When tracking OEE, the best way to monitor production quality depends on your production and quality inspection process. In this article, we will explore four different ways that you can set up Evocon to register scrap.

4 Ways to Monitor Production Quality Using Evocon

Here are the four possible ways of how our clients use Evocon to monitor their quality. The first three options are fully automated and the last option is for processes where full automation is not yet possible.

- Monitoring input and output

- Monitoring scrap with a sensor

- Using existing data

- Registering scrap manually

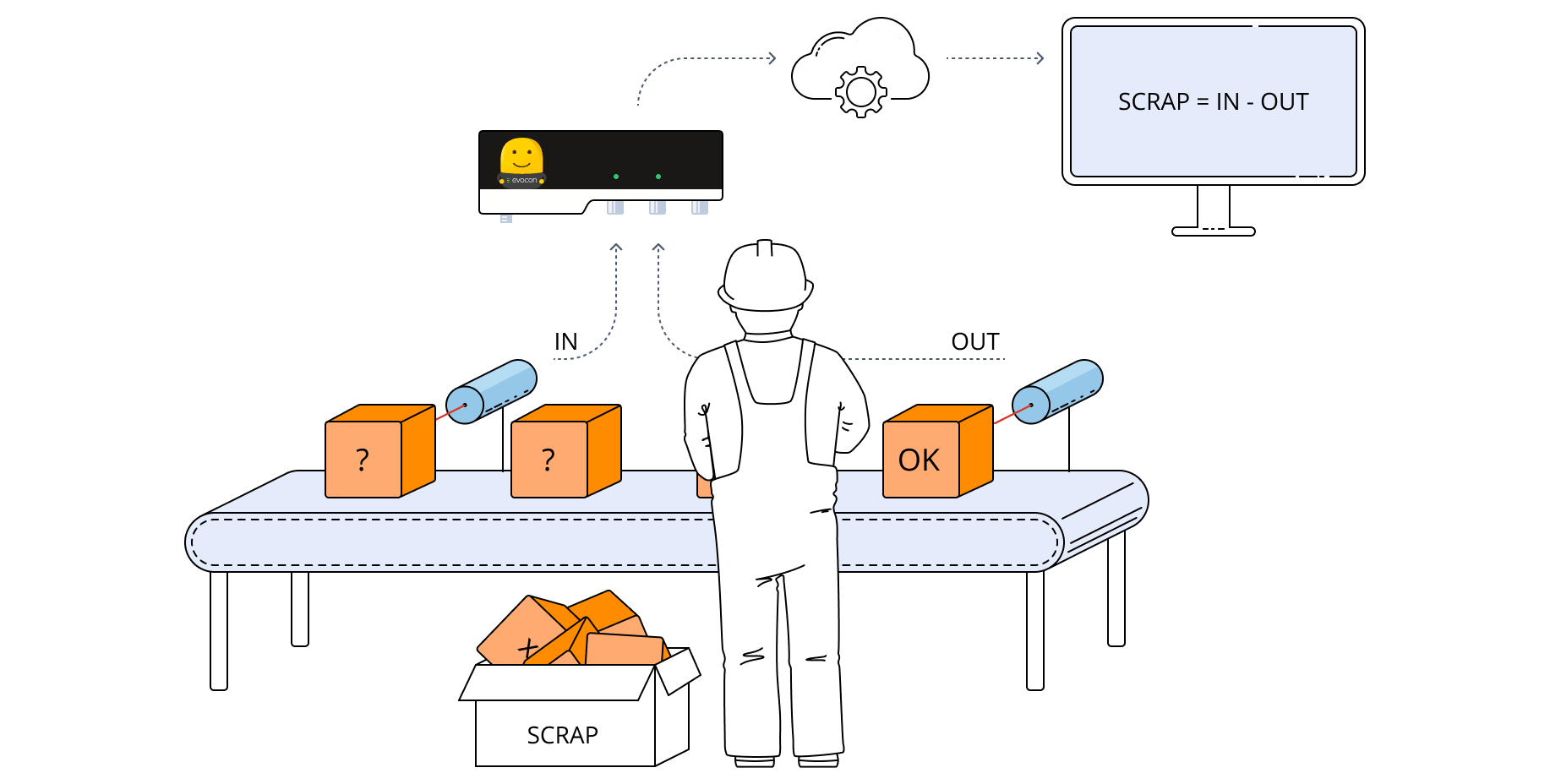

1. Monitoring input and output with sensors, then calculating the difference to get the quantity of scrap

How does it work?

