This case study explores the digital transformation of Melissa Kikizas, one of Greece’s leading pasta producers, as they moved from manual, handwritten production tracking to real-time, data-driven manufacturing. Facing challenges with inaccurate efficiency metrics and “hidden losses” from untracked OEE, the team struggled to identify the true causes of inefficiencies.

By implementing Evocon’s IIoT monitoring platform, Melissa Kikizas gained complete production visibility across more than 20 lines, overcame initial operator resistance to turn data into an “improvement game,” and ultimately increased daily production, reduced scrap, and built a new culture of company-wide collaboration.

Impressively, shortly after the platform was installed, users began to wonder how they had managed to work without it. A range of data and statistics became immediately and reliably available, with excellent real-time analysis capabilities.

About Melissa Kikizas

Founded in 1947, Melissa Kikizas is one of Greece’s largest and most respected food companies. It was born from the vision of Alexandros Kikizas, and is led by the third generation of the Kikizas family today. The company currently exports its products to more than 45 countries worldwide.

With an annual production exceeding 65,000 tons, it confirms its leading position in the country while also securing its international partnerships with innovative products and traditional recipes, always of excellent quality — the “Greek version of Mediterranean cuisine”.

The Challenges Faced

Before the project, Melissa Kikizas did not fully track Overall Equipment Effectiveness (OEE). The team’s efforts focused on recording major breakdowns and overall waste (rework and scrap), which meant they were missing a large portion of the production story. Small stops, speed reductions, and inefficient product changeovers — what the team calls “hidden losses” — went unrecorded, limiting their ability to identify the true causes of inefficiency.

The primary method for data collection was handwritten notes taken by operators at the end of each shift. According to Dimitris Bakodimos, Plant Manager at Melissa Kikizas, this method lacked the accuracy and detail needed to identify the root causes of efficiency problems.

As the business grew, this lack of clarity became a critical issue. The factory needed a clear, live view of production to understand where time and resources were being lost and to improve planning.

The transition to a digital system also posed a human challenge. Operators were already handling multiple improvement projects, creating fatigue and skepticism. It was essential to introduce the new solution as a support tool, not as a system for monitoring employees, to ensure it would be embraced rather than resisted.

The initial difficulties were overcome relatively quickly as the first results began to appear. The recordings led to problem-solving and improvements in the operators’ daily work. The cycle continued with new recordings and further improvements.

An Easy-to-Use, Real-Time Tool: Evocon Implementation

With a clear understanding of the factory’s challenges, Melissa Kikizas set out to find a solution that would give them live production data, actionable insights, and an easy-to-use interface for operators. Choosing the right tool marked the turning point from manual tracking toward real-time, data-driven improvement. Melissa Kikizas had clear criteria for a new solution. The platform had to:

- Provide live data

- Offer a complete picture of production losses and improvement opportunities

- Be easy for operators to use

Dimitris emphasized that ease of use was critical — the goal was to find a tool that would genuinely help the team, not burden them.

“We needed a tool that provides live data, is easy to use for operators, and gives management the visibility needed to drive continuous improvement. Ease of use was critical; we didn’t want something that felt like extra work for the teams.”

Dimitris Bakodimos, Plant Manager, Melissa Kikizas

The rollout was strategic. The team started with a pilot program on 16 packaging lines, focusing on a manageable scope to demonstrate early results. Once the benefits became visible, they expanded the system to 7 production lines, connecting more than 20 lines in total.

Within a year, the system had been fully integrated, allowing management to focus on real problems rather than subjective impressions. Past assumptions could now be validated with hard data or, conversely, proven insufficient with clear evidence. This enabled the team to develop action plans based on objective information.

Challenges during implementation

Defining stop reasons

One of the first technical challenges was defining stop reasons correctly. The team had to find the right balance — detailed enough for actionable insights, but not so complex that it would overwhelm operators. They also worked to reduce “uncommented stops” by showing operators how important their correct logging was for reliable analysis. Accurate stop categorization allowed the team to identify recurring issues and take immediate corrective action, rather than waiting until the end of a shift.

The classification of stop reasons is an ongoing process. The causes change according to their significance. They become more detailed the more frequently they recur, or they are grouped into larger categories when they lose their importance.

