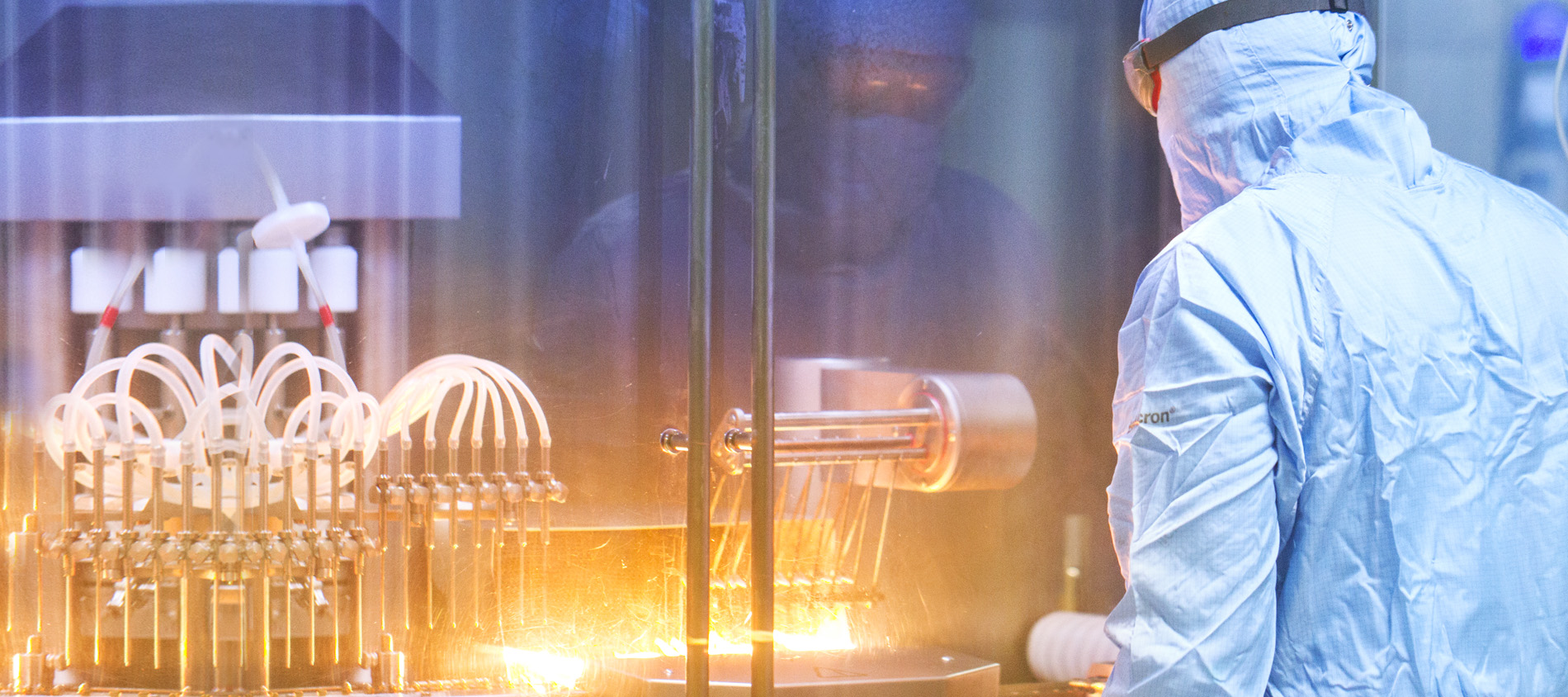

Megalabs provides a world-class standard in pharmaceutical production. Present in 20+ countries, they partner with valued brands, offering over 1,800 products to improve the health of millions across Latin America. With such a vast reach and commitment to excellence, MegaLabs recognizes the critical importance of operational efficiency to uphold their reputation for quality and ensure the timely delivery of life-saving medications. In line with this commitment, Santiago Avellino joined Megalabs as the Industry 4.0 Lead, aiming to enable everyone, from the shop floor operators to the management, to see the production data and understand how to improve efficiency.

The Challenge: Enhancing Visibility and Efficiency

In 2021, MegaLabs embarked on an ambitious transformation of its operations. Santiago Avellino, Industry 4.0 Lead at MegaLabs, was tasked with leading this initiative. One of the primary issues identified was the lack of visibility and standardized measurement of efficiency across their various plants. MegaLabs struggled with:

- Limited visibility on efficiency metrics

- Inefficient manual processes for capturing and analyzing operational data

- Disparate ERP systems complicating data consolidation

- Resistance to change due to local cultures and unionized environments

From Manual to Automated Data Collection with Evocon

MegaLabs sought a solution that was user-friendly, required minimal installation effort, and could be rapidly deployed across multiple sites. Evocon emerged as the ideal choice due to its cloud-based platform, ease of installation, and powerful yet simple user interface. The implementation covered key areas of focus including automation, control, and equipment efficiency.

Implementation Process

The journey towards implementing Evocon began with a comprehensive search for the right tool. MegaLabs prioritized cloud solutions for their flexibility and ease of deployment. After identifying several potential candidates, they initiated a trial phase to evaluate their effectiveness. Evocon stood out due to its straightforward and fast setup, as well as its robust, yet easy-to-use functionality, making it the top choice.