This setup requires two sensors. You need to position one of them anywhere before the quality check and the other one anywhere after it. The system calculates the difference between the two to find out the number of faulty products.

When is it suitable?

This method is usually applied when a person does the quality inspection.

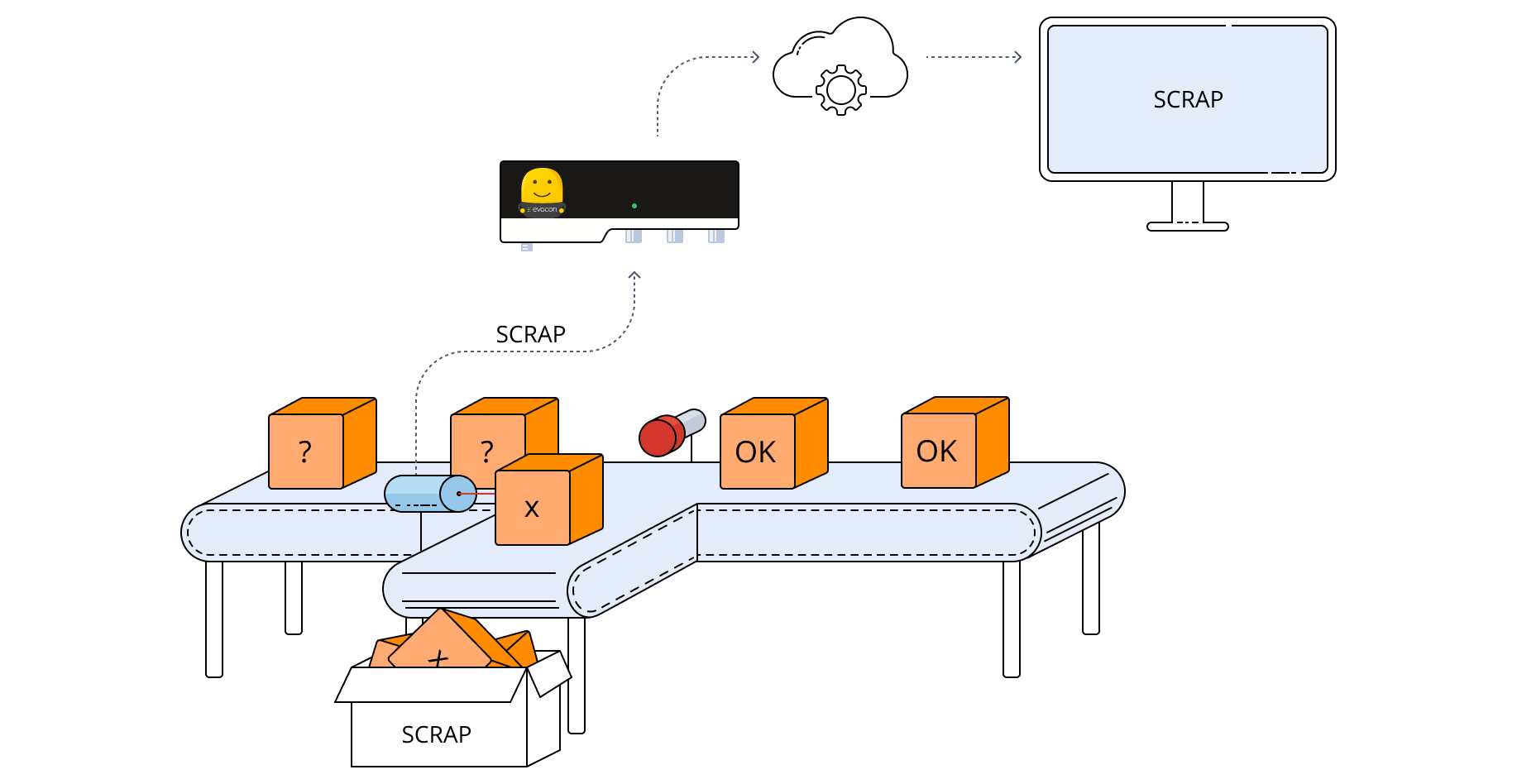

2. Monitoring production quality with sensor(s)

How does it work?