Operator resistance

Another issue was the initial resistance from operators. They were already dealing with multiple improvement projects, which caused fatigue and initial hesitation. Over time, they began to see how Evocon helped identify problems faster and reduced unnecessary work. The critical point was for them to see immediate solutions, even for small everyday problems. Small, quick wins can potentially change their perspective immediately. This happened relatively quickly for Melissa Kikizas.

Collaboration of Different Departments

Successful implementation required close cooperation between production, technical teams, and management from the very beginning.

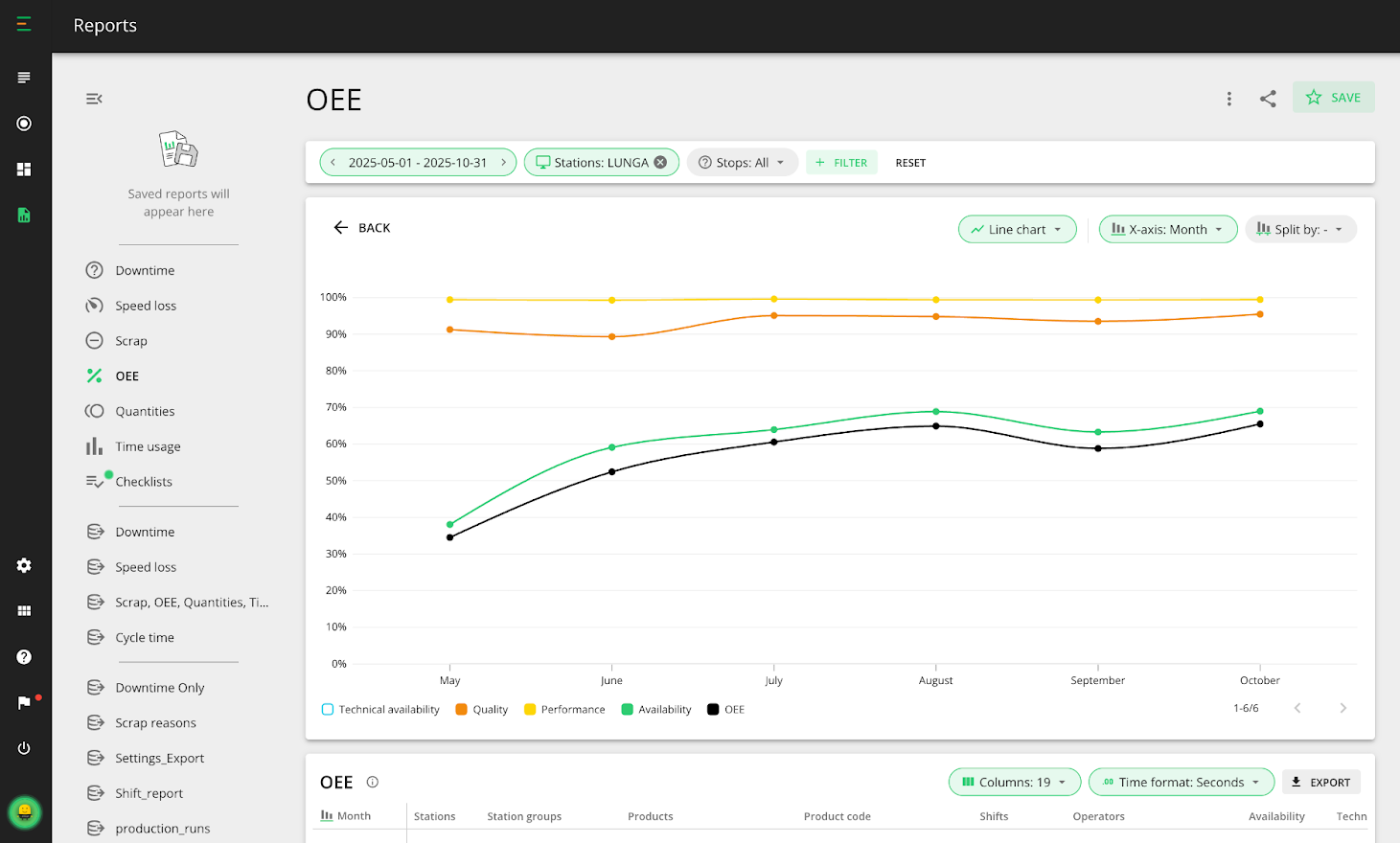

Management actively utilized Evocon’s dashboards and reports for a real-time view of problems and bottlenecks, in particular using the dashboards for performance reviews and tracking trends.

This data was quickly integrated into daily and weekly meetings, becoming a common point of reference. Line-level reports helped supervisors and engineers identify recurring issues and prioritize improvements.

This shared access to live data brought the teams together to solve problems based on facts rather than assumptions. Consistent adherence to meetings and continuous follow-up are critical elements for the success and establishment of the program.

The Results

The most significant change for Melissa Kikizas was gaining full visibility of production. This new clarity had an immediate impact: teams began to collaborate better, decisions were made faster, and all actions were based on real data.

“Evocon made it possible to quantify inefficiencies and losses that were previously invisible.”

Dimitris Bakodimos, Plant Manager, Melissa Kikizas

Although there was no precise OEE baseline for a direct comparison, the improvements were clear to the entire team. Production became more stable and the lines more efficient.

This stability led to concrete gains in other key metrics:

- Daily production increased

- Scrap (“fyra”) decreased

Operator resistance turned into engagement as the team saw their performance visualized in real time, motivating them to actively participate in improvements. Dimitris described this as an “improvement game”:

“As the results became visible, resistance turned into engagement. Today, Evocon is seen as a natural part of our operation, and operators themselves often refer to dashboards to track their performance.”

Dimitris Bakodimos, Plant Manager, Melissa Kikizas

Evocon is now fully integrated into the factory’s daily operations, supporting both performance and collaboration across all teams. Furthermore, the belief in the objectivity of the data was reinforced. The operators know that they themselves provided the information. Therefore, any subjective judgment of the supervisor has been eliminated.

Before and After: Examples

Here are a few examples of how Evocon helped the team solve problems and improve performance.

Identifying and reducing micro-stops

Small, recurring micro-stops on a packaging line were adding up to a substantial loss of time each shift. By analyzing Evocon data, the team identified the exact causes and adjusted machine settings and the maintenance schedule. These changes immediately reduced downtime and increased throughput. Operators could see the impact of their adjustments in real time, which encouraged participation in the improvement process.

At the same time, the spirit of cooperation between the operators and the technical department was strengthened, as operational problems were resolved more promptly.

Solving mysterious “slow output” complaints

Before Evocon, the team often received complaints about slow output without a clear explanation. After implementation, they could see exactly when and where losses were occurring. The delays were traced to product changeovers and material supply issues, allowing targeted solutions that increased throughput. This visibility also helped operators understand the reasons behind delays.

Lessons Learned

Reflecting on the project, Dimitris shared two key pieces of advice for other factories beginning this journey.

1. Stop reasons and operator training

Dedicate time at the beginning to correctly define stop reasons and train operators on how to categorize them. Dimitris emphasized that this foundation is critical — accurate data depends on it, and it ensures actionable insights in the future.

2. Start simple and involve operators from day one

Begin with a simple implementation and involve operators from the very beginning. Demonstrating early positive results helps build trust and motivates teams to embrace the system.

“Data alone doesn’t improve performance — people do. Evocon makes it visible.”

Dimitris Bakodimos, Plant Manager, Melissa Kikizas

The Future

Today, the biggest challenge for the factory is maintaining high performance while managing increasing demand and complexity. Keeping all production lines balanced and efficient remains a daily focus.

With Evocon now fully integrated into their processes, the Melissa Kikizas team plans to analyze product changeovers in greater detail and reduce unplanned stops, using the data to target continuous optimization opportunities. Operators and teams can use real-time data proactively, making improvement part of their daily routines. Dimitris sees this as part of a larger trend:

“The food industry is moving fast toward digitalization and sustainability. The companies that can translate data into daily decisions will lead the way. Evocon is part of that journey — it bridges technology, people, and performance.”

We’d like to thank Dimitris for sharing his experience with us, as well as John Lelis, authorized Evocon Partner in Greece.