In the face of a global shipping crisis, semiconductor shortage and lingering coronavirus pandemic, it’s more important than ever for firms to accelerate their digital transformation initiatives and remain as competitive as possible in their marketplaces.

But for many traditional manufacturers, implementing new technological solutions and tools can be daunting. The investment needed at the start and skill sets required going forward often mean that such projects cannot be completed without serious consideration and calculation.

There is one way, however, that manufacturers can realize significant benefits through digitization and that’s by measuring, tracking, and improving their OEE.

What Is OEE?

Enter a manufacturing production line or shop floor and you’ll likely hear the term ‘OEE’. But what is OEE and why do so many manufacturers measure it?

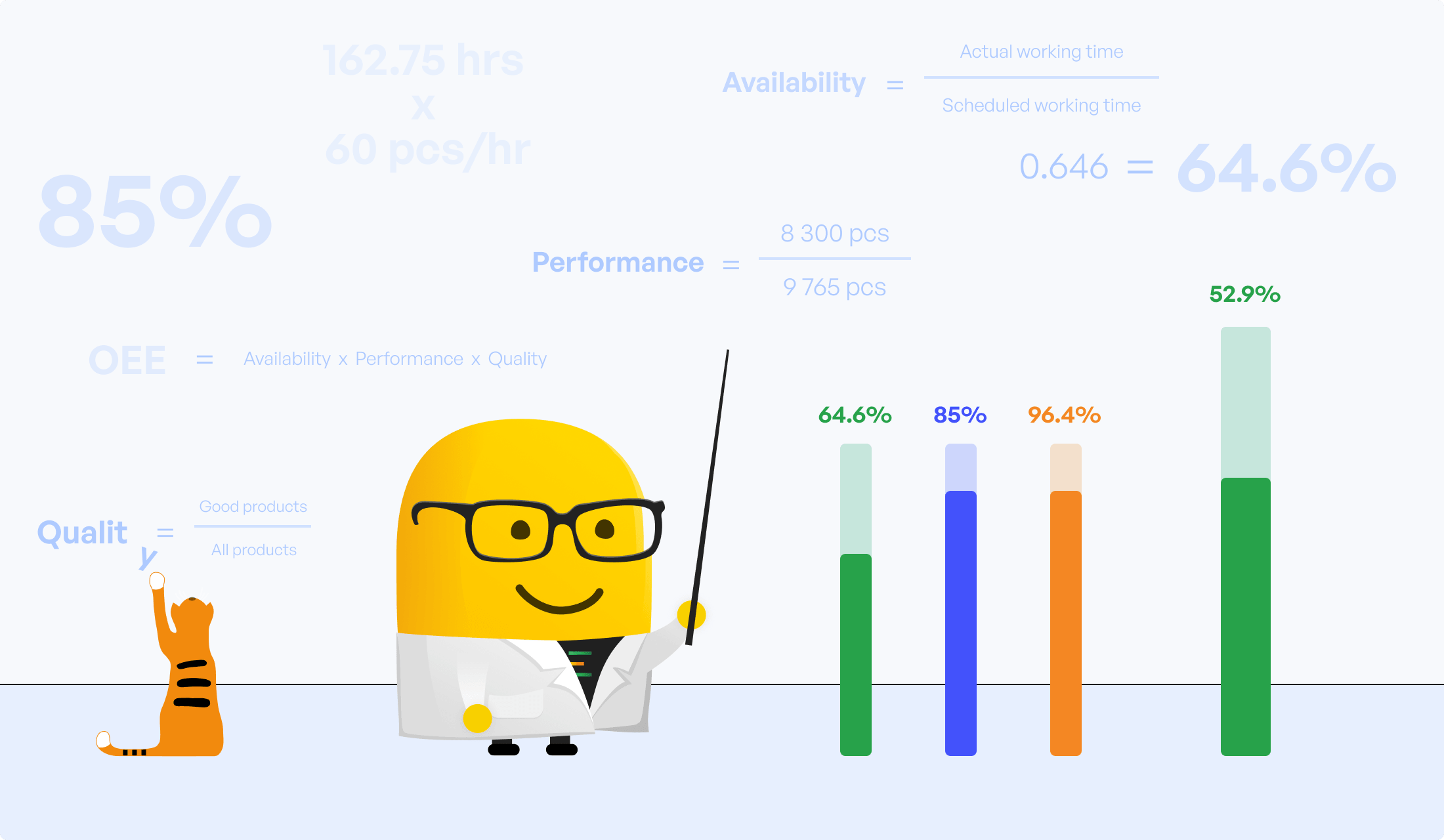

OEE is an acronym for Overall Equipment Effectiveness. It shows the percentage of manufacturing time that is truly productive and is considered the gold standard KPI for measuring manufacturing productivity. In other words, OEE is a measure of how close a firm is to achieving production perfection.