Faulty products are counted with a sensor. In case there is more than one quality checkpoint, each of them needs a sensor. The system adds up the readings from all checkpoints to get the quantity of scrap.

When is it suitable?

This option is suitable whenever it is possible to set up a sensor to detect faulty products.

Start monitoring production quality

Get the real-time data needed to improve quality and reliability. Free for 30 days.

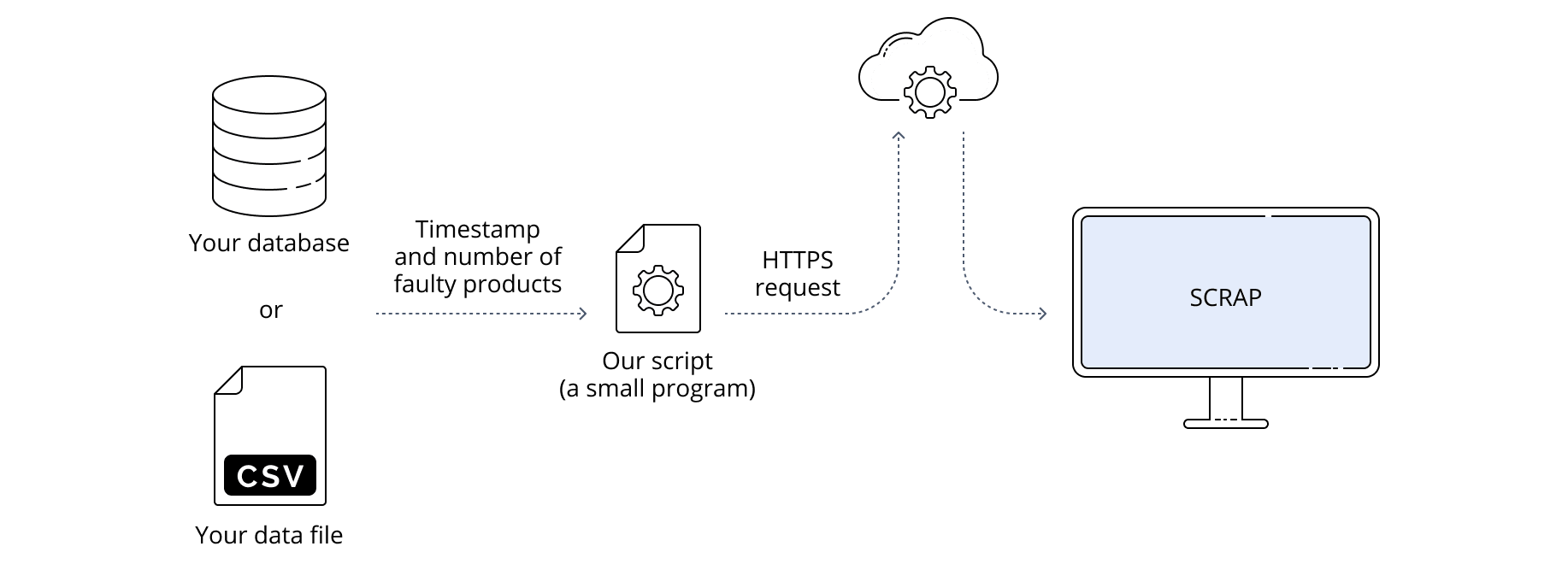

3. Using data of production quality that you are already collecting

If the machine is already registering scrap quantities in a database or cloud, we can use a script to pull them into our system.

How does it work?

We supply you with a script that takes the data and sends it to our system. If you have an IT team with programming experience, they could set up the script on their own.

Some production equipment today allows you to configure it to send data, which means that you don’t need our script.

Read more about how Evocon visualizes existing data without any additional hardware.

When is it suitable?

If your equipment already registers quality data, this method is ideal, because it does not require additional hardware to monitor quality.

