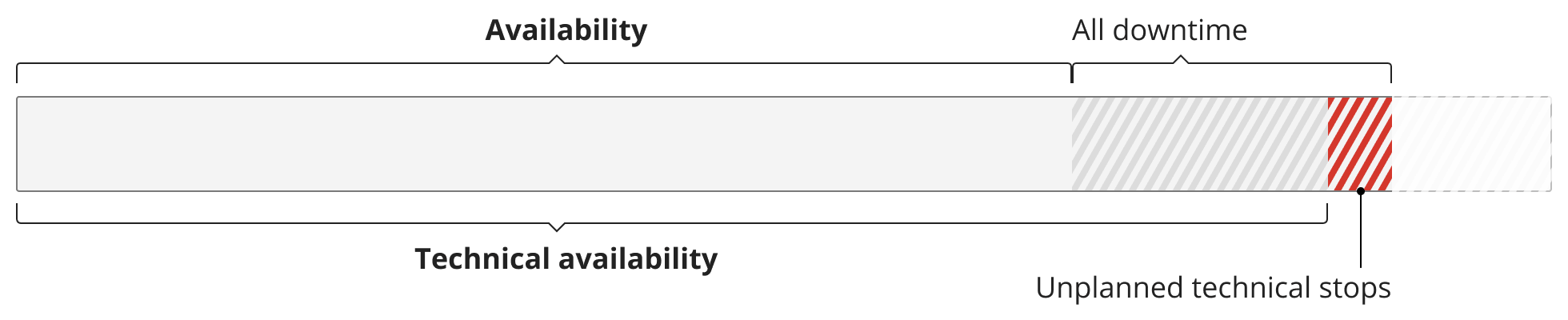

Tracking Technical Availability (TA) or sometimes also called “Maintenance Availability,” is very useful in the context of OEE (Overall Equipment Effectiveness) because it allows you to assess how well your maintenance is performing. The calculation of technical availability shows the percentage of planned production time without unexpected technical difficulties or maintenance needs.

Let’s take a closer look at both availability and technical availability to see what the difference is and how to calculate both of these critical KPIs in manufacturing.

We’ll also look at how Evocon’s OEE software automates this for more effective analysis and improvement.

What is Availability?

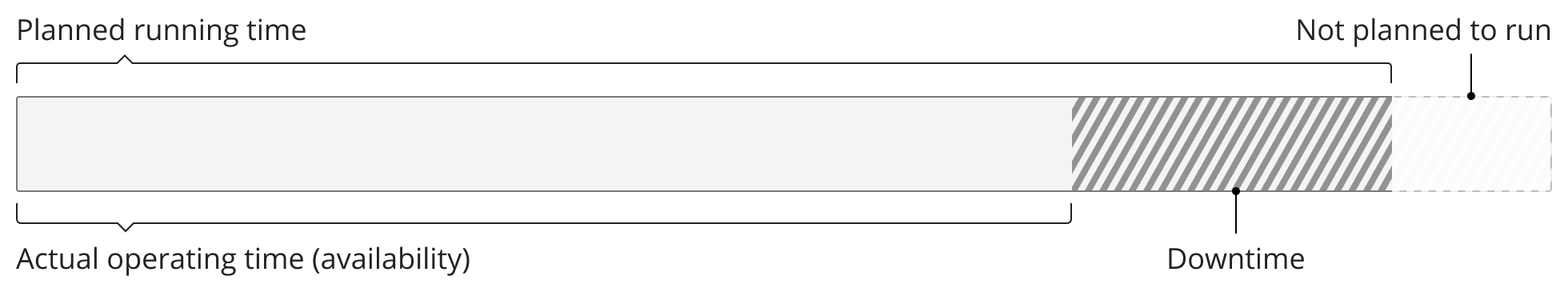

First, let’s consider what availability is so that we can understand how it differs from technical availability. Availability is the proportion of planned running time which is available for production. The time lost is downtime.

