Efficient manufacturing operations are central to a successful production company, and downtime is the sworn enemy. In manufacturing, downtime can be broadly categorized into two types: Planned Downtime and Unplanned Downtime. Understanding these categories, their impacts, and management techniques is vital for optimizing Overall Equipment Effectiveness (OEE) and enhancing productivity.

Planned Downtime

Often factored into the production schedule, planned downtime refers to periods when production is deliberately halted for a variety of reasons:

- Routine Maintenance and Inspections: Like a vehicle needing regular oil changes, manufacturing equipment requires frequent upkeep. This includes cleaning, servicing, calibrating, and replacing parts to ensure the machinery runs smoothly.

- Changeovers and Setup Time: When production shifts from one product to another, machinery must be reconfigured. The process involves changing tooling, resetting parameters, or modifying the physical setup.

- Employee Breaks and Shift Changes: Human resource factors like lunch breaks, shift changes, or training periods also contribute to planned downtime.

While planned downtime seems like a productivity impediment, it’s essential for long-term operational health. Strategic planning can minimize its impact on OEE. Scheduling maintenance during off-peak times or investing in machinery with faster changeover capabilities can significantly improve efficiency.

Unplanned Downtime

Unplanned downtime, the nemesis of efficient operations, strikes unexpectedly and can have disastrous consequences for production schedules. It typically occurs due to:

- Equipment Failure: A sudden breakdown or malfunction of machinery halts production unexpectedly, often requiring extensive repairs.

- Material Shortages: Insufficient supply of raw materials or delays in material delivery can bring production to a standstill.

- Unscheduled Stoppage: This includes unexpected events like power outages, human errors, or safety incidents that require an immediate halt to operations.

To mitigate unplanned downtime, preventive maintenance, backed by real-time downtime tracking software, can be a game-changer.

Downtime Tracking Software

Start measuring and optimising your downtime with Evocon’s 30 day free trial.

Understanding OEE: The Influence of Planned and Unplanned Downtime

Understanding how OEE calculation works in the light of planned and unplanned downtime is imperative if your goal is to know your actual OEE and how much potential exists.

With unplanned downtime it’s easy – no matter the reason, it must be included in the OEE calculation and it must reduce OEE. The more unplanned downtime you have, the more potential you have unused. What about planned downtime?

OEE theory says (from OEE at Work): “Planned activities such as maintenance shutdowns and major plant hoverhauls (”turnarounds”) are not categorized as availaibilty loss and are therefore NOT used in the calculation of OEE. Similarly, where lack of demand or seasonality dicates that certain shifts or workdays are not required to be worked, these should also be excluded from the calcualtion of OEE.”

What this means is that most planned stops should be included in the OEE calculation. However, this is not what we see among our clients. Instead, there is a tendency to exclude all planned downtime from OEE calculation. This is good for two reasons – shop floor is not penalized for downtime that is planned and you can report a higher OEE. But it’s very bad for one reason – if you exclude most planned downtime from OEE you are not getting a realistic picture of what you can actually achieve. Let’s illustrate this with an example.

Downtime due to changeover form one product to another is unavoidable. As such most manufacturers define it as planned and exclude from OEE. But what if it takes 25min at times, then at other times it takes 40min and occasionally it takes 20min? If the fastest we can complete a changeover is 20min, then we are mistakenly inflating our OEE every time it goes above 20min and we are losing valuable production time. The goal would be to set a changeover limit for 20min (exclude it from OEE) and every minute that goes over the limit is categorized as unplanned and reduces OEE. That is an easy way to optimize your downtime tracking for maximum transparency.

Learn more: Step-by-step guide to reduce downtime by 15% in 6 months

The Primary Driver of Downtime: Is it Planned or Unplanned?

