To count products is the most popular method to monitor OEE and production downtime. This article explores the different ways you can achieve this using Evocon.

What Hardware is Needed to Count Products?

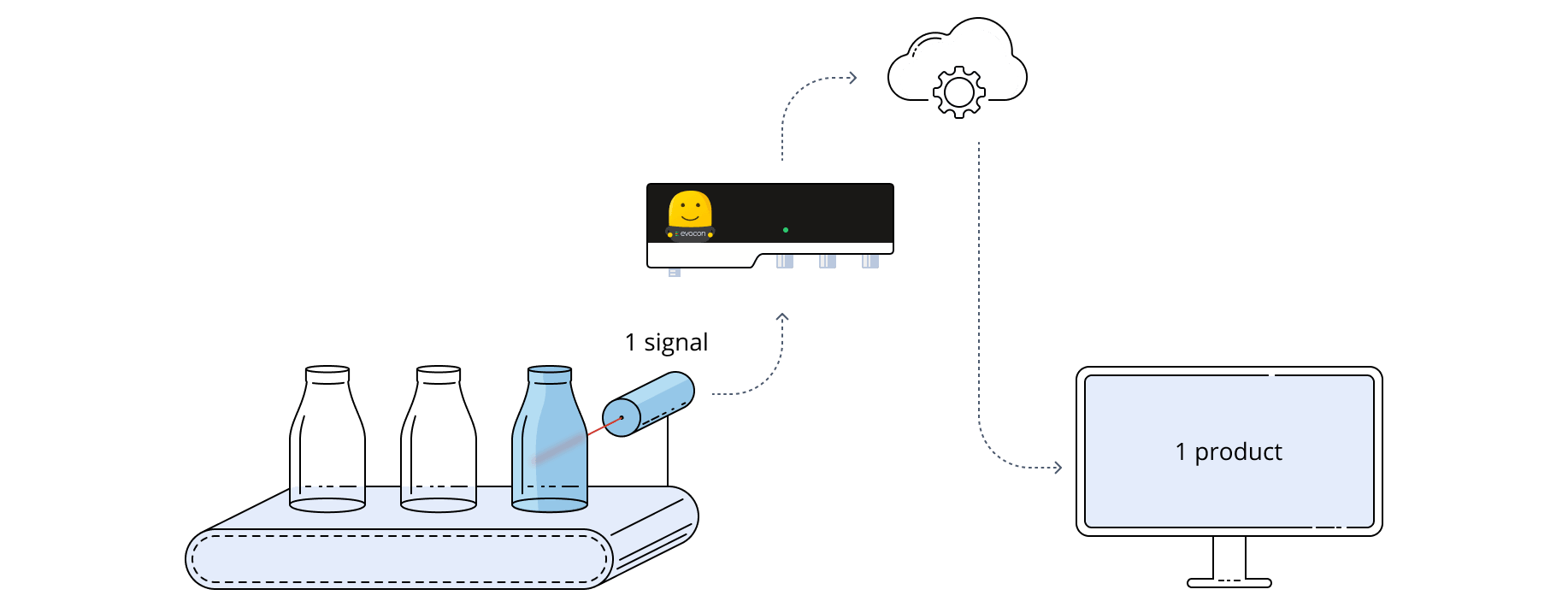

When counting products, you need hardware that sends one signal per cycle (in other words, one signal for each product registered). Here are the types of hardware capable of this task:

- sensor (the most popular option)

- PLC (programmable logic controller, which is essentially a small computer)

- button (sends the signal when pushed manually)

- any other electrical system, connected through a relay

- finally, there is also a hardware-free solution (using HTTPS requests)

Whatever hardware you choose, it creates signals that are registered by the Evocon’s IIoT device. The device sends these signals to our server. Evocon system processes data and displays it. All of this happens instantly, and you see the data displayed in real-time.

