To implement Evocon and start monitoring your production, you may need hardware. Our team provides some of it and the rest you will need to procure yourself. This article gives you all the information you need to know.

Overview of the Hardware You Need to Monitor Production Using Evocon

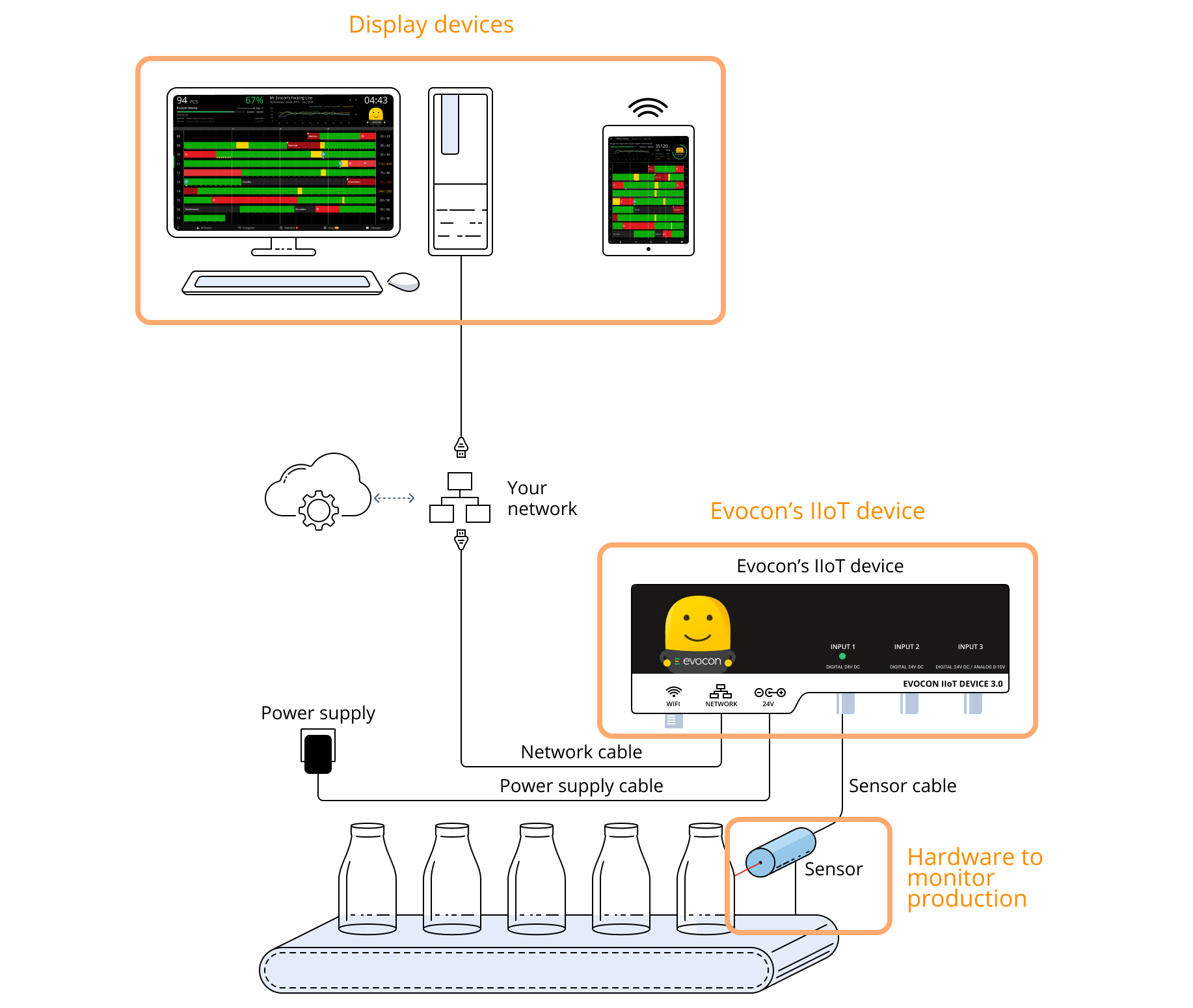

Generally, there are three types of hardware you need to get started: a display, the Evocon’s IIoT device, and hardware to get production signals from your production process (i.e. sensor, PLC, cable, and connectors).

