Before implementing Evocon, common thinking at Yara Operations was that an organization should be mature on their lean journey before implementing an OEE software or production monitoring solution.

Yara Operations was not mature, but they challenged the convention. They didn’t wait for that perfect day in some distant future. Instead, they started their digital transformation process with small steps, which turned out to be a success story.

Driving Digital Transformation Globally

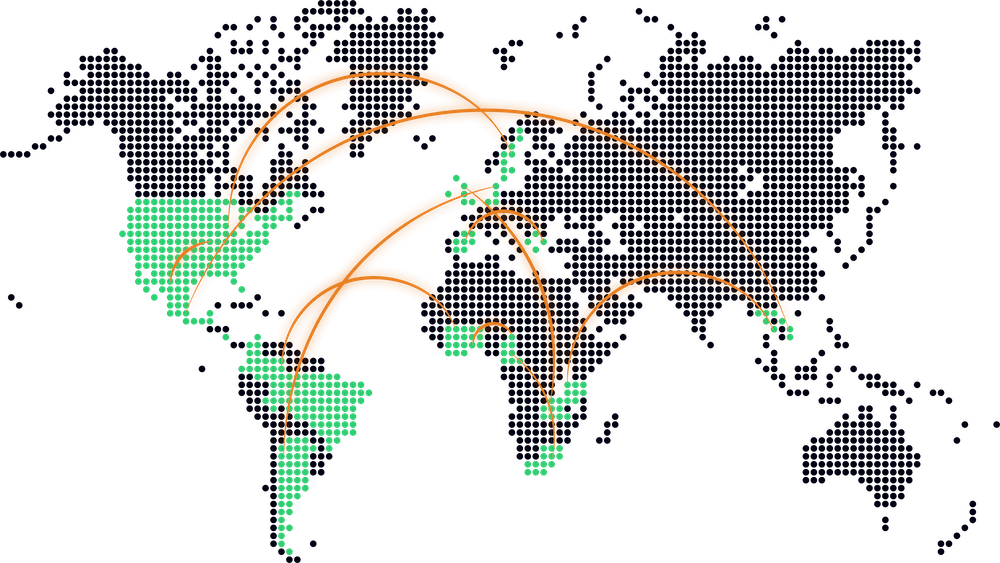

To better understand the scope of the digital transformation that Yara Operations team was looking to undertake, it is essential to understand the company and how truly global their operations are.

For over a century, Yara International has experienced continued growth. Founded in Oslo, Norway, in 1905, the company has earned the reputation as the world’s leading fertilizer company. Today, Yara International operates in over 60 countries and employs 17,000 people.

Yara’s Sales and Marketing division (YSM) sells the products in the markets, but also operates a truly global supply chain with fertilizer blending, bagging, and liquid terminals. YSM spans 5 continents and operates in 22 countries. This was the scope of the digital transformation initiative that the management team at YSM Operations was looking at.

As is common for an operation of its size, Yara had adopted lean principles to remain competitive. A part of its lean program was the implementation of OEE. Despite understanding the importance of OEE, the company struggled to roll out the program in its fertilizer terminals.

At this point, YSM Operations management approached Evocon with a challenge.

The Challenge: Manual Collection of OEE Data

Importance of OEE and Digital Transformation

The primary driver that lead YSM to Evocon was a desire to reap the potential benefits of implementing Overall Equipment Effectiveness (OEE). It is one of the fundamental concepts in lean manufacturing and is a key performance driver for any production plant. The concept of OEE, applied using new technologies, like data automation and visualization, is also a key digital transformation driver in manufacturing.

Correct use of OEE allows us to understand the true potential of a production process. Moreover, it enables us to systematically evaluate production losses and ultimately eliminate the root cause at their core in an effort to maximize the value chain.

