Manufacturing is often divided into two categories: discrete and process. The two are differentiated by the products they produce. Discrete manufacturing involves producing individual, countable products, whereas process manufacturing uses formulas or recipes to make products — often in bulk quantities of liquids, powders, or chemicals.

This article explores both types, their key characteristics, the technology and software required for each, the challenges of measuring OEE for each type, and includes real-world case studies where Evocon has helped both discrete and process manufacturers.

What is Discrete Manufacturing

Discrete manufacturing creates individual, countable products that you can touch, pick up, and take apart. Each finished product has its own identity and can be disassembled back into its original components.

Definition and Characteristics

In a discrete operation, you’re putting together pieces to make something complete. Picture an assembly line where workers or machines add parts individually until you have a finished product. Here’s what makes it discrete:

- Products can be taken apart and put back together

- Units often have their own serial number or identification

- Production happens in steps along a line

- You can count exactly how many products you made

- Quality checks happen on individual parts and the final product

Real-World Use Cases

You probably interact with discrete manufacturing products every day:

- Cars and trucks — assembled from thousands of individual parts

- Electronics — smartphones, laptops, and TVs built from components

- Furniture — chairs, tables, or cabinets made from separate pieces

- Appliances — washing machines, or refrigerators with distinct parts

- Machinery — industrial equipment built from multiple components

Production Flow

Discrete manufacturing typically follows this path:

- Get materials — order and receive all the parts you need

- Make components — create or machine individual pieces

- Build sub-assemblies — put smaller groups of parts together

- Final assembly — combine everything into the finished product

- Test and inspect — make sure everything works properly

- Package and ship — get products ready for customers

Subtypes

Discrete manufacturing can generally be divided into these subtypes:

- Job shop — low volume, high variety, custom (e.g., custom furniture, machine shops)

- Batch production (in discrete operations) — moderate volume, runs of items (e.g., seasonal toys)

- Repetitive manufacturing — high volume, low variety, standardized items on assembly lines (e.g., household or office appliances, some consumer electronics, such as routers, monitors, and similar items)

- Assembly line / mass production — very high volume (e.g., cars, phones, packaged foods at the final packaging stage)

One example of an Evocon client using discrete manufacturing is TMI Automotive. As a family-owned manufacturer of industry-leading automotive interior components, they create specific, individual parts and have made a business of quick response, fast-to-market, prototype-to-production, and low-volume/high-mix offerings. Read more.

What is Process Manufacturing

Process-based setups involve producing a product using a formula or recipe, combining raw ingredients to create a finished product. This product cannot be separated into individual components and has different challenges from those made in a discrete manufacturing setup, particularly with quality control and inventory management.

