-

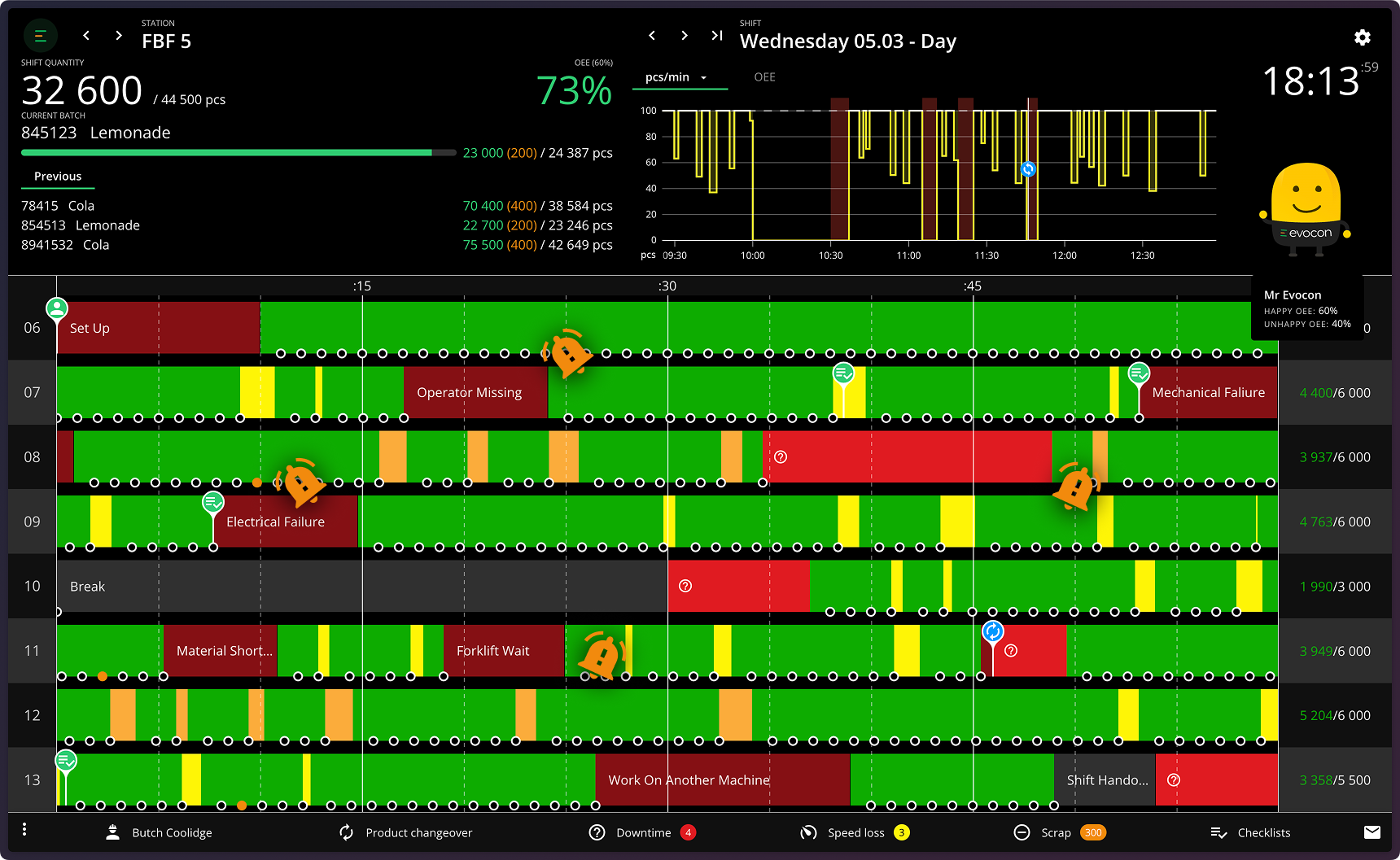

Real-time data tracking

Evocon is a real-time source of truth for daily production monitoring, providing operators and managers with instant visibility into performance. Clear indicators highlight stoppages, inefficiencies, and the status of recurring checks, enabling teams to quickly identify issues, take corrective action, and keep production on track.