1. Displays

Tablets, phones, or computers with monitors.

Do I need it?

Yes, absolutely.

Does Evocon provide it?

No, but we can recommend which display devices suit you best.

2. Evocon’s IIoT device or devices

Do I need it?

If you already have your production data in your database, then you don’t need it. We have a hardware-free solution for you.

If you haven’t automated the collection of your production data, then you need one or more Evocon devices.

Does Evocon provide it?

Yes, we provide it. We provide one device for the 30-day trial free of charge. After subscription, we provide as many devices as you need.

3. Hardware to monitor production

Do I need it?

Same as above: if your production data is stored in your local database, then you don’t need it. You can proceed with our hardware-free solution.

However, if you need to start collecting production data from your machines, then you need hardware to monitor production.

Does Evocon provide it?

Our clients typically use their own hardware, but we can provide sensors, relays, cables, and connectors, if requested, at an additional charge.

Below we look into each type of hardware in more detail.

Displays

In order to visualize production data, you need displays. Those can be either PCs with full-HD monitors or TVs or tablets. Displays are useful in the office and absolutely necessary on the shop floor.

The way you set up displays depends on your industry and production environment. For example, in the food industry displays might need to have IP-rated protective cases. Similarly, in the wood industry, where there is a lot of dust, you also need to protect the displays.

We have a lot of experience with different industries and are ready to suggest the best solution.

Easy-to-set-up OEE Software

Start tracking and analyuzing the performance of all your production shifts across different stations, factories and countries. Free for 30 days.

