-

Automated quality monitoring

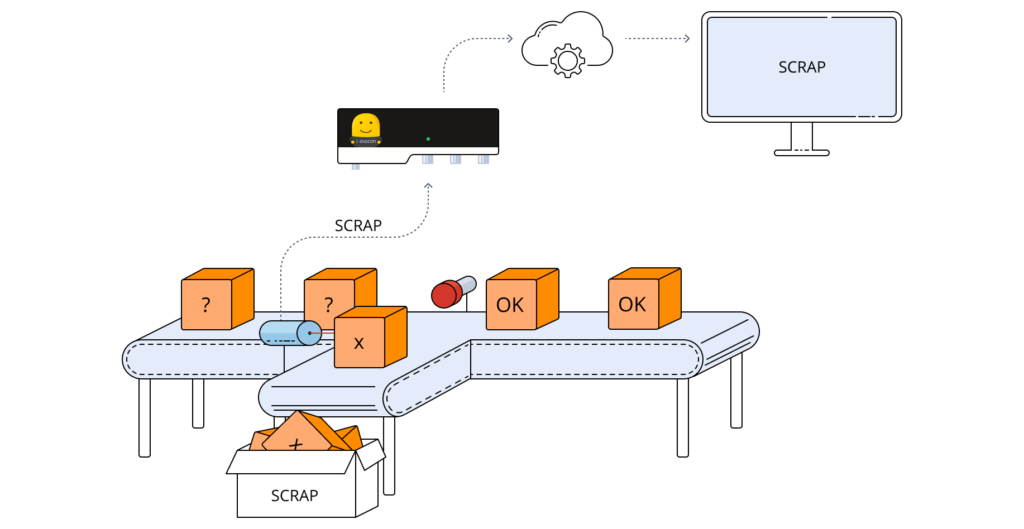

Evocon provides automated quality tracking capabilities through the continuous monitoring of production inputs and outputs, real-time detection of defective products, and the ability for manual data entry as required. Early identification of quality issues allows manufacturers to minimize waste, streamline processes, and enhance OEE.