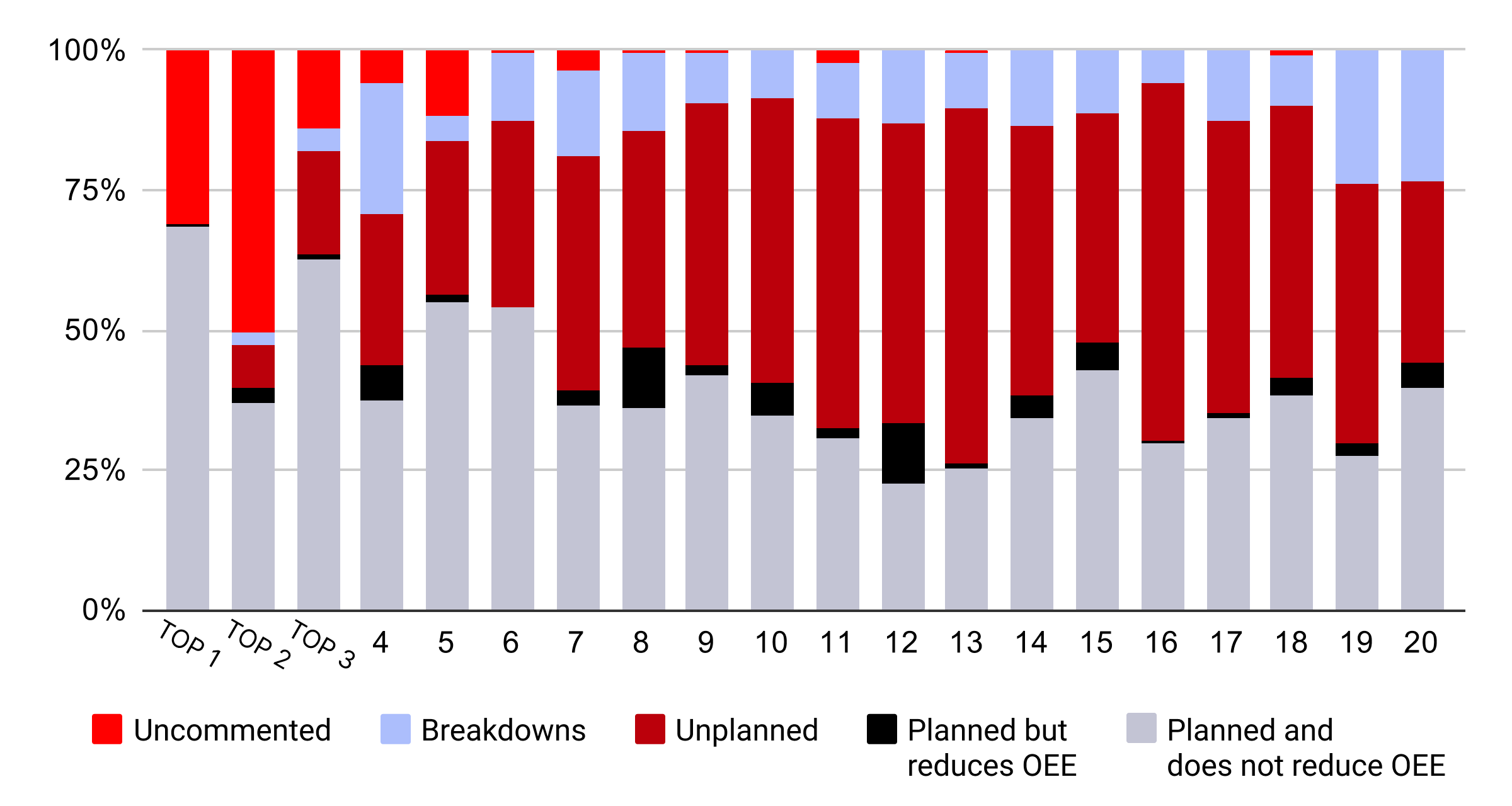

In our post “Exploring Hidden Factors of Downtime in Manufacturing,” we analyzed the data of our clients to see which of the downtime types has a bigger impact on availability. The reason for doing this is that the majority of people equate downtime to breakdowns and assume that most downtime loss is due to unplanned stops. However, data tells a different story.

From the chart below we can see that a lot of potential is “hiding” in unknown or planned downtime.

The Bottom Line: Averting Downtime

Every minute of downtime, planned or unplanned, can cost manufacturers significant amounts. Studies from Aberdeen Research indicate that downtime can cost companies as much as $260,000/hour.

Thus, comprehensive downtime management should involve:

- Optimizing Planned Downtime: Use lean manufacturing principles and smart scheduling to minimize the duration of maintenance, changeovers, and breaks.

- Preventing Unplanned Downtime: Invest in maintenance and real-time OEE monitoring software. Utilize data-driven insights to identify potential issues before they morph into costly problems.

Evocon’s OEE software helps minimize both planned and unplanned downtime. It’s designed to help manufacturing businesses boost productivity and maintain the operational health of their machines, ensuring maximum uptime and profitability.

Remember, effective downtime management isn’t just about reaction—it’s about anticipation. With the right tools and strategies to reduce machine downtime, you can transform downtime from a costly enemy into a manageable aspect of your manufacturing process.