Downtime consists of planned and unplanned stops.

Unplanned stops happen when you schedule your machines to produce but events that are unplanned occur. Examples include equipment breakdowns, unplanned maintenance, lack of operators or materials, etc.

Planned stops happen when you schedule your equipment to produce but various planned events stop this from happening. Examples include product changeovers, tooling adjustment, cleaning, planned maintenance, and quality inspection. Paid rest breaks, meetings, toolbox talks, etc., also fall into this category.

Learn more: Step-by-step guide to reduce downtime by 15% in 6 months

How to calculate availability?

Availability = Actual Run Time / Planned Time x 100%

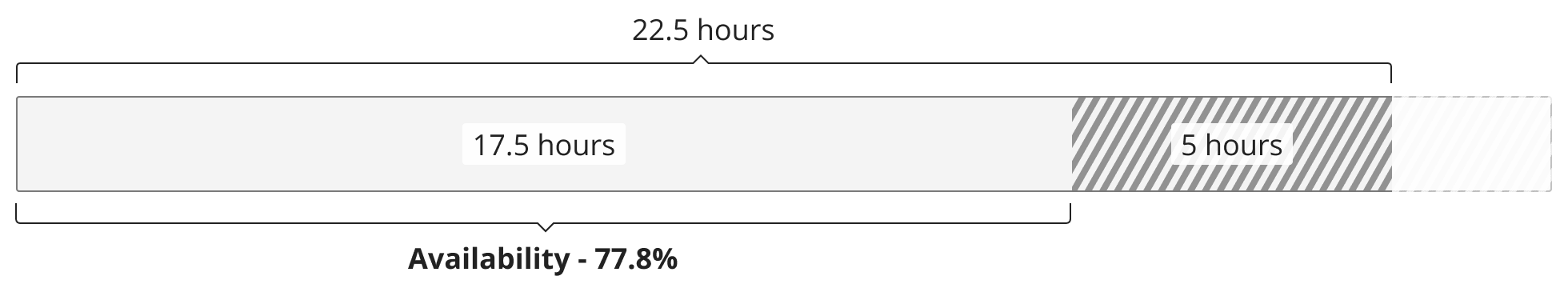

Example calculation:

Planned operating time 22.5 hours

Production Downtime 5 hours

Actual run time 17.5 hours

Availability = 17.5 / 22.5 *100% = 77.8%

Learn more: Availability formula explained

What is Technical Availability?

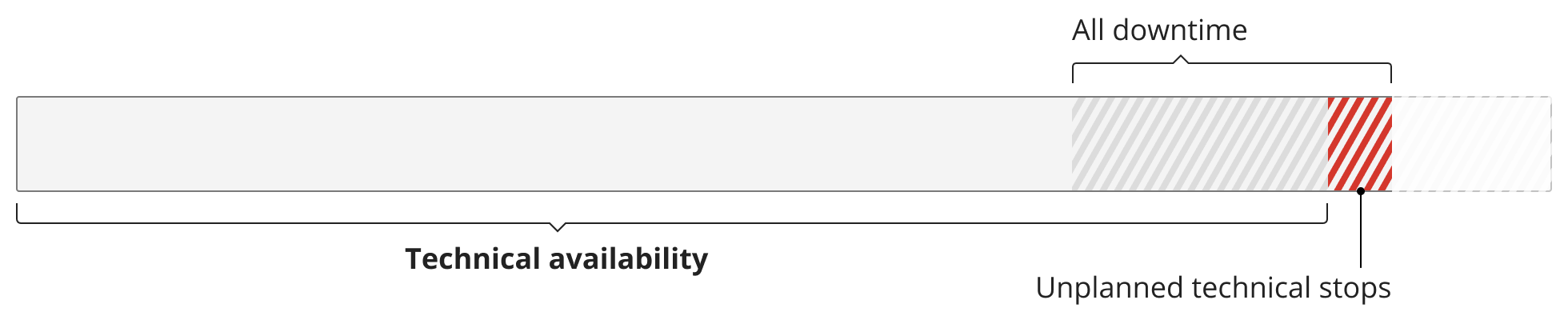

Technical availability is the percentage of planned production time without unexpected technical difficulties or maintenance needs.