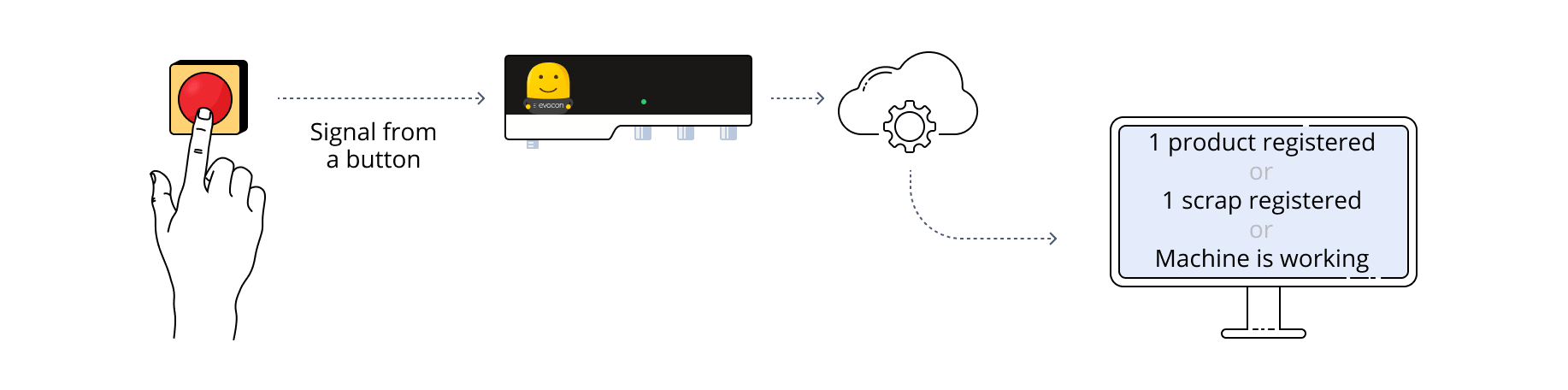

4. Registering scrap manually

There are two ways to register scrap manually:

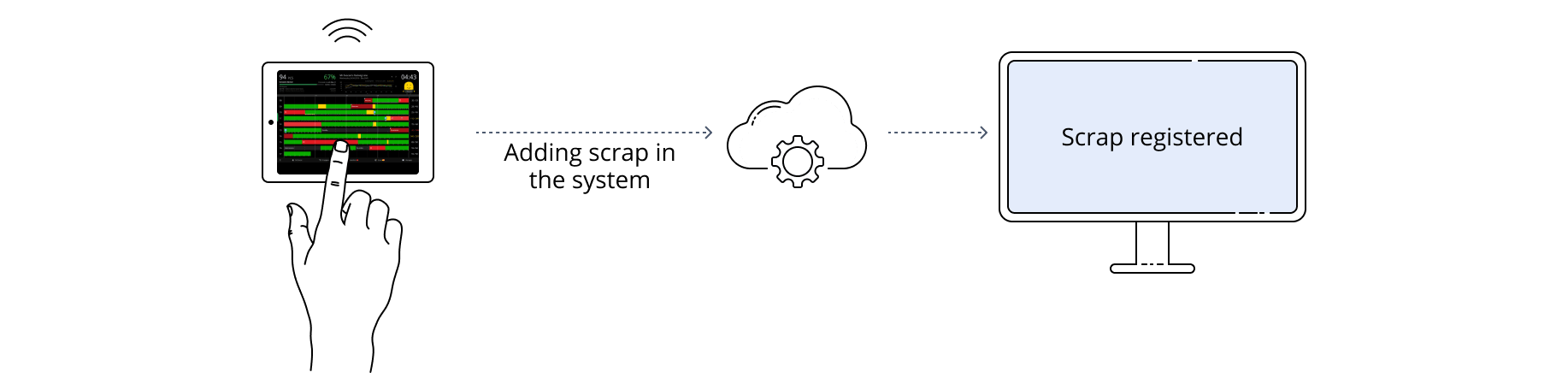

1. Operators enter the quantity of scrap into the system via the Evocon interface

2. Operators press a manual push-button after discovering a faulty product