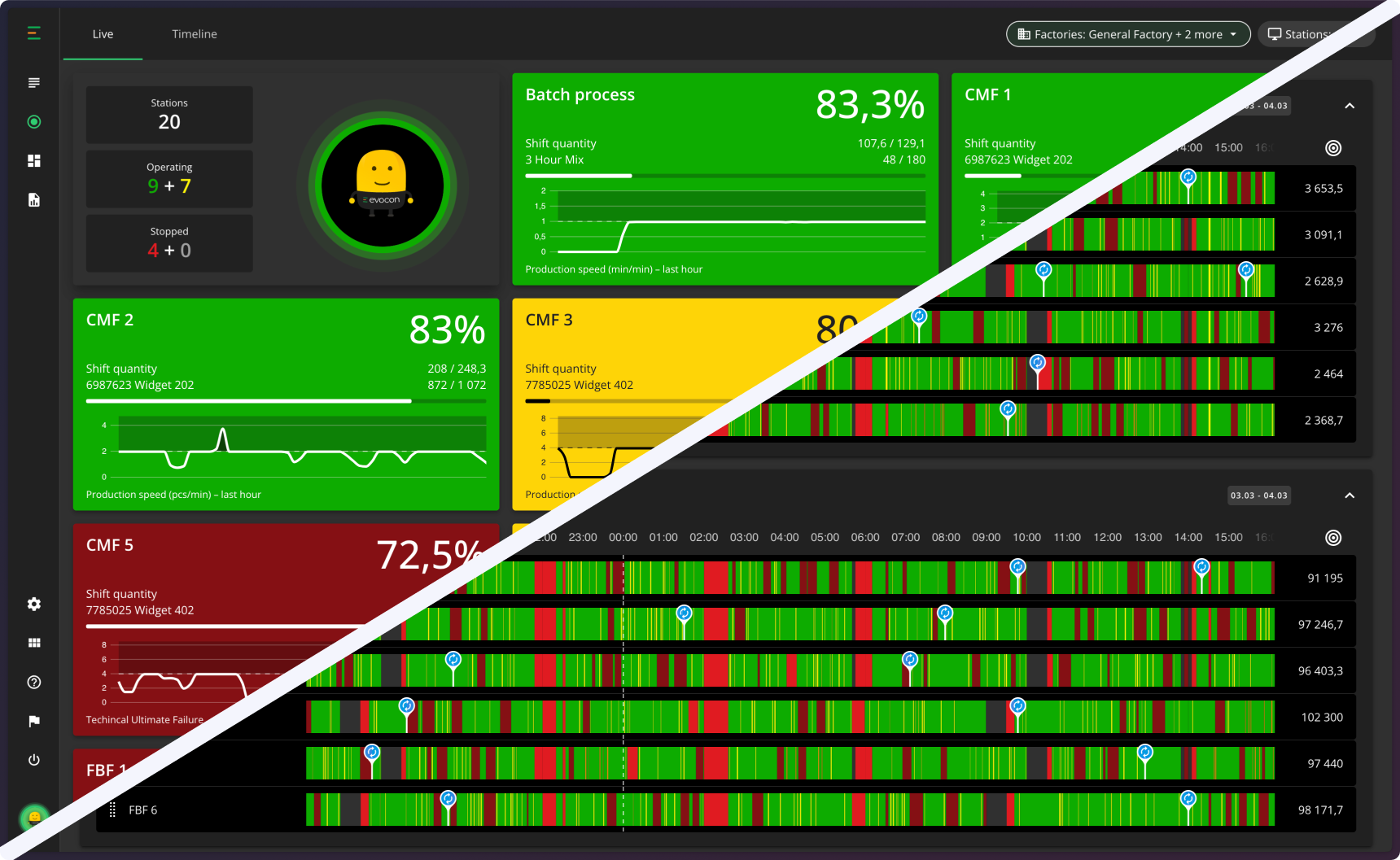

Monitor the performance of shifts in real-time

Shift View helps you, in real-time, track and analyze the performance of all your production shifts across different dates, stations, factories, and countries. No more gut feelings, guesses, or finger-pointing.