Sensor

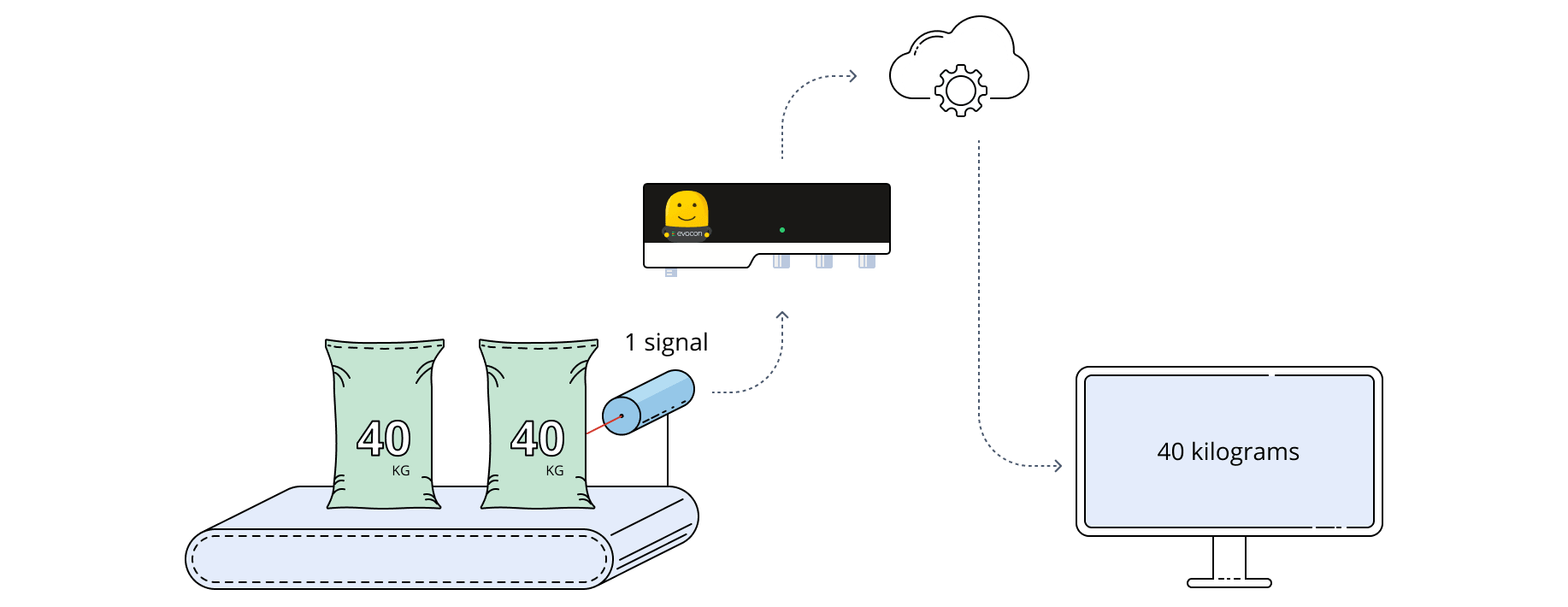

The picture above illustrates counting products using a sensor, which is by far the most popular method.

