Why leading packaging manufacturers trust Evocon

Trusted by packaging manufacturers worldwide, Evocon provides the tools needed to optimize production performance and minimize waste. Real-time monitoring and data-driven insights help streamline operations, enhance equipment efficiency, and ensure consistent product quality.

-

Nova Packaging’s journey to excellence

To enhance production visibility and monitor OEE, Nova Packaging implemented Evocon in early 2024. This integration provided real-time insights into machine performance, enabling the team to identify inefficiencies and focus on continuous improvement. As a result, Nova Packaging achieved more accurate data collection and a deeper understanding of their production processes, leading to increased operational efficiency.

“Until now, we saw our production through the windows. But we didn’t understand it. Now, Evocon’s TV screens are our real windows into the production.”

-

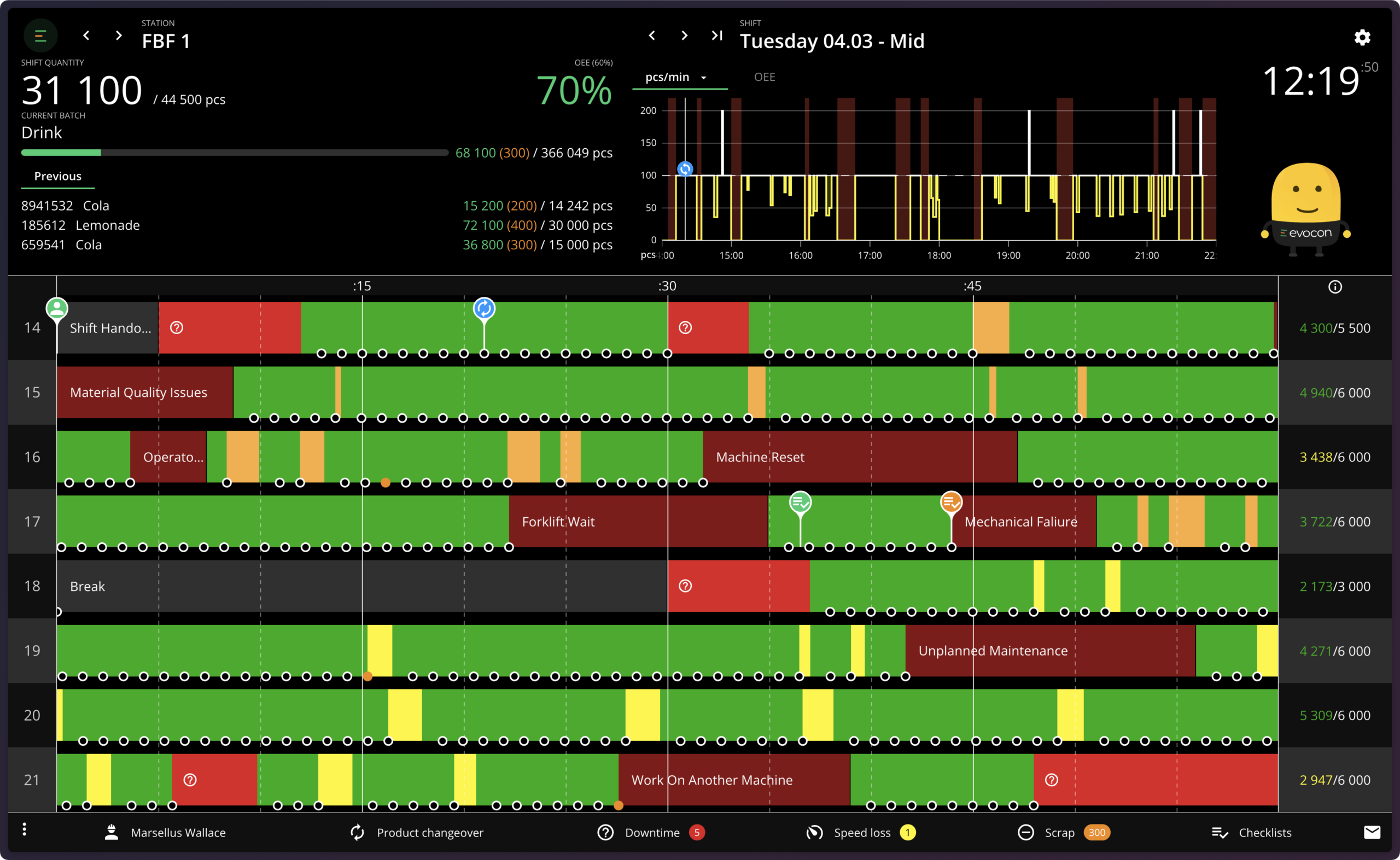

Actionable OEE insights

Evocon’s intuitive interface makes complex production data easily understandable for everyone on the factory floor, from operators to management, fostering a culture of continuous improvement and driving performance gains.

-

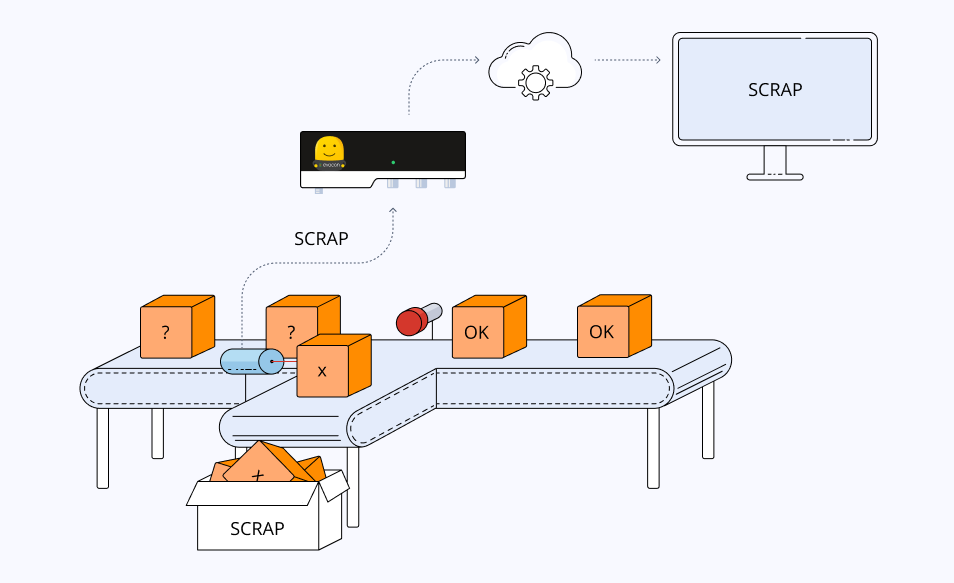

Automated quality monitoring

Evocon provides automated quality tracking capabilities through the continuous monitoring of production inputs and outputs, real-time detection of defective products, and the ability for manual data entry as required. Early identification of quality issues allows manufacturers to minimize waste, streamline processes, and enhance OEE.

-

Real-time OEE dashboard

Gain visibility into production performance across shifts and operators. Evocon provides detailed analytics to uncover inefficiencies, monitor machine usage, and support data-driven decisions to improve efficiency and productivity on the shop floor.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

-

Talk to our team

Our experts are ready to help you unlock the full potential of your production process. Schedule a call with our team today and start your journey towards greater efficiency and profitability.

- Get tailored advice and solutions specific to your production needs.

- Our team will guide you through the setup and optimization process.

- Afterwards, you can try Evocon in your factory free for 30 days.