-

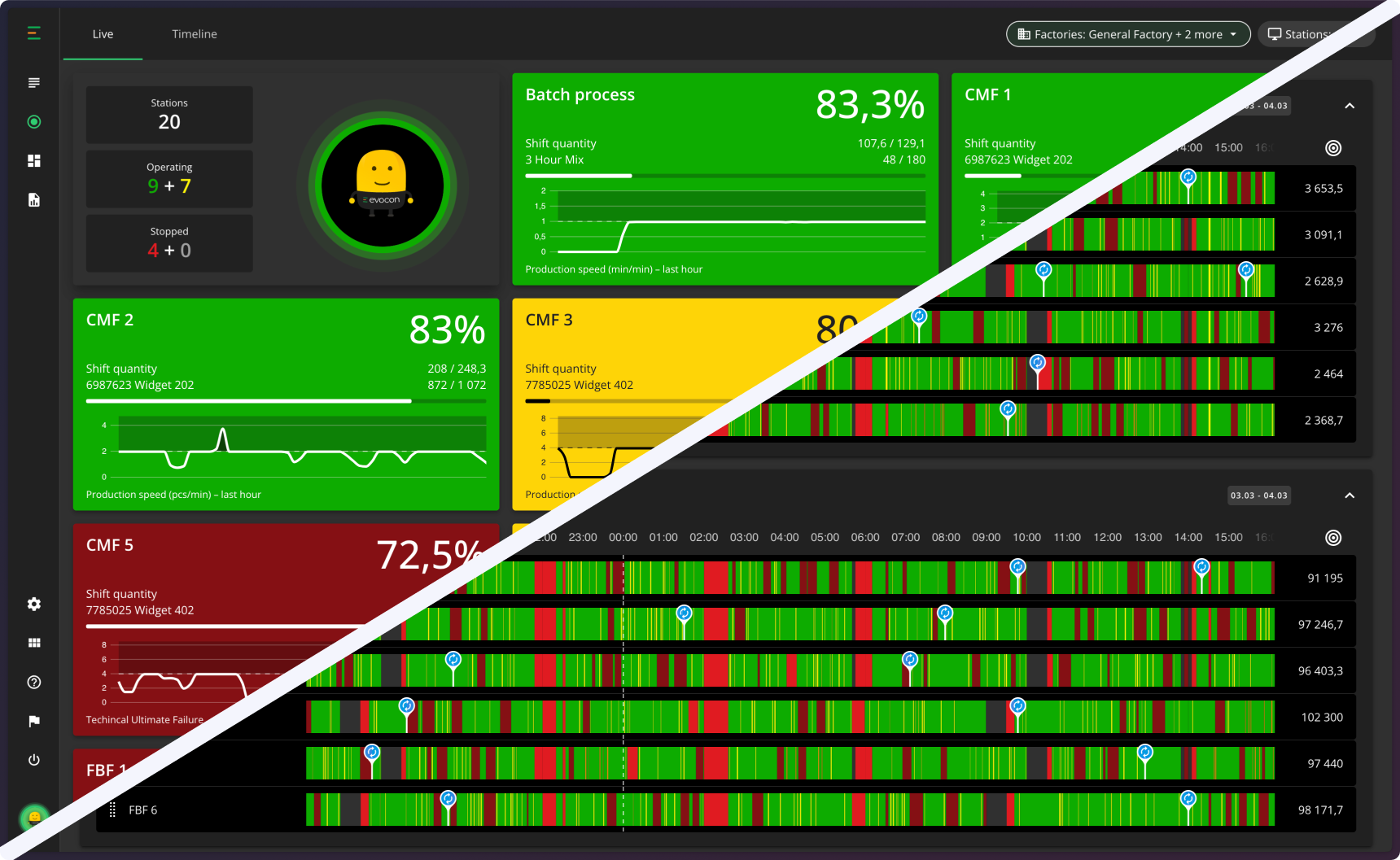

Customizable production dashboards

Evocon’s production tracking tools provide a real-time source of truth for downtime, speed loss, and quality, giving teams complete visibility into production inefficiencies. By supporting customizable dashboards, managers can quickly identify root causes, implement corrective actions, and optimize efficiency.

-

Downtime analysis and alerts

Evocon’s production monitoring system delivers instant insights into stoppages with standardized event logging and detailed information on each event. Real-time alerts notify teams the moment issues arise, enabling quick response to minimize disruptions and keep production on schedule.

