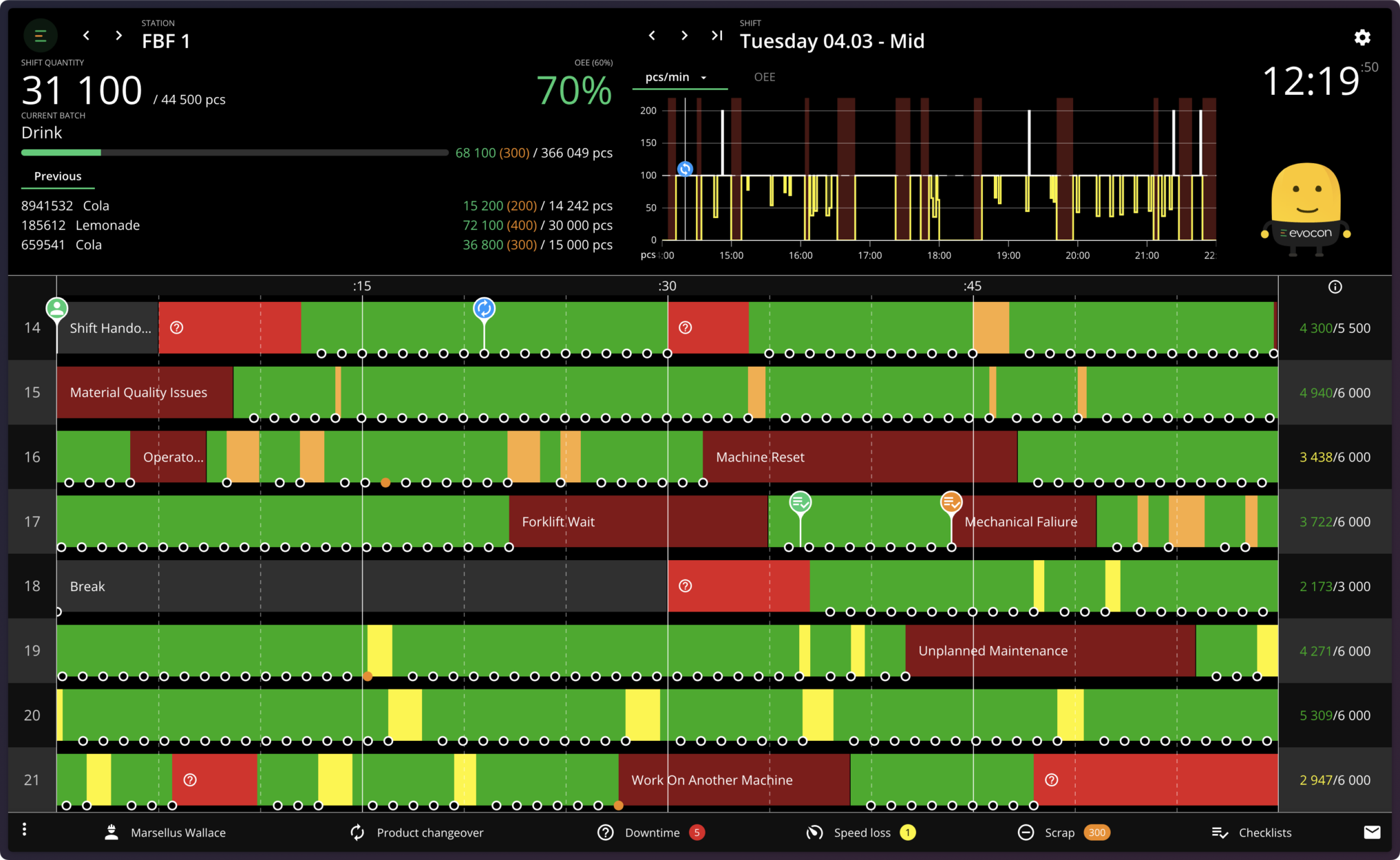

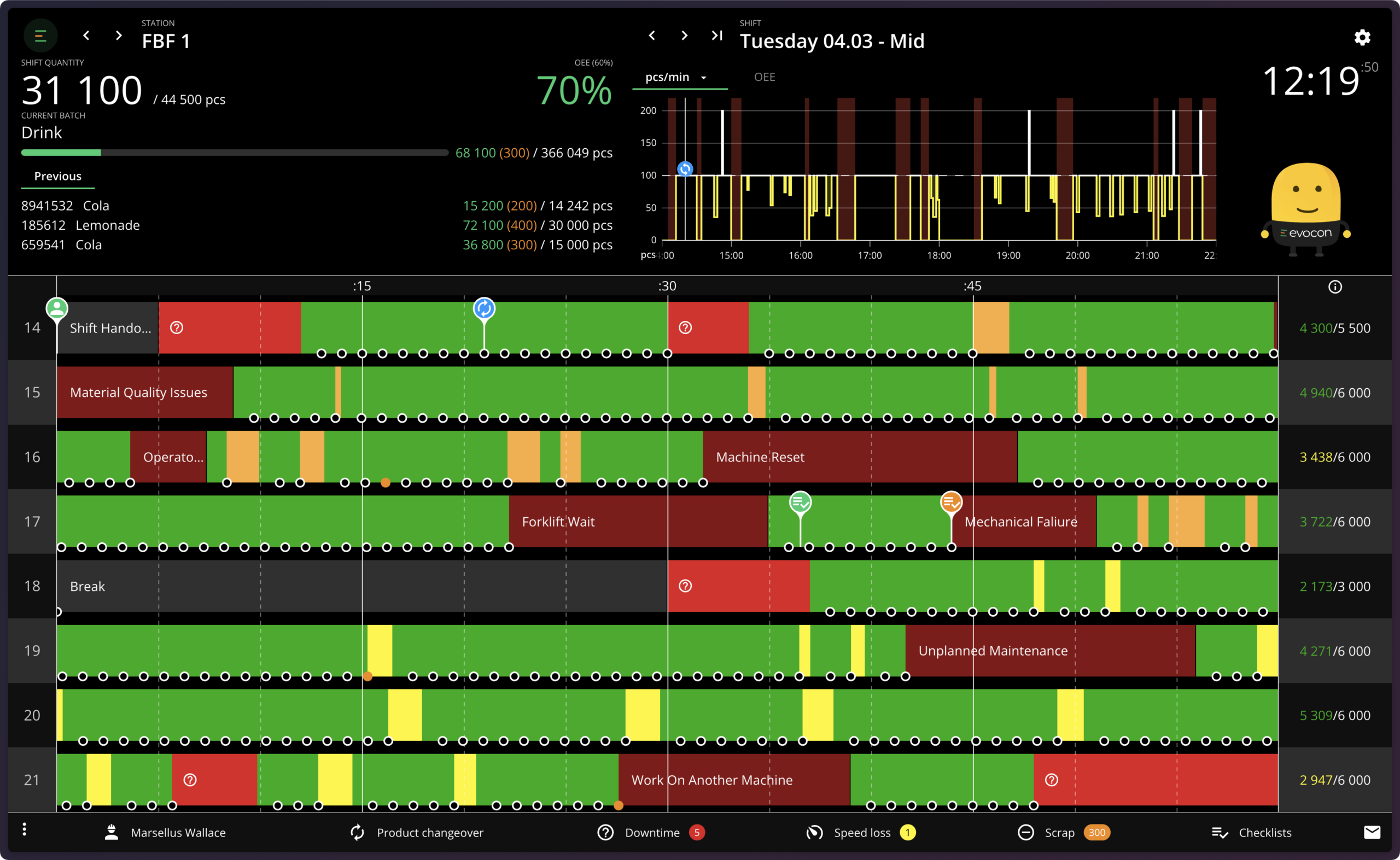

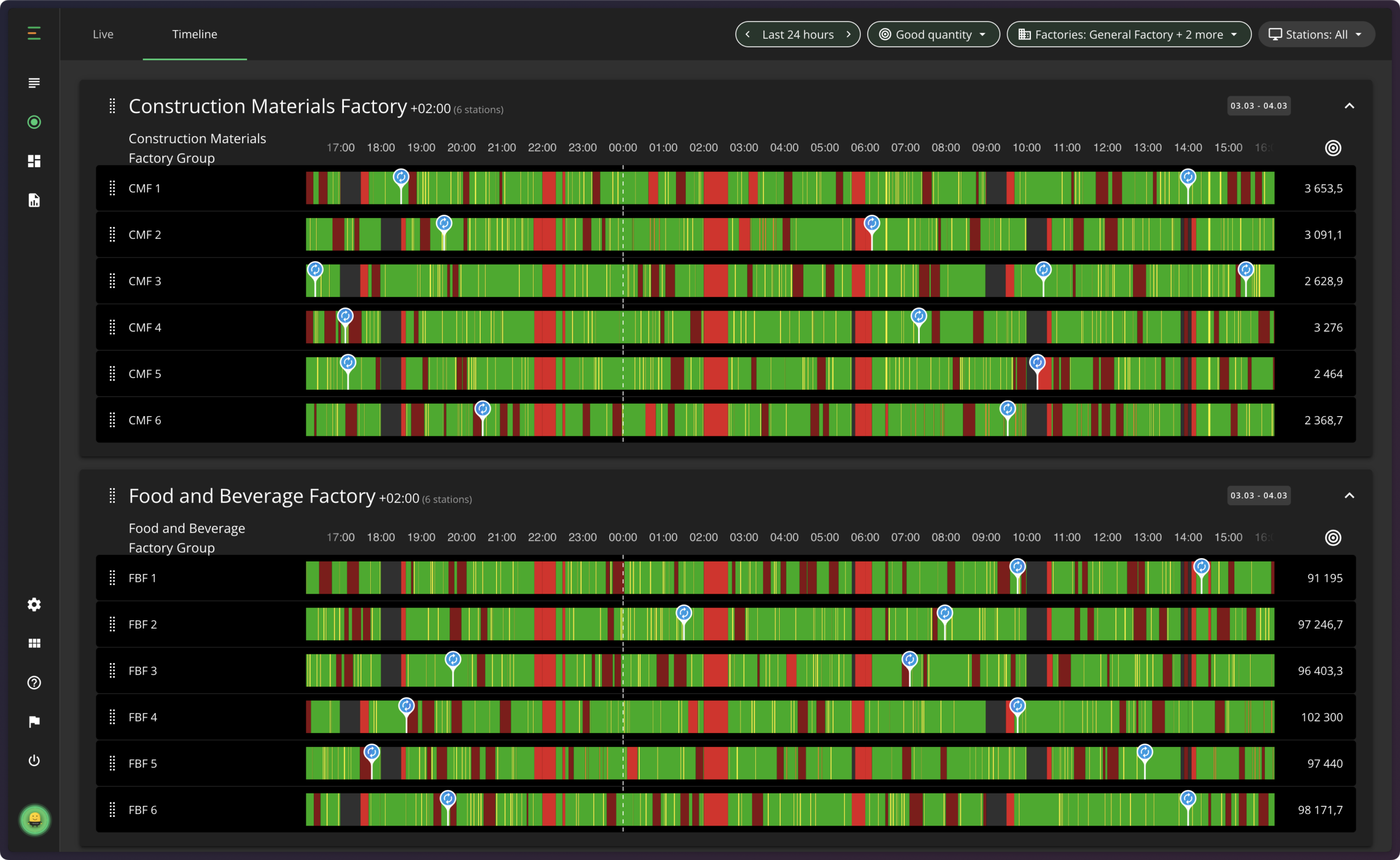

Real-time OEE dashboard

Evocon’s real-time dashboard provides a comprehensive overview of your key manufacturing KPIs, including OEE and downtime, empowering you with at-a-glance insights for immediate action and trend identification.

