Why leading packaging manufacturers trust Evocon

Evocon empowers paper product manufacturers to boost efficiency, minimize downtime, and reduce waste. With real-time monitoring and actionable data, manufacturers can streamline operations, improve machine performance, and drive continuous improvement.

-

The transformational journey of Tecpap, Ajdir, and Dimyal

To improve efficiency and reduce waste, Tecpap implemented Evocon across multiple sites. With real-time data and clearer visibility into production, the team was able to unlock their factory’s full potential and focus on continuous improvement.

"Evocon is not there to pressure operators to work faster or increase output at any cost. Instead, it’s there to help them become more efficient, increase productivity, and succeed together."

-

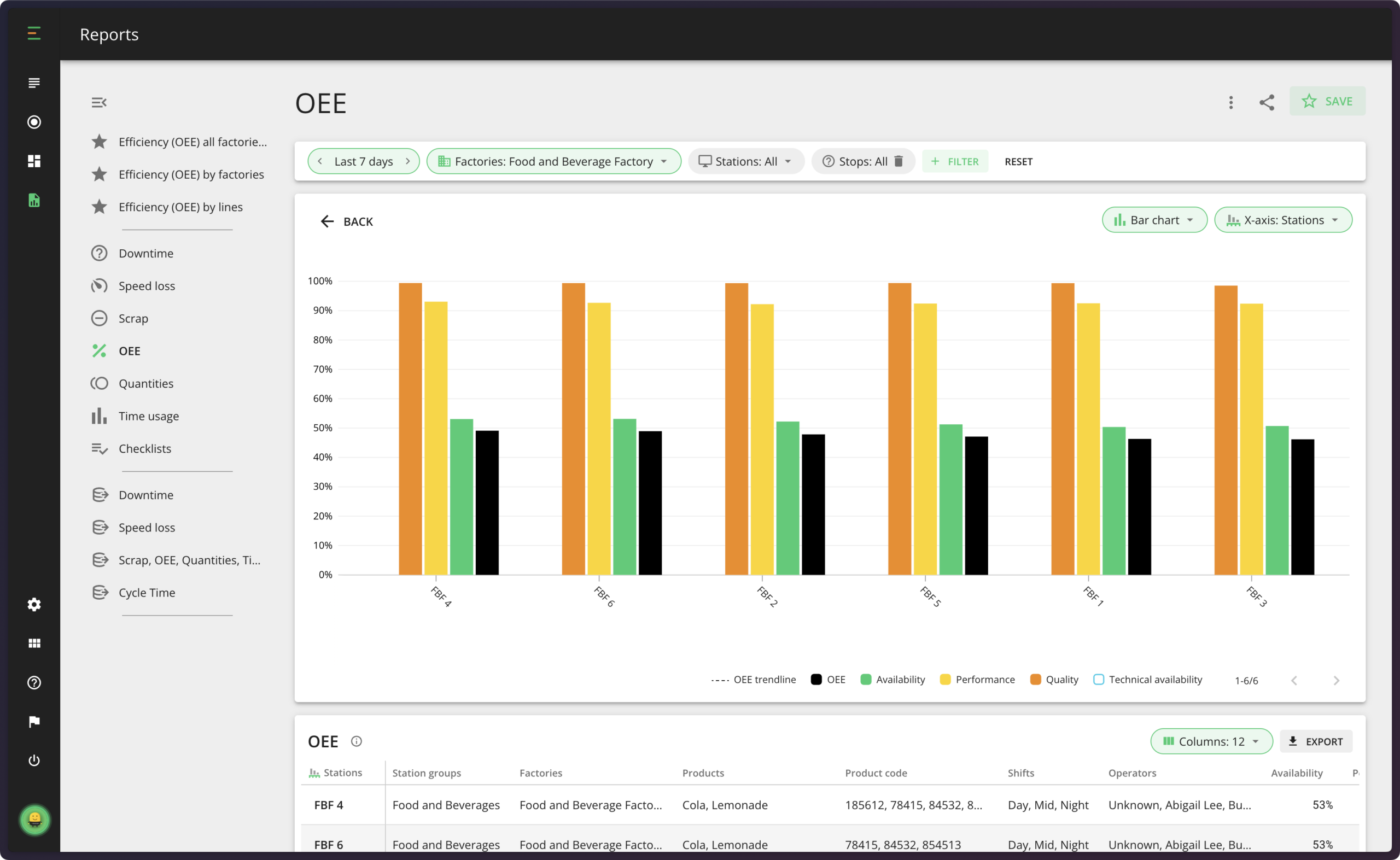

Powerful OEE analytics

Evocon’s powerful analytics track OEE trends and allow for detailed performance comparisons across various production parameters, enabling manufacturers to identify best practices, pinpoint areas for improvement, and make strategic decisions for sustained efficiency gains.