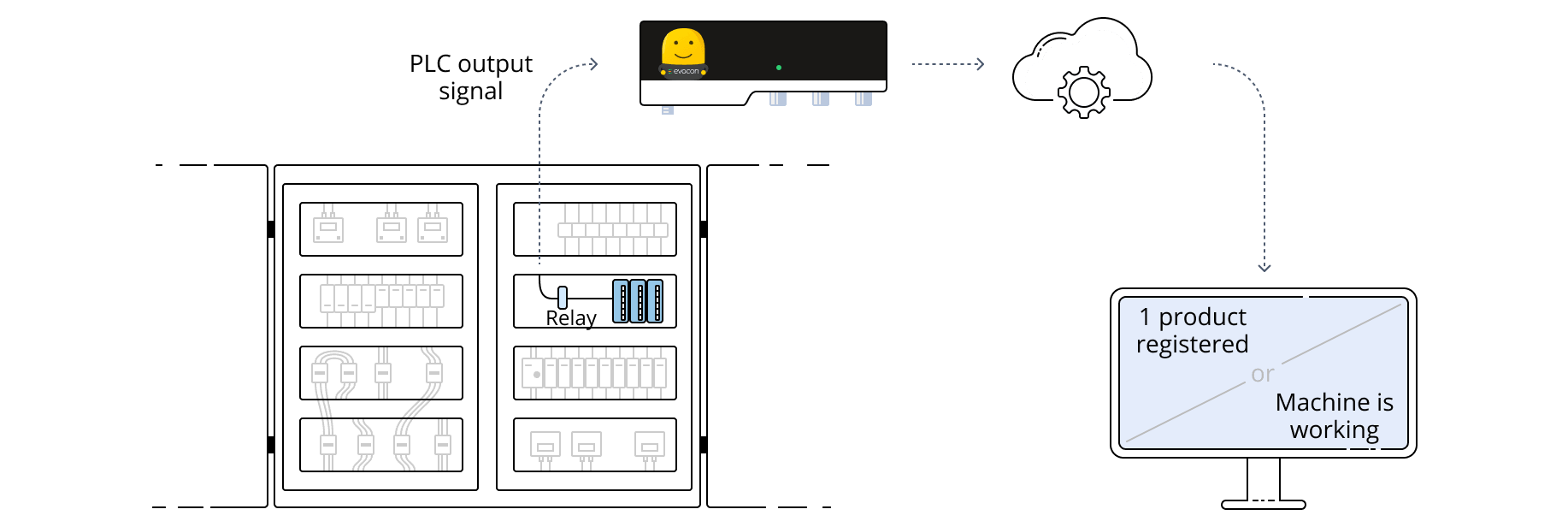

PLC

PLC is a small computer connected to your equipment directly. Newer automated machines usually have PLCs built into them. If there is a PLC signal available that corresponds to a product made, it is best to choose this method over a sensor.

One advantage of that is that any problems with PLC would be spotted and fixed sooner than if something happens to the machine or a sensor. Also, PLC outputs are generally more stable than sensor outputs.

PLCs are useful not only for counting products but also for determining machine working time.

The picture above illustrates how Evocon uses a PLC installed in an electric cabinet.

Relay

An example of counting products through a relay is a CNC machine. It is possible to program a modern CNC machine to close a relay on a circuit board when it finishes a part. CNC machines are a special case, if you have one, please read an article about monitoring CNC machines.

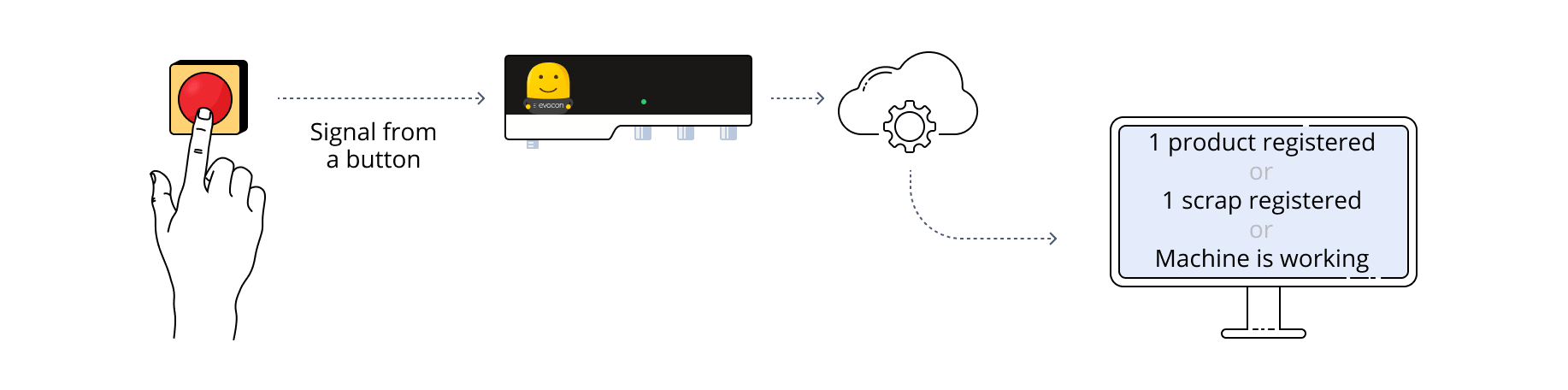

Push-button

When an automated solution isn’t possible, you can count products by installing a button which operators pushed manually upon completion of a product. It is not the most reliable method, but it makes sense in situations when products take more time to complete, are fairly complex, large, or custom. Therefore, we discuss the usage of buttons in our article about other types of production.