Problems Collecting OEE Data Manually

Yara’s Production division which runs large chemical plants, was using a production loss accounting system too heavy for the needs of YSM fertilizer terminals. Hence, before implementing Evocon, YSM collected OEE data using pen and paper or Excel. This limited the extent of OEE’s benefits that they could have realized.

When OEE and production performance are tracked manually, be it a paper or computer-based system, we tend to see the same kind of issues. This was also true for YSM, where they observed the following.

- Inconsistent. The inconsistency in collecting data, both people and process, left descriptions of production losses and stops in a state of subjectivity. Thus, they did not have a comprehensive understanding of production downtime.

- Incomplete. If the operators on the line were too busy due to equipment failure or employee absence, the first responsibility that was dropped was collecting and entering data.

- Inaccurate. Reliance on humans for manual data collection made the data prone to error and open to argument. When production performance was favorable, it was correct. When the performance was poor, the data was “wrong”.

- Inefficient. Tedious, non-value added work assigned to highly skilled and well-paid operators.

- Ineffective. By the time supervisors received the production reports, they could be looking 2-4 days in the past. They needed reporting to be as close to real-time as possible. This allowed discussions to occur while events were fresh in employees’ minds.

Learn more: Manual vs. automated data collection in manufacturing

Automate Your Production Data Collection

Enhance data accuracy and reliability to discover the true potential of your factory. Free for 30 days.

5 Requirements for Digital Transformation

YSM Operations management team had an evolving vision for what they required from an OEE software to start the digital transformation process, and the team at Evocon helped to bring these requirements to life.

1. Facilitate lean Implementation

A top requirement for YSM was to use OEE as a vehicle to assist its global lean implementation. A staggering undertaking, the plan aimed at standardizing the use of OEE in all their 50 blending and bagging terminals in 22 countries on 5 continents.

2. Simplify the recording of production losses

The next requirement was for the solution to simplify the process of recording production losses. They needed operators to find the process both easy and intuitive.

3. Visualize OEE data in real-time

When manually tracking OEE, there is an inherent delay between real-time events and reporting. It is far too long and a significant shortcoming of manual collection. The moment to make a difference and correct the situation has passed.

This is why they required real-time visualization of OEE and production downtime.

4. Enhance Daily Meetings with Accurate, Timely Data

Their daily production meeting was mainly a qualitative discussion of subjective opinions about performance. Now, they sought to transform daily meetings into a coaching sessions that would feature production data and insights from leadership. To be truly meaningful, insights would need to be based on timely and accurate data.

5. Leverage Scale to Reduce Cost

The final point that YSM management team requested was a lower threshold for investment in the solution. Moreover, Evocon would also reduce the time required for installation and implementation. This made the solution even more attractive to YSM.

The Solution for Digital Transformation

When evaluating different software on the market, as well as the one used by chemical production in Yara, it became obvious that Evocon’s simple OEE solution would be a good fit to start YSM’s digital transformation process.

They would install Evocon’s IIoT devices with sensors at count points along the packaging lines. With the sensors in place and counting, the Evocon devices would then transmit the production data to a secure AWS cloud database.

The simple solution worked, and it made OEE recording a semi-automatic process. Now machine operators could work directly with a list of predefined machine downtime causes in Evocon. This meant they would only need to perform a few mouse clicks or taps when a production stop occurred.

The approach and user interface of Evocon were both intuitive and appealing. Some even called it fun. But the main achievement was that operators began cultivating a sense of ownership of the process and its data.

Implementation Process of Evocon

Evocon’s Software-as-a-Service (SaaS) architecture and minimal design made the solution cost-effective. Further, it was also “IT” light, making installation fast and easy. Because all processing and computation of data took place in the secure AWS cloud, there was no need to require programs to be installed on local PCs.

While several site visits were conducted as a matter of relationship building and project steering, the implementation of Evocon was mainly performed remotely.

“The Evocon program was so intuitive that user training was successfully done remotely via webinars.”