-

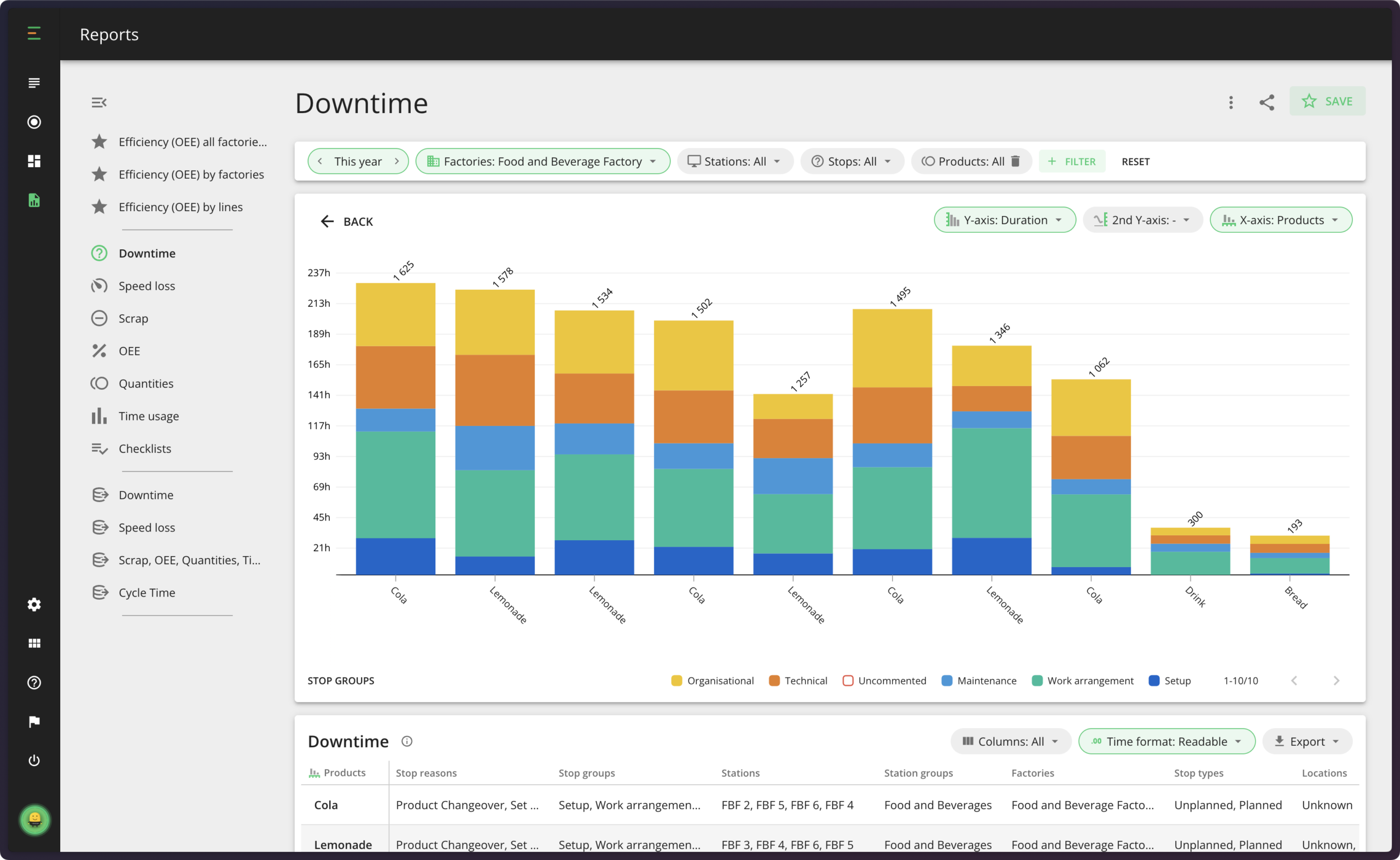

Analytics for production monitoring

Evocon’s manufacturing monitoring system keeps analytics simple and yet effective. It helps reveal bottlenecks, optimize the production process, and enhance quality, saving time and reducing costs. Transform your manufacturing process with clear, actionable reports tailored to your needs—all in one user-friendly platform.

-

Monitor all factories in one platform

Evocon offers centralized, real-time production performance monitoring across all factories, ensuring a consistent and data-driven approach to efficiency. By consolidating data in one platform, managers can track trends, benchmark performance, and quickly address any issues, fostering collaboration, standardization, and continuous improvement across multiple locations.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Evocon

Implementing Evocon's real-time production monitoring system empowers manufacturers with immediate access to critical production data, fostering a culture of continuous improvement. By visualizing performance metrics and identifying inefficiencies, teams can make informed decisions that enhance productivity and operational excellence.

“The operators engage with Evocon because of two main reasons. First, they appreciate this transparent and data-driven approach. And second, they see that Evocon makes their contribution measurable, valuable, and visualized.”

-

Get real-time production insights

See how Evocon’s production monitoring software can help you get real-time insights, enhance operational efficiency, and streamline manufacturing processes for improved output and performance.