Evocon is a versatile production monitoring and OEE software, currently used by manufacturing companies in more than 25 industries. This article will help you determine how to use Evocon to monitor production and track OEE in your factory.

Is Evocon Able to Monitor My Production Process?

The most popular way of monitoring production with Evocon is to count products, pieces, and boxes. Still, the system can also measure the weight of products, length, or volume and monitor machine working time. If you have a CNC machine, you can either count products or measure time. If your production doesn’t quite fit into the categories mentioned, it is possible to use a combination of methods to set up a unique monitoring solution.

Below you will find an overview of how to monitor production with Evocon and what hardware you need. You can also explore each method in more detail by following the links under each paragraph.

Do you need to count products, pieces, or boxes?

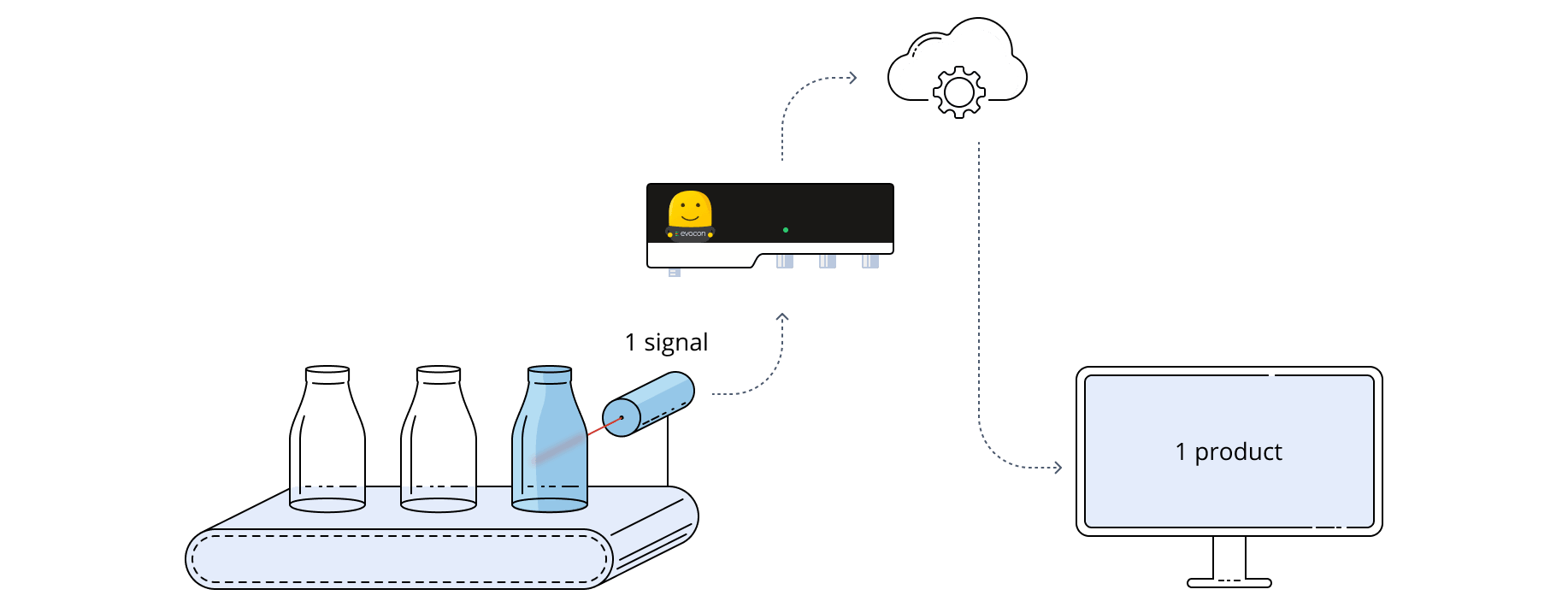

Counting single products is the most widely used method for monitoring production, OEE, and machine downtime. It is very common, for example, on bottling lines where we count single bottles using a sensor.

An item or product, moving in front of a sensor, creates a signal, and our Evocon’s IIOT (Industrial Internet of Things) device registers it. The device then sends this signal to our server for processing. Afterwards, the system displays collected data in real-time on the shop floor or in the office.

