Your solution for pharmaceutical manufacturing

Evocon provides pharmaceutical manufacturers with powerful real-time monitoring tools designed to enhance production efficiency, ensure regulatory compliance, and maintain strict quality control. By offering complete visibility into production processes, Evocon helps identify inefficiencies, reduce downtime, and optimize equipment performance. This data-driven approach supports continuous improvement and ensures that every batch meets the highest industry standards, from manufacturing consistency to regulatory reporting.

-

Megalabs’ journey to Industry 4.0

Megalabs provides a world-class standard in pharmaceutical production. Present in 20+ countries, they partner with valued brands, offering over 1,800 products to improve the health of millions across Latin America.

"We're using Evocon to reduce manual work and lighten the load... We're finding out what the tool will do for people in the offices and the people on the factory floor. It's going to simplify their lives!"

-

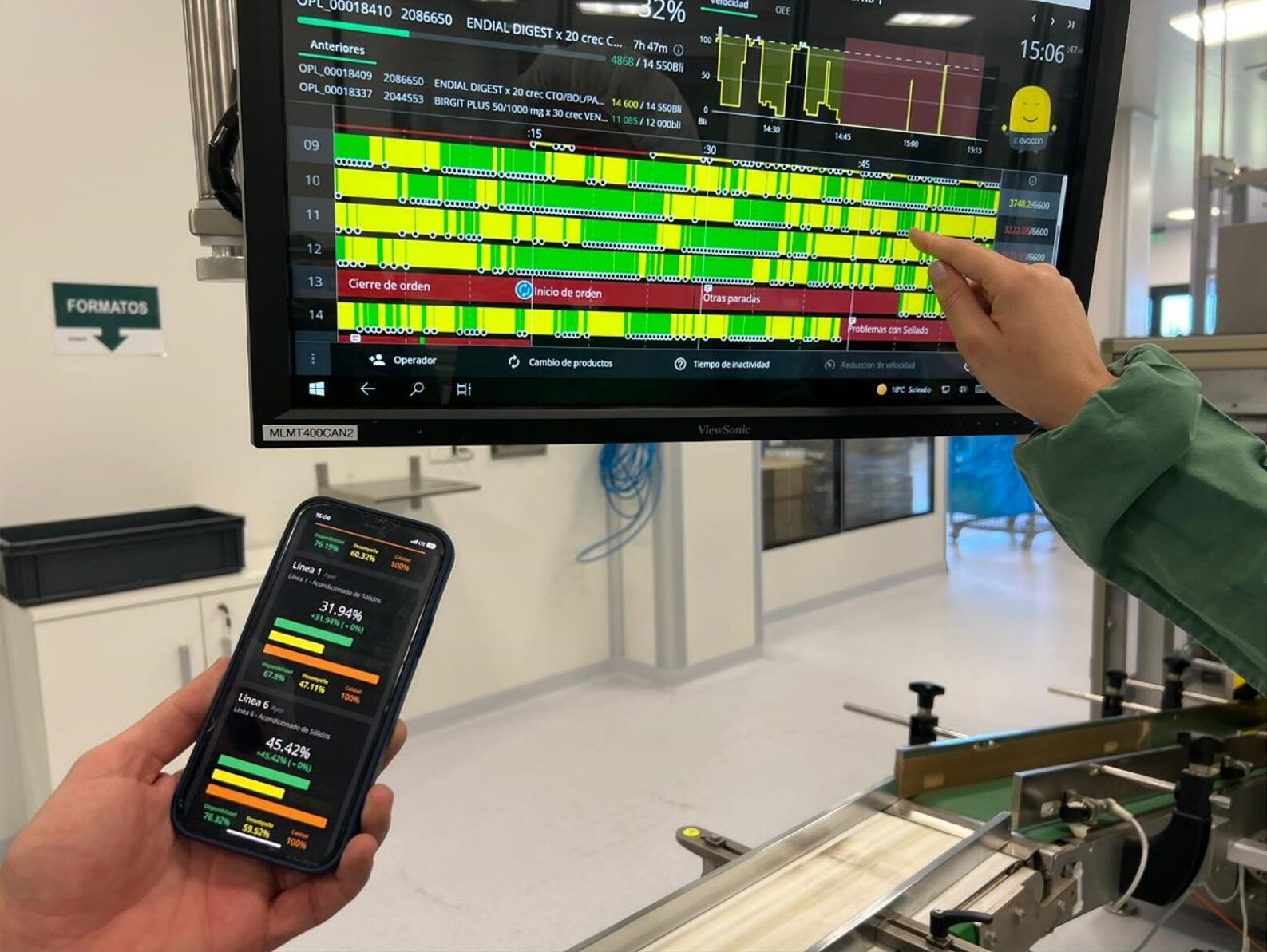

Real-time data collection

Capture production data automatically in real time to ensure accuracy and consistency. This feature enables pharmaceutical manufacturers to track performance, monitor equipment efficiency, and quickly respond to deviations to maintain regulatory compliance.

