Automated and real-time production monitoring enhances productivity and efficiency. And when done with the right tools, production monitoring can transform an entire manufacturing company. It helps reduce costs, find opportunities for improvement and aid in achieving goals.

The benefits you can expect from Evocon’s OEE software extend to the whole company, regardless of the size, industry, or production process.

How Does Evocon’s OEE Software Solution Benefit the Whole Company?

This article reviews ten of the most significant benefits that Evocon provides. We chose these benefits based on reviews on Capterra given to Evocon by our clients. The overview of the benefits and quotes from our clients will help you better understand what to expect when you start to monitor your production and OEE. We also invite you to read these reviews on Capterra so you can hear directly from our end-users themselves in their own words.

1. Remove unnecessary paperwork

Today, Evocon clients in 14 industries use our production monitoring and OEE software to free employees from unnecessary paperwork.

We use our IIoT device to collect all relevant information from production by utilizing sensors, PLC outputs, and HTTPS requests. We then securely store the data on Amazon AWS servers so that you can access it anywhere and anytime.

Learn more: How to Monitor Production and Track OEE Using Evocon?

As a result, you no longer need to enter the collected data into Excel, saving your workforce countless work hours that you can use more productively. More importantly, you free your people from the burden of manual data collection and let them do value-added tasks. Furthermore, it means you no longer have to worry about data accuracy.

Learn more: How Production Data Visualisation Drives Engagement & Productivity

Tip: Read HKScan’s case study to learn about the benefits of data automation and removing unnecessary paperwork.

2. Automate your production reports

Reports are an essential way of understanding the effectiveness of your production process and the impact your efforts have on improving the process. You must keep track of OEE, downtime, performance, quality, and more.

All this data can quickly become a burden for any team. Having to track, aggregate, put together, and present different KPIs each week and month, manually, really is a waste of time.

“It is good to have in real-time, wherever you are, the production output and reasons of stoppages and losing of speed on the production line. Not to mention the use of the reports, that are easily linked with our reporting system.”

That’s why automating your production reports with Evocon is a significant benefit, because it helps you:

- Save time and save money.

- Get data that you haven’t been able to get before.

- Increase the reliability and accuracy of your reports.

- Visualize your production data in an easy-to-understand way.

- Utilize the potential of your staff by freeing up their time.

Automated Production Reports

Get the tools to automate your production reports and improve factory performance. Free for 30 days.

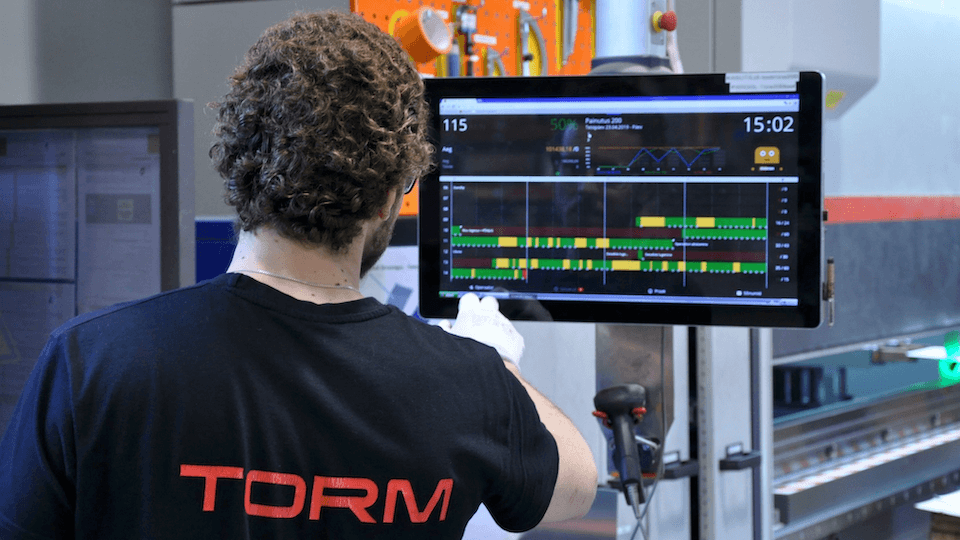

3. Give visual feedback to machine operators

The only way to get reliable data about the production process is to make OEE usable for machine operators on the shop floor. The key to achieving this is by giving them a tool that is easy to use and highly visual.