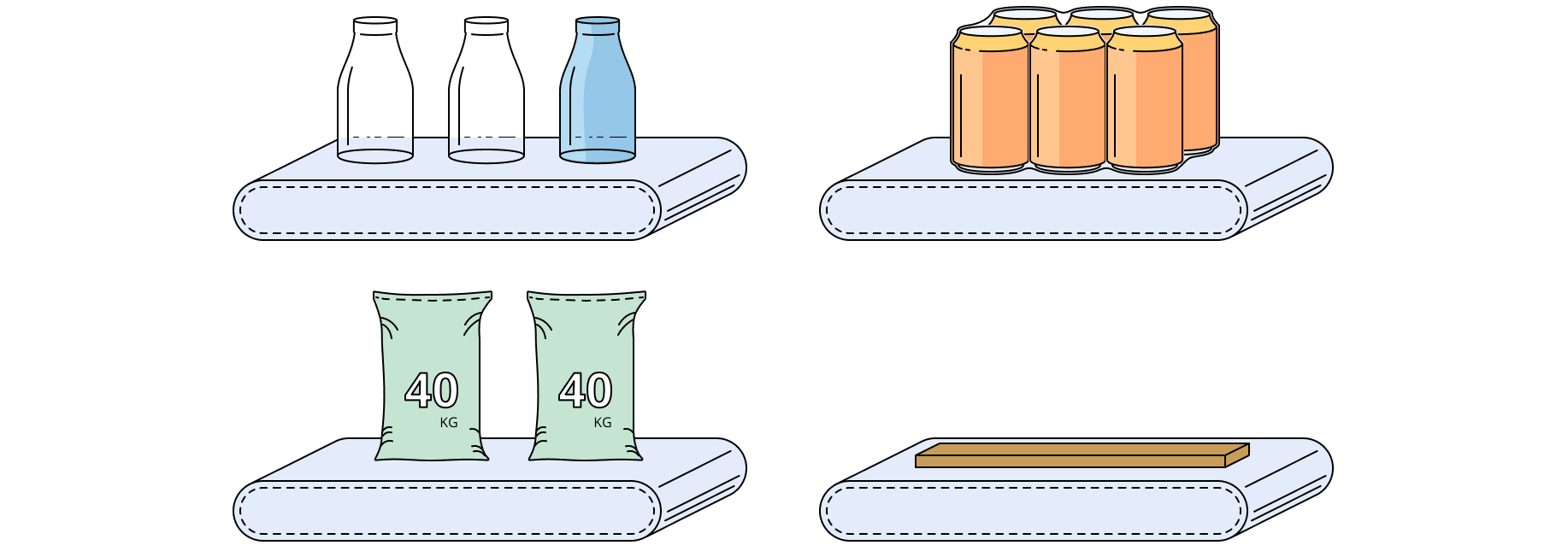

The abovementioned way ideally suits mass production: large quantities of standardized products. But what if you make products in groups, and not in a continuous stream?

You can monitor product groups in the same way as single products, and the signals generated will be converted into the correct number of products.

For example, let’s say the sensor registers a box that is moving on a conveyor. If there are six items in a box, we convert one signal to represent six products.