-

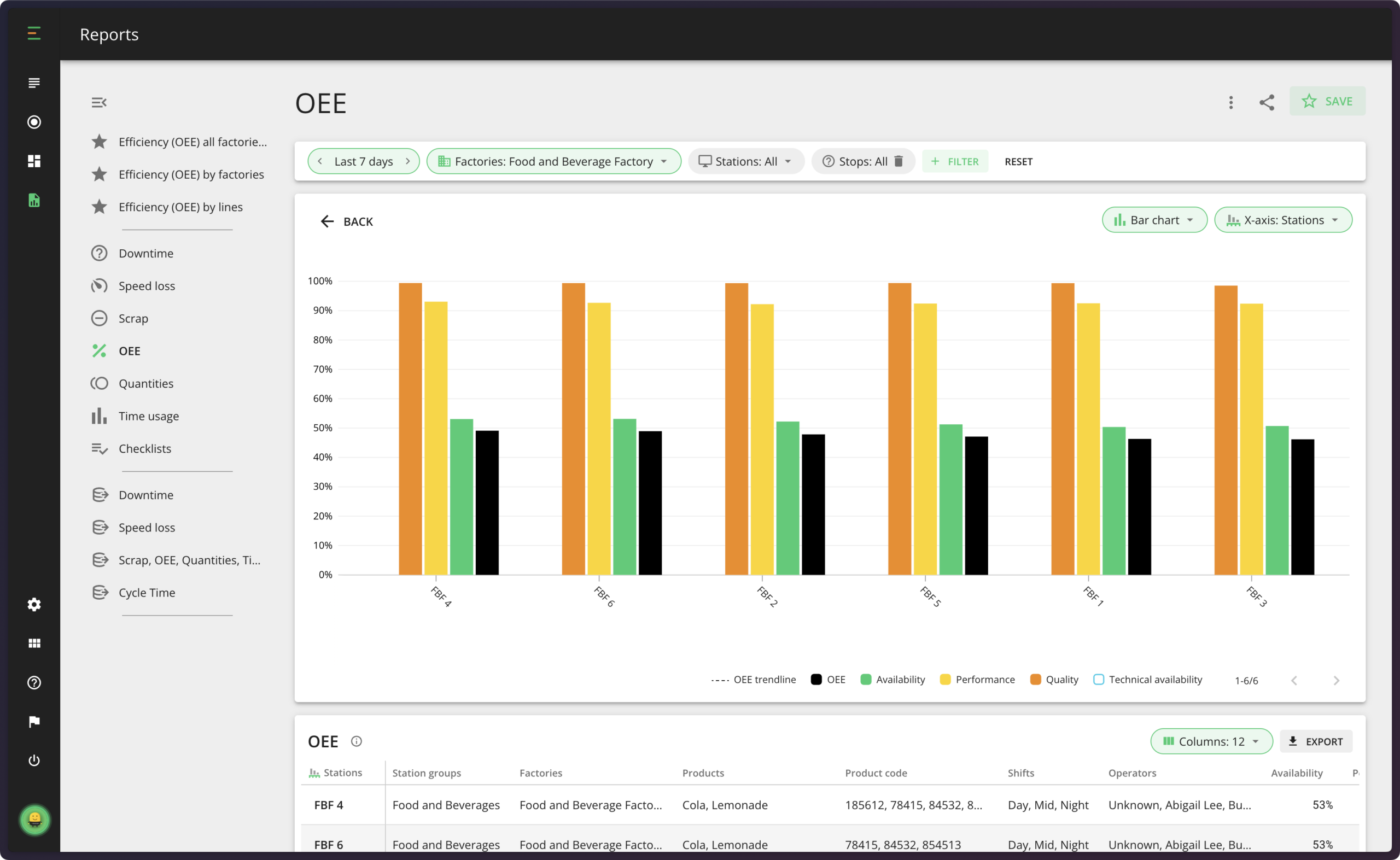

Powerful OEE analytics

Evocon’s powerful analytics track OEE trends and allow for detailed performance comparisons across various production parameters, enabling manufacturers to identify best practices, pinpoint areas for improvement, and make strategic decisions for sustained efficiency gains.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Evocon

Evocon’s OEE monitoring software empowers your team to track, analyze, and improve performance effortlessly. It’s built for the factory floor and it's valued by teams worldwide for its practicality and real-world impact.

"Evocon as a real-time OEE tool has engaged the whole shop-floor working with the losses, resulting in faster solving of problems and improved quality of waste elimination projects."

-

See Evocon in Action

Discover how our intuitive OEE monitoring software helps you track performance, reduce downtime, and optimize production effortlessly.

Watch a quick 5-minute demo and request your free trial today to take control of your factory’s performance.