Evocon’s IIoT Device

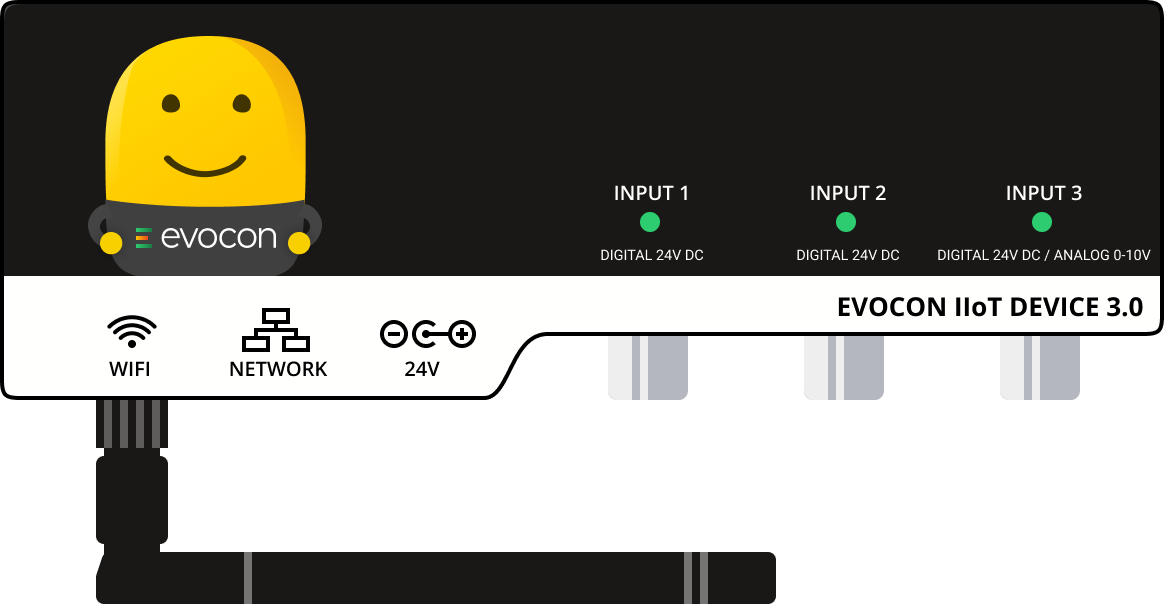

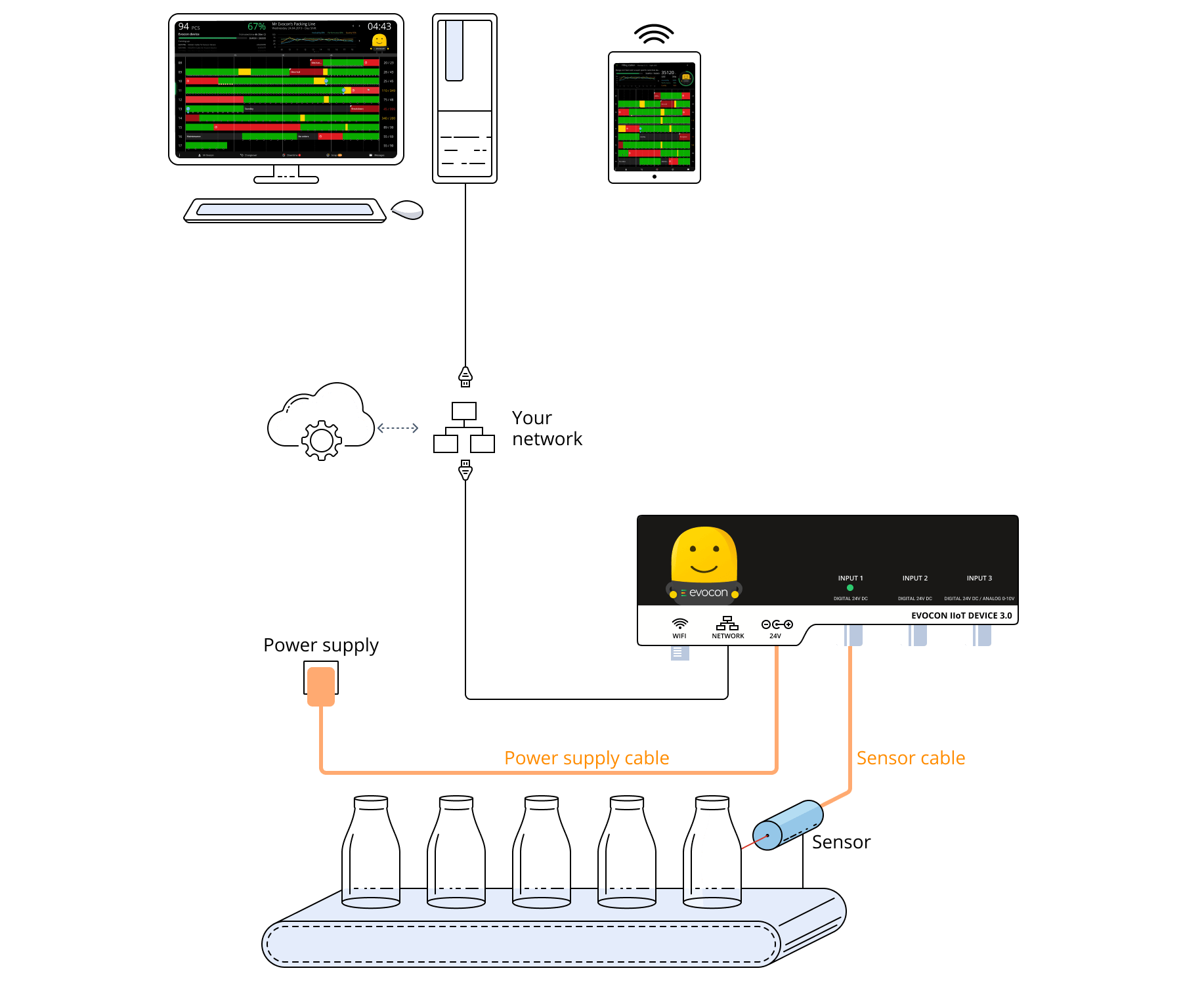

Evocon’s IIoT (Industrial Internet of Things) device has three inputs. It means that it can register data from up to 3 different machines, or 3 different monitoring points.

