As production digitalization develops and matures, it opens up new ways to set up data automation and production monitoring. For example, some new machines already capture data about production and store it in a local database. This allows for a hardware-free solution to track OEE and other relevant KPIs. This article explores how you can set up Evocon’s OEE software as a hardware-free solution to monitor your production.

How Does the Hardware-Free Solution Work?

You can also set up production monitoring using only HTTPS requests. By using this method, our system pulls all the relevant data from your database and removes the need for any hardware. Thus, making Evocon a software-only solution. Then you no longer need the Evocon device, nor do you need sensors or other hardware from us.

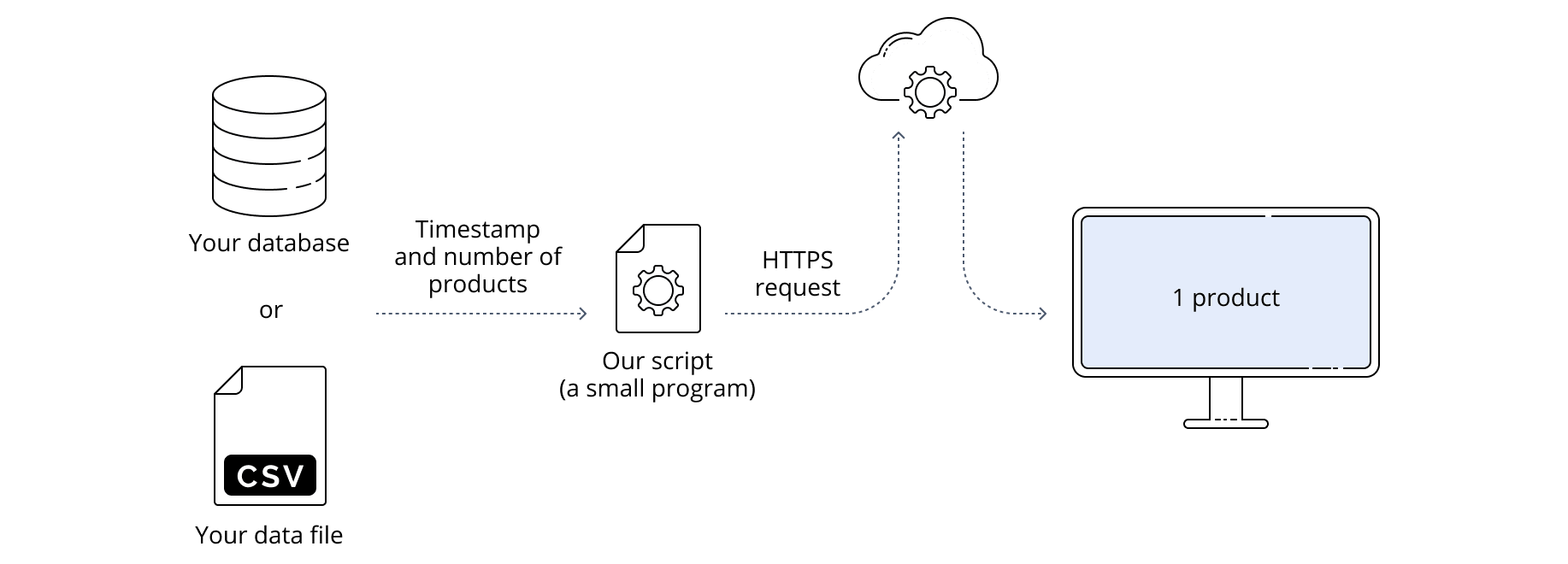

Instead, you need a database or a data file that has this production information:

- the number of products produced,

- the timestamp of when these products were produced.

After you let us know what type of database or a data file you have, we supply you with a script that takes the pieces of data mentioned above, converts them into HTTPS requests, and sends them to our system. The system processes the data and displays it on your screen.

If you have an IT team with programming experience, they could set up the script on their own based on the examples our support team provides.

A hardware-free solution is a quick and convenient way to use our system. However, keep in mind, the quality of data on the screen will be only as good as the quality of data in your database.