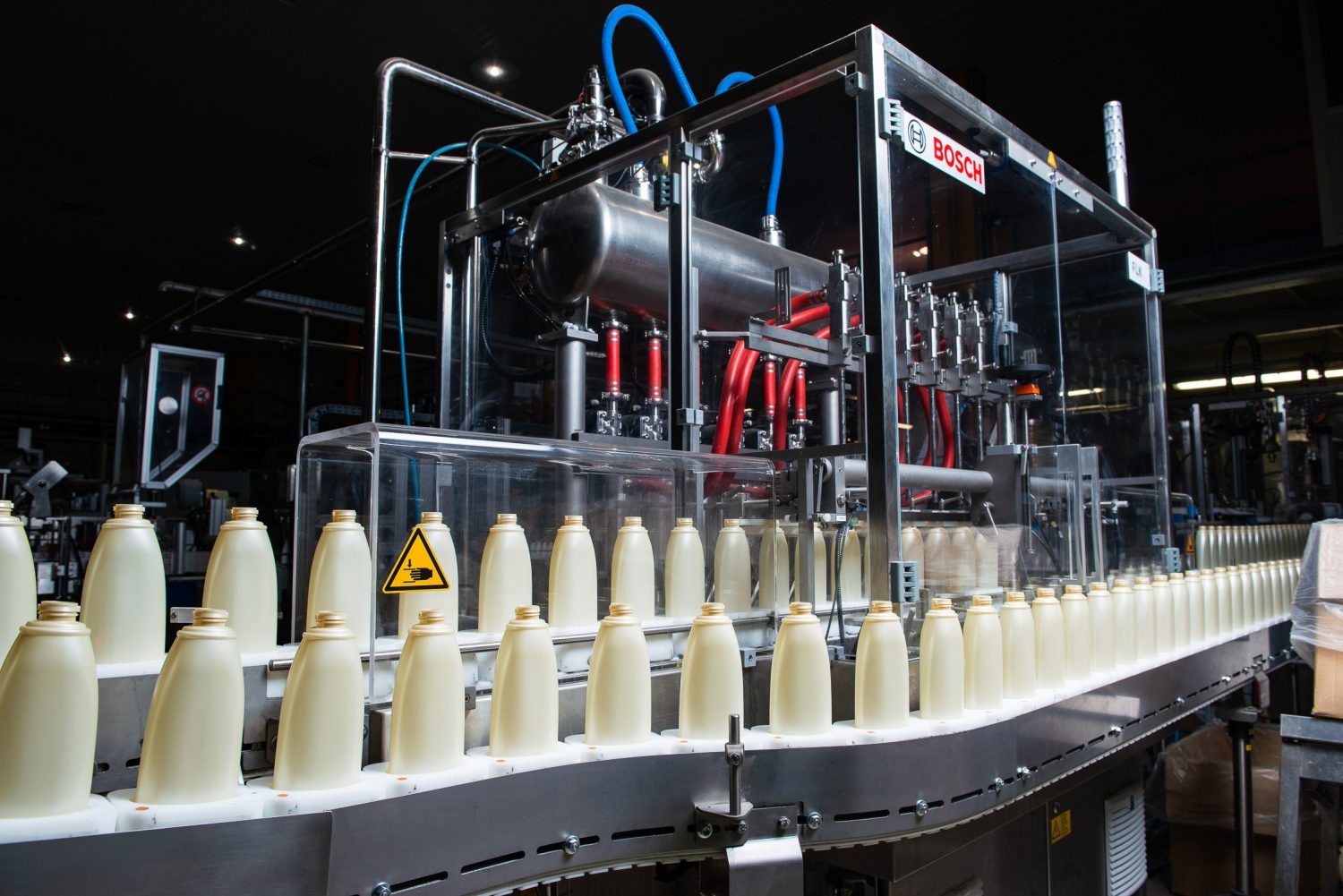

In practice, many industries use a mix of methods — for example, process manufacturing for the product itself, and discrete methods for packaging and distribution. Take liquid soap, for instance — each bottle is packaged and sold individually, but the soap itself is created in large batches. This is a good example of manufacturing with multiple methods. While the soap base is made through process manufacturing, the packaging stage (filling bottles, labeling, boxing) often uses discrete manufacturing methods.

Definition and Characteristics

Process manufacturing is about transformation, not assembly. You’re mixing, heating, cooling, or chemically changing raw materials to create something entirely new. Once it’s made, you can’t easily separate it back into the original ingredients. Key traits include:

- Products are created through chemical, biological, or physical transformation

- You can’t disassemble the final product into its original materials

- Production follows recipes or formulas, not assembly instructions

- Quality depends on process conditions (temperature, pressure, timing)

- You measure materials by weight, volume, or chemical composition

Real-World Use Cases

Process manufacturing creates products we use constantly:

- Food and drinks — soft drinks, dairy products, baked goods, and processed foods

- Chemicals — cleaning products, fertilizers, and industrial compounds

- Pharmaceuticals — medications, vitamins, and medical treatments

- Oil products — gasoline, motor oil, plastics

- Personal care — shampoo, lotion, cosmetics

Production Flow

Process manufacturing works differently from discrete:

- Recipe development — creating and testing formulations

- Material prep — measuring and preparing raw ingredients

- Processing — mixing, heating, cooling, fermenting, or chemically reacting materials

- Quality testing — checking that the product meets specifications

- Packaging — filling and sealing bulk products into consumer-ready containers

- Storage and shipping — storing and distributing to customers

Subtypes

There are different subtypes of manufacturing in process manufacturing. These can usually be split into:

- Batch production (in a process-based setup) — production in a specific number of runs (e.g., making a batch of shampoo)

- Continuous production — 24/7 non-stop production (e.g., oil refining, chemical plants)

Batch Production: Discrete, or Process Manufacturing?

You may have noticed that “batch production” appears as a subtype in both discrete and process manufacturing. The difference comes down to the nature of the product.

In discrete manufacturing, batch production means making a group of countable items before switching to another design or product. For example, producing a run of toys for Christmas and then changing the setup to make Valentine’s Day toys.

In process manufacturing, batch production means creating a specific quantity of material or formula in a controlled run. For example, producing a batch of shampoo.