-

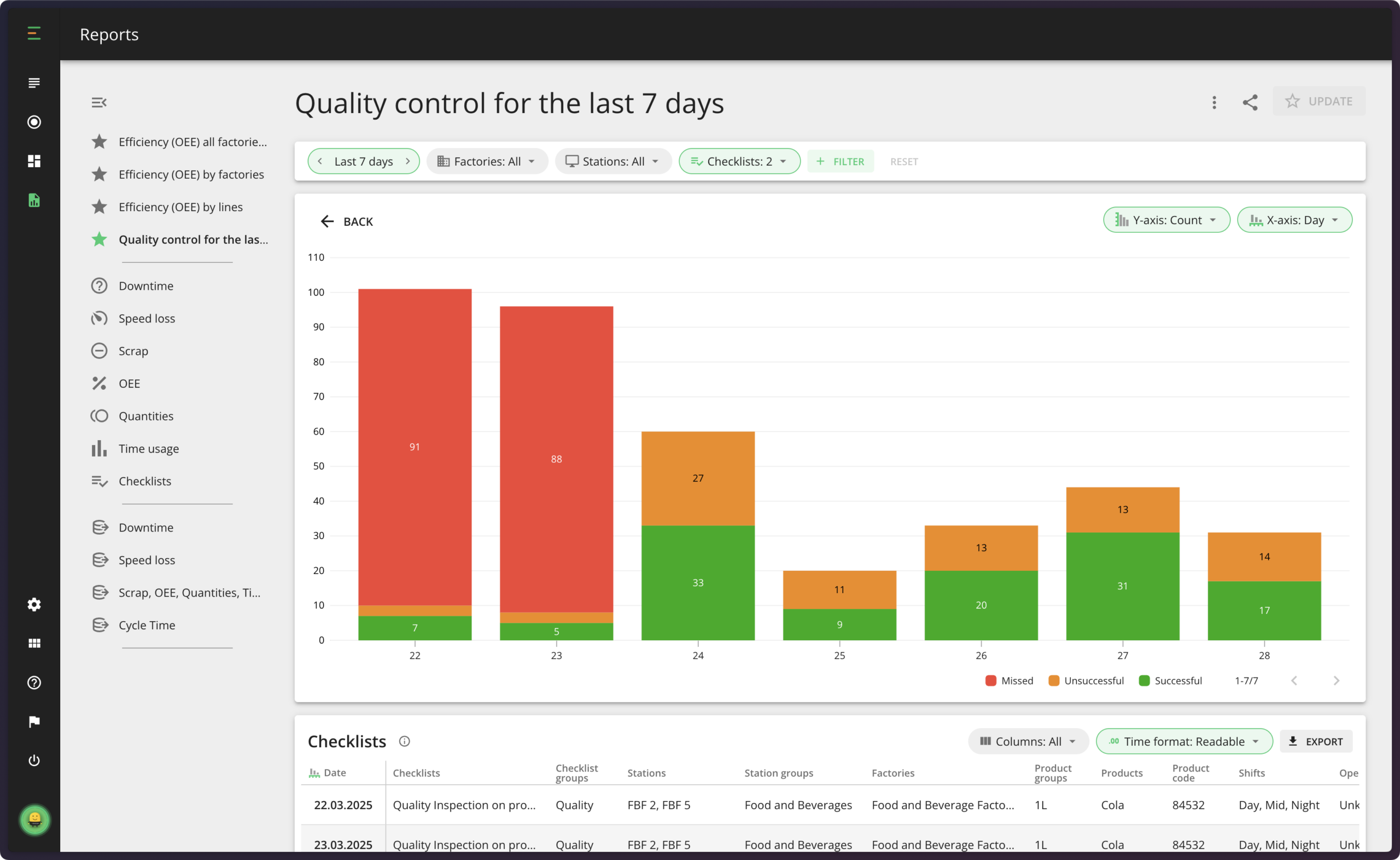

Quality control analytics

Evocon’s manufacturing quality control software delivers analytics to pinpoint process areas needing adjustment. It identifies patterns across stations, products, and shifts, enabling targeted improvements. Enhance efficiency, reduce defects, and optimize production with real-time insights and data-driven decisions.

-

Automated downtime tracking

Automatically detect and record machine downtime, eliminating the need for manual tracking. This feature helps identify the root causes of equipment failures, minimize production interruptions, and improve overall equipment effectiveness across all shifts.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

-

Talk to our team

Our experts are ready to help you unlock the full potential of your production process. Schedule a call with our team today and start your journey towards greater efficiency and profitability.

- Get tailored advice and solutions specific to your production needs.

- Our team will guide you through the setup and optimization process.

- Afterwards, you can try Evocon in your factory free for 30 days.