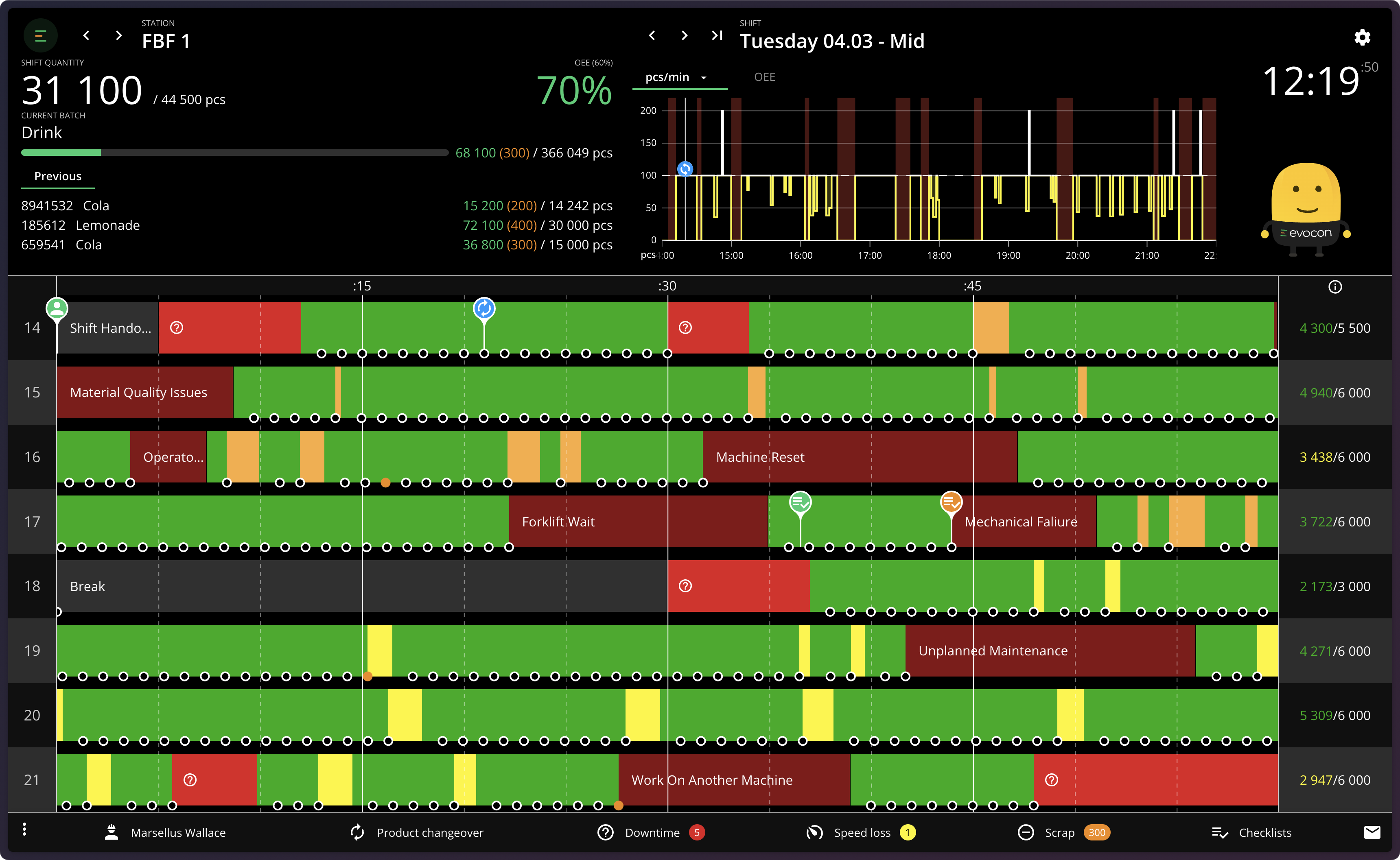

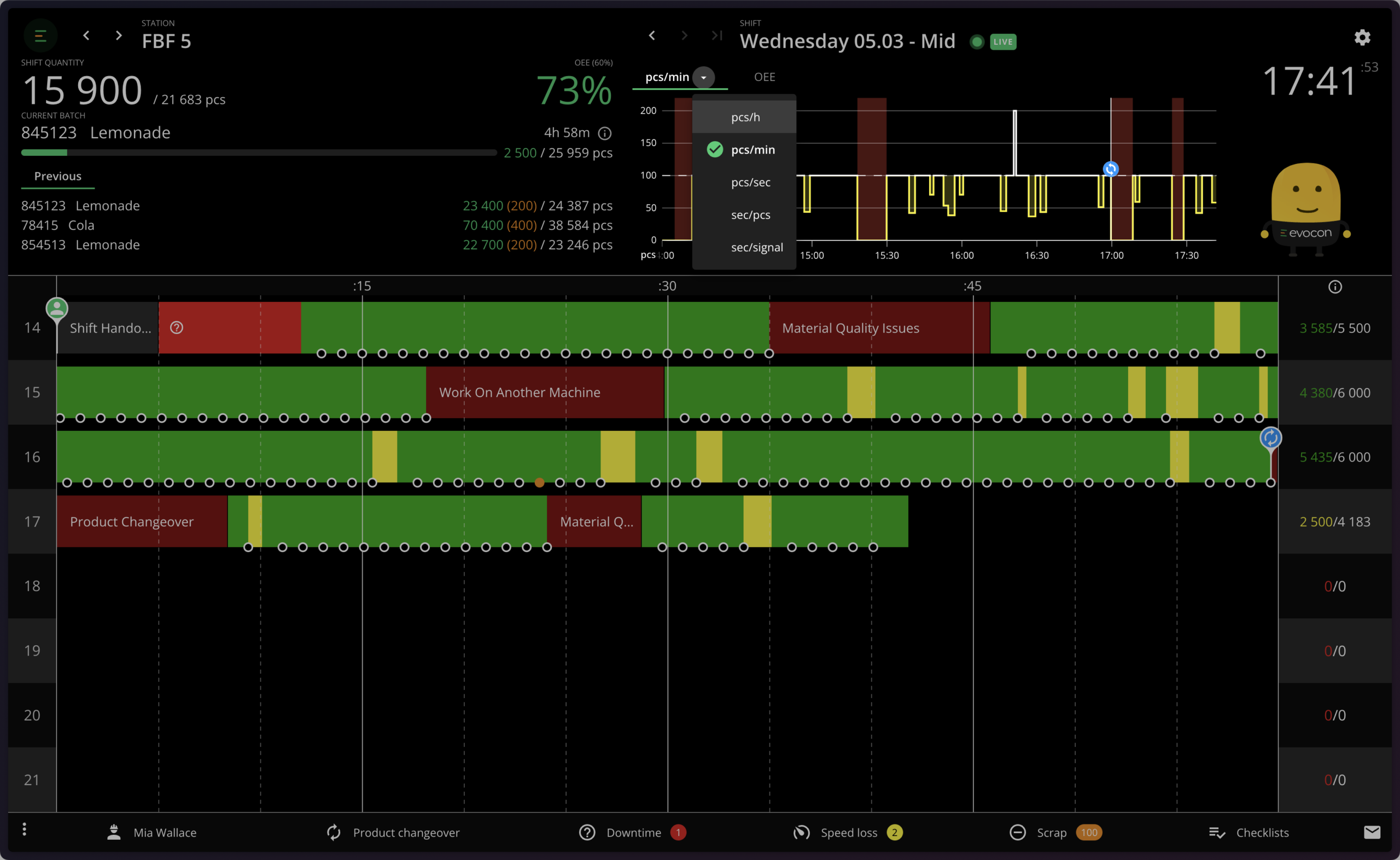

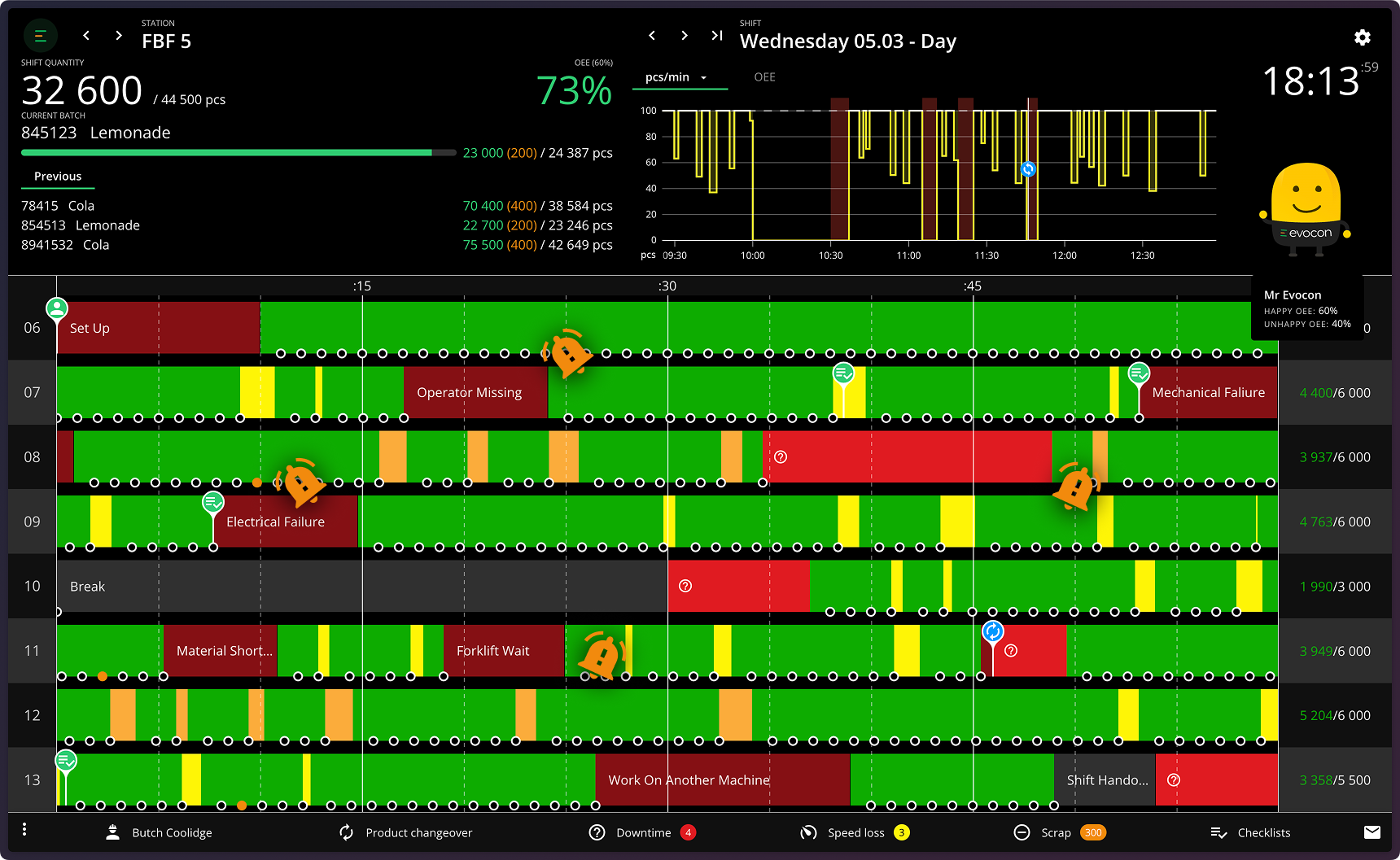

Visual production timeline

With Shift View, performance is visualized hourly in an easy-to-understand way, allowing operators to get real-time feedback about their work.

Green = all is good; yellow = speed loss; red = unplanned downtime; gray = planned downtime.