-

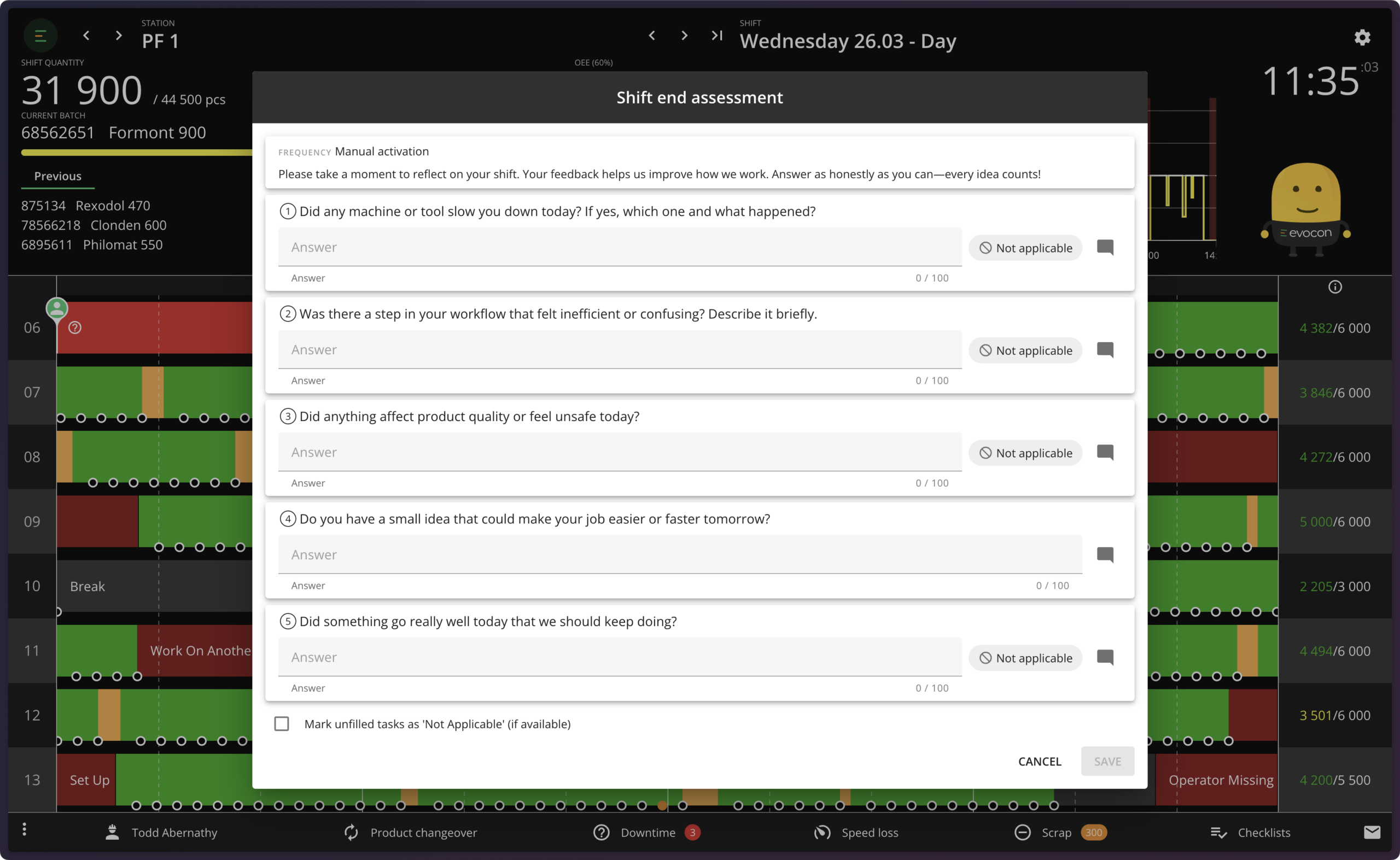

Capture ideas that work

Evocon supports continuous improvement in manufacturing by encouraging operators to log their ideas after or at the beginning of the shift. This allows you to collect potential improvement opportunities, pick the winners, and assign owners to get it done. It’s all about turning good ideas into real fixes, not just collecting data.

-

Customizable production dashboards

Evocon’s production tracking tools provide a real-time source of truth for downtime, speed loss, and quality, giving teams complete visibility into production inefficiencies. By supporting customizable dashboards, managers can quickly identify root causes, implement corrective actions, and optimize efficiency.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

-

Talk to our team

Our experts are ready to help you unlock the full potential of your production process. Schedule a call with our team today and start your journey towards greater efficiency and profitability.

- Get tailored advice and solutions specific to your production needs.

- Our team will guide you through the setup and optimization process.

- Afterwards, you can try Evocon in your factory free for 30 days.