One well-known company that uses process manufacturing as well as discrete manufacturing is Coca-Cola. Equatorial Coca-Cola Bottling Company (ECCBC) implemented Evocon to improve its line performance and achieve operational excellence. Beyond standard OEE monitoring, ECCBC used the ability to connect additional metrics like CO2 and Concentrate to calculate Yield performance and understand its impact on line performance. Read more.

OEE Monitoring Solution

Monitor production in real time and get a true picture of what's happening on your shop floor. Free for 30 days.

The Key Differences

Below is a snapshot of discrete and process manufacturing’s production methodologies and how they differ in inventory management, quality control, and production planning.

| Discrete Manufacturing | Process Manufacturing |

| Production Methodology Usually similar to an assembly line. Products move through distinct steps, and you can track each batch or individual item as it progresses. | Production Methodology Think continuous flow or large batches. Once you start a process, it often runs for hours or days. |

| Inventory Management You count everything. You could have 247 bolts, 156 circuit boards, and 89 finished products. Each part has a specific part number and location. | Inventory Management Everything is measured. Materials are often stored in tanks, silos, or bulk containers. |

| Quality Control Quality checks happen at multiple points — when parts arrive, during assembly, and on finished products. If something’s wrong, you can often fix it or replace the faulty component. | Quality Control Quality is all about the process — temperature, mixing time, pH levels, or pressure. If a batch goes wrong, you usually can’t fix it. You might have to start over or find a way to use the leftover product somewhere else. |

| Production Planning Planning focuses on having the right parts at the right time. You need to coordinate component deliveries, manage assembly sequences, and handle changeovers between different products. | Production Planning Planning is about recipes, batch sizes, and process timing. You must manage raw material supplies, schedule equipment cleaning between products, and optimize batch sizes for efficiency. |

Technology & Software Considerations

The technology and software needs are quite different between the two types. Discrete manufacturing needs systems that can handle complex parts lists and track individual components through assembly, while process manufacturing needs systems focused on recipes and process control.

When selecting the different technologies, hardware, and software for your company, focus on your specific needs:

| Discrete Manufacturing | Process Manufacturing |

| Software requirements – Manufacturing execution systems (MES) to manage shop floor operations – Systems to track which parts go into which products – Tools to manage complex assembly sequences | Software requirements – Process control systems for real-time monitoring – Recipe management to ensure consistent formulations – Laboratory systems to track quality testing |

| ERP requirements – Strong bill of materials (BOM) management – Good shop floor integration – Serial number and lot tracking capabilities – Support for complex routing between work centers | ERP requirements – Recipe and formula management – Batch tracking and production history – Quality management integration – Process costing capabilities |

| IIoT Sensors and Real-time Monitoring Uses sensors to track machine status, count products, and monitor quality at individual workstations | IIoT Sensors and Real-time Monitoring Uses sensors to continuously monitor temperature, pressure, flow rates, and chemical composition |

| Data Analytics Focuses on optimizing production schedules, predictive maintenance needs, and improving quality | Data Analytics Emphasizes process optimization, improving yield rates, and maintaining consistent quality |