If, for example, your technical availability is at 85%, then you know that 15% of your planned production time is lost due to technical issues that can be resolved by improving maintenance and reliability.

How to calculate technical availability?

Technical Availability = (Planned Time – Unplanned Technical Stops) / Planned Time x 100%

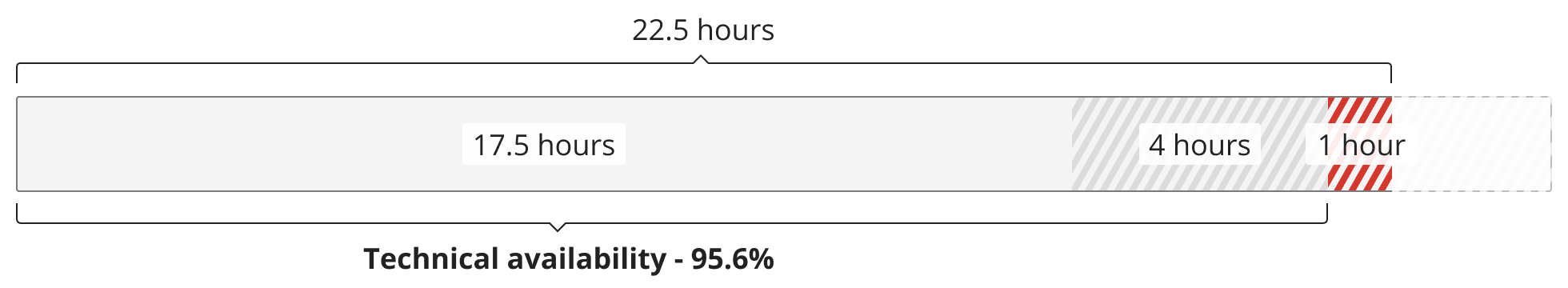

Example calculation:

Planned operating time 22.5 hours

Production Downtime 5 hours, whereas downtime due to unplanned technical stops is 1 hour

Technical Availability = 21.5 / 22.5 *100% = 95.6%

This says that we lost 4.4% of the planned operating time due to technical issues. We can resolve this by improving maintenance and reliability.

What is the Difference Between Availability and Technical Availability?

As you can see from the explanations and calculations, technical availability only focuses on understanding how much of the planned time you lost due to unplanned technical issues with the line or machine.

How to Track and Improve Technical Availability (TA) in Evocon?

