The importance of OEE in manufacturing has steadily increased since its introduction with the TPM movement and its widespread adoption as a lean manufacturing tool. Today, OEE is the gold standard KPI for manufacturers in various industries.

What is OEE in Manufacturing

Overall equipment effectiveness (OEE) is all about measuring both efficiency and productivity in manufacturing. It is a combination of metrics that addresses how effectively a manufacturing operation is utilized.

By monitoring OEE, manufacturers can quantify and measure equipment potential and identify sources of loss. Further, with its focus on potential and the sources of loss that prohibit equipment potential from being reached, it has become the de facto approach to identify improvement opportunities.

Ultimately, OEE aims to reduce waste (production losses), thereby lowering cost while also improving productivity. A second-order benefit of using OEE is that it can extend the useful life of equipment through increased awareness and focus on machine health and productivity.

Learn more: What is OEE and how does it work?

OEE as a Lean Manufacturing Metric

Lean manufacturing is all about the relentless elimination of waste. And the thinking behind lean presumes that everything can be continuously removed that is unnecessary. OEE is a great tool to use in this effort because it allows manufacturers to understand and quantify the sources of the six big losses.

Learn more: The Six Big Losses framework

It makes sense then that OEE is a lean manufacturing metric because it is a practical way to monitor and categorize equipment-related losses in manufacturing.

Moreover, it helps manufacturers understand where they should focus their process improvement efforts.

The Application of OEE in Manufacturing Industries

Which industries are best suited to using OEE? As much as we would love to say all of them, OEE has a sweet spot: industries with expensive machines, high output, and a higher degree of automation. Nevertheless, our experience shows that with creative approaches, you can apply OEE as a concept to almost any production process.

It is not surprising then to see that Evocon’s OEE monitoring software has been applied in numerous manufacturing industries. So far, we have clients in 14 different industries, ranging from food and beverages to pharma and metal. The reason for its broad application comes down to its usefulness in maximizing production output and optimizing cost.