OEE Software for Each Type

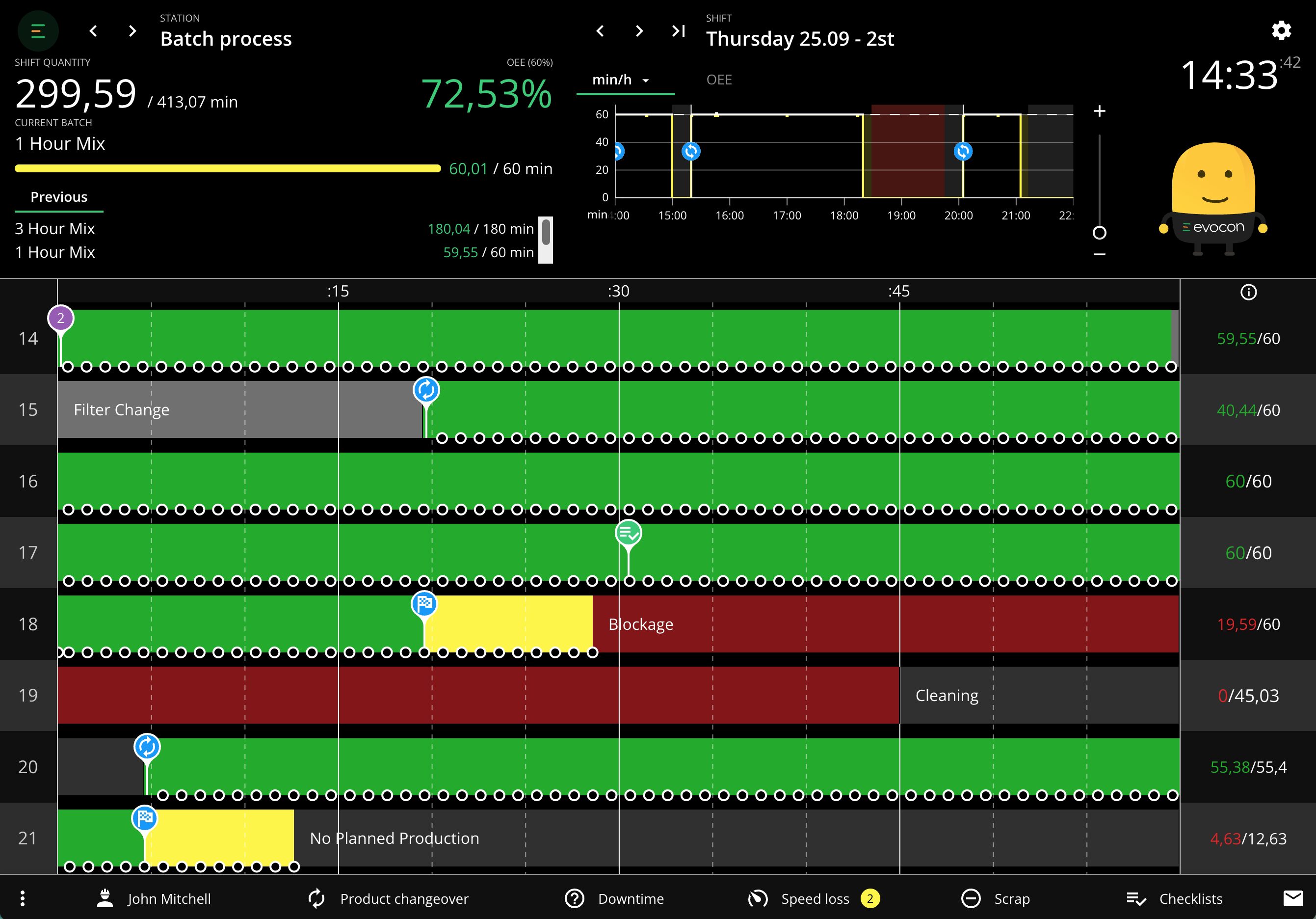

Overall Equipment Effectiveness is a lean manufacturing tool and universal best practice to monitor, evaluate, and improve the effectiveness of a production process. This could be an assembly line, packaging line, filling machine, etc. It works for both types of manufacturing, but you measure different things:

| OEE for Discrete Manufacturing | OEE for Process Manufacturing |

| Tracking availability shows how much time your equipment is actually running | Availability includes time for process startup and shutdown |

| Performance measures how fast you’re making products compared to your target | Performance measures the time the process takes compared to its planned duration |

| Quality tracks the percentage of products that meet specifications | Quality measures how well batches meet specifications |

Flexible Monitoring for Both Types

Whatever your approach, Evocon adapts to your specific setup by using two different modes — standard mode and time mode. Using standard mode, the platform tracks individual piece counts, cycle times, and machine availability in real time for discrete manufacturing operations. Operators can see exactly how many units they’ve produced, when machines stop, and what’s causing delays or quality issues.

For process manufacturing, Evocon has Time Mode, which monitors continuous operations based on duration, flow, or weight rather than piece counts. This works perfectly for mixing processes or any operation measuring success by time and process parameters rather than individual units produced.

This means that both monitoring modes use the same intuitive interface. Whether your operators are tracking parts per minute or monitoring a long chemical process, they’re using familiar screens and workflows. This consistency makes training easier and ensures everyone can access the insights they need, regardless of their production type.

Key Takeaways

Understanding the difference between discrete and process manufacturing impacts every decision you make about technology, planning, and operations.

Discrete manufacturing is about assembly and counting. You’re putting pieces together to make products that can be taken apart. Process manufacturing is about transformation and measuring. You’re mixing and changing materials to create something entirely new.

The differences show up everywhere: how you track inventory, manage quality, plan production, and choose technology. But many manufacturers do both. You might have discrete assembly operations and process-based surface treatments in the same facility.

The key is choosing flexible solutions that adapt to your reality. Whether assembling cars, making shampoo, or a mix of both, the right technology should give you visibility and control over your specific processes.

Don’t get caught up in trying to fit into one perfect category. Focus on understanding your operations, choosing the right tools, and continuously improving your processes. That’s what really drives success.