Data collection made easy

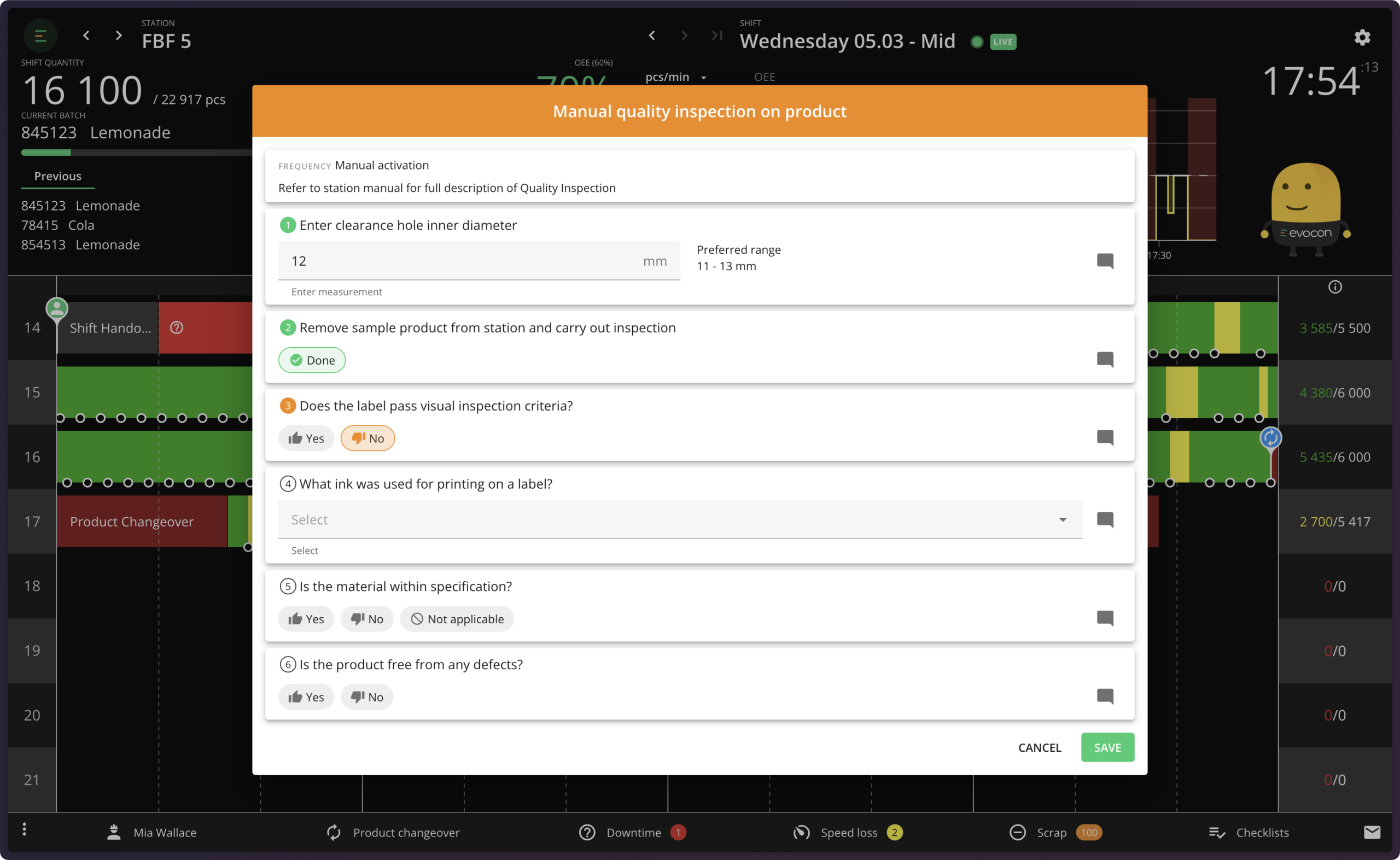

Shift View won’t tie up your operators’ time with data collection. It’s user-friendly at its core, needing very little training.

Most operations can be completed with a few clicks, allowing shift operators to focus on their main work – keeping machines running.