To achieve an OEE score of 100% a manufacturer would have to make only perfect parts in terms of quality, in as fast a time as possible and with zero downtime i.e. 100% quality, 100% performance and 100% availability.

For manufacturers today, measuring OEE has become best practice and doing so affords valuable insights into a firm’s manufacturing process.

Why Is Measuring OEE Important?

OEE is widely considered the number one metric for identifying aspects of the production process that are underperforming. This enables firms to benchmark their progress with a view to improving the productivity of their manufacturing equipment going forward.

While manufacturers can obtain a loose sense of how good (or bad) their OEE is by asking the production manager to keep track, such an approach is littered with potential areas for inaccuracy.

For example, let’s take downtime. With a manual setup, production operators are usually tasked with keeping track of it by recording all instances as they occur. However, the operator may neglect to record every instance of downtime, especially those that only last for less than a few minutes and do not require maintenance input. After all, the operator’s main focus is on ensuring production actually happens. But the reality is all these short stoppages add up and can have a significant impact on a line’s overall OEE.

Obtain a true picture of what’s happening on the shop floor

By not measuring every instance of downtime, manufacturing firms will never truly know how efficient their operations are. They could be losing hundreds of hours of production time each year due to minor stoppages. What’s worse, these stoppages might be being caused by a very simple issue which, once resolved, could dramatically boost productivity.

So while business leaders can ask questions of their production managers to get a sense of the shop floor OEE, they will never really obtain a true picture of what’s happening. And with no clear view of the current situation, the manufacturer cannot set a benchmark on which to improve upon.

Learn more: What Is OEE and How Does It Work?

An Intuitive, Effortless, Automatic Approach to OEE Monitoring

So what options do manufacturers have for moving away from manual processes and taking their OEE game to the next level?

Fortunately, there are advanced OEE monitoring solutions that automatically capture data, enabling manufacturers to monitor production in real-time via intuitive dashboards. Such solutions eliminate the need for manual OEE tracking, solving the following issues in the process:

- Under-reporting of production downtime, breakdowns, or smaller issues due to them lasting only a short time and perhaps being deemed irrelevant.

- No more time-consuming, potentially inaccurate manual data collection, which allows production managers to focus on the line and value-add tasks.

- Inability to monitor, visualize and react in real time to production issues.

With an OEE monitoring solution, manufacturers can automatically, intuitively, and effortlessly monitor the OEE of their production lines. As well as allowing the manufacturer to verify whether its continuous improvement efforts are having a positive impact, OEE monitoring solutions also afford a number of financial and cultural benefits.

OEE Monitoring Solution

Monitor production in real-time and obtain a true picture of what’s happening on your shop floor. Free for 30 days.

The Financial Benefits of OEE Monitoring Solutions

While OEE is often seen as a shop floor manufacturing metric, it should also be used as a financial KPI for executives too.

The most effective and simplest method for linking OEE to financial benefits is to consider the three aspects OEE monitors (availability, performance, and quality) and assign each a monetary equivalent.

- The monthly cost of downtime (availability) can be calculated by multiplying the number of downtime hours by the hourly cost of downtime, which would include employee time, fixed machines costs, etc.

- The cost of production under-performance can be realized by calculating the costs associated with running a machine or line longer to make up the deficit.

- The cost of below-standards production (quality) can be calculated by multiplying the number of rejected products by the cost of each. However, this does not reveal the true impact as it does not include the rework cost.

Using these simple calculations, manufacturers can gain at least a sense of the financial impact of production inefficiencies.

Once known, any OEE improvement strategies that focus on boosting quality, performance and availability, can then be measured in financial terms, highlighting just how much inefficient production lines can impact a firm’s bottom line.