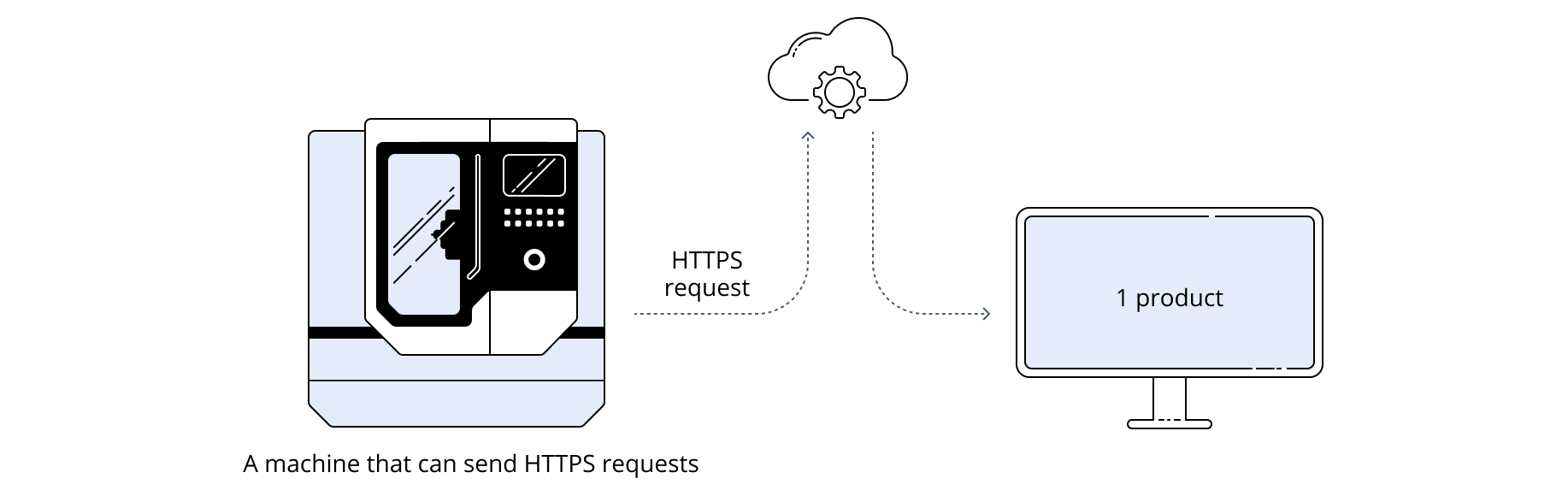

Some production equipment today have components that allow you to configure it to send data as HTTPS requests, which means that you don’t need our script to convert data into HTTPS requests.

Hardware-free OEE Software

Monitor your production without the need to set up any hardware. Free for 30 days.

Examples from Our Customers

A small change enables Evocon’s hardware-free solution at a wood processing plant

One Evocon client implemented the hardware-free solution at their wood processing plant. At the plant, they dry wood in kilns, and one central system manages the process. The system interfaces with PLCs that control the kilns. It receives the current status of temperature and humidity and provides parameters and instructions for the procedure of drying.

Evocon helped the client make a small change to the central system. After the change, the program started sending the status of the kilns to the Evocon system as HTTPS requests, with a frequency of one per minute.

Dutch fertilizer company uses Evocon system to visualize their existing data

A fertilizer company, shipping its product worldwide from the Netherlands, was already collecting data on their vessel loading operations. Their distributed control system (DCS) was good for gathering and analyzing data from the machinery. However, it did not have the functionality for efficiency analysis and improvements.

Since DCS could export the data as a CSV file, there was an easy way to use Evocon’s reporting capabilities and implement it as a hardware-free solution. DCS simply generated a new up-to-date CSV file and sent it to the Evocon system every minute. This enabled real-time visualization of their already existing data.

A meat processing company integrates its weighing equipment with Evocon

A meat processing company operating in Estonia sought to integrate their weighing equipment with Evocon to visualize the amount of meat produced.

The equipment was weighing vacuum-sealed packs of meat and printing labels with the description of the product and its weight. The goal was to send the weight readings to the Evocon system. To do that, the scales needed a special communication card.

With the card installed, the equipment could save the product description, weight, and timestamp in a local database. Then, Evocon created a small script to read this database and send the information to the Evocon system.