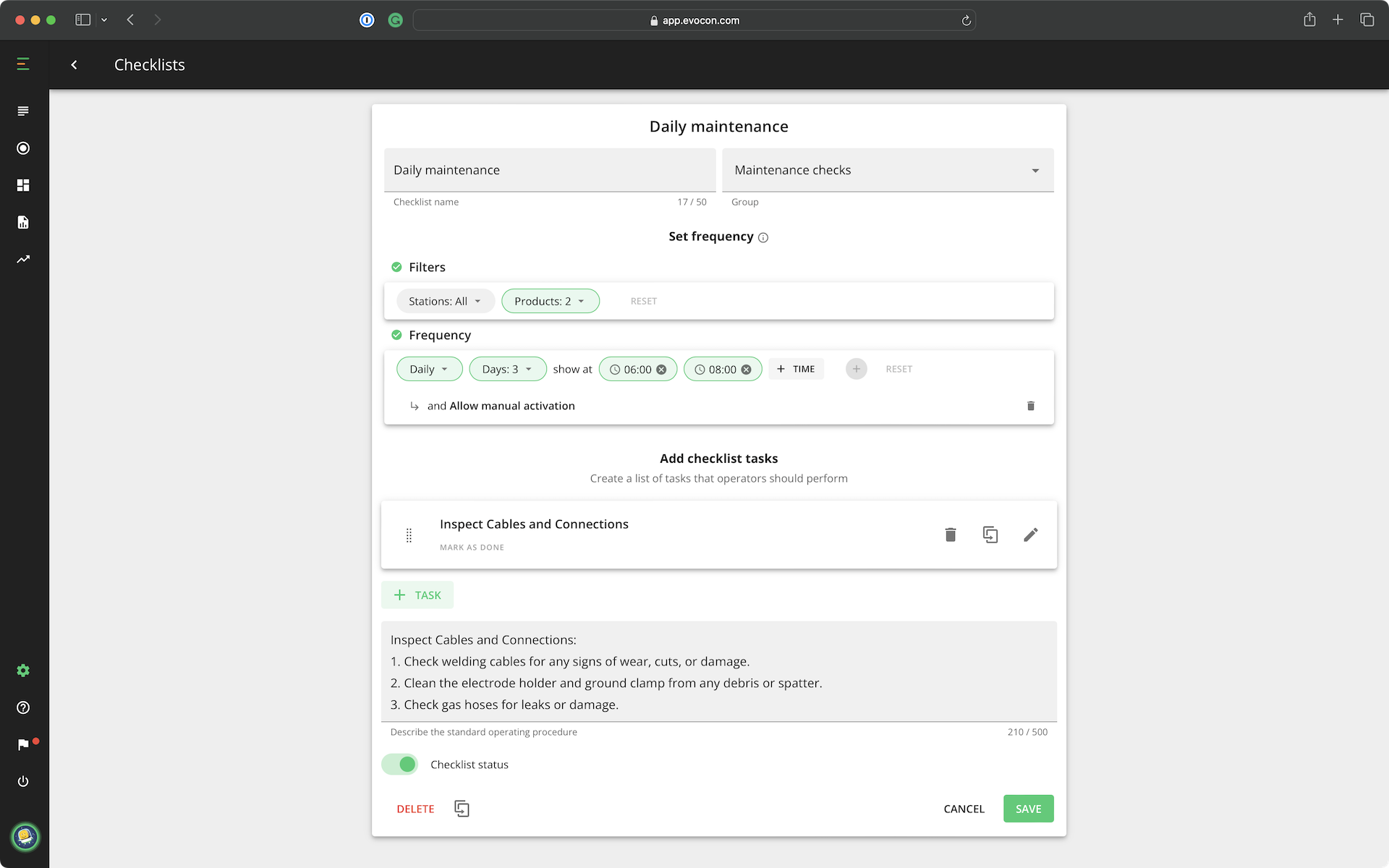

Elevate operations by digitizing and automating checklists

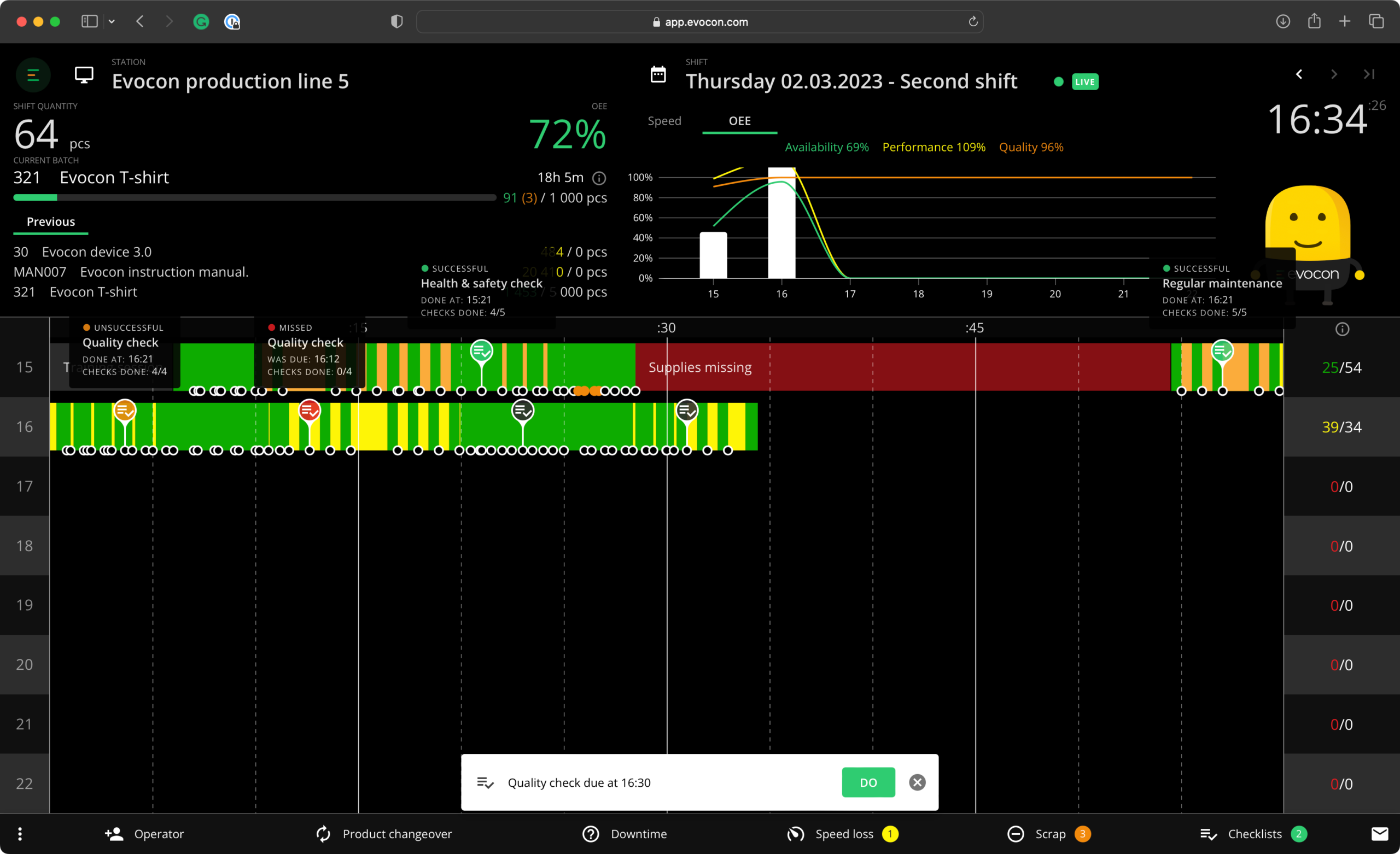

Checklists digitize and automate your recurring production checks. By using real-time machine data, operators can perform the right tasks at the right time—boosting efficiency and quality across the board.