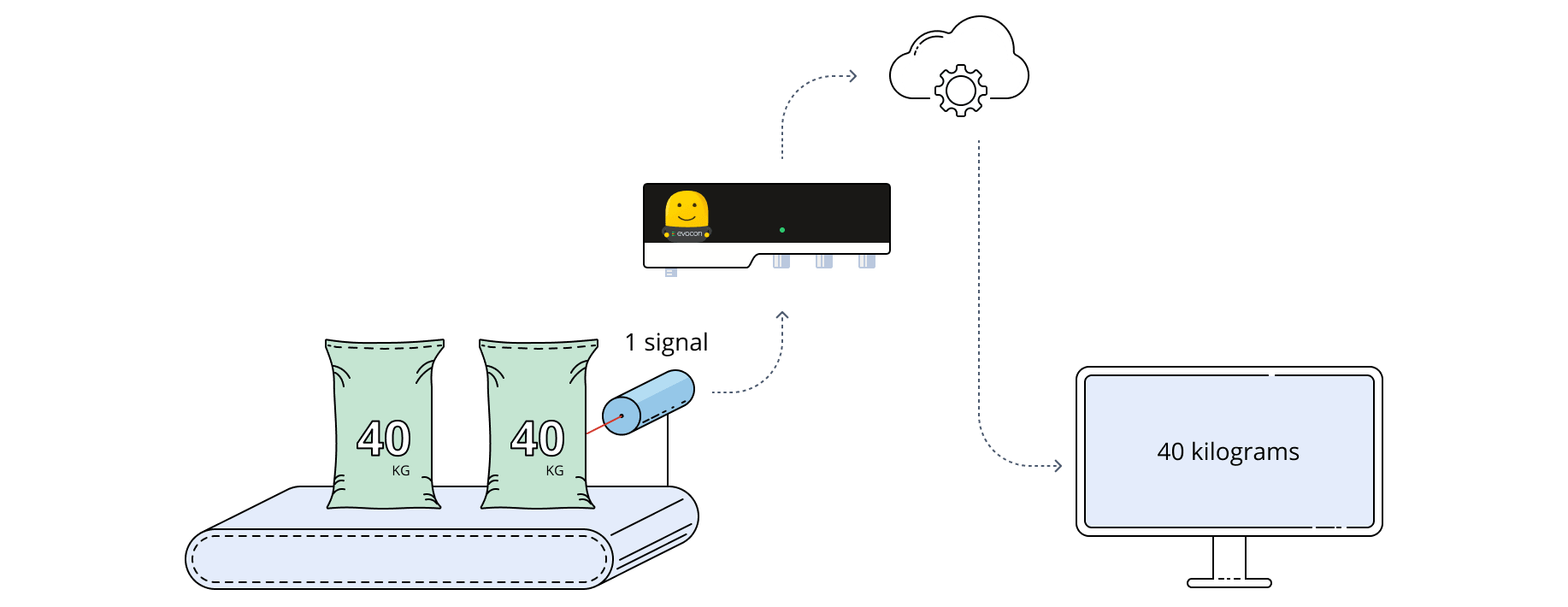

Conversion is also useful if you want to count products, but display the quantity of products not in numbers, but other units. For example, you could count bags, but display information in kilograms.

Another example is counting wooden boards using a sensor. If you need to know how many meters of boards you have produced, you may use a measuring wheel to register length, but you could also use a sensor to count boards and configure the system to convert that number into meters.

Read the technical article explaining how Evocon counts products

Do you need to measure the weight of a bulk product?

Let’s say your production is continuous: materials are manufactured, produced, or processed without interruption, in constant motion.

An example of that would be fertilizer production. It is usually possible to measure the weight of a bulk product by separating it into batches (for example, using hopper scales) and counting batches in the same way as you would count single products. Then, the system converts the number of batches into the weight units of your choice.

Another example is sand processing. Sand dosing system doses, let’s say, 15 kilograms of sand every 15 minutes. Therefore the most straightforward method is to measure working time and convert the result into kilograms. You can get the working time from a PLC output signal.

Read the technical article explaining how Evocon measures the weight of a bulk product

Do you need to measure product length or amount of liquid?