Santiago and his team started with a pilot project, installing Evocon on a single line to evaluate its effectiveness. This involved extensive planning, where Santiago’s team outlined the phases of implementation, from the initial signal reception to the point where clean data would be used in daily meetings.

Learn more: The Modern Manufacturer’s OEE Implementation Guide

The fast implementation and intuitive user interface of Evocon facilitated a seamless transition from manual to automated data collection. Santiago appreciated Evocon’s independence in installation, too. Installing the software on one production line wasn’t risky or disruptive, thanks to the 30-day free trial.

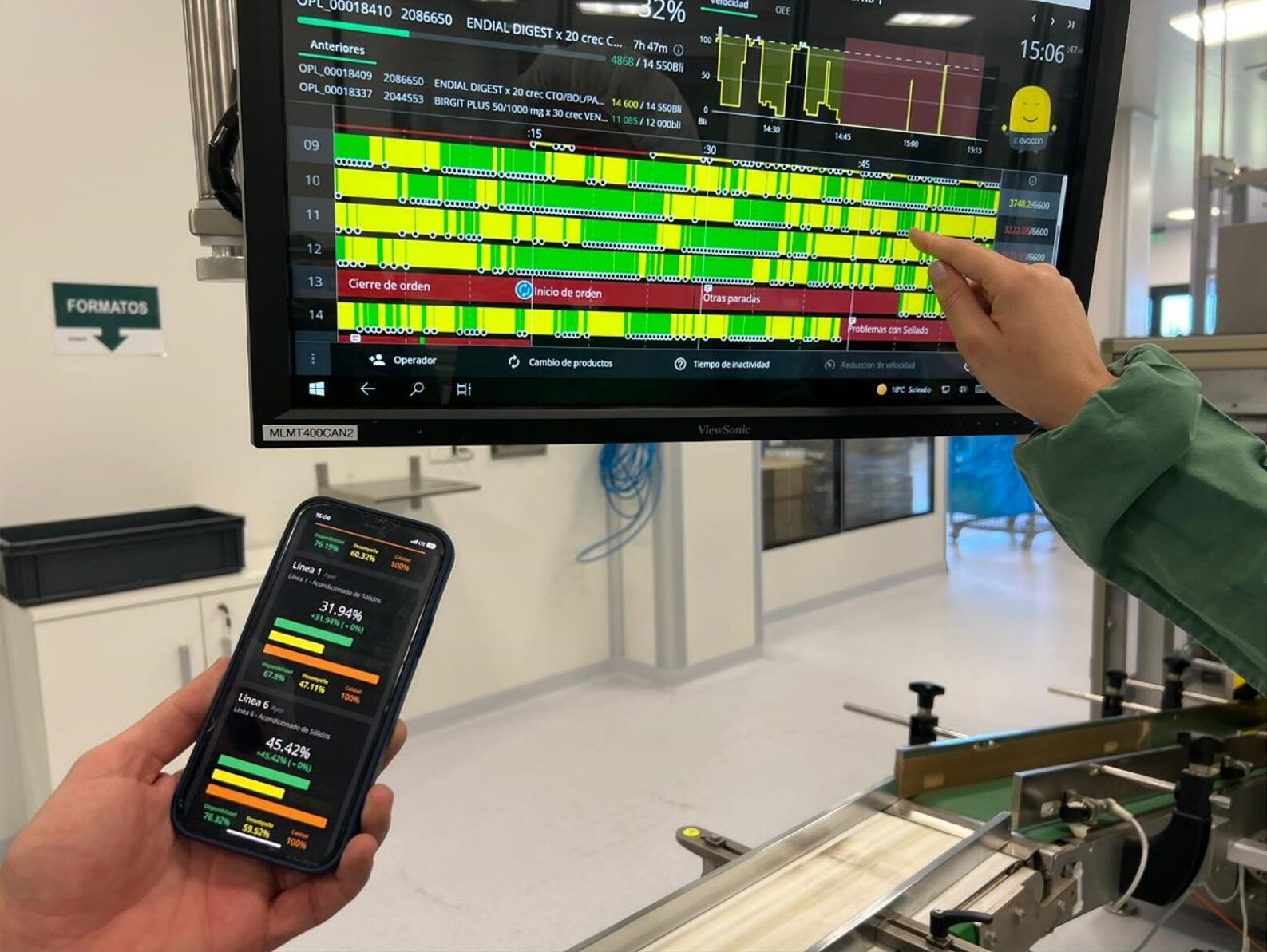

The Shift View was appreciated thanks to its visual appeal and ease of use. Evocon shed light on what was really happening on the shop floor, so decisions are no longer made from the gut, but based on real-time data.

The successful pilot led to a broader rollout across multiple plants, with a focus on standardizing practices and integrating Evocon into the existing ERP ecosystem. As Evocon is a plug-and-play and scalable system, Megalabs was able to install it in 8 countries across the Americas.