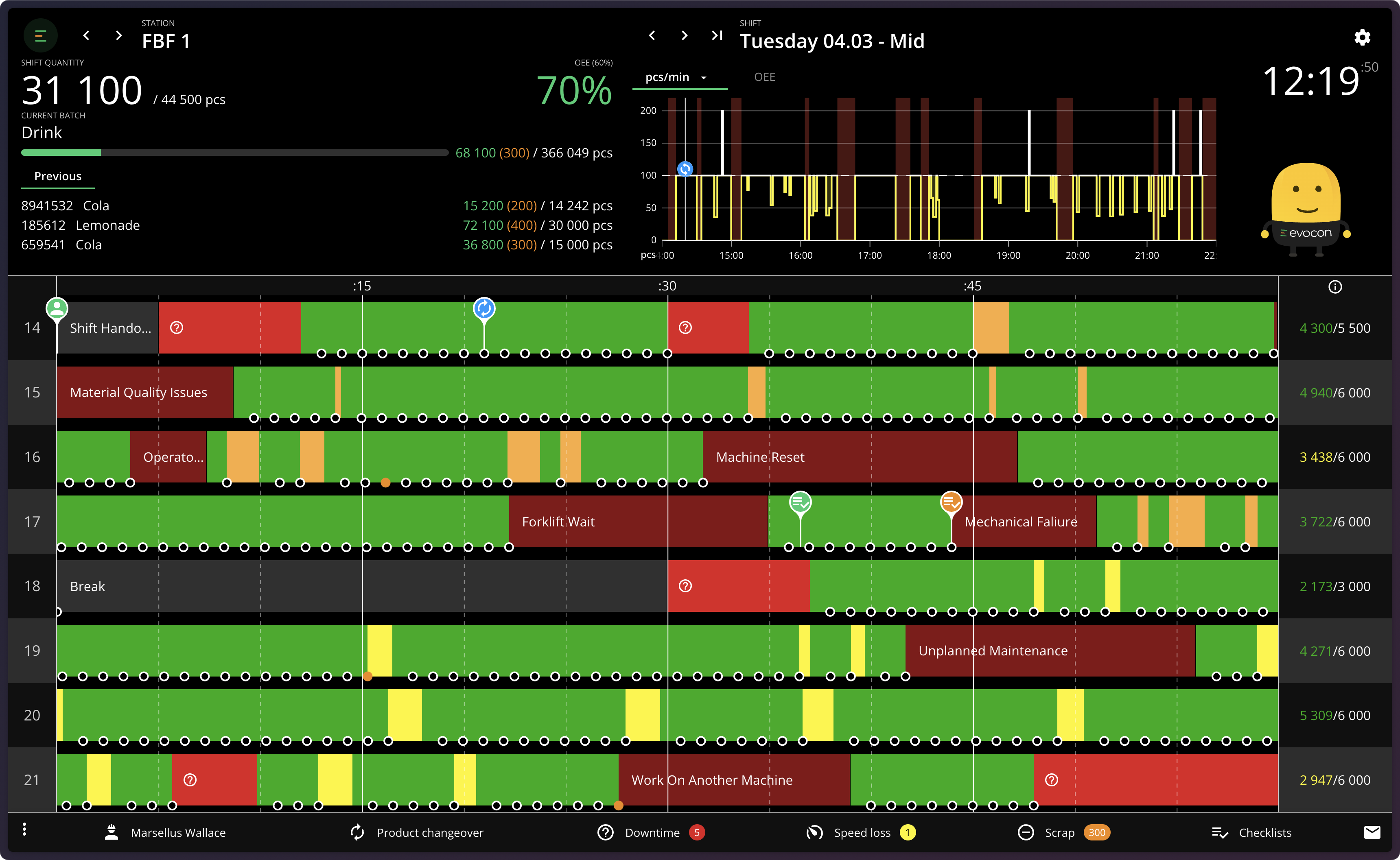

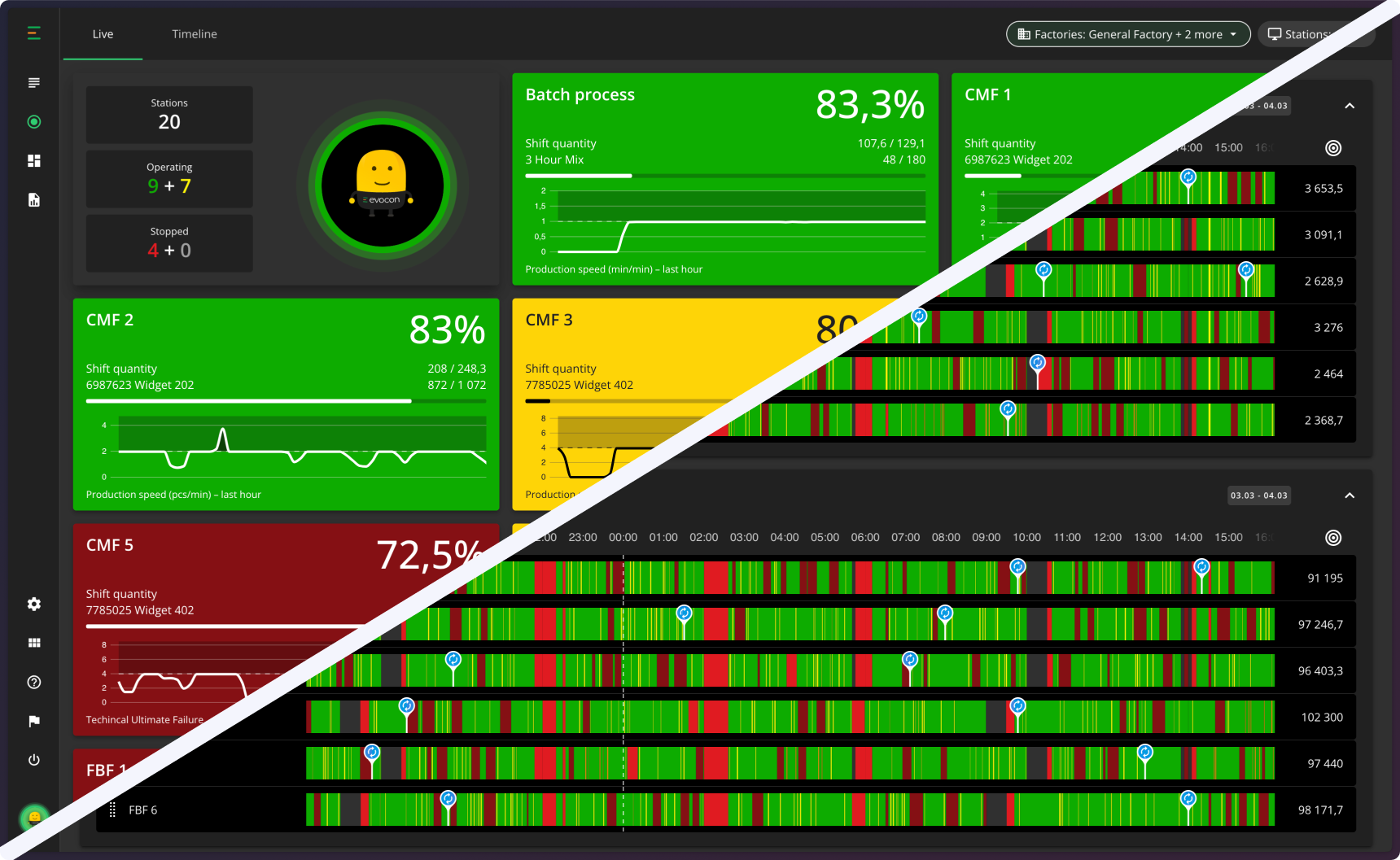

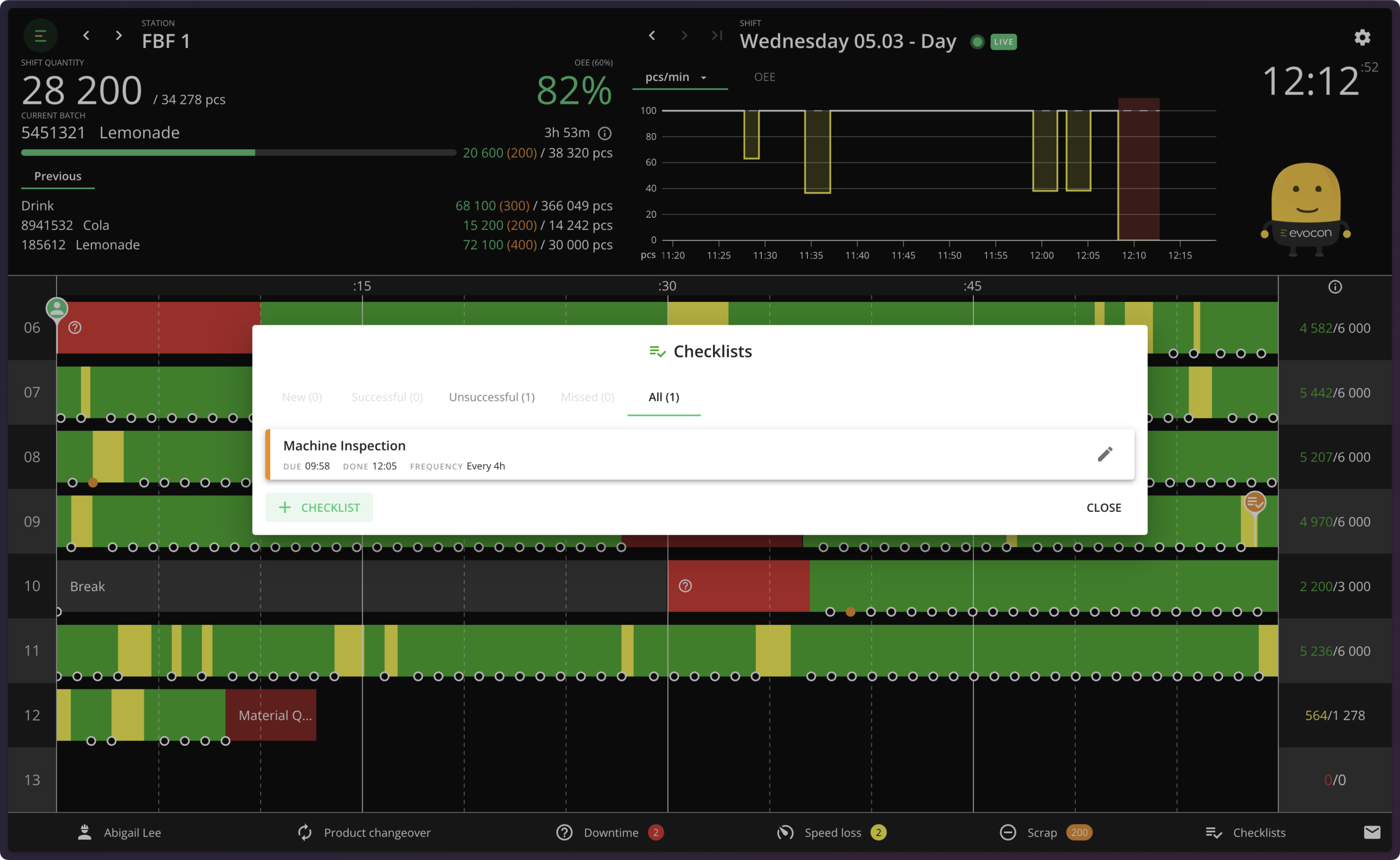

Visibility into all checks