For example, an Evocon device can have two inputs on one production line: one registers filled bottles, the other registers defects.

For each device you install, you need an internet connection (via Ethernet) and a power source.

How many Evocon devices do I need?

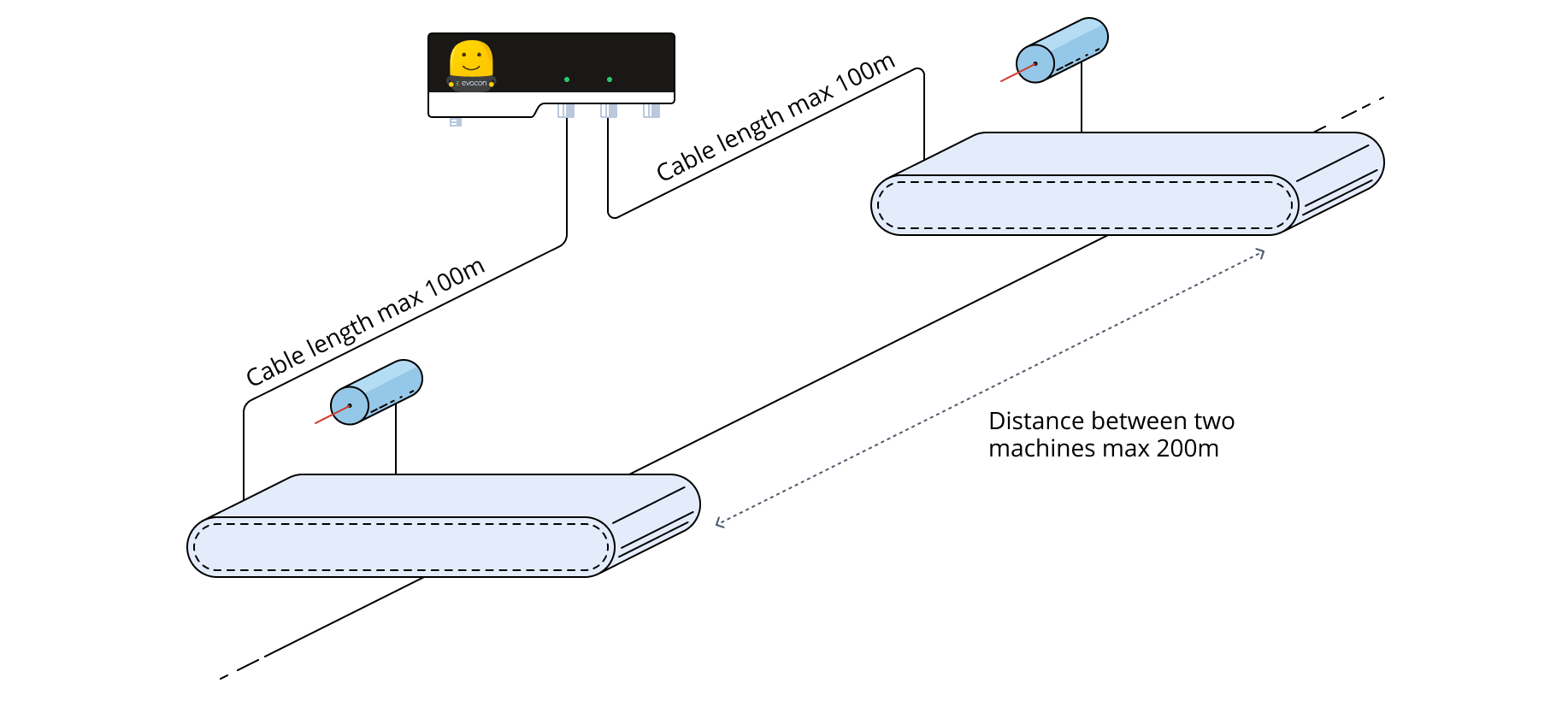

Typically, one device per 3 machines (or 3 points on the production line) that are monitored, but one more thing to consider is the distance between these monitoring points. The quality of the signal tends to decrease with the length of the cable. If your cable is of good quality, you may use two 100m long cables to connect two machines that are 200 meters apart, to one Evocon device.

Hardware to Monitor Production

Which hardware you need to monitor production depends on the type of your production. Types of production and ways to monitor it are outlined in this article: How to monitor production and track OEE using Evocon?