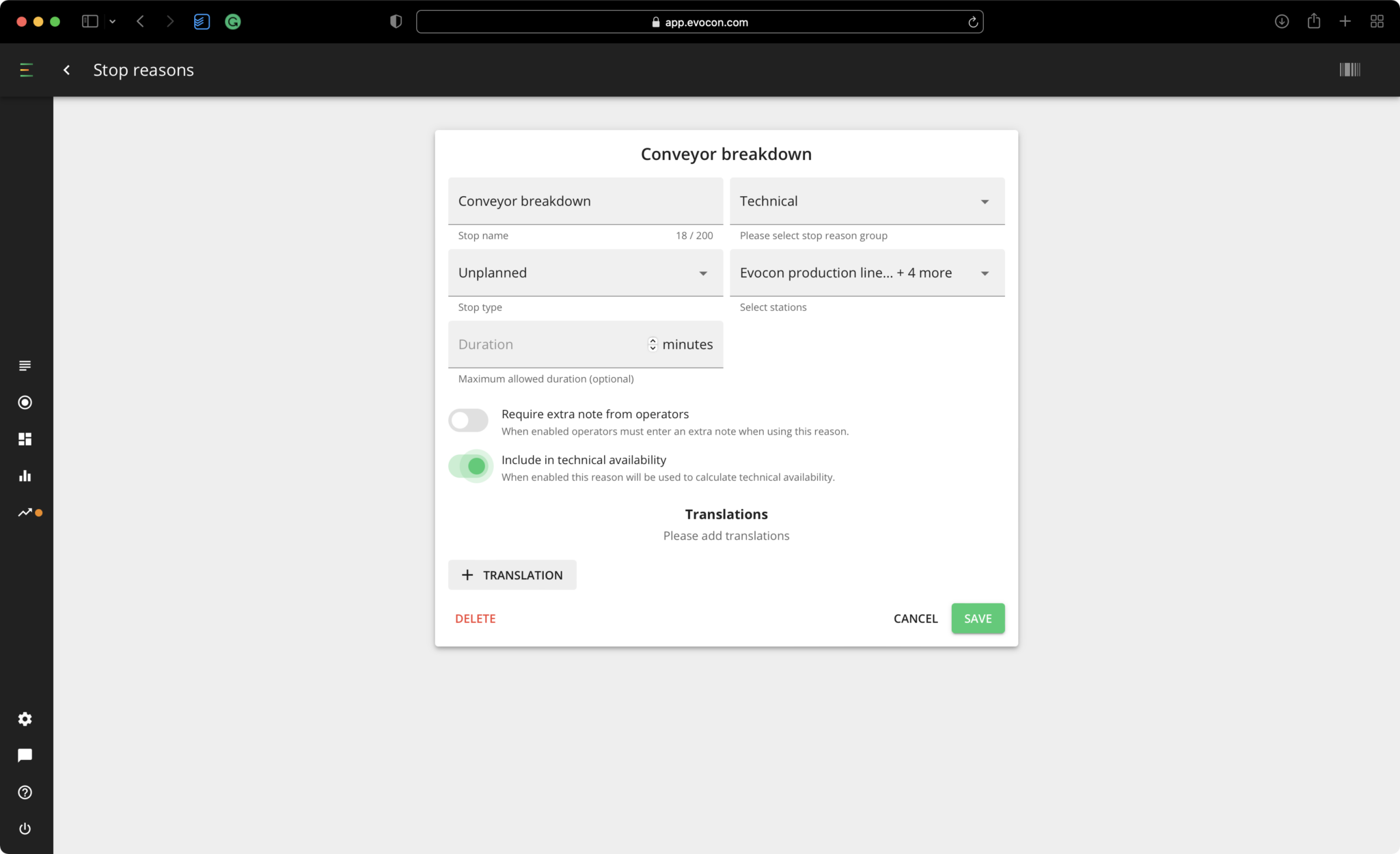

First, you must define which production downtime reasons in your factory you consider as technical difficulties or unexpected maintenance issues. This ensures you can correctly track how this KPI changes in time and is the basis for continuously improving your maintenance efforts.

How to include production stops in the TA calculation?

Evocon clients track their TA by marking specific production stop reasons as unplanned technical issues to be included in the calculation. Afterward, our system calculates everything automatically.

Production Reporting Software

Track and analyze the technical availability of any of your production lines or machines. Free for 30 days.