“We are using Evocon to get better data from operators, why machines are not working. Right now, it does its job perfectly. Office and operators get more visual feedback, how the shift went, was it good or bad.“

Visual feedback matters because it drastically improves our ability to work with and understand complex data. Not only can we comprehend the information faster, but relationships are easier to identify.

Learn more: Production Data Visualisation Drives Engagement & Productivity

Making production data actionable to operators helps them understand how their performance affects the overall progress of the shift. Moreover, they will learn to understand what they can do to improve.

By having visibility into your production process, your company can seek a way forward based on what the data says — increasing productivity and removing waste along the way.

“Evocon as a real-time OEE tool, has engaged the whole shop-floor working with the losses, resulting in faster solving of problems and improved quality of waste elimination projects.”

Learn more: How do Machine Operators Benefit from Evocon?

4. Track and understand machine downtime

Most manufacturers start optimizing their production by looking for ways to eliminate unnecessary and unplanned machine downtime. To do this, you first need to clearly understand how much downtime you have and the reasons that are causing it. Then you can review this information and work on implementing solutions.

“Evocon allows us to track all our downtime, so we can go back as a management team and see where we can improve.”

By automating machine downtime tracking and making it easy for operators to register downtime reasons (a few clicks from a predefined list of breakdown reasons), Evocon provides you with the data you need to understand which issues are most relevant and where to focus your attention.

“By starting to use Evocon, we saw what our real problems are. And now it is easier to deal with problems that really need to be solved.”

Analyzing and understanding collected production data can open up new possibilities and resources for your company that previously might have been completely overlooked.

Learn more: Downtime Tracking and Analysis – Find Out What’s Really Happening on the Shop Floor

Downtime Tracking Software

Start measuring and optimising your downtime with Evocon’s 30 day free trial.

5. Get insight into real-time production performance

Understanding how your production process is performing against expectations, what is the estimated time to complete an order, and how much time is lost due to micro stops and slow cycles, helps empower you and your team with an ability to plan your resources more effectively.

“It is good to have in real-time, wherever you are, the production output and reasons for stoppages and understanding why you are losing speed on the production line.”

Instead of buying a new machine, you can pull up the information from Evocon and decide how much hidden potential you still have. Over time, you can minimize the gap between what you are producing now and your real potential.

6. Identify bottlenecks and improvement areas

Keeping your attention on what is most important in production is one of the most essential ingredients if you want to be able to:

- Stick to your production goals.

- Continuously improve the production process.

- Stay competitive in your industry.

Like most things, this is, of course, easier said than done. It’s easy to get distracted, feel overwhelmed, and stressed out. When this happens, you end up doing things that do not contribute to the success of your company and team. But with reliable data as a starting point and real-time production monitoring by Evocon, you can keep out the daily clutter and focus your attention where it matters most.

“Evocon has visualized our entire production process, and now we precisely know what our challenges and bottlenecks are.”

Using Evocon, we will help you understand the real problems in your production so you can prioritize improvement activities accordingly.

Learn more: 7 Best Practices to Improve OEE and Productivity

7. Enhance discipline, communication, and collaboration

Another OEE software benefit is a new layer of transparency that it helps provide. This helps everyone see what is happening in production and what are the real problems.

“When people could see how they work and how many technical stops they had, then some processes improved by itself. Due to that, people started to bring out their ideas on how to make their work more effective and how to reduce technical stops. In some cases, just a small change in work organization gave 20% efficiency.”

Once you and your team have a clear picture of what is happening on the shop floor, finding solutions to productivity issues becomes a lot easier. Instead of accepting bottlenecks as “the reality of your shop floor,” you can start eliminating them.