Using OEE to drive business decisions

The true value of production monitoring is unlocked when different streams of data are combined — a practice at the core of manufacturing analytics. OEE is a powerful KPI capable of driving business decisions. For example, a company might be facing a surge in demand that it cannot currently fulfill. The knee-jerk reaction is usually to invest in additional capacity in the form of new equipment. But by having a clear understanding of the production process, including issues and efficiency figures, management can look to maximize their existing asset utilization in the first instance, instead of making a capital expenditure in new equipment.

Moreover, by having accurate, timely information regarding cycle times, manufacturers can take advantage of more intuitive resource planning strategies and benefit from greater resource utilization as a result. This allows for not only potentially larger profit margins but also enables manufacturers to adopt more competitive pricing, differentiating themselves in their marketplace.

With OEE directly linked to financial outcomes, firms can prioritize targeting the most inefficient areas of their production lines and literally put money back on the balance sheet.

Unsure of How Much Impact OEE Improvements Can Have?

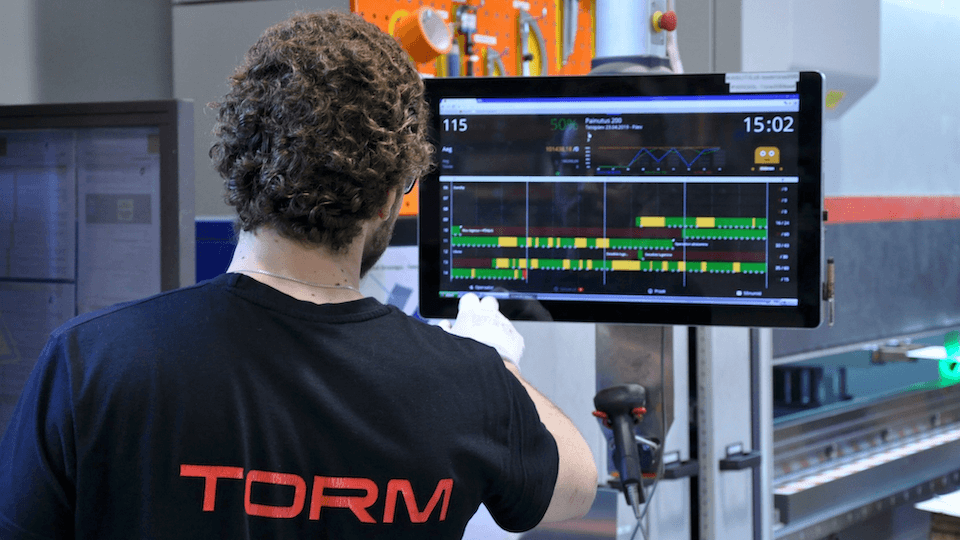

Estonian manufacturer Torm Metall had a production line machine that spent the majority of its time sitting idle, causing a worrisome drag on productivity. In fact, the machine was only operating at 35% capacity.

When questions were asked about the reason for the machine’s under-performance, nobody at the company really knew the answer. That’s because Torm was not utilizing real time OEE monitoring.

After implementing Evocon’s OEE solution, Torm could now automatically capture production line data, track machine downtime and see in real time the state of its production process at any given time.

With this information now available, Torm could identify the root cause of the problem machine’s under-performance and implement steps to resolve it. As a result of making a few small changes, the machine quickly went from operating at 35% capacity to operating at 70% capacity, effectively doubling its output.

This remarkable transformation all came from implementing a simple to install and cost effective OEE monitoring solution.

Learn more: TORM Turns to Production Digitalization to Stay Competitive

The Cultural Benefits of OEE Monitoring Solutions

In manufacturing, cultural disconnects between the C-suite and the shop floor are not uncommon. As a result, communication between the two entities can sometimes be lacking, especially when it comes to the efficiency of production lines.

Manually logging and feeding back OEE scores requires the production manager’s time and effort. Then there’s the associated pressure that comes with ensuring the information relayed is full and accurate.

By utilizing an OEE monitoring solution, manufacturers can relieve some of the pressure placed by OEE monitoring on their production managers. This affords these individuals more time to spend focusing on the production line and value-add tasks, rather than logging and reporting. Not only does this provide a morale boost, it also helps to bring senior management teams and shop floors closer together, simultaneously narrowing the cultural disconnect that often exists between the two.