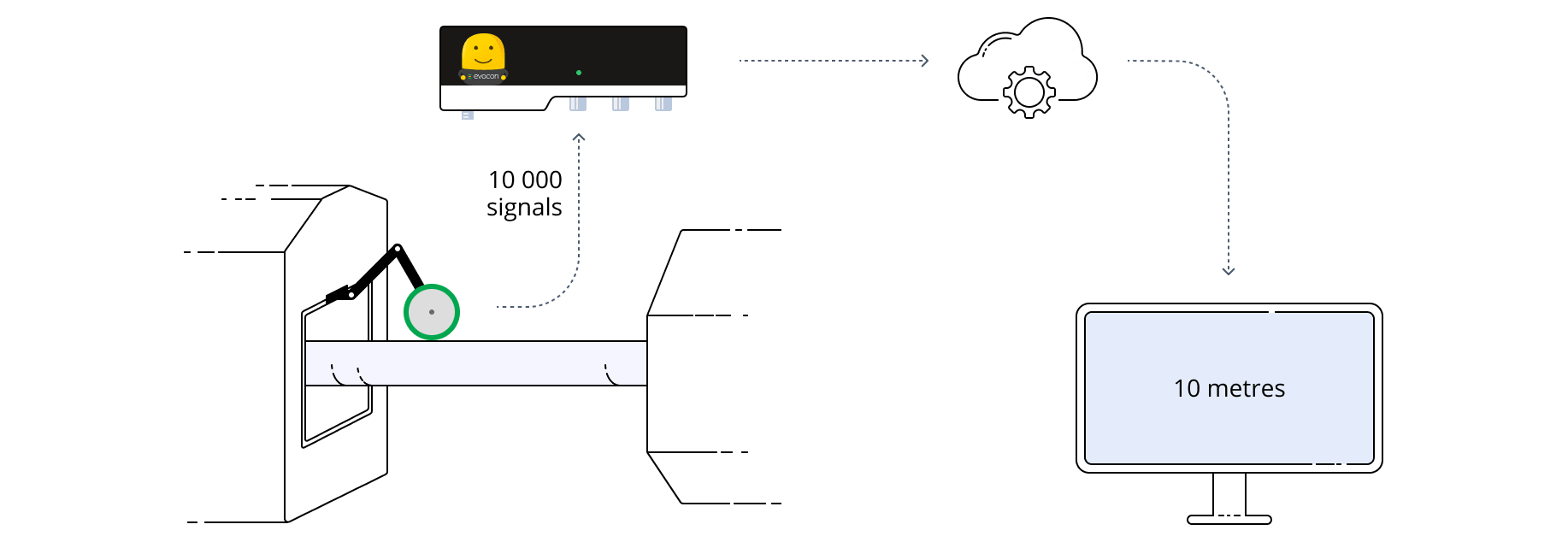

Other types of continuous production may require you to measure length or volume, rather than weight — typical examples: wood planing or extrusion of pipe or filling canisters/buckets (filling operations).

You can monitor your production and measure length with a measuring wheel and a rotary encoder, as shown in the picture below.

You can measure the amount of liquid using flow meters, as it moves through the pipe.

Alternatively, if the liquid is in canisters, bottles, or tanks, it might be possible to count filled containers with a sensor and configure the system to convert that number into volume units.

Just like it is possible to count the number of products and convert it into weight, length, or volume units, the reverse is possible as well – measuring length or volume and converting this information into the number of products.

Read the technical article explaining how Evocon measures product length or amount of liquid