YSM Management

In fact, Evocon’s full physical implementation process only consists of cabling the IIoT devices and sensors on the production line and establishing an internet connection. An implementation process that takes only a few hours. A key criterion when starting the digital transformation process in manufacturing.

However, there was still work to be done. YSM’s global scale of operations required some further development of the program to ease user rights management, include more languages, and to facilitate standardization of production stop reasons.

The entire process of implementing Evocon in over 135 production lines over 22 countries, took the YSM team only around 18 months.

In addition to the software updates, the program also needed to roll out globally. Most large global initiatives covering a similar number of countries and facilities could easily take more than 3 years.

First-Year Results of Digital Transformation – OEE Increased by 15%

Standardized Visibility into Production Losses

Real-time OEE monitoring dramatically improved visibility into their production losses. This new visibility continued to cascade improvements through to other functions, such as Maintenance, Customer Service, Planning, and Logistics.

YSM has now standardized the loss-monitoring process and reporting for over 135 production lines worldwide. This enabled them to accurately benchmark differences between countries, regions, and terminals. Global standardization enabled them to speak the same language across all operations. The result is an increasing awareness and expertise on a global level, as well as sharing best practices and learnings. What is more, OEE increased by 15% on average on all the production lines.

As YSM’s production data volume grew, so did its insights about other factors that influenced OEE. Of note is that areas outside production, such as material handling and supply chain, negatively affected OEE performance.

Start your OEE implementation journey

Get the visibility you need to start improving your production processes. Free for 30 days.

Improved Operator Engagement

Perhaps the most important benefit was the increasing engagement of the whole shop floor in working to reduce losses and improve OEE. Operators developed a sense of urgency and ownership of their process by connecting with the data.

Improved Equipment Availability

As operator engagement grew, so did their ability to respond in real time to issues. Today problem solving is faster, and this has led to improvements in equipment availability. Moreover, YSM continues to reduce production stops related to downtime.

Quality Performance

Quality performance improved with the implementation of OEE monitoring. In particular, their lean program that focuses on waste elimination improved significantly. Today, most of their improvement projects use analytics that uses data extracted from Evocon.

Shop Floor Communication

Communication has become efficient and synchronized across the plant thanks to Evocon. Now, the same performance is being seen from the multiple screens across the shop floor. This provided a common “pulse” for other functions besides production, such as maintenance and planning.

Simply put, YSM has seen improvements in collaboration across and between functions due to the availability of real-time productivity data.

Culture Change

One of the significant “soft benefits” YSM realized from implementing Evocon was a shift in their internal culture. Where before it was challenging to track production losses with any regularity, it has now become how production operates globally. A rather remarkable achievement considering that anyone who has taken on a large scale change in an organization will tell you, it is not for the faint of heart and is not easy to overcome the inherent resistance to change.

“Without Evocon we would not have been able to realize the step-change in our continuous improvement program.”

Aivar Künnapuu, VP Operations, Sales & Marketing, Yara International ASA.

As the quote points out, Evocon has enabled substantial improvements for the company. Due to the success of its digital transformation, YSM remains heavily involved with production monitoring.

They have even found value in holding annual boot camps in coordination with Evocon, a process they initiated to formalize a channel for feeding key learnings to Evocon based on their global use of the service. This feedback is then routed to development teams at Evocon, where the ideas are explored further for potential inclusion in future updates.

Takeaways That Challenge the Status Quo

Before implementing Evocon, there were certain thoughts regarding where an organization should be on their lean journey before implementing a data automation and production monitoring solution.

This status quo thinking was simply that an organization should have a very mature lean program, which YSM did not have at this point, before moving into an OEE software or automation solution.

This turned out not to be true in their case, as conventional wisdom predicted that the implementation of Evocon would not have experienced the success it did. That’s why it’s better to start with small steps rather than wait for the right moment of lean maturity. As YSM’s case demonstrates, it pays to challenge the status quo.