-

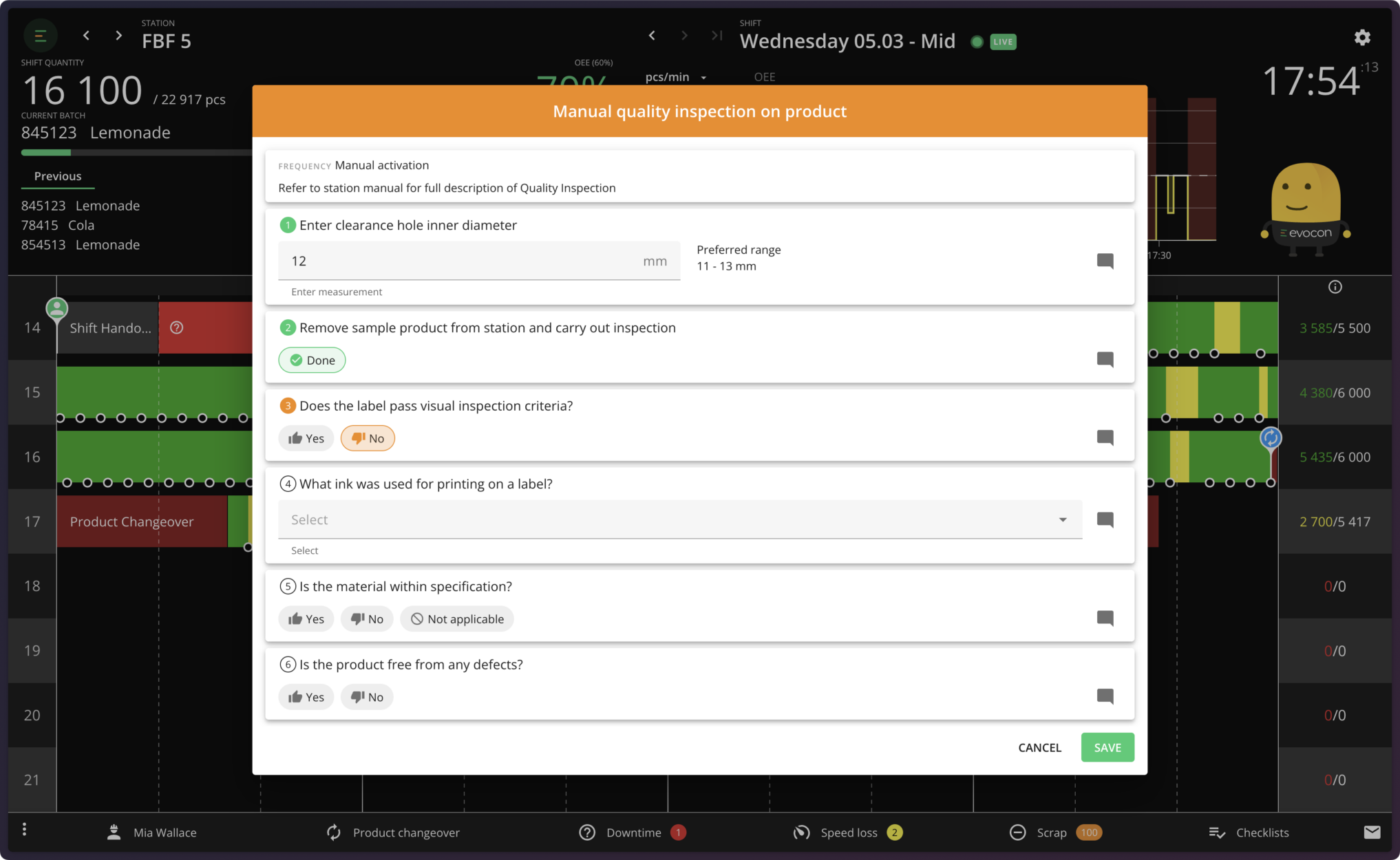

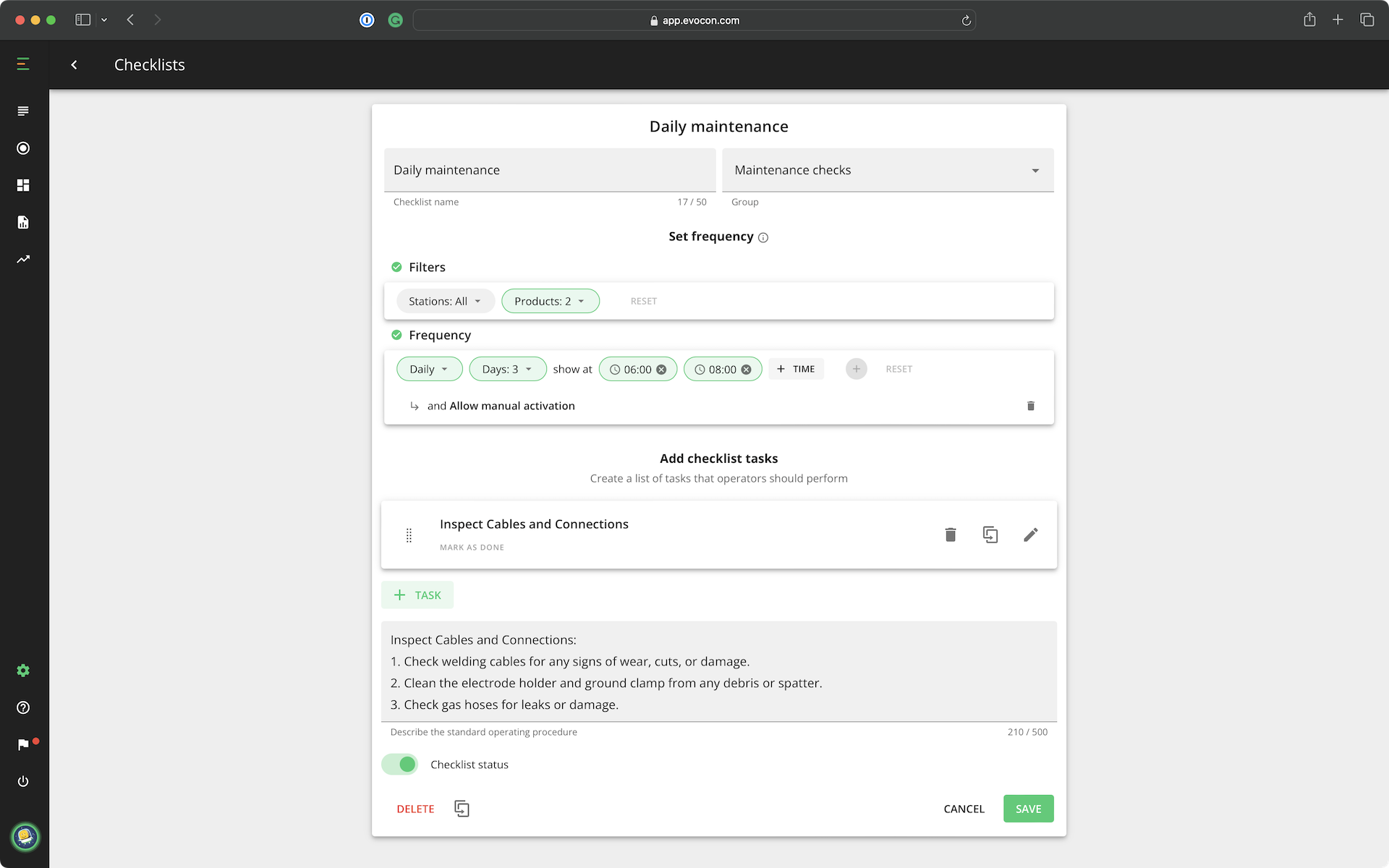

Data-based inspection criteria

With Evocon as your manufacturing quality control software, you can define inspection criteria based on exact needs and requirements. This allows you to tailor quality control to your unique production process and products. Recurring checks can be triggered based on different production events captured in Evocon.