The Human Side of Digital Transformation

Change management played a crucial role in the successful implementation of Evocon. Santiago’s team implemented strategies to address resistance to change.

They introduced gamification techniques to engage employees and highlighted how the new system would simplify daily tasks by automating OEE measurements. These efforts were crucial in easing the transition and fostering a culture of acceptance and enthusiasm for the new system.

“We’re using Evocon to reduce manual work and lighten the load… We’re finding out what the tool will do for people in the offices and the people on the factory floor. It’s going to simplify their lives!”

– Santiago Avellino, Industry 4.0 Lead at MegaLabs

Evocon also made people realize how slow and tedious the old manual systems were. Today, there are no more manual logs, forms, or checklists – this saves everyone a lot of time, leading to improved productivity.

Overcoming Obstacles Along the Way

Throughout the implementation process, MegaLabs encountered several obstacles and valuable learnings.

For example, connectivity issues occasionally arose, leading to the need for improved signal diagnostics and data logging solutions to ensure consistent and accurate data capture.

Strategic planning and change management were also critical components. Santiago emphasized the importance of having a comprehensive implementation plan from the outset. This plan included not only the technical steps but also strategies for engaging and aligning all managerial levels and union representatives. By adopting agile methodologies, the team ensured continuous feedback and adaptation throughout the deployment process, significantly enhancing the chances of success.

Despite encountering challenges during the implementation, including technical hurdles and resistance to change, MegaLabs overcame these obstacles with the assistance of Evocon’s dedicated support team.

“I know Evocon is always 1 message away, and I’m really thankful for that. They’re really passionate…and give us the best support.”

– Santiago Avellino, Industry 4.0 Lead at MegaLabs

Results and Impact

- Enhanced Efficiency and Productivity:

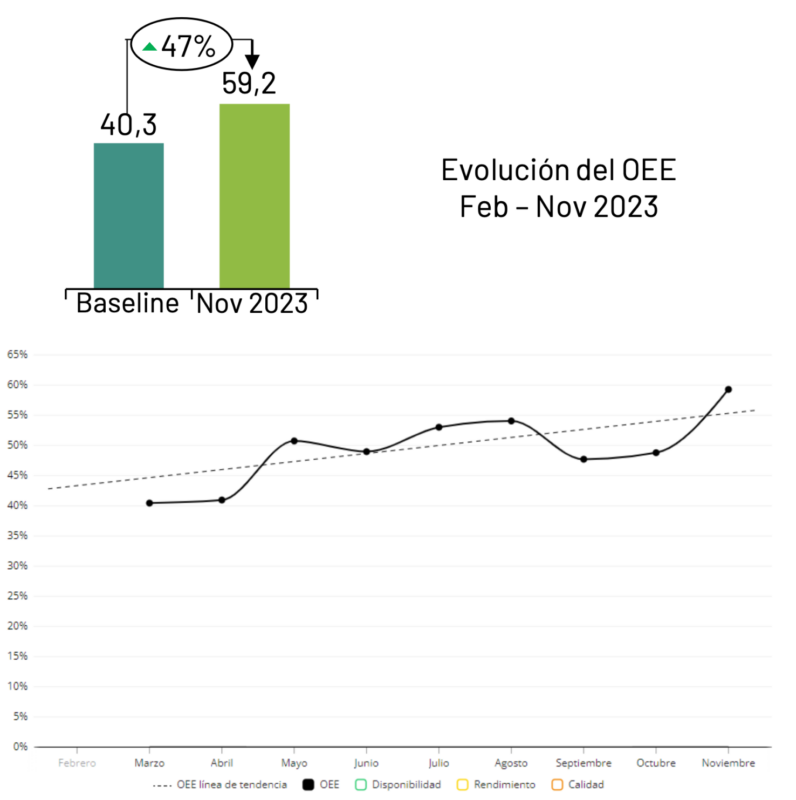

- Evocon enabled real-time visibility into KPIs such as Overall Equipment Effectiveness (OEE), highlighting inefficiencies and areas for improvement.

- In a liquid filling line for Rowe, OEE improved by 47% in 9 months, from 40,3% in February 2023 to 59,2% in November 2023.

- Evocon enabled real-time visibility into KPIs such as Overall Equipment Effectiveness (OEE), highlighting inefficiencies and areas for improvement.

- Data-Driven Decision Making:

- The adoption of Evocon facilitated a shift from gut-feeling-based decisions to data-driven strategies.

- This transition highlighted surprising insights and helped in focusing efforts on critical areas for improvement.

- Operational Standardization:

- By integrating Evocon with their ERP systems, MegaLabs streamlined their operational data into a unified space.

- Future plans include developing digital twins of production lines, and further enhancing monitoring capabilities beyond downtime and OEE.

The Ongoing Journey

MegaLabs’ successful implementation of Evocon showcases the transformative potential of data-driven solutions in the pharmaceutical industry. By enhancing visibility, standardizing operations, and fostering a culture of continuous improvement, MegaLabs has positioned itself for scalable growth and sustained operational excellence.

Santiago Avellino’s leadership and strategic approach have been instrumental in navigating the complexities of change management and technological adoption across diverse and geographically dispersed operations.