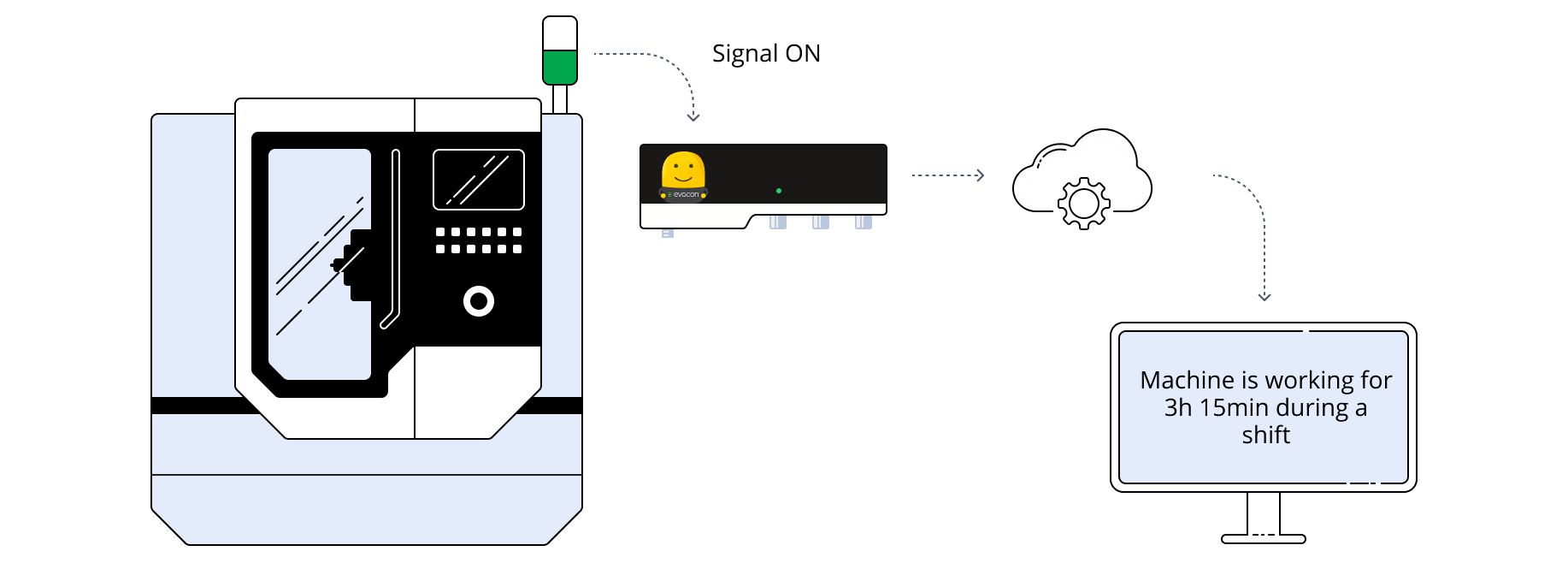

Do you need to monitor machine working time?

You may want to monitor how long your machines work or how long your conveyor line runs.

A typical example is a laser (or plasma) cutting machine. Evocon can get signal from the machine directly (from an Andon light, status light, PLC) and determine how long it runs.

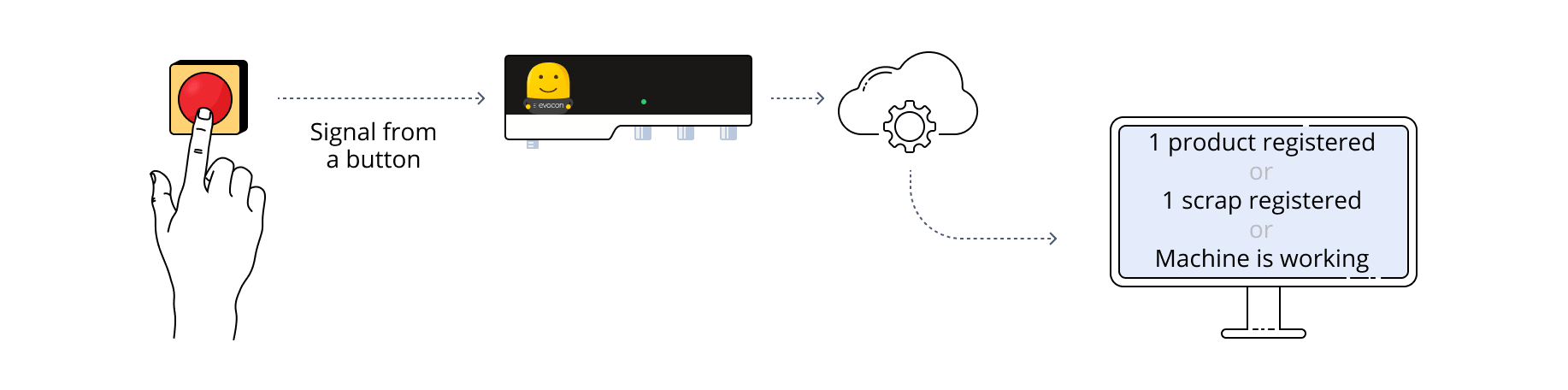

If the machine isn’t able to provide its run-time information, it is possible to generate it manually, by pressing a button.

If you need to monitor conveyor belt running time, you can track the conveyor motor signal.

Read the technical article explaining how Evocon monitors machine working time

Production Tracking Software

Start tracking production in real-time and boost your OEE with Evocon’s 30-day free trial.

Do you have a CNC machine?

CNC stands for “Computerised Numerical Control”. It is a high-precision computer-controlled tool that makes repeated, accurate movements.

CNC machines make complex parts from wood, metal, and other materials.

If you have a CNC machine, you can monitor its working time, count pieces produced by it, and evaluate its performance. Most of our customers start with monitoring working time. Some of them, but not all, move on to counting pieces produced. It depends on our customers’ needs.

Read the technical article explaining what and how can be monitored if you have a CNC machine

How about other types of production?

Finally, in the case of one-off production, sometimes called job production, products can be very complex and take a longer time to make. Typical examples of this are large metal objects (e.g. ship parts), modular houses, or manually assembled items.

This type of production is not very common among Evocon users. Nonetheless, we have experience with tracking OEE in such processes. A typical method is to use a manual push-button (sometimes a sensor at a dedicated location on a table or conveyor is also possible). For example, an operator finishes a product and pushes a button connected to our device.

Read the technical article on how Evocon could measure other types of production

Finding What Is Right for You

No matter the industry you are in, our team will help you find the best possible solution to monitor your production. We will also let you know if we can see that our system is not the best option for you.