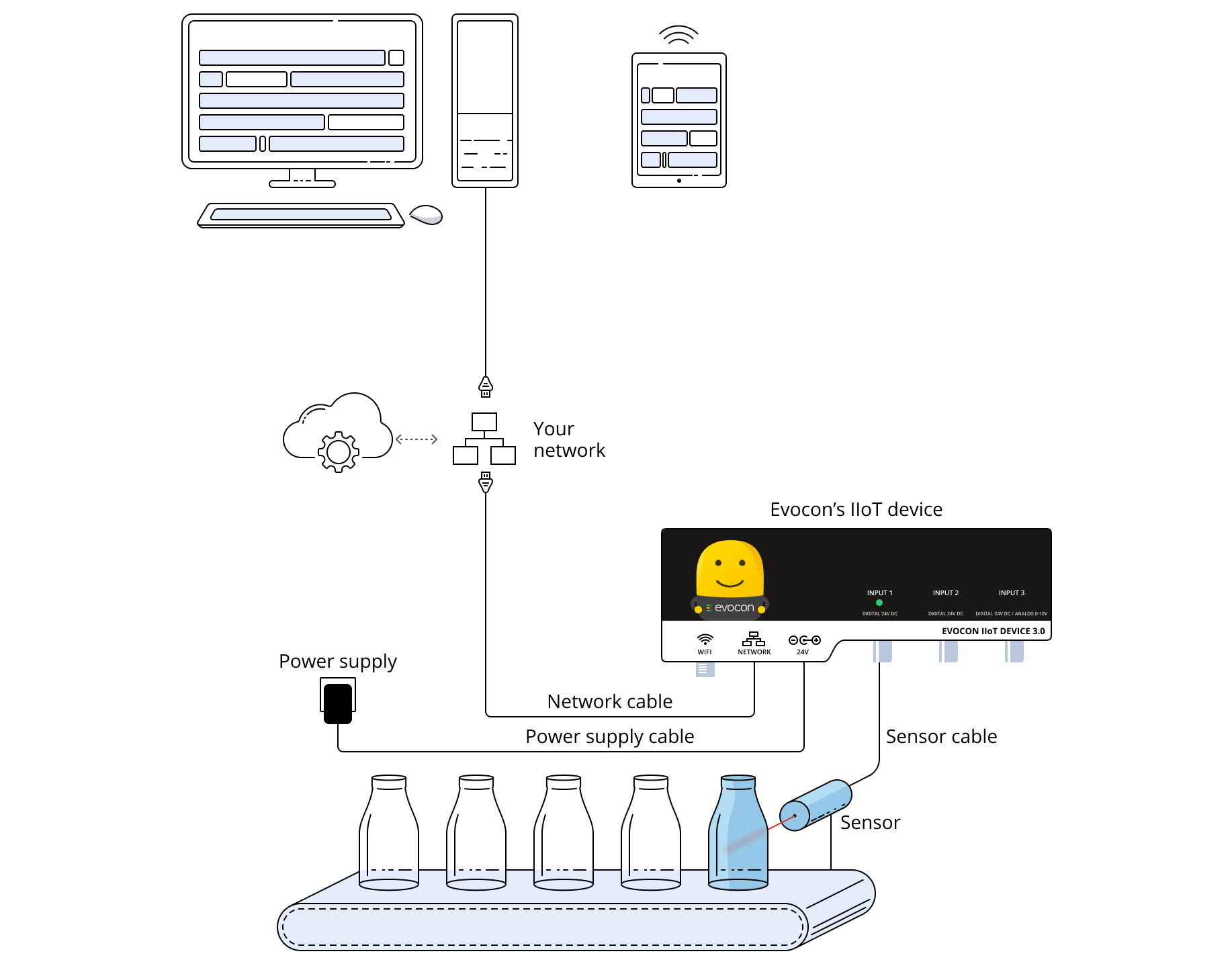

Which Hardware Is Provided by Evocon?