This paves the way for collaboration, communication, and trust among your employees. Because once people understand that Evocon is a way to report back to management about the issues on the shop floor instead of scrutinizing them, it is seen as a tool that empowers them.

8. From reactive to preventive maintenance

With Evocon monitoring your downtime and technical availability, there is a history of recorded production stops with clearly linked explanations.

“Evocon gives a ‘pulse’ for the production; it is visible on multiple screens in production, maintenance and planning, improving our internal communication.”

This information helps initiate proactive repair and preventive maintenance procedures. Plus, it prevents some breakdowns altogether. It also means that machine operators become more involved and aware of machine stoppages and their causes.

“We use Evocon on our morning meetings, to sum all stops, and to provide the maintenance department with facts.”

Once you capture all stoppages in real time, you give your maintenance department the information it needs to become proactive rather than reactive.

9. Accurate production planning based on OEE data

Most manufacturers have a production schedule, but how many consistently meet it? And what is the basis of their production plan? Scheduling always happens before the execution of the scheduling plan. That’s why you must base your plan on objective and accurate data.

“Our managers work with Evocon for gathering various information about future planning, demands, overall equipment efficiency, quality charts, shift management, operators comparing.”

With Evocon monitoring your production equipment, you’ll know right from the beginning whether your estimate is feasible and what is the utilization rate of your assets. With this knowledge comes an achievable schedule and plan.

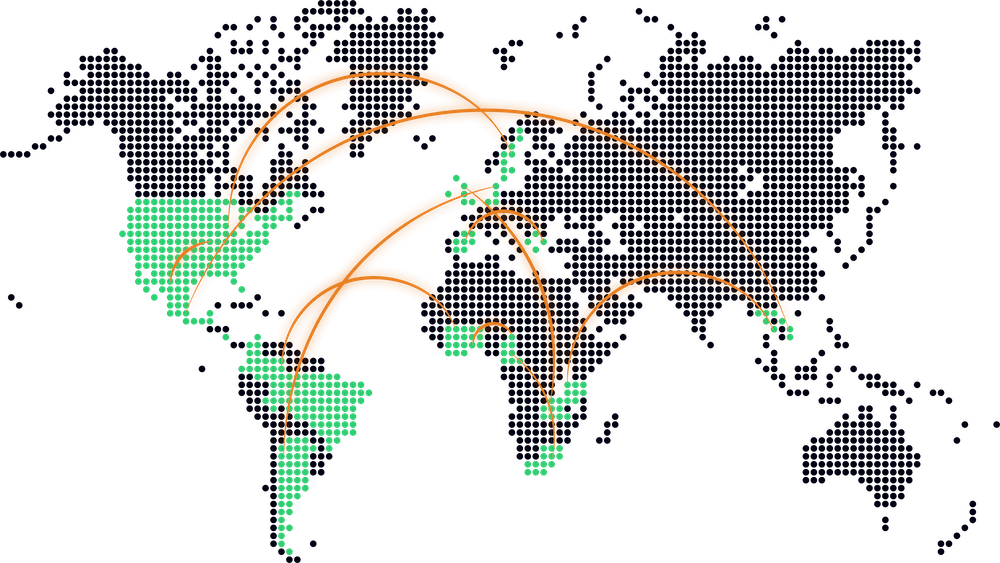

10. Cross-factory benchmarking globally

If you are working in a large multinational corporation, then you probably have production facilities in both hemispheres, and with data collected and stored by Evocon, you can begin to analyze, benchmark, and optimize your production globally.

Our clients with cross-border operations have started to realize this benefit.

As we discuss in our case study on Yara, Evocon has been effectively used to roll out lean manufacturing, OEE, and standardized loss reporting for over 135 production lines worldwide.

This standardization of OEE tracking helps you benchmark differences between countries, regions, and factories more accurately than ever before. Leading to increased awareness, expertise, and sharing of best practices on a global level.

Ultimately, global standardization enables your company to speak the same language across all operations.