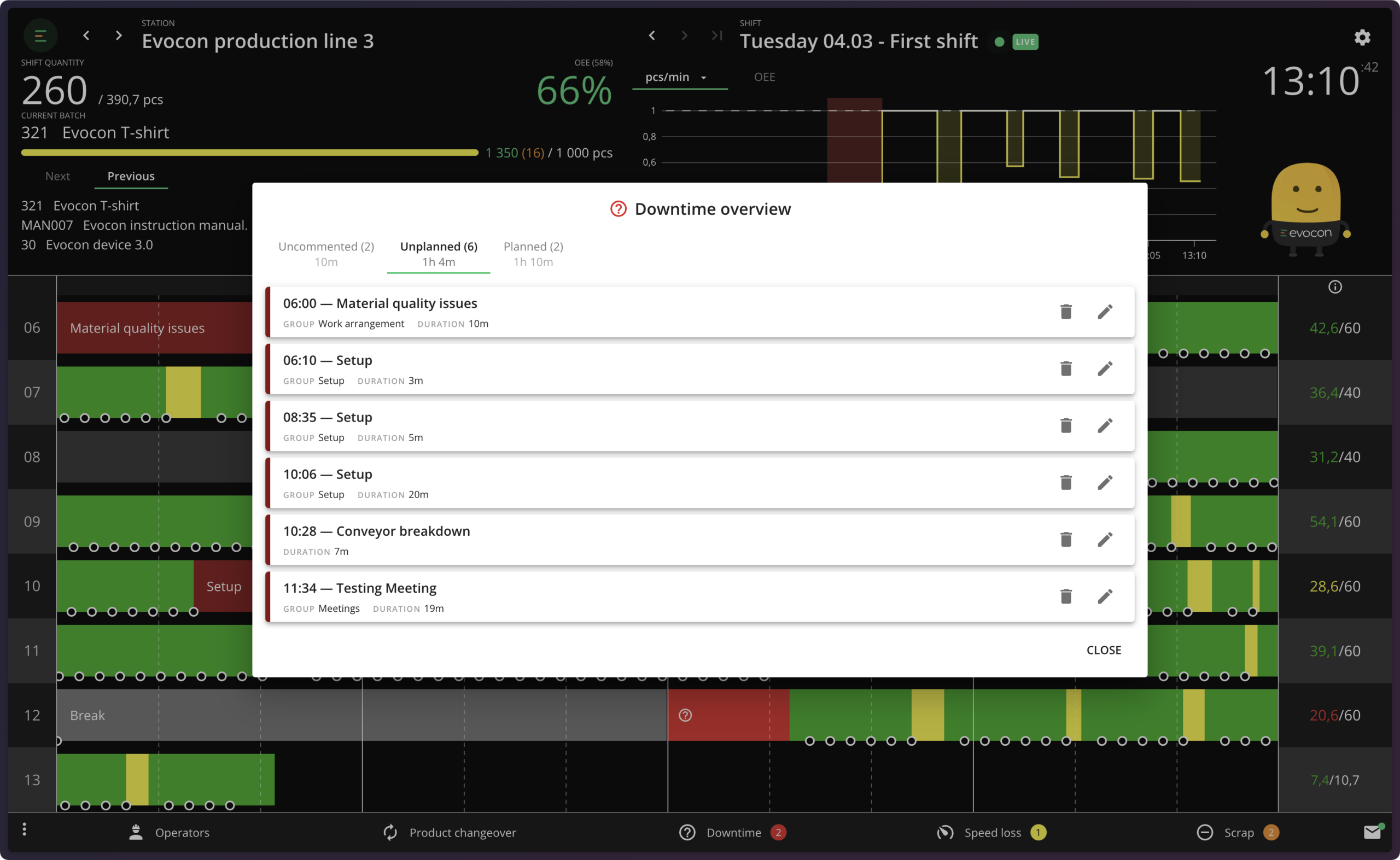

Downtime, speed loss, and quality

Shift View gives a detailed overview of all OEE losses and events. All operators have to do is map reasons to events with a few clicks, giving you the understanding of which issues are most relevant and where to focus your attention.