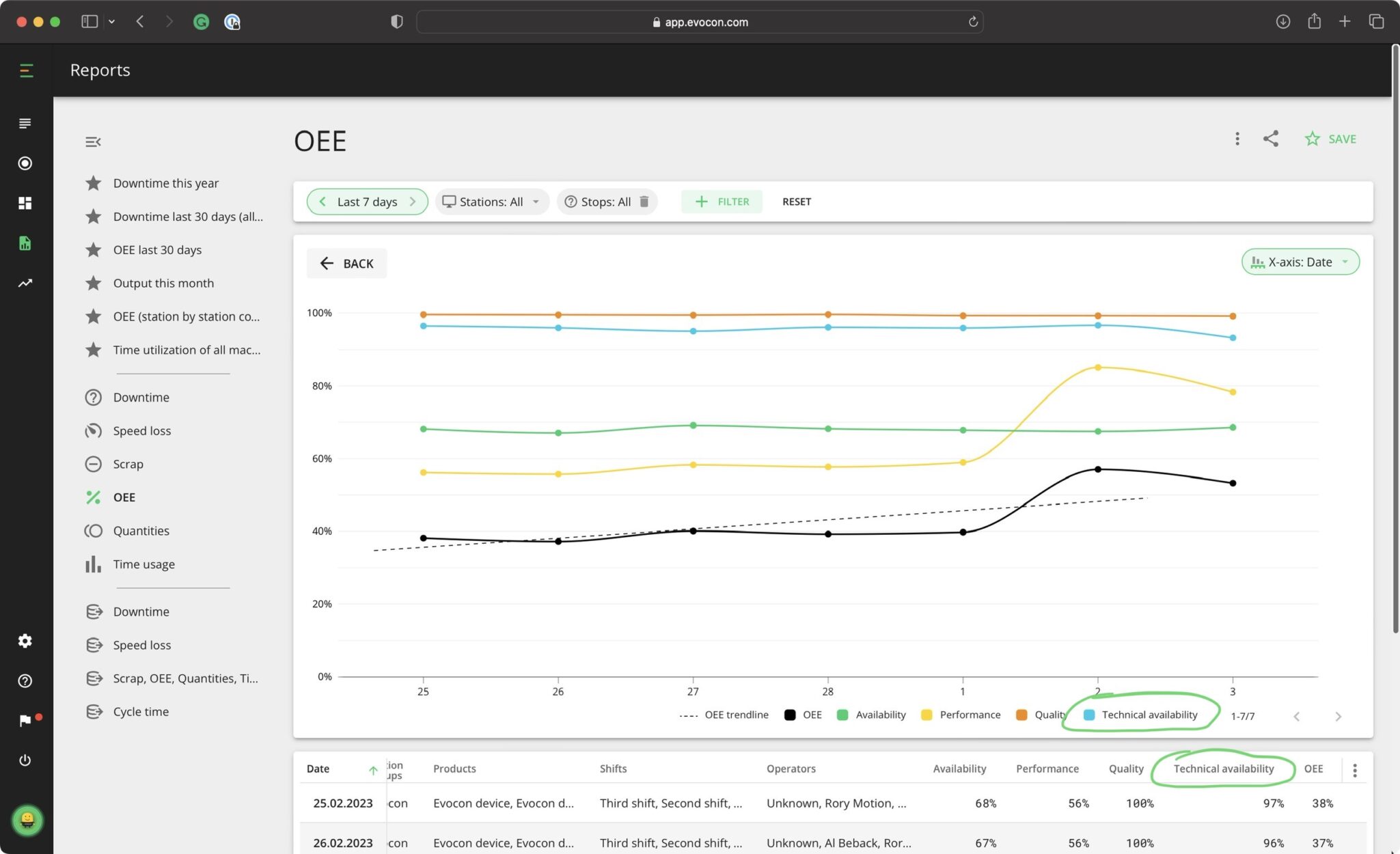

How to track TA in Evocon’s OEE report?

By pulling up the OEE report in Evocon’s production reporting software, you can quickly analyze the TA for any of your production lines or machines.