-

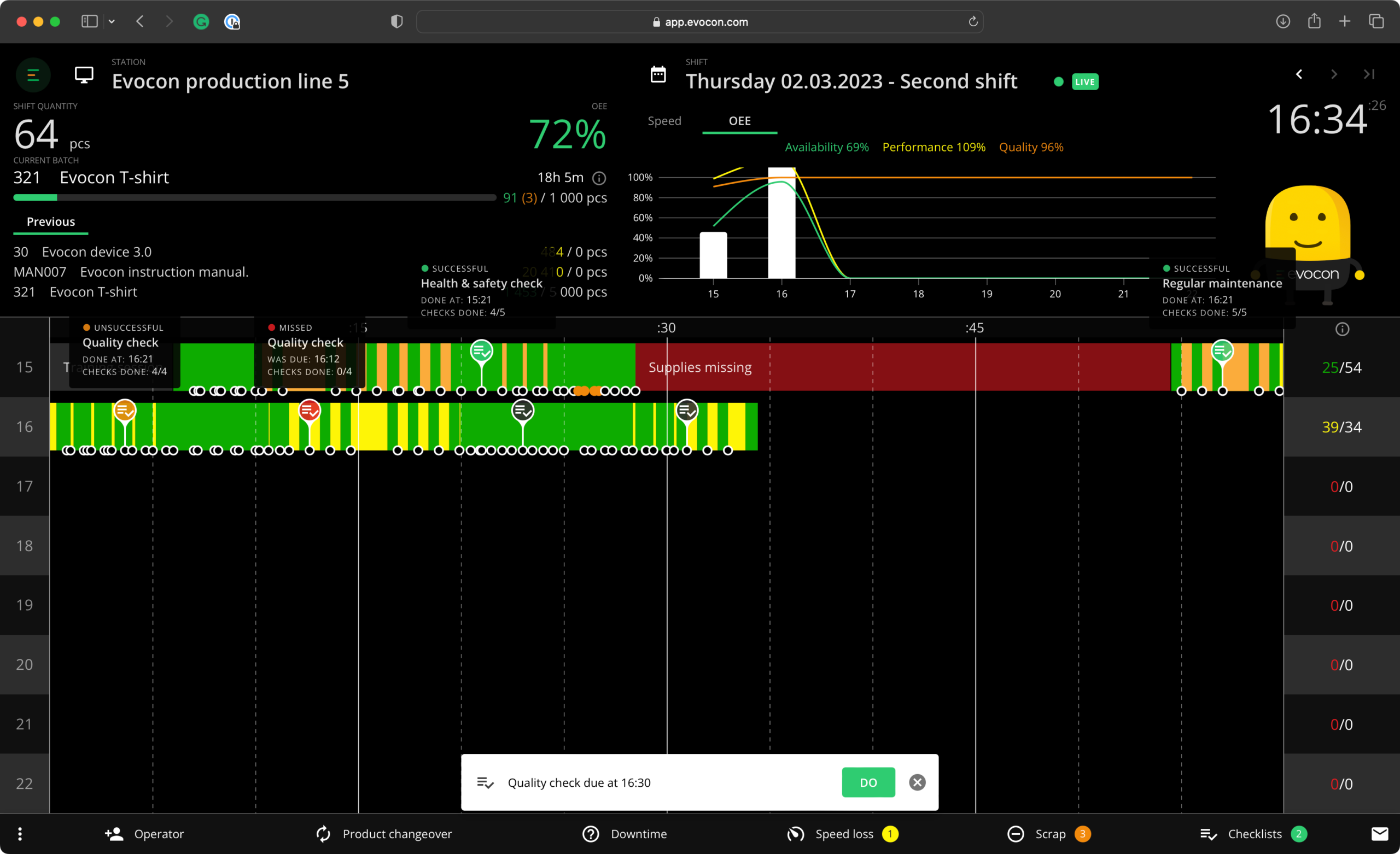

Real-time visibility and alerts

Evocon strengthens quality control by continuously monitoring the production process and automatically triggering quality checks when they matter most. Results are displayed clearly on a live production timeline, with instant alerts pinpointing when things go wrong. This lets your team react to issues fast, fix them before they snowball, and keep everyone in the loop.