Insight into production speed & targets

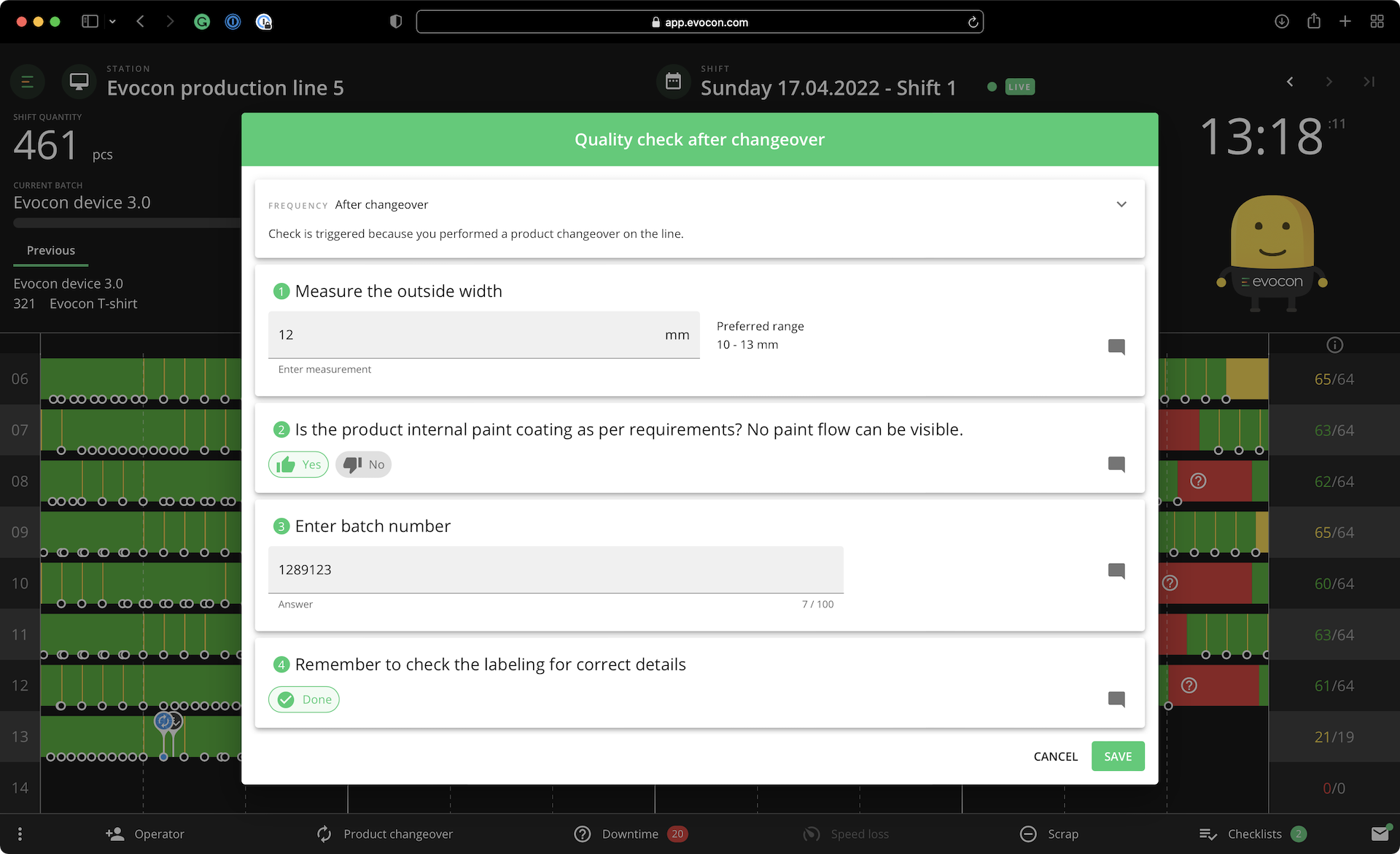

Complete recurring checks

Shift View also comes empowered with our Checklists feature, which triggers relevant recurring quality, maintenance, and other checks at the right time to ensure your operation keeps running smoothly.

Alerts when things go wrong

With alerts, when unplanned events happen or quality checks fail, you can ensure that the right people are notified and that actions are taken promptly to restore your operations to normal.

Improve operational discipline

By implementing Shift View on the shop floor, you empower operators with real-time production data and the ability to report on actual issues in production, improving operational discipline and enhancing employee involvement.

"Evocon as a real-time OEE tool has engaged the whole shop-floor working with the losses, resulting in faster solving of problems and improved quality of waste elimination projects."

Aivar Künnapuu

VP Operations, Sales & Marketing

Yara International ASA

Features that support improving shift performance

-

Downtime, speed loss and quality tracking

-

Performance of current and historical shifts

-

Hour-by-hour OEE information

-

Real-time production speed overview

-

Hourly production quantities

-

Information on current and previous production batches

-

Standardised list of loss reasons

-

Language selection for operators

-

Quality and maintenance checklists

-

Integration with ERP system

-

Auto-commenting of scheduled stops

-

Messaging possibility with operators