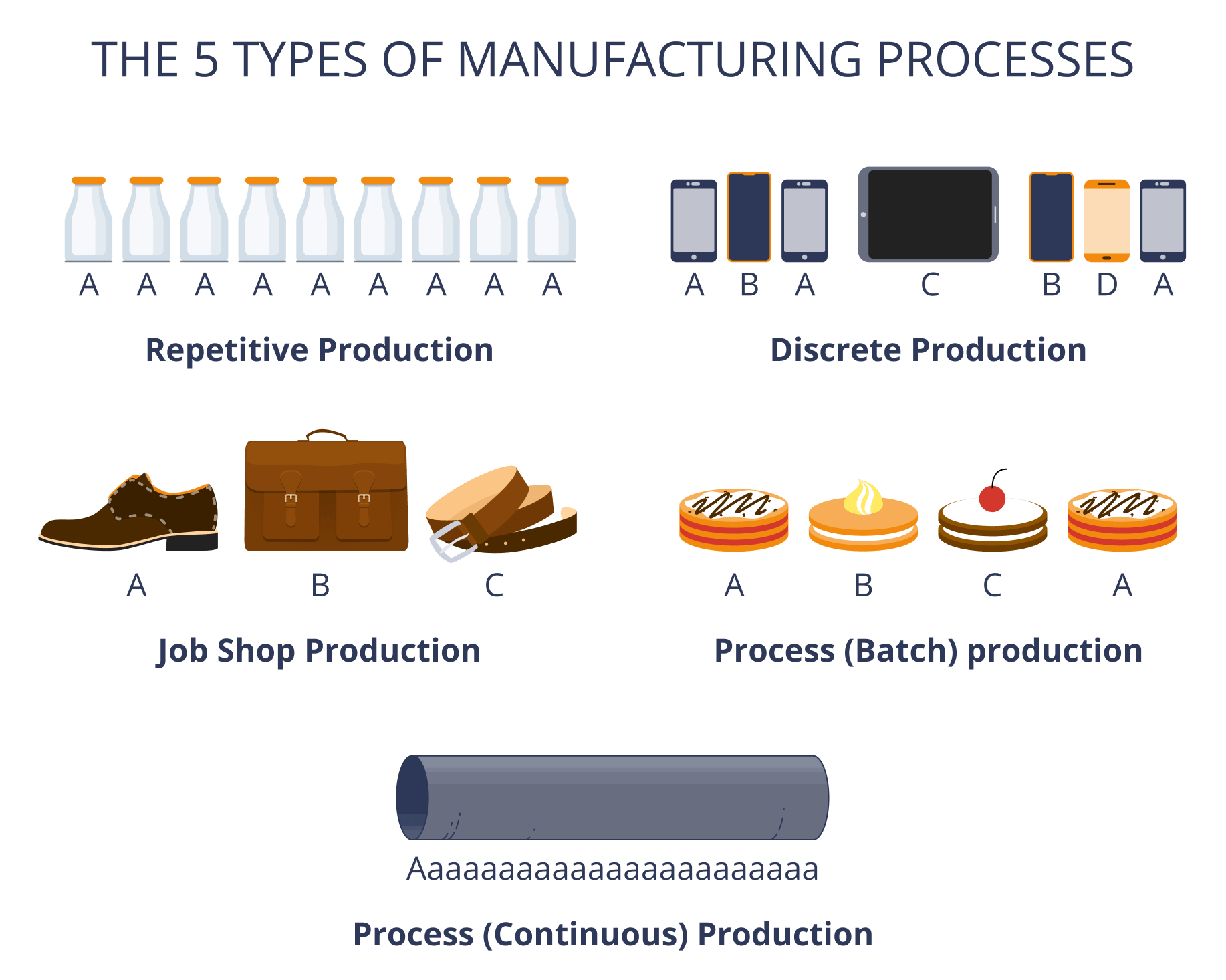

That said, manufacturers with repetitive, discrete and batch production are ideal. That is manufacturers whose output can easily be counted, such as pieces, length, volume, bulk produce, etc.

Industries where OEE is usually more complex to apply are continuous process industries and job shops (i.e., one-off production). An example of the former would be an oil refinery. While it is true that oil refineries have expensive machines, high output, and a high degree of automation, the difference is the use of a continuous production process.

Continuous production does not have easily distinguishable, recognized, touched, and counted units. So calculating OEE requires a more sophisticated solution. At Evocon, we have the experience, for example, measuring liquid nitrogen and extrusion of pipes.

Learn more: How to Monitor Production and Track OEE Using Evocon?

Real-time OEE Software

Monitor production in real-time and boost efficiency with Evocon’s 30 day free trial.

Why Use an OEE System in Manufacturing

Manufacturers should use an OEE system to take advantage of automated data collection and production efficiency tracking. Without this degree of automation, manufacturers are left with pen and paper or excel, both of which present similar problems:

- Production downtime, breakdowns, or smaller issues might not be noticed, and if they are, they could be deemed irrelevant and not reported.

- Manual data collection is time-consuming, not value-added from a lean perspective, and has more opportunities for human error.

- Unable to monitor, visualize, and react in real-time to production.

The cumulative effect is that the collected data is inconsistent, ineffective, incomplete, and inaccurate.

By utilizing an OEE system, manufacturers minimize the role of people in data collection, enhance information accuracy, and reduce cost by freeing workers from the collection task.

Furthermore, it allows us to easily track and verify whether the continuous improvement efforts have a positive effect or not. As well as apply it in ROI analysis.

Example: OEE in Food Manufacturing

HKScan is a publicly listed food company with over one hundred years of experience in responsible Nordic food production for customer and consumer needs.

In 2017, this large food manufacturer began working with Evocon when they needed to:

- Understand and visualize the current state of production

- Identify reasons for waste

- Find ways to improve their processes

- Maximize machine utilization

The key challenges HKScan faced in maximizing machine utilization were:

- A lack of transparency in the production process

- An inability to answer questions in the actual use of planned production time

- Typical problems of paper-based production monitoring (as previously discussed above)

Today, HKScan benefits from:

- A tablet or pc at every packaging machine to visualize production and give live feedback to operators

- Granular visibility and understanding of the entire production process

- Weekly production downtime meetings based on meaningful data

- Empowered operators utilizing an easy system of registering issues

These benefits have allowed them to improve OEE by 20% in 6 months and is an excellent example of what other manufacturers can expect when they apply OEE in their food manufacturing process.

Learn more: How HKScan Uses Evocon to Maximize Machine Utilization

Do you know if your machines are running at full potential?

Summary

OEE finds use in various industries, such as food, metal, pharmaceutical, and plastic manufacturing. This is due to OEE’s usefulness as a universal KPI and as a lean tool to eliminate waste through continuous improvement of the production process.

Manufacturers who implement an OEE system position themselves to maximize its benefits by automating data collection and reporting.