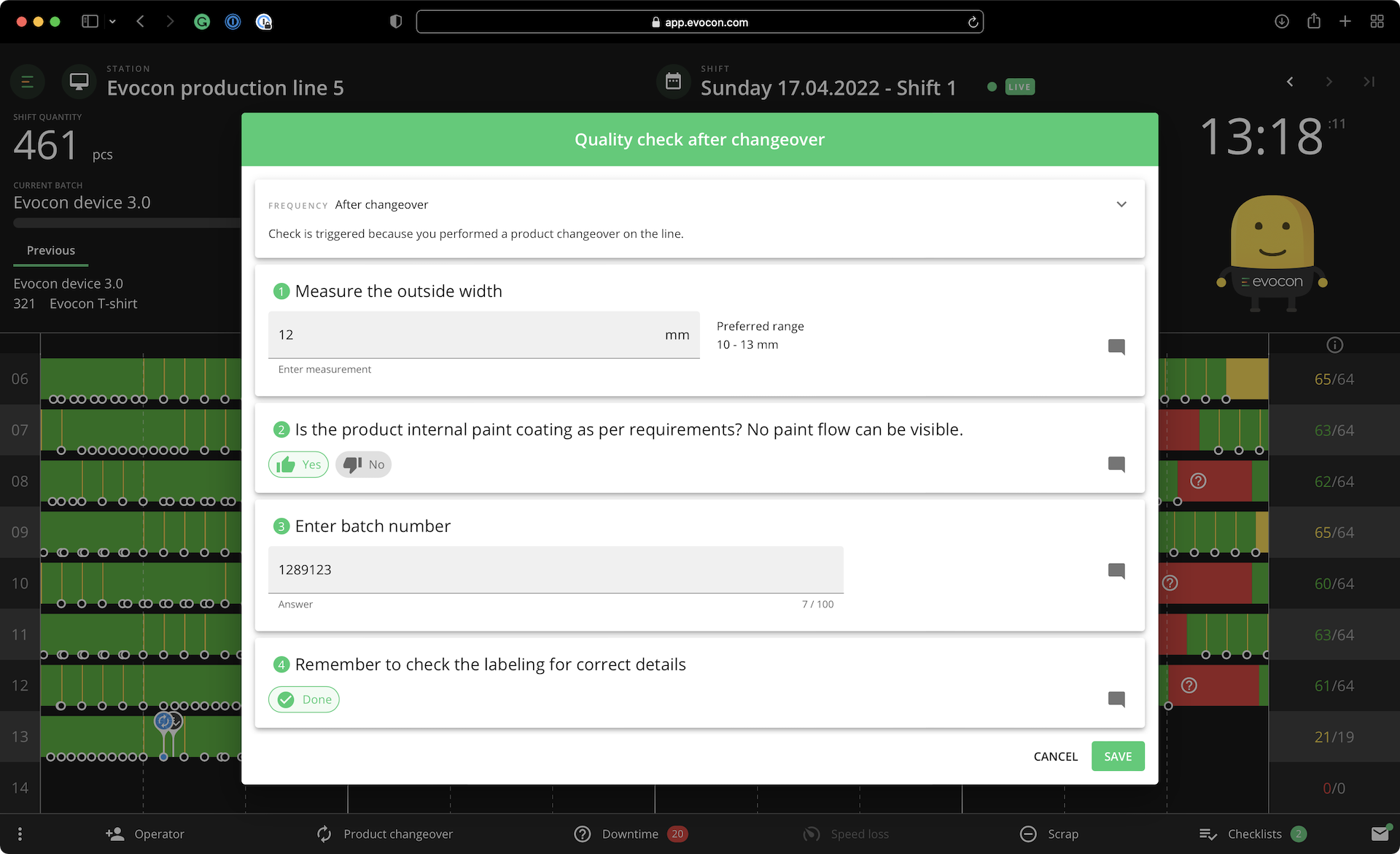

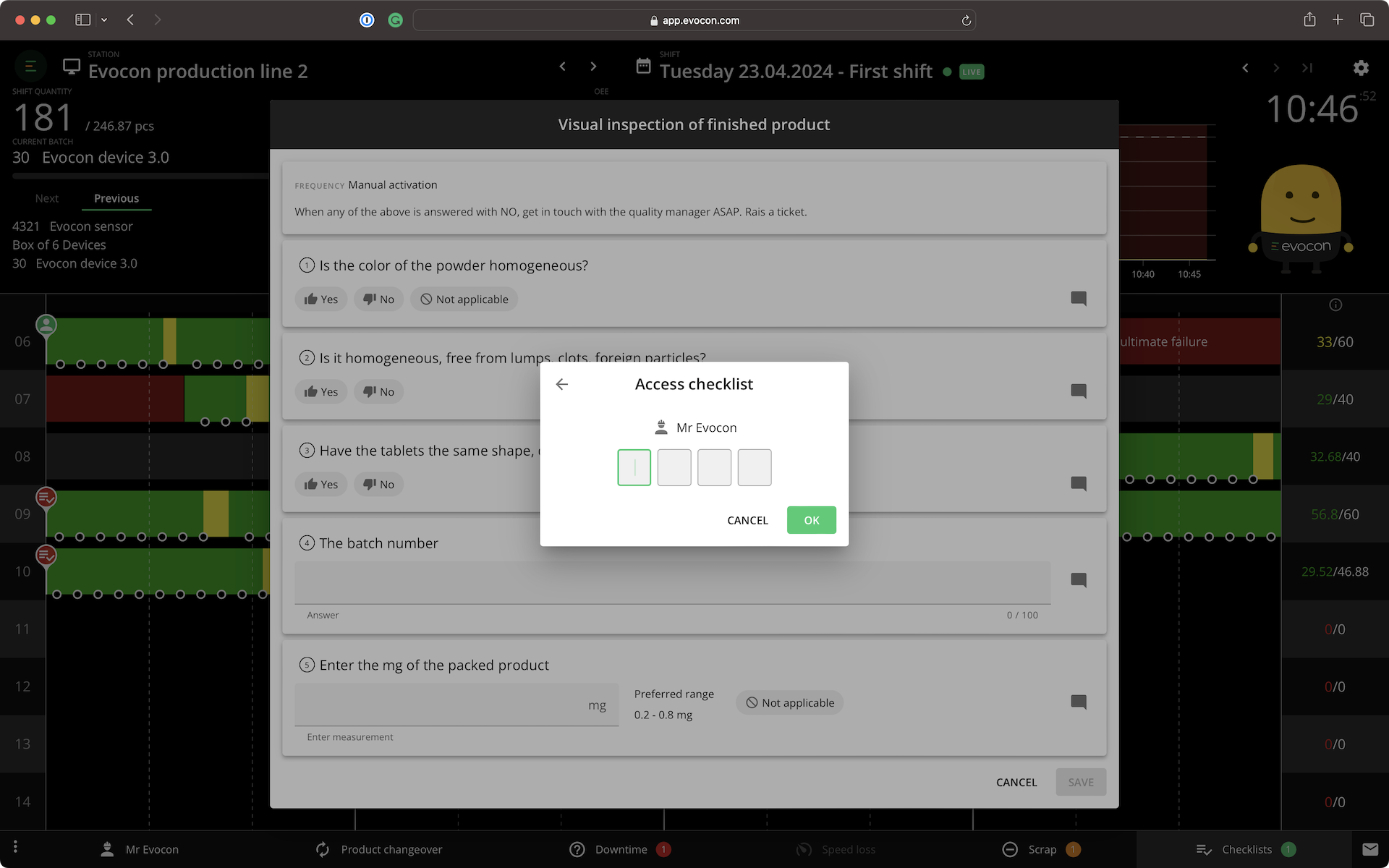

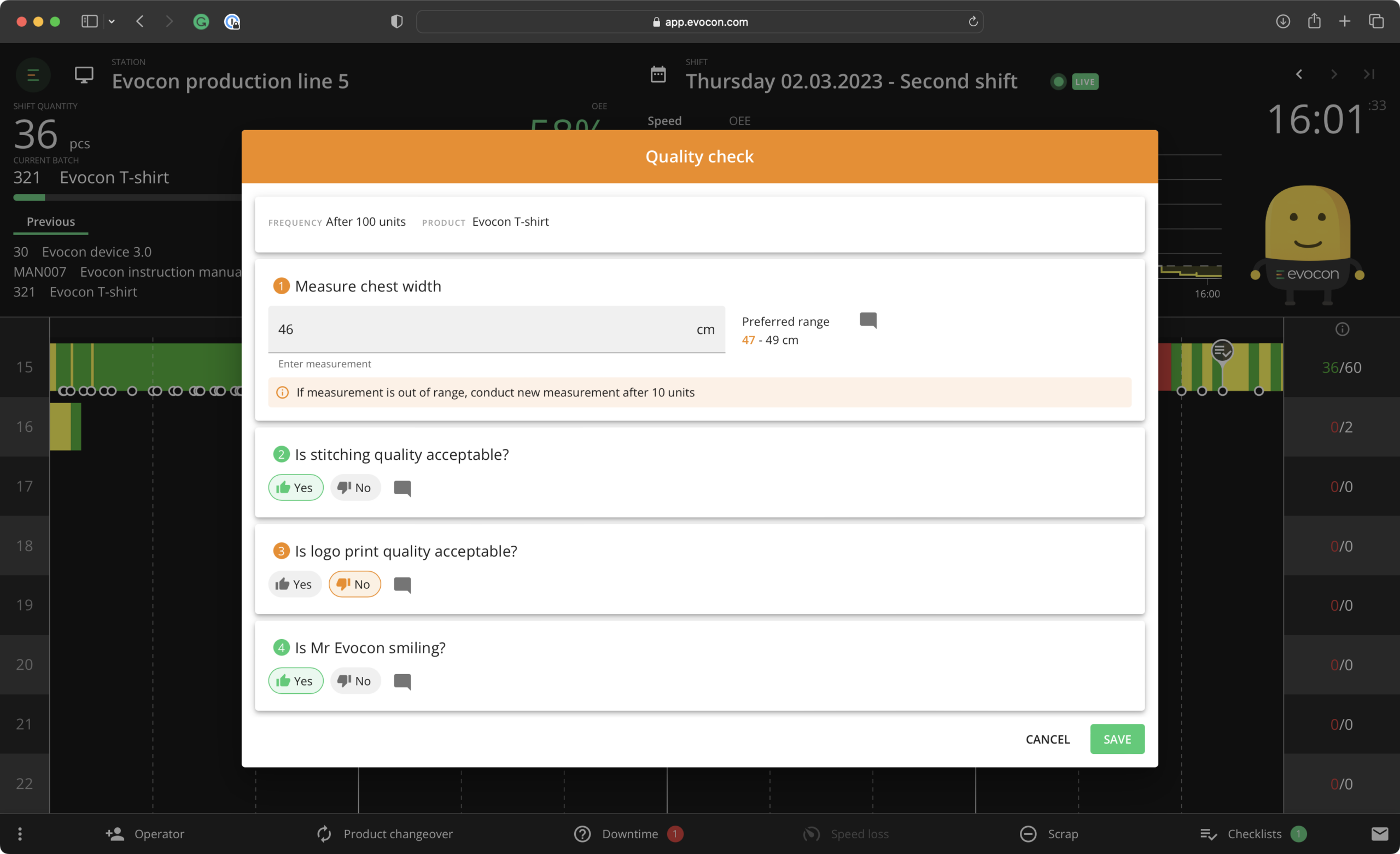

Data-based inspection criteria

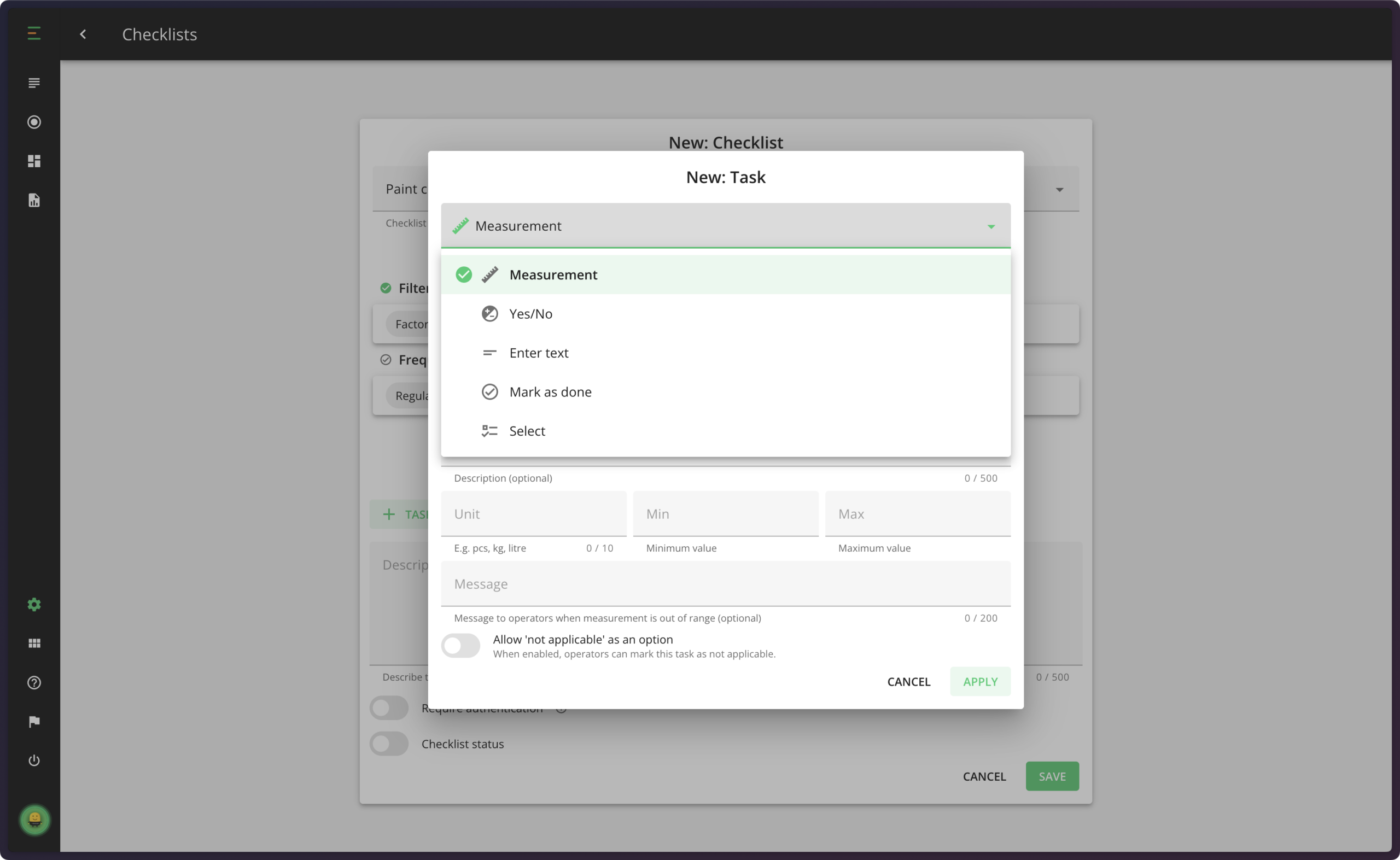