-

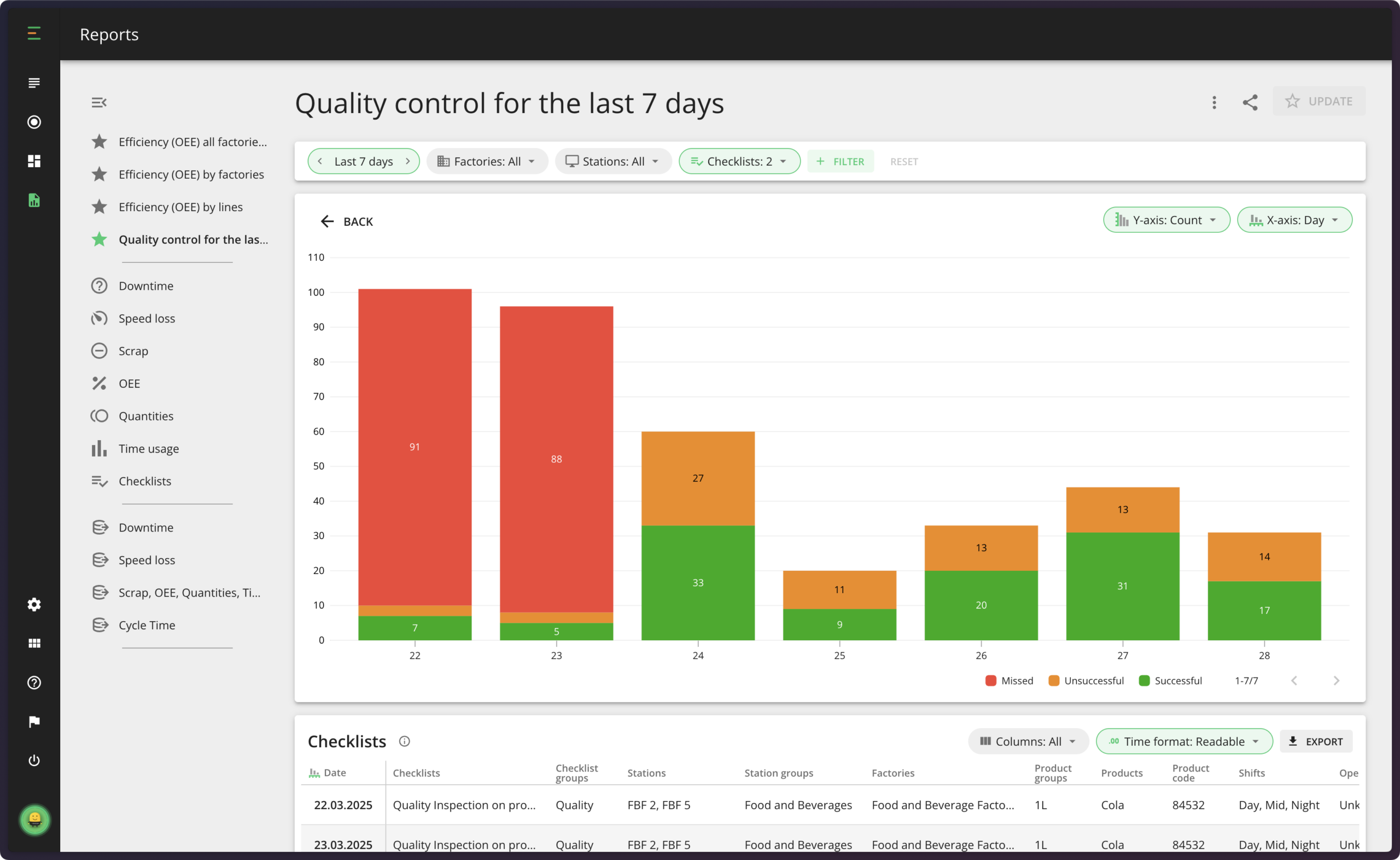

Quality control analytics

Evocon’s manufacturing quality control software delivers analytics to pinpoint process areas needing adjustment. It identifies patterns across stations, products, and shifts, enabling targeted improvements. Enhance efficiency, reduce defects, and optimize production with real-time insights and data-driven decisions.

Setting up Evocon is as easy as 1-2-3

Install

The sensor is placed to detect products on a production line or machine and connected to Evocon's IIoT device.

Connect

The device is connected to the internet which sends collected data to Evocon's OEE software for analysis.

Visualize

Collected data is displayed on the shop floor where operators can use it to defeat inefficiency.

Benefits of Evocon

Implementing Evocon enables manufacturers to automate quality assurance processes, reduce manual errors, and ensure compliance with industry standards. With real-time data and precise scrap tracking, companies can proactively identify defects, minimize waste, and enhance product reliability, leading to greater efficiency.

"Scrap is not just product lost, it’s also valuable time lost on the line. At CHALA we promise the best quality for our customers – Checklists makes that possible."

-

Choose a modern way to do quality control

Discover how Evocon’s manufacturing quality control software can transform your quality assurance processes. Request a free trial today and take the first step toward better product quality.