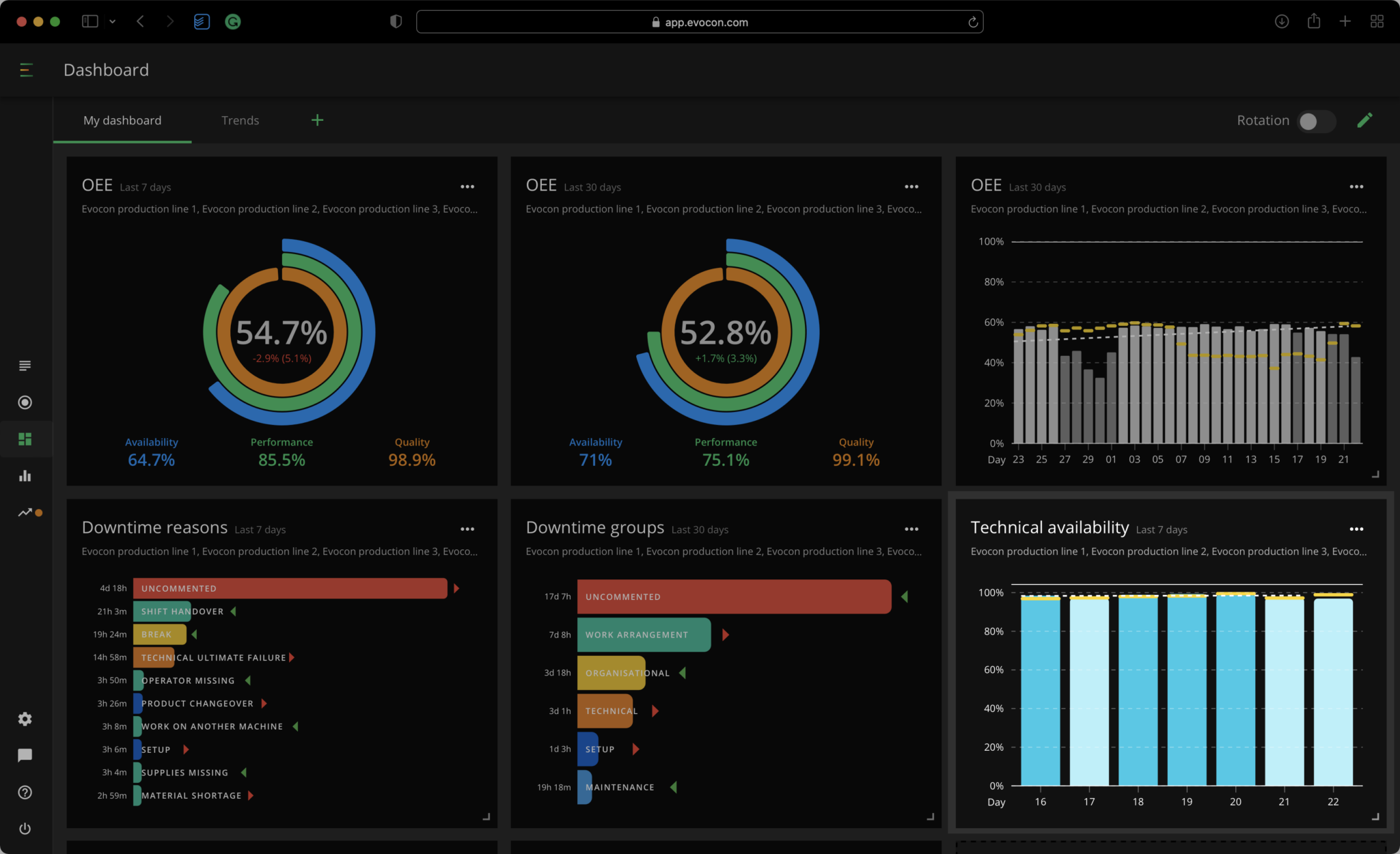

How to track TA in Evocon’s Dashboard?

Each user in Evocon has a personalized production dashboard. This comes especially handy when you want to give your maintenance team access to collected production data.

By enabling this, they can create a dashboard that tracks all of the data needed to improve the reliability and maintenance of your machines.

Have any questions or issues? You can always contact our support; we will help you sort everything out.