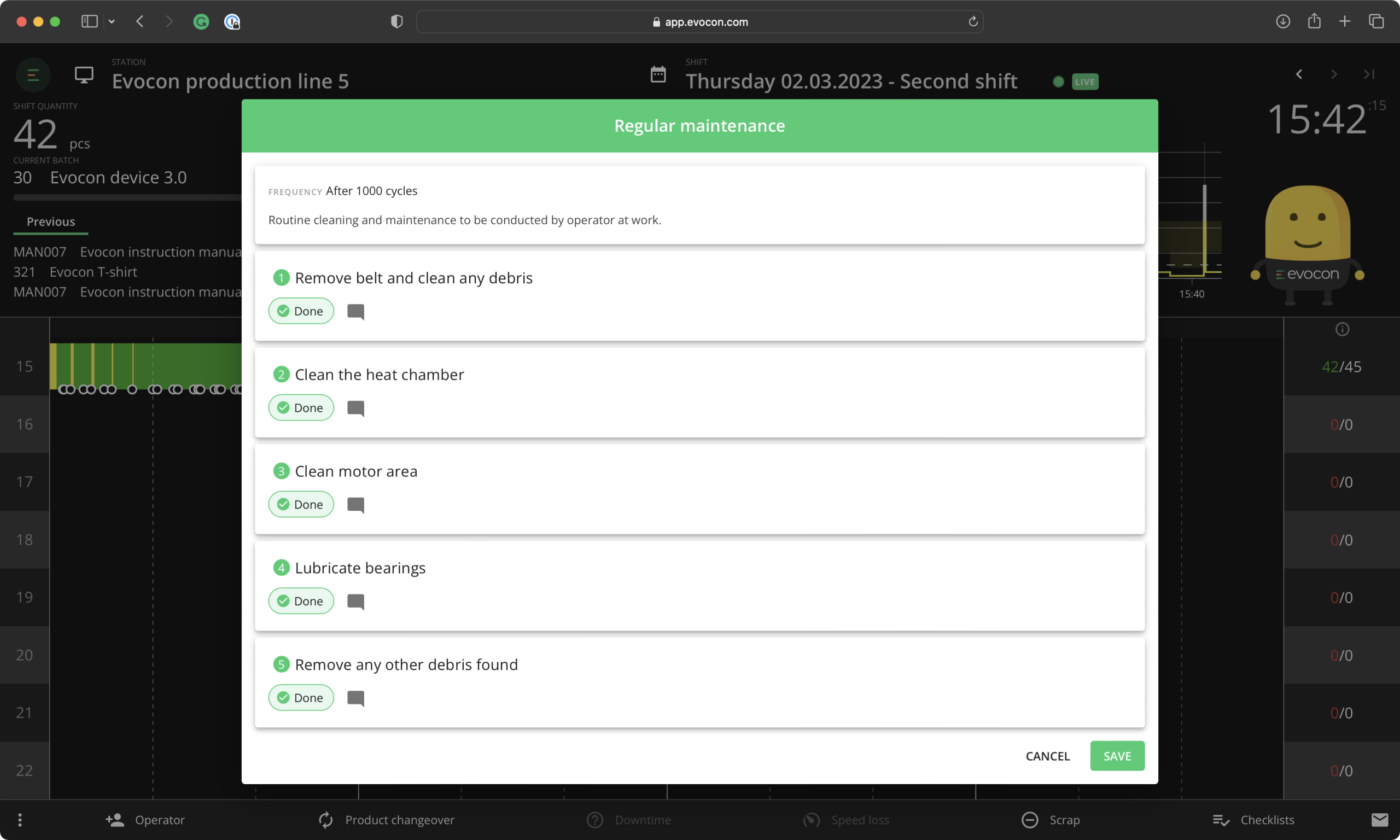

Different types of checks

Get alerted when needed

Ensure accountability with authentication

Improve production quality

Automate maintenance checks

How to start using Checklists?

To start using checklists, upgrade to Professional or Enterprise plan. Check Pricing

"Checklists have changed our company’s culture for the better. Operators want to ensure that all checks are done on time and according to expectations. As a result, decisions are made faster if adjustments to the machines are needed, and we have reduced the number of scrapped products by 20%."

Sebastián Cardona Gómez

Improvement Manager

Chala S.A.S