We provide the Evocon’s IIoT device, together with the power supply. You need to have sensors (or other hardware mentioned above) and cables. If requested, we can supply the sensors and necessary connectors and cables at an additional cost.

Below is a picture illustrating Evocon setup, including connection to the network and display devices. For more information, please read our article about setting up Evocon.

Converting the Number of Products into Other Units

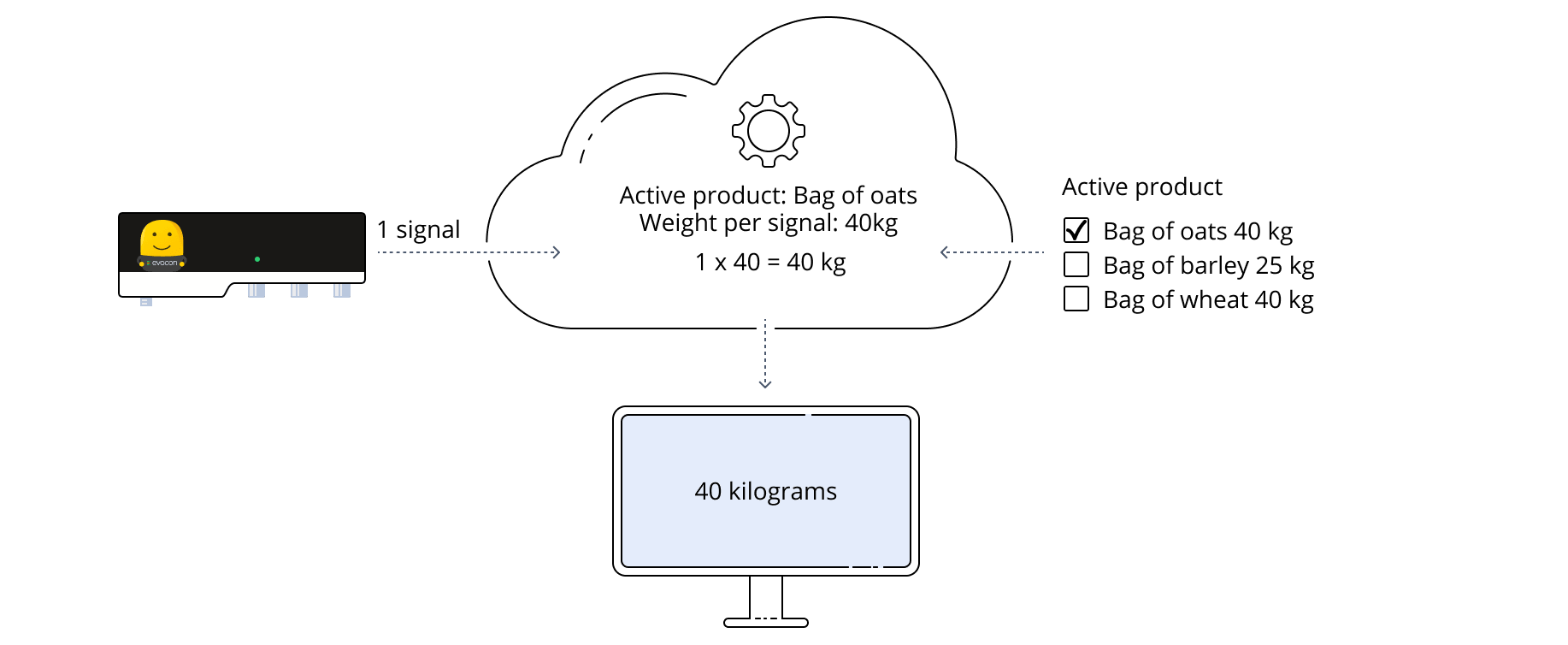

Sometimes, when you count products, you need to see the information displayed in different units, such as kilograms, meters, or any other measuring unit rather than merely the number of products. Our system achieves this by converting signals to other types of information.