Many companies display their OEE in real time on large screens located in the production area. These visual displays allow production workers and managers to see exactly how a line is performing at any point in time. This reality empowers every shop floor worker with the information they often wish they had.

Drive productivity and attract talent

Manufacturers are even taking this real-time OEE displaying further by using it to add a little competition between production teams. This kind of OEE gamification can compel production teams to strive to be the best — a little friendly competition — boosting production efficiency and effectiveness across lines in the process, without jeopardizing the quality.

Finally, by implementing OEE monitoring solutions, manufacturers emphasize their commitment to embracing new technologies. This is an important factor for attracting the best new talent. Individuals today, particularly those from younger generations, want to take advantage of the latest solutions. That’s why they will often gravitate towards firms that are seen to have their fingers on the digital pulse.

How Different Areas of a Business Can Use OEE Information

OEE monitoring solutions do not just provide valuable insights for production teams. The information they capture and visualize can also be leveraged by other departments within the manufacturing organization.

Take the sales department as an example. The team there could have received a request from a customer to produce a small run of products. A situation like this would typically involve the sales team liaising with production to see what the state of play is before committing to the order.

With an OEE monitoring solution in place, the sales team can immediately see for itself all the useful production metrics needed to make a decision on the potential order. Furthermore, as production information is captured and displayed in real time, sales teams can also keep customers up to date on the status of any orders they’ve placed. Being able to relay this information back to a customer at the first point of contact improves the overall customer experience.

Real-time OEE monitoring allows for more intuitive root cause analysis

Likewise, maintenance teams can also glean valuable insights from OEE monitoring solutions. For example, it might be the case that a certain line has a habit of going down on a particular day or at a specific time — not unlike Torm’s situation. With this information, maintenance teams can ensure there is always a technician available at the time when they are needed the most.

This can be taken a step further too. Because OEE monitoring solutions capture and visualize information in real time, production and maintenance teams can be alerted to line issues as they happen. This enables production managers and maintenance teams to investigate the slowdown in real time — which is a key element to being able to ascertain the root cause.

The bottom line is knowing a production line experienced a slowdown at 11am the previous day isn’t that useful. Investigate it as it’s happening though and there’s a stronger chance of the issue being resolved permanently.

Why Implementing an OEE Monitoring Solution Doesn’t Need to Be Difficult or Cost Prohibitive

Most manufacturers run at least some legacy machinery or equipment. As a result, they often believe they can’t take advantage of OEE monitoring solutions because of incompatibility issues.

The reality, though, is that many best-in-class OEE monitoring solutions are tailored to be compatible with older production line equipment. In fact, the best OEE monitoring solutions actually allow manufacturers to install a simple piece of hardware and then glean the valuable insights they require from a cloud-based system. This makes such solutions literally plug ‘n’ play.

In addition, because such solutions are cloud-based and do not require manufacturers to invest capital in new IT infrastructures, such as servers and networking equipment, the costs are kept to a minimum.

Capital expenditure expectations are often misconceived

This was one of the main drivers behind Mexican IT services firm INTEGSA offering Evocon OEE monitoring to its manufacturing clients.

While many Mexican manufacturers understand the importance of tracking OEE, most dismiss implementing advanced OEE monitoring solutions because of a misconceived perception about the associated capital expenditure costs.

Sergio Lewis, Digital Manufacturing Manager at INTEGSA, was surprised at just how easy Evocon was to implement and use. He says the maintenance team installed the hardware element in a matter of hours. Intuitive dashboards, widgets, and reports soon followed — all aspects that would normally require a developer.

Evocon’s visual nature also meant that there were few challenges when training shop floor workers how to use it.

Here you save on training, since Evocon is easy to use, and if the company feels the need to have training sessions, we can easily go to them and organize the training locally.

Sergio Lewis, Digital Manufacturing Manager at INTEGSA, Mexico.

Learn more about Evocon and INTEGSA’s partnership in this case study.

The benefits to manufacturers of implementing a bespoke OEE monitoring solution are clear. And with solutions like Evocon’s simplicity and affordability, there really are few barriers to implementation.