Sergio Lewis joined Integraciones Generales, SA (INTEGSA) when the company decided to open a new line of business offering Digital Manufacturing solutions for the Mexican market. Before that, Lewis worked as Continuous Improvement Manager at a plant in Monterrey of one of the biggest automotive parts manufacturers in Mexico, and had been in charge of implementing Evocon in one of its factories.

Before offering Digital Manufacturing solutions, INTEGSA served mainly the data center service market for 20 years. Cabling, memory, internet infrastructure, and servers. Within its clients, INTEGSA has many manufacturing companies. When they started asking for help with Digital Manufacturing solutions, they saw the opportunity to offer Evocon in the Mexican market through a strategic partnership. Now Evocon is the most prominent solution they provide in this additional new line of business.

Lewis, Digital Manufacturing Manager at INTEGSA, talked to us about the problems Mexican manufacturers face, how Evocon adapts to the particularities of the market, and why INTEGSA decided to partner with Evocon.

Learn more: How to become an Evocon partner

The Problem: High Costs of an Initial Investment

Many big Mexican manufacturers made significant investments in digitalization 20 years or so ago. At the time, the hardware and software they invested in were cutting edge. They required a lot of initial investment in infrastructure (data centers, for example), software licensing, or developers to personalize or build the solutions from scratch.

Twenty years later, some of these manufacturers are still using those early solutions because they don’t want to make significant investments again, either in software or machines.

Medium and small Mexican manufacturers were left out from this first wave of digitization since they didn’t have the resources to invest considerable sums in machines or software.

At the factory in Monterrey where Sergio Lewis used to work as Continuous Improvement Manager, they didn’t have the resources to acquire the system to collect production data and track OEE that the IT department at the headquarters of the group had approved to use. He had to search for a solution that fit their needs and was affordable for them, and that is how he first found Evocon.

Lewis, now an Evocon partner, says that he has encountered many manufacturers in Mexico with this problem. They want to improve the reliability of production information available to them, usually gathered manually by operators. This inaccuracy of data, in turn, prevents companies from deploying initiatives to fix problems because the data is wrong, to begin with, Lewis explains. But companies don’t consider digitizing these processes because they believe it would require a significant initial investment.

Digital Transformation Projects Need IT and Manufacturing to Work Together

Lewis posted a survey to his LinkedIn network asking how they were measuring OEE, and 64% of the respondents chose “partly automatic (Excel)” or “manually”.

“A customer will never come to us with the specific problem of digitizing OEE,” says Lewis.

“They come to us with the problem of having low production rate, or a lot of scraps, delays in their production plans. And how can they solve these problems? With Evocon. Having this information in real-time allows them to make corrections quickly and allows them to meet their goals. Evocon is a service, but we sell it as a solution”, says Lewis.

As in other parts of the world, in Mexico Information Technology and Manufacturing departments don’t communicate. “In the past, you didn’t need this communication between the areas, but right now, in the digital era we live in, any digital transformation project needs input from both the IT and Manufacturing areas, and in Mexico, this is not happening,” Lewis says.

Lewis explains that the IT department starts researching a solution, and they tend to think in terms of complex software requirements. They do not always think about the final customer and the needs of the manufacturing areas, such as a short time to implement and ease of use.

Learn more: How to Monitor Production and Track OEE Using Evocon?

A Digital Solution From Estonia

When Lewis first found Evocon, he was surprised to see how easy it was to implement and use. He says that it took the maintenance team in the plant a couple of hours to install. He was also surprised to see how intuitive it was to create dashboards, widgets, reports, and personalize different aspects of the software, something he says would have required a developer to do in many other existing manufacturing software solutions.

But convincing the company to have an international provider was not easy since Mexican companies need to deal with much bureaucracy and paperwork to work with outside companies, usually taking several months to deal with this barrier. That is why finding a trusted local partner that could offer Evocon played a crucial role in the company’s decision where Lewis was working to adopt Evocon.