For example, if you are packing bags and want to monitor production in weight, you can do so by configuring the system to convert each product into a specified number of your chosen weight units.

You can have many different conversion definitions in the system. When you change from one product to another, a different definition applies. Here is how it works:

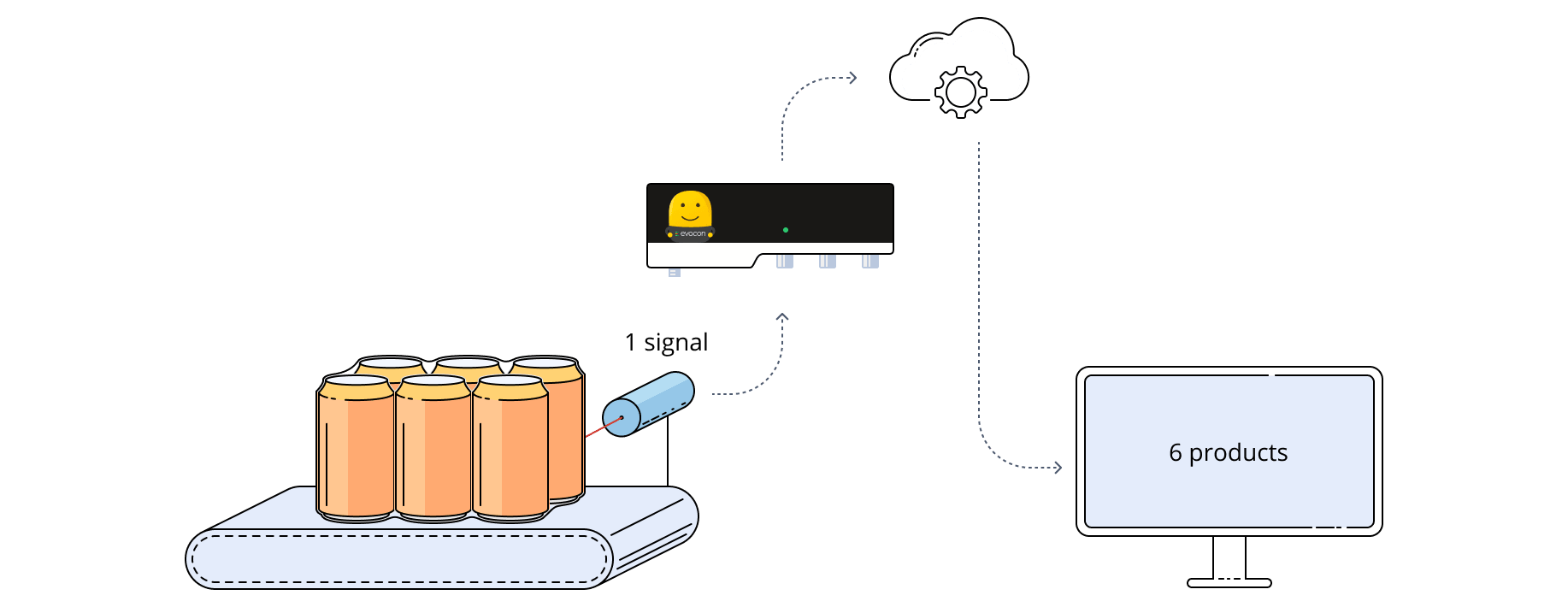

Similarly, it is possible to convert the number of products into a different number, for example, if your sensor registers boxes of products, but you want to see the total number of products in the system.