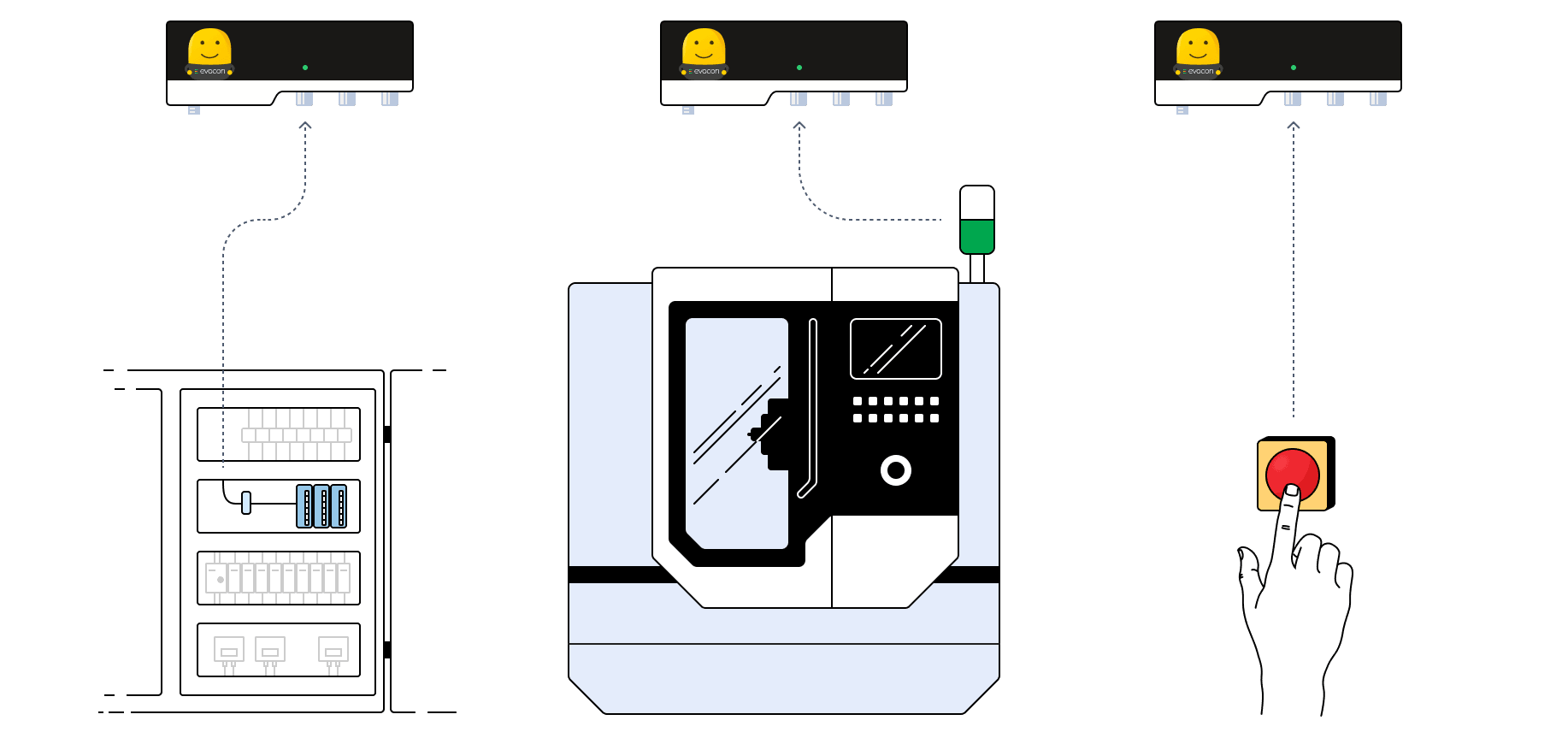

Sensors and relays

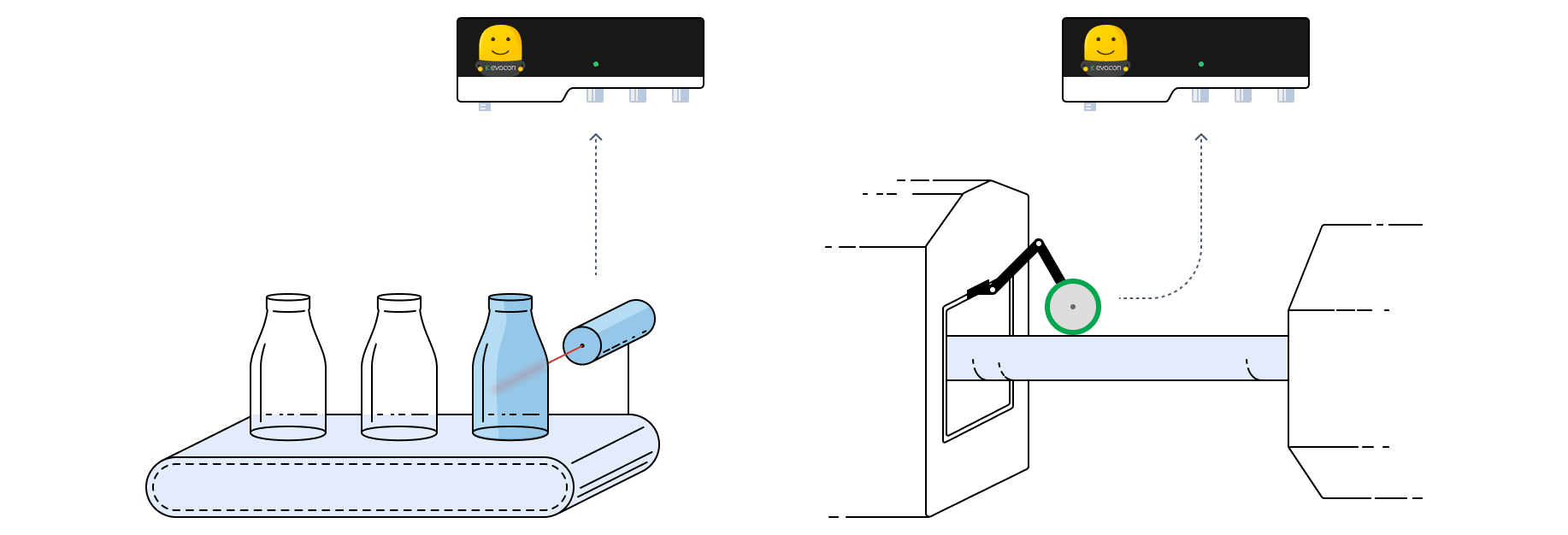

Depending on your production process, you may have to use sensors to measure or count products directly.

Alternatively, you may get signals from PLCs or Andon lights of your machines using a relay, or simply install a push-button to generate signals manually.

Cables and connectors

We will provide a power cable for the Evocon device and cable and connectors for sensors if needed.

Which type of power plug and what kind of sensor cables and connectors we provide, depends on your situation. We will discuss it with you before we ship the hardware.