“When you tell Mexican manufacturers that Evocon is from Estonia, they don’t know much about the country. In Latin America, people are more familiar with the UK, Spain, and other countries in Europe and think about Estonia as being too far. They don’t know the country. They usually think that the software might not be in Spanish. So we talk to them, and it helps to have a local trusted partner that can provide Evocon”, says Lewis.

Lewis explains that Evocon is easy to implement in the Mexican context because it is available in Spanish and it is very visual. In Mexico, most machine operators are not trained to use software or hardware, they are focused on operating the machines, and if you ask them to work with an Excel file, for example, they struggle. Instead, Evocon offers an intuitive user interface, which makes a big difference in the easy adoption on the floor. “Here you save on training, since Evocon is easy to use, and if the company feels the need to have training sessions, we can easily go to them and organize the training locally,” Lewis explains.

The other main advantage for Mexican manufacturers looking to implement digital transformation projects is that Evocon is provided on the cloud through Amazon Web Services, so companies don’t need to invest in data centers infrastructure in the plants.

Start your digitization journey

Get the tools you need to start tracking your production without any significant investment. Free for 30 days.

Evocon Fits the Needs of Mexican Manufacturers

“I believe Evocon adapts to the needs of the Mexican market because they want something easy to use, implement, can be paid monthly, and they don’t need to make a long-term commitment,” says Lewis.

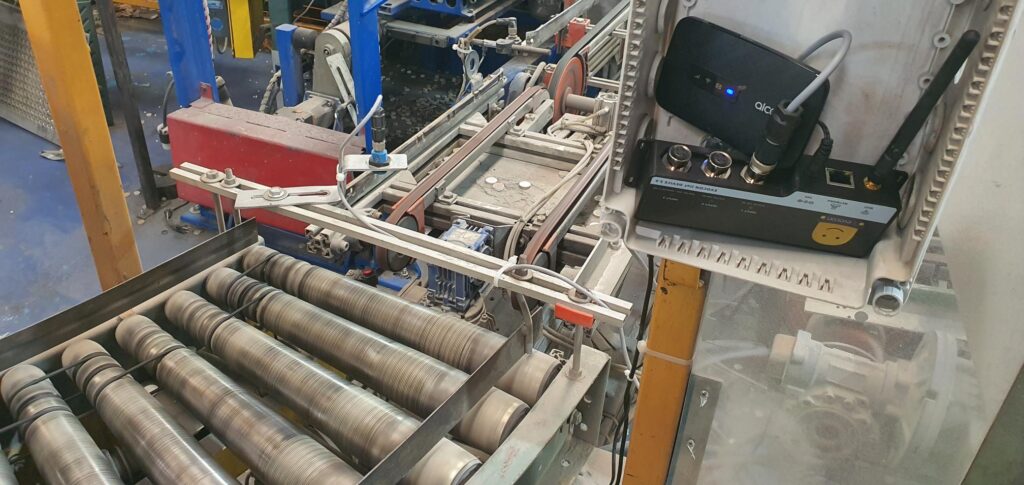

For small and medium companies in Mexico, Lewis explains that Evocon can digitize a line without investing in new machines. As is the case in many countries in Latin America and worldwide, many machines are not digital yet. Instead of making a significant investment, it is possible to use Evocon’s hardware to count pieces, weight, length, and many other use cases and retrofit their existing machines.

For INTEGSA, its partnership with Evocon has allowed them to have a new line of business for their Digital Manufacturing solutions offerings and has increased existing ones. Lewis says that due to the internet infrastructure in Mexico, many factories are in areas where they only have access to a poor internet connection. These companies looking to connect Evocon’s hardware on their lines or expand their existing licenses to cover more lines come to INTEGSA and request a more stable internet connection, a service they have been offering for many years.

“We consider ourselves as problem solvers. How does Evocon help us with that? OEE and other manufacturing KPIs were already measured in plants. Still, they need human input, and creating and analyzing all this information takes time, and all this information is delayed by several days or weeks. So as solution providers, we saw Evocon as a way to digitize all this process, and help our customers to identify and solve their problems”, Lewis concludes.

Do you have any questions? Please send us an email at info@evocon.com.