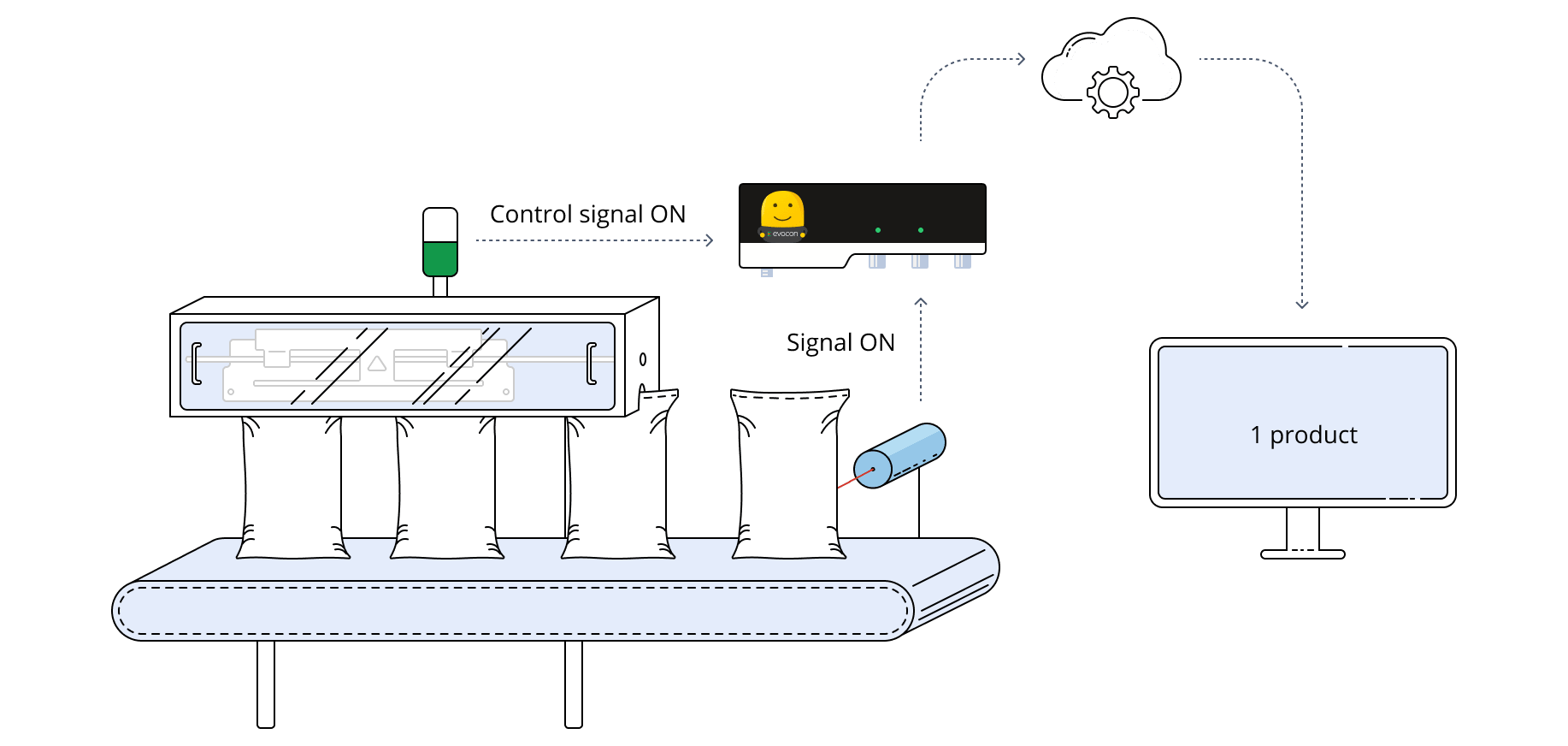

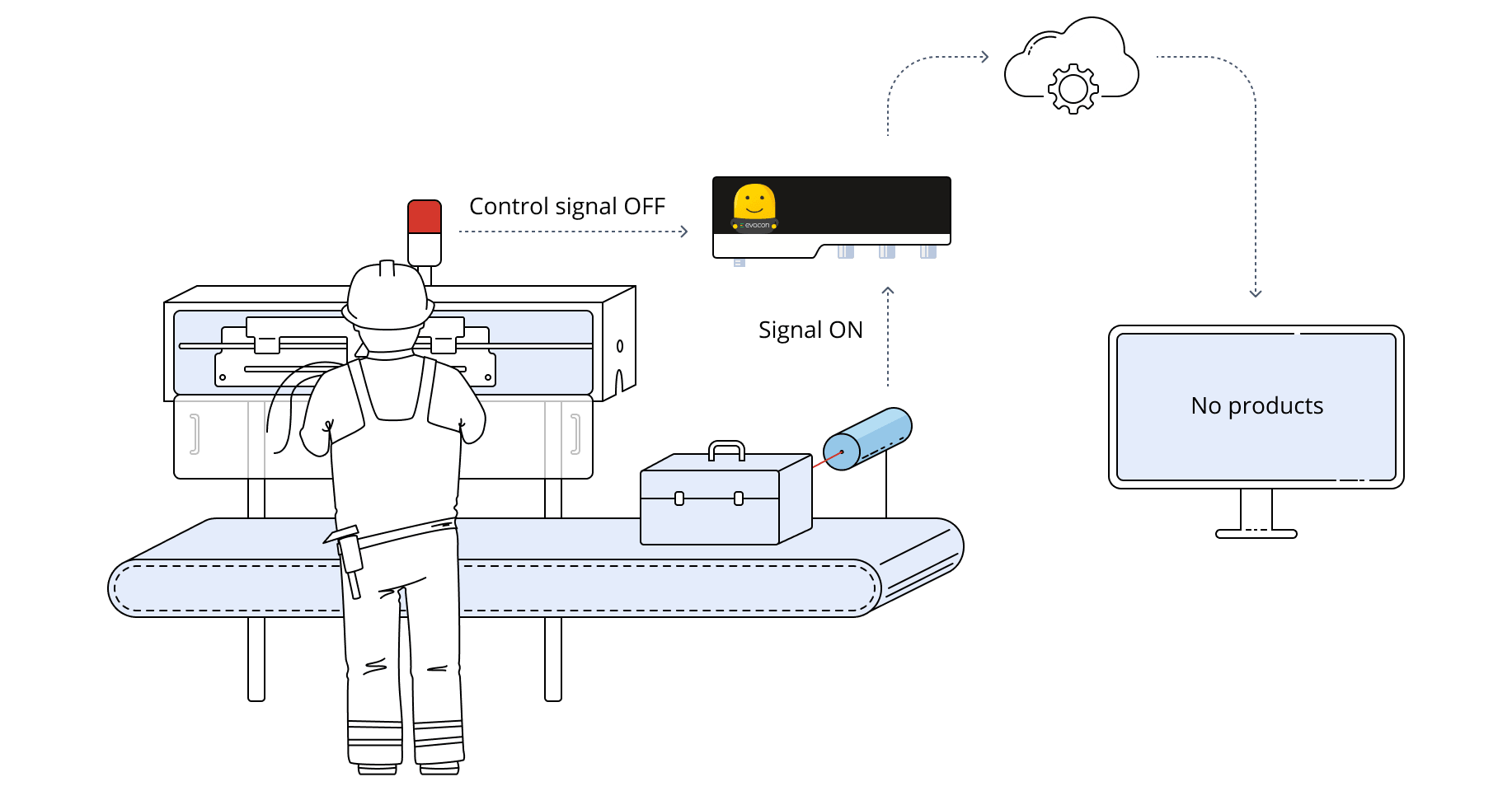

Using a Control Signal to Increase the Reliability of Data

In some situations, it is practical to “verify” the validity of the signal by backing it up with a second signal. For example, you may want to make sure that accidental signals, triggered by the sensor during the maintenance or cleaning process, do not influence your OEE data.

Another example is the extrusion of pipes, in which case we can use multiple control signals from the machine to get accurate production data.

This is how the previous example would work:

Here you can see that the primary signal comes from the sensor and the secondary signal – from the Andon light. When the Andon light is on, the Evocon’s device registers sensor signals as usual. When the Andon